Provided you install a high-quality product, install it correctly and follow the operating rules, you are unlikely to have to think about how to change a double-glazed window in a plastic window. But sometimes such a need still arises. What to do in such a situation: whether to replace only one damaged glass or the entire double-glazed window yourself, whether to call a specialist - each homeowner decides for himself. But before making a decision, it is advisable to thoroughly study this issue and soberly assess your capabilities.

Broken glass is an absolute reason to replace double-glazed windows Source prodigywindowsolutions.ca

What is double glazing

A double-glazed window consists of two glasses hermetically connected by a contour frame.

We replace double-glazed windows in plastic, wooden and aluminum windows. In “Oknoved” you can order the production of a new double-glazed window of any shape, be it rectangular, oval or trapezoidal. You can choose a double-glazed window with both regular glass and special properties:

- Triplex glass. It is a multilayer laminated glass.

- Energy-saving double-glazed window. Special design that will not release heat from your home.

- Reinforced glass. The glass is reinforced with a special thin steel mesh.

- With film coating. Protect from sunlight and ultraviolet radiation.

All production work is carried out in accordance with GOST 24866-2014.

Kinds

Glass packages for windows can be of many different types and types. In residential premises, two-chamber options are mainly used.

But other types can also be used.

- Packages containing the most common glass. Such structures are installed quite often, especially in industrial buildings. Moreover, its popularity is explained by its low cost.

- Low emission. They let in a lot of light, but at the same time effectively retain heat inside the room. Constructions of this type are popular if the windows face the shady side of the building.

- Highly durable. In this case we are talking about triplex glass. They are manufactured using special technologies. For example, with a strong impact, glass will not shatter into small fragments, but will retain its shape, but in the form of a web.

- Soundproofing. Such glass is also of the triplex type and does not allow extraneous noise to enter the room.

- Self-cleaning. Under the influence of ultraviolet rays and rain, all organic compounds that appear on the surface of the window as a result of operation are simply eliminated. For production, a special technology is used that allows the introduction of this property.

- Sun protection. In some cases, on one side, the glass does not allow the sun to pass through and hides everything that happens inside from prying eyes, while the room can be viewed outside.

Also, window packages may differ in the number of air chambers between the glass surfaces.

Cost of seals for metal-plastic structures

Manufacturers offer different options to add functionality to Euro-windows.

The most common methods:

- Replacing a single triplex with glass with two chambers will improve the thermal insulation characteristics.

- Anti-resonance glazing improves noise insulation in the room.

- Energy-saving “stained glass” windows allow you to retain heat.

- Triplex – reliably protects against noise and cold.

This material is used for glazing private households, apartments, country cottages, gazebos and open verandas.

Reasons for replacing double glazed windows

Most often, a double-glazed window is forced to be replaced when the old one breaks. However, some of our customers request replacement for other reasons.

Common reasons for contacting:

- A broken glass unit is the most common reason for calls.

- Violation of tightness, appearance of condensation inside.

- It was decided to replace the double-glazed window with a more functional one: however, double-glazed with two-chamber, noise-proof or tinted.

- Improve the aesthetic appearance of double-glazed windows (spars, false linings, filter glass).

Replacing a double-glazed window with a double-chamber one

Natural desire in the Russian climate. When you want to insulate a window without completely replacing it, you can use the service of replacing the double-glazed window with a double-glazed one. From 4000 rubles per m2.

Only an inspection by a master can give an accurate answer as to whether it is possible to replace the double-glazed window in your profile with a double-chamber one.

Replacing glass in a double glazing unit

The most cost-effective option for repairing damage if the window is broken. As you know, a double-glazed window consists of 2 or even 3 glasses, hermetically connected to each other. Sometimes replacing one of the glasses is sufficient.

The disadvantage of this method is the need to pay for delivery to the repair shop.

How much does a service cost in organizations?

