In suburbs and cottage villages, central sewerage is extremely rare. Not to mention dacha cooperatives and villages. But this does not mean that their residents are deprived of basic amenities - it’s just that waste disposal takes place differently. There are several types of storage and treatment facilities. One of the most common local treatment systems is sewerage made from concrete rings.

One of the simplest and most popular wastewater treatment schemes is a two-chamber septic tank made of concrete rings with a filter well Source pochtidoma.ru

Features and advantages of concrete rings

The choice of materials for constructing containers, the main elements of an autonomous sewage system, is large: brick, metal, plastic, monolithic reinforced concrete, concrete rings.

Ordinary ceramic brick is used for these purposes if it remains in excess after construction. Its porous structure, hygroscopicity (water absorption of at least 8%) and the presence of a large number of masonry joints require comprehensive internal and external waterproofing of the tank using coating and roll materials to prevent groundwater from seeping in and wastewater from leaking out.

Metal containers can be used with a reservation - only in anaerobic septic tanks, when the flow of oxygen inside is limited by the design and principle of operation. In aerobic septic tanks in a humid, aggressive environment with forced air injection, the walls, and especially the welds, will quickly rust.

Plastic containers have virtually no disadvantages. But there are restrictions on use - they are “light”, and even when filled with wastewater, they will remain lighter than denser soil. When exposed to soil heaving forces, they can be literally squeezed out to the surface if they are not secured to a reinforced concrete slab installed as the base.

If the plastic septic tank is not secured, then heaving forces can very soon squeeze the container to the surface Source mirhat.ru

It is also advisable to strengthen the walls of the pit and provide a protective structure for the tank so that it takes loads from above.

Pouring monolithic reinforced concrete into formwork and its maturation takes a long time, significantly increasing the time from the start of construction to the commissioning of the sewerage system

Sewerage for a private house from concrete rings is built quickly, the design of the tanks has high rigidity and strength, and construction costs are low. And the reliability and durability of this material is evidenced by the fact that the main components of the central sewerage treatment facilities are made of precast reinforced concrete.

Purpose of wells

Various types of concrete ring structures are used in the construction of a number of objects, differing in their purpose for the following types of products:

- intended for installation of inspection type wells;

- for the installation of urban sewer systems and collectors;

- water intake wells;

- for equipment of wiring and protection systems for underground cable communications;

- for the construction of filter wells.

Sewage schemes made of concrete rings

Sewerage from concrete rings is made according to different schemes. The specific type depends on the seasonality of residence, intensity of operation, financial capabilities for purchasing additional equipment and paying operating costs.

The following options can be distinguished:

- Storage septic tank. Behind this name lies an ordinary cesspool with a waterproof bottom and walls. Tightness is a mandatory requirement, failure to comply with which, according to the administrative code of the Russian Federation, is regarded as damage to the land. When the wastewater fills the container, a sewage disposal truck is called.

A storage septic tank is simply a container into which wastewater is collected Source pinterest.pt

The smaller the capacity and the higher the intensity of operation of the points connected to the sewer, the more often you need to call the car. This is often how country sewer systems are constructed from concrete rings.

Note! The term “septic tank” in this case is not used entirely correctly, since by definition it is a treatment facility with waste flowing from chamber to chamber.

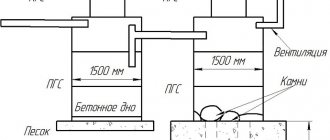

- Anaerobic septic tank. Two-, less often single-chamber, septic tanks, in sealed containers of which wastewater is purified by anaerobic bacteria (without access to oxygen). The number of chambers and their volume are chosen so that at the exit of the septic tank the wastewater is purified by 65-75%. Post-treatment occurs in filtration wells (“without bottom”), trenches or fields with aerobic bacteria (it is called “biological treatment”). Only after this can wastewater be discharged into the ground. The scheme is very popular among owners of country houses and dachas due to the simplicity of the device and energy independence. The disadvantage of the scheme is that it is necessary to periodically change the sand and crushed stone in the filter structures, in which case they have to be opened and the used material must be disposed of (although this is done infrequently).

Diagram of an anaerobic septic tank made of reinforced concrete rings Source o-cemente.info

See also: Catalog of companies that specialize in water supply and sewerage.

- Aerobic septic tanks and biological treatment stations. There is also a phase of primary accumulation and partial processing of feces with the help of anaerobic bacteria. The principle of operation is the clarification of wastewater in the absence of oxygen, and additional purification in the last chamber by aerobic bacteria under conditions of forced air injection. The purity of the wastewater at the outlet is considered to be 95-98%, and it can be discharged into the ground or used for irrigation. Disadvantage: aerobic bacteria die if the air supply compressor does not work. And this happens when the network is poor due to power outages.