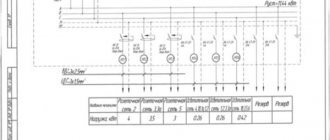

The final price of the work is determined by many factors. Therefore, we present the average lower and upper limits of the price lists of several companies in St. Petersburg and Moscow as of December 15, 2022:

- Replacement of a two-chamber double-glazed window - 2,000-4,200 rubles/m2 (delivery included);

- Repair of double-glazed windows - from 1,000 rub./m2 to 2,300 rub./m2 - work only. This does not include transport costs and the cost of glass.

For reference: the cost of a new double-glazed window starts from 1,300 rubles/m2 from little-known companies. For recognizable brands it starts from RUB 2,050/m2.

A glass unit is broken - what to do?

Possible damage to glass in a plastic window:

- Crack,

- Skol,

- Through hole.

First aid

Crack or chip in glass unit

If the glass unit has received minor damage and the integrity of the structure is not compromised, try not to use the window sash with damaged filling. This will avoid further destruction of the glass unit. However, in order to use the window properly, broken glass must be replaced.

Through hole - a hole in a double-glazed window

In some cases, double-glazed windows may be damaged through and through. In this case, the first thing you need to do is attach to the window, for example, with tape, a piece of cardboard or other material that prevents the penetration of air from the street - which is especially important in the cold season, and begin the process of replacing the broken glass unit as quickly as possible.

Should I insert glass or replace the entire window?

Plastic windows are a combination of reliability, long service life, and excellent performance properties. However, despite their strength, such products sometimes require repair. Even a new double-glazed window can easily fail.

First of all, in a PVC window you can only change the entire glass unit. The same applies to metal-plastic windows or aluminum windows. This service is in demand if the structure has become cloudy, cracks or scratches have appeared.

Temporary conservation

If one glass is damaged and there is no through hole in the block, then the crack must be preserved while a new element is being manufactured. This will help temporarily reduce heat loss in the room, prevent drafts and reduce noise levels.

Even a small crack leads to depressurization of the window system

To do this, use a transparent sealant specially designed for use with glass. With its help, the crack will not grow further. Apply the composition twice, maintaining a technological break of 2-4 hours. Detailed information on working with the material is indicated on the packaging.

Silicone sealant for glass

Prices for silicone sealant for windows

Silicone sealant

You can also use optical glass glue, which will strengthen the crack and prevent it from spreading further.

Optical glue

What tools will be useful

In order to replace a double-glazed window in a plastic window, great attention must be paid not only to the choice of the device itself.

It is worth preparing the necessary tools. No complex or expensive equipment is required for this work. Must have:.

- A shoe knife or an ordinary chisel. The tool must be sharp without creases.

- A hammer that is made of rubber. Such hammers can be used in construction, for example, to lay laminate or other materials.

- If possible, it is necessary to use special suction cup handles. Without them, replacing a broken double-glazed window is sometimes completely impossible due to the impressive size of the panel. If it is not possible to find such pens, you can invite friends or a neighbor to help, or you can use the services of specialists.

How to take measurements

Initially, before replacing, you need to take measurements. To do this, follow an algorithm.

- The easiest way is to use the dimensions of the old double-glazed windows, and send these dimensions to the manufacturer to order a new glass structure.

- If it is not possible to use old glass for measurement, for example, it is completely broken, then in this case it is necessary to take into account three main indicators: the required width, thickness and length. Measuring them will not be difficult.

Removing the glass unit

The technologies for removing a bag of glass from a plastic window and a wooden window are different.

How to remove double glazing from a plastic window

The double-glazed window in PVC windows is supported by plastic beads, which are fixed to the frame by snapping a tongue-and-groove locking connection. To pry up the bead and disconnect the joint, you need a knife with a hard blade or a narrow spatula. Some people prefer a small ax or a regular chisel.

In any case, the blade should look like this:

- thin enough to fit into a very thin gap;

- rigid so that it does not bend too much when used as a lever;

- not very sharp so as not to damage the plastic.

Start from any long side - more leverage when pulling the bead out of the groove of the window frame:

- The knife blade is inserted into the gap between the bead and the frame approximately in the middle.

- Using the knife as a lever in the plane of the window, slightly move the gap apart.

- A thin plate is inserted into the slot to fix its condition.

- Moving the knife up and then down, push the glazing bead and pull it out of the frame.

Then the glass unit is released from below. This is easier to do starting from a free corner. Move to the other long side and end at the top, holding the block so it doesn't fall out of the window.

Advice. The beads must be numbered (can be in pairs) in order to be put in their places later.

The nuances of removing double-glazed windows

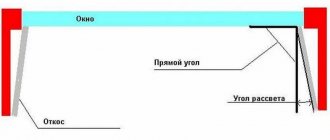

At the window, the glass package is responsible for the correct geometry of the frame. Unlike a triangular frame, a quadrangular frame is not a rigid figure. And the spacer monolith with glass holds the frame and ensures right angles.

When manufacturing a window at the factory, the glass unit in the frame is wedged with seam inserts and bridges (straightening plates). Together with the package they ensure the correct frame geometry. There can be from four to eight bridges. And when removing double-glazed windows from the movable frame, it is important to remember their position in order to then put them in the right place. Otherwise, the frame may become skewed - the window will begin to close poorly, and cracks will appear from which it will blow.

After the glazing beads have been pulled in, the window must be photographed and the bridges numbered. For reliability, their positions in the factory installation are marked on the frame.

To remove the package from the frame, the bridges are pressed away from the liners and pulled out. The sequence for dismantling bridges is as follows - first the sides, and then the bottom. Do not touch the upper part - the block should come out of the frame easily, with a slight tilt forward.

How to remove a glass unit from a wooden window

A double-glazed window in a wooden window frame is supported by glazing beads, which are nailed down with thin nails. And to ensure the tightness of the connection, the grooves in the frame around the block are filled with sealant. This results in double fixation - with nails and sealant. Therefore, the extraction process itself takes place in two stages.

First, the glazing beads are pulled out.

Note. The order doesn't matter, but you have to finish at the top. Here you can no longer use a tool with a metal blade - you can damage not only the paintwork, but also break off a piece from the frame or wooden bead. For this purpose, special plastic spatulas are used.

Do this one at a time, inserting the spatula blade between the two attachment points and moving from the center to the corner. When the fastener is sufficiently loosened, a wider gap has formed between the bead and the frame, the spatula is inserted closer to the nail, and it is carefully removed from engagement with the frame.

After the glazing beads have been removed, the sealant is cleaned off and the glass unit is pulled out.

Advice! All grooves on the frame must be cleaned of residual sealant and dirt. When installing a repaired unit, the contact surfaces must be clean for normal adhesion to the sealant.

Installation of windows with and without unpacking: sequence, features, advice from professionals

The installation of plastic windows is specific, so this work requires a special set of tools and materials, without which it is almost impossible to install windows correctly and accurately. If you can’t buy the things you need in a specialized store, you can contact a window company - the professionals will definitely find what you’re missing.

Below is a list that you can simply print out and take with you when you go shopping for tools and materials:

- plumb and level

- screwdriver and hammer drill

- drill with a set of drills

- gun and mounting foam;

- hacksaw or jigsaw

- small crowbar or pry bar

- silicone gun

- chisel or knife with a wide blade

- mounting wedges

- tape measure and pencil

- roll moisture-proofing material

- sheets of iron (galvanized) and metal scissors (needed for making drains yourself)

The main stages of installing PVC windows:

- dismantling the previous structure and window sill;

- preparing a new window for installation;

- marking the frame for subsequent fastening;

- fixing fasteners to the frame;

- making holes for fasteners;

- leveling the plastic structure;

- securing the structure in the opening;

- installation of low tide (can be done at the end of the process);

- intermediate adjustment of fittings;

- foaming the cavities between the window opening and the frame;

- window sill installation;

- final adjustment of fittings.