The operating principle of aerobic septic tanks is that electricity is required for operation. Source prostroyer.ru

External waste disposal system

Sewer rings are the main component of its outer part, performing the functions of containers for various purposes in a wastewater treatment system. Products used are walk-through, without a bottom and equipped with bottoms. In addition, covers in the form of concrete slabs with a passage opening for maintenance are a mandatory element. For filter wells, rings with perforated walls are also used, in which a bottom filter is installed.

The finished container is equipped with two lids - an inner wooden one and an outer plastic or cast iron one. Concrete sewerage products are immersed in the ground to a depth that ensures that only the top cover protrudes outward.

The advantages of using such products include the following properties:

- strength, allowing you not to fear damage when the soil freezes in winter;

- durability - high-quality products of standard quality can serve in the sewerage system for up to 50 years;

- ease of installation - do-it-yourself reinforced concrete sewerage is quite affordable for most performers;

- cost savings on purchasing rings compared to ready-made plastic containers.

The main disadvantage of concrete sewer systems is the large volume of excavation work, but this property is equally inherent in any external drainage and wastewater treatment systems.

Volumes of septic tanks, dimensions of concrete rings, bottoms and ceilings

The total volume of the septic tank is determined as the three-day water requirement at the rate of 200 liters per person. The filter well is not included in this calculation.

Note! It is believed that the cycle of separation and purification of wastewater is 72 hours.

For a single-chamber septic tank, the entire volume falls on the first chamber; for a two-chamber septic tank, the containers are usually divided in the ratio of 2/3 and 1/3. Although many “simplify” the circuit and make both containers the same, in this case the first of them must be no less than 2/3 of the calculated volume.

Knowing the volume of the septic tank, you can choose the optimal dimensions from the standard range of KS wall rings in accordance with GOST 8020-90.

Typically, sewer rings are selected from the KS15 or KS20 range.

KS7 is used as a well neck (when needed).

KS10 has a volume of 0.24 m3 with a maximum ring height of 89 cm. Three elements of the first tank of a two-chamber septic tank will only be enough for wastewater from the life of one person. They can be used in a two-chamber or three-chamber septic tank scheme as rings for the second and third tanks, if the family consists of no more than three people.

Concrete rings KS can be selected for any septic tank Source rinnipool.ru

Which manufacturer to choose

In the Russian Federation, about 250 manufacturers are engaged in the production of reinforced concrete rings, covering the entire territory of the country. Therefore, traveling outside your region in search of cheap prices is not economically profitable. The savings will be consumed by transportation. However, the products of some factories are in special demand. We can highlight:

- "VTG Stroy" in Mytishchi, Moscow region, shipping its products throughout the country. Their KS 10.9, KS 15.9 and KS 20.9 rebated and flat models complete with a lid and hatch are in particular demand. The average cost is 2.1 thousand rubles.

- OJSC "Plant of Industrial Construction Parts", operating for more than 45 years in Tyumen. It has its own accredited construction laboratory, which allows not only to monitor quality, but also to develop new technologies.

- in Novokuznetsk is a supplier of high-quality reinforced concrete products throughout the Kemerovo region. In addition to producing standard designs, the company is also willing to accept orders for individual projects.

- in Krasnodar is distinguished by a wide range and high production capacity. Prices for reinforced concrete products start from 1.4 thousand rubles.

These manufacturers strictly monitor production technology and guarantee the quality of their products.

Choosing a location for a septic tank, installing a filter well

The choice of location for the septic tank is carried out taking into account regulatory requirements (5 m from the house, 30-50 meters from the water intake or reservoir). The second criterion is service. Although septic tanks do not require frequent pumping like cesspools, the containers must be freed from solid sediments - otherwise they will form a large layer of “mineral” deposits at the bottom, and this will reduce the performance of the treatment system.

When biologically purifying wastewater in wells or fields, it must be taken into account that they are installed in soils with good filtering properties - sand and sandy loam.

Restrictions when installing septic tanks Source 1beton.info

For low-filtration soils, filter trenches are installed after the septic tank to collect water in storage tanks for irrigation or discharge into a nearby body of water.

If, based on the geological features of the site, a scheme with trenches and filtration fields is chosen, then it must be taken into account that only a lawn can be laid out on their area or small shrubs with a shallow root system can be planted.