Each stage of installing a plastic window should be considered separately.

Dismantling old window structures

- When dismantling a window without sashes, simply remove the glazing beads and then remove the glass. If the windows are opening, then the sashes are removed from the hinges. If it is impossible to do this, remove the sashes along with the glass. However, if the windows are very old and rickety, then it is necessary to remove the glass.

- We saw through the old frame in several sections. This is done with a hand saw or grinder (just take a circle on concrete, other circles jam or break, which is quite dangerous). After sawing, the old frame can be easily removed using a crowbar, hammer drill and other tools. A wooden frame in good condition can be left. Inspect the condition of the block, remove damaged, rotten areas, treat the frame surfaces with fire and bioprotective compounds. However, experience shows that wall material is better for installation: the size of the window increases, a reliable fastening is obtained and there is completely no risk of the frame rotting in the future. The only exception is when the windows are intended for wooden buildings. Then the windows cannot be placed directly into the wall of the house, otherwise they will be damaged when the building shrinks (details here - Installing plastic windows in a wooden house with your own hands).

- We dismantle the wooden window sill in the same way as the frame: saw through it and remove it in parts, helping ourselves with improvised tools. You will need to tinker with the concrete window sill: it is not so easy to break it. Use a jackhammer or grinder. There is no need to break a good window sill, you can leave it. But a plastic window sill is still warmer. In addition, when leaving a window sill, be prepared for the fact that there will be a gap between it and the window frame. It needs to be sealed with a mixture that is thrown over the “skeleton” of mesh. In this case, cracks almost always appear. To avoid this, you can lay tiles at the top of the window sill.

- Cleaning the window opening from dirt, debris and dust.

Preliminary stage: preparing the window for installation

Windows with movable sashes are mounted closed. When installing a window open, there is a risk of deformation of the structure (the foam that will fill the gap between the opening and the frame can bend the frame). After foaming, the window is left for 12 hours, during which it cannot be opened. And to avoid accidental opening of the sash, you can postpone the installation of the handle until the installation of the window is completed.

It is not recommended to remove the tape that covers the surface of the window to protect it from damage until the installation of the structure and finishing of the slopes are completed.

PVC window installation sequence

Marking on the frame for fastening points

We retreat 5-15 centimeters from the corner of the frame and mark a place for the outermost fixing element. The frame needs to be fastened on 4 sides, the fasteners are located every 70-100 cm. If a stand profile is used, the frame is not fastened from below.

Fixing the fastener to the frame

Fastening elements include self-tapping screws, anchor plates, and U-shaped hangers for drywall.

Anchor plates and hangers have the same price - $0.05 (wholesale), $0.15 (retail). However, anchor plates are thicker than hangers. When purchasing, give preference to products made from thicker metal.

The fastener must be tightly secured in the metal frame frame. In order for the element to secure well, the screws must be used for metal. Such products have a drill at the end and a diameter of 4 mm. You can also use simple self-tapping screws, only in this case you need to first mark the holes in the frame with a drill.

Applying recesses for fasteners

We place the frame with the fasteners attached to it in the window opening, then knock out recesses in the opening in the appropriate places (depth 2 - 4 cm, width similar to the size of the fasteners). The fasteners will later sink into these recesses. By completing this procedure, we will make it easier for ourselves to finish the slopes.

Tip: when installing a window without a mounting strip, you should place blocks of wood or other dense material under it so that it rises to the height of the window sill. Then it will be possible to attach the window sill not to the window frame, but under it. If there is a mounting plate, the frame will automatically rise to the desired height. Typically, the mounting strip is already fixed to the frame and does not require additional fixation.