Sewerage from rings Source pinterest.com

The filter well does not have a sealed bottom - instead, it is backfilled with a mixture of gravel (crushed stone) with screenings or coarse sand. The height of the backfill is about 30 cm. They no longer do it due to difficulties during subsequent replacement.

The rest of the load for filtering treated waste is taken up by the backfill around the “perforated” walls of the well. The recommended layer thickness is 30 cm. Perforation of the walls should start from the bottom and end at the level of the pipe entrance from the overflow of the last chamber of the septic tank. For the walls, either ordinary well rings are used, in the walls of which, before installation, holes with a diameter of 3-6 cm are made (with a total area of at least 10% of the total), or special perforated rings for drainage wells are installed.

Construction options

Most often, one-, two-, or three-level septic tanks are used in suburban areas. In this case, the first septic tank is always sealed. This is where the majority of sewage solids settle.

The remaining wells serve as filter elements. They are not sealed, that is, they do not have a bottom. Secondly, manufacturers today offer perforated concrete rings. Through holes are formed in their walls during the production process.

Single level

This is one well for which filtration fields will need to be built. Or at least a filtration ditch. Not the most effective cleaning option, so it is recommended to construct it from large diameter rings.

Two-level

Ideal for a small country house. Usually the wells are the same size, but this is not necessary. The first one is sealed, the second one is not. They are erected on the same level. But you can lower the second lower than the first.

Three-chamber

From the name it is clear that this is a septic tank of three compartments, which are connected to each other in series, regardless of their location. The arrangement scheme can be as follows: in one line, in the form of the letter “G”, in a triangle.

Typically the first element has a larger volume than the other two individually. Moreover, it is the latter that perform filtration functions. The first is a collection of sewage, where heavy sewage settles.

Installation features

The sewer rings are installed on the bottom slab, which acts as a slab foundation. A prefabricated reinforced concrete structure must have a stable and reliable foundation. Here you also need to prepare the bottom of the pit: leveling, compacting, backfilling with a layer of sand and crushed stone.

During installation, it is necessary to seal the seams with cement mortar, followed by treating the entire surface with waterproofing compounds.

Advice! You can choose rings “with a quarter” - profiled ends. They provide a more reliable connection in terms of joining accuracy, structural strength, and seam tightness.

The recommended height of wells is no more than three rings. If you make it higher, the structure will be “weaker”.

Stage of installation of sewerage in a private house made of concrete rings Source 1beton.info

The entrance hole to the first well is mounted no lower than 30 cm from the lid. And the overflow holes are made with a slight decrease. This leads to a decrease in the “working” volume of the septic tank, which must be taken into account when choosing ring sizes.

How to install correctly

It is difficult to install reinforced concrete rings with your own hands, but sometimes this is done due to the impossibility of special equipment access to the territory. Otherwise, you buy reinforced concrete rings at the construction site, hire a manipulator, and he performs loading, delivery to the customer’s site, and unloading. Unloading can be understood as direct installation.

Before installation, experts recommend going deep to the required depth, compacting the bottom, and adding a cushion of sand. Concrete will draw moisture from the ground, so a pillow is simply necessary. Do not skimp on this layer, and fill up to 10 centimeters of sand, inclusive. To some extent, this will level the base. Place a concrete bottom on the sand, then begin the phased installation of the rings.

Each of them has special hooks. They serve to secure the manipulator slings and to connect the rings together. After the first reinforced concrete product is lowered, the slings are released, the metal hooks are bent, and the second product is installed. Then, all the screams can be linked together using a welding inverter. The work is not difficult and even a novice welder can handle it.

When a well is being constructed and the work is done manually, it is not always possible to use the services of a manipulator. In this case, install the first ring and gradually dig inside it, which allows the rings to fall down.

Next, when the first one is lowered to its own height and stands parallel to the ground at the top, the second reinforced concrete product is installed and work continues in the same way. Experts recommend using a hole drill, with the ability to drill to a depth of 10 meters or more.

This will allow you to drill through the entire internal diameter, install the ring and dig manually only under its walls. You will save the required amount of time and get the job done professionally. To make your work easier manually, you will need a powerful winch. It should be firmly fixed, which will facilitate the process of raising and lowering the products.

Prohibitions

There are a number of restrictions for installing treatment facilities:

- It is prohibited to locate treatment plants within the boundaries of sanitary water intake zones;

- It is not recommended to install the system on non-draining soils or soils that threaten subsidence;

- It is also worth refraining from installing treatment facilities in areas with a sharp slope, threatening landslides with excess moisture in the soil;

- If the groundwater level is high, installation of treatment plants is also prohibited;

- It is impossible to install closer than the approved construction and technological distances between the structures on the site and the septic tank.