Leveling the window structure

This stage is the longest in the entire window installation procedure. However, by aligning the window in the vertical and horizontal planes, we automatically give it the correct rectangular shape. To level the structure, you need wooden wedges or bars that are placed under the frame. The first pair of lower wedges is set, then you can immediately fix the window from above with an anchor plate. Next we place two wedges at the top, then on the left and right at the bottom and top of the window. If there is an impost, you also need to put a wedge under it. During these actions, it is important to ensure that the vertical posts do not deviate to another plane. It is convenient to level the window with two people, when one supports the structure, the second inserts wedges.

Attaching the window to the opening

Having achieved a perfectly level position of the window, i.e. Having set it correctly in level, we can proceed to fastening the structure. To do this, use dowels (diameter 6-8 mm, length 75-80 mm) or anchors (diameter 6-8 mm). The latter have a higher cost, but provide more reliable fixation. They are recommended to be used if the wall consists of shell rock, brick or foam concrete. Fastening on anchor plates is used if the block structure contains a thermal insert and the frame in the mounting plane cannot be mechanically secured. A dowel driven into concrete can withstand a load of up to 60 kg, which is quite enough to fix a window. For wooden walls, you can use screws with a diameter of eight millimeters.

Advice: do not immediately tighten the screws on the sides of the frame completely, leave 1 cm until they stop. There is no need to screw in the construction screws in the upper part of the structure yet. The frame will not go anywhere, and you will have the opportunity to check the uniformity of the gaps on the sides and, if necessary, move the frame in one direction or another. After the final fastening, this will be more difficult. If the uniformity of the gaps is satisfactory, the horizontal/vertical structure is maintained, you can completely fix the frame by screwing in the screws on top and tightening the remaining screws on the sides. After this, it is worth checking the horizontal and vertical structure again.

Fastening the ebb of a plastic window

Installation of ebb tides can be done at the very end. You can buy the ebb ready-made or make it yourself. It is best to secure this element under the window - this will prevent the penetration of water where it connects to the frame. Upon completion of the installation of the drain, the space between it and the profile is filled with foam. If it is not possible to attach the ebb under the frame, it is fixed directly to it, for which 9 mm metal screws are used.

Intermediate adjustment of fittings

It is necessary to tighten or loosen the window hinges so that the sash moves silently and freely when opening and closing. An open sash should not slam shut on its own. Correctly adjusted hinges will allow it to remain in the desired position.

When moving, does the sash “strike” where the locking hardware is installed? Move this element a little lower or higher.

Foaming the gaps between the opening and the frame

It is important to fill the gaps so that there are no voids left. Large cracks (more than two centimeters) are foamed in several stages, with a break between them of two hours. With this approach, there is no danger that the foam will deform the window as it expands. In addition, the consumption of polyurethane foam is saved, there is no excess that has to be cut off, and the quality of the assembly seam improves.

Since the foam hardens under the influence of atmospheric moisture, a lack of humidity in the room can lead to poor-quality polymerization. To avoid this, you need to lightly spray the area between the window opening and the frame with water before foaming, and after filling the cavity, spray the surface of the foam itself with water. If the air temperature during installation does not exceed five degrees, then winter or all-season foam is used. In warmer weather, you can use summer foam.

After polymerization of the foam, it is necessary to protect it from exposure to ultraviolet radiation. This stage can be combined with finishing the slope. But if you don’t want to make slopes yet, or plan to do it later, then the foam needs to be covered immediately, since it quickly collapses due to exposure to direct sunlight. In this case, we prepare a cement-sand mortar at the rate of 1 part cement and 2 parts sand, or dilute tile adhesive and cover the foam with any of these materials. In addition, you can purchase PSUL tape (vapor-permeable self-expanding sealing tape) at a hardware store and cover the polyurethane foam with it. However, the cost of the tape is quite high (from $3 per linear meter), so the first options are used more often.

Window sill installation

1. Trimming. The window sills have a standard length and width and have a good margin, both in length and width. Before installation, the window sill is cut using a jigsaw, grinder or saw with small teeth.

2. Leveling. We move the window sill to the support profile and level it using wooden blocks or other available materials.

We cover the side sections of the window sill with end caps. It is better to glue the plugs to the ends with super glue.

By lightly pressing the window sill with your hand, we make sure that it does not sag. In some cases, the window sill is not installed level, but at a slight angle (no more than 3 degrees) “from the window.” Thanks to this slope, possible condensation does not flow under the window.

We foam the cavity under the window sill.

After foaming, place something heavy on the surface of the windowsill (you can use plastic water bottles or books for this purpose) and leave it like that for 0.5 days.

If you do not press down the window sill with a load, it will bend upward under the influence of foam.

3. One day is enough for the foam to completely harden. After which its remains, sticking out unsightly from the crack under the window sill, need to be cut off using a utility knife.

4. If the window sill was initially uneven, then during installation there may be a gap left between its upper part and the frame. It is carefully filled with silicone. It is worth considering that this material has low biostability and can turn black from fungus. A gap will not appear if galvanized iron plates in the shape of the letter “Z” are fastened to the window sill profile in advance (before installation). In addition to the fact that these plates will allow you to grind the window sill tightly, they will simplify the task of leveling it.

Final window adjustment

At this stage, you can remove the protective tape from the window structure and finally screw on the handle. If finishing the slopes is postponed, do not remove the tape until all finishing work is completed.

Is it possible to change it yourself?

When replacing a double-glazed window yourself, it is necessary to distinguish several stages of work:

Freeze. Before ordering the manufacture of a double-glazed window, it is necessary to carefully measure it. Pay attention to the border between the window frame and the glazing bead. Also, do not forget to allocate 1-1.5 cm for the deformation gap.

Dismantling the old one. To work you will need a knife or chisel. It is necessary to separate the glazing bead from the frame in the following sequence: right, left, top, bottom. After this, you can remove the glass unit. Using special suction cups will simplify the process.

Installing a new one. For level installation, straightening plates must be used. The installed double-glazed window must be secured with sealing rubber and secured on top with a bead.

A double-glazed window is one of the most expensive components of a window system, so we recommend not to take risks and entrust the installation to professionals. After all, an error during measurement may result in re-ordering the double-glazed window, and incorrect dismantling or installation may even damage the frame.

Features of glass measurements and its preparation for installation

The visible dimensions in the window differ from the actual dimensions of the glass - part of the dimensions are covered with glazing beads. But you also cannot measure from the outer edge of one bead to the outer edge of the other - there is still a certain gap between the frame plus the thickness of the sealant around the perimeter of the block with glass.

Note. Of course, you can first remove the block for accurate measurements. But then it will have to be inserted into the frame again until the new glass is cut out. Not only is this extra work, there is a chance that the fragments may simply fall out.

Is it possible to take measurements without dismantling? Can. To do this, measure the distances from the outer edge of one bead to the outer edge of the other on each side of the frame, and subtract 10 mm from the obtained values. To check the correctness, they also measure the diagonals, reduce them by 14 mm (10x√2), check them using the Pythagorean formula as the hypotenuse of a right triangle.

The sharp edges of the cut glass must be treated before installation - it is safer to work, there is better adhesion to the sealant, and there is less chance of chipping during installation. Polishing, of course, is unnecessary (not a shelf), but you need to sand it a little. This can be done manually by wrapping a wooden block with sandpaper with a grain of 300-600, or with a drill and an attachment with the same abrasive grain.

It is also important to wash the glass thoroughly before installation, degrease it and dry it with paper towels. Especially the surface that will face the inside of the camera.

Instructions for replacing a broken glass unit yourself

Steps for replacing broken double-glazed windows

- Measure the glass unit

- Make a new double-glazed window to replace the broken one

- Install a new double glazed window

To replace a double-glazed window, perform the following sequential steps:

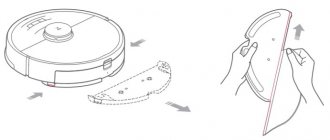

- Remove the glazing beads holding the broken glass unit. First long, then short. To pry, use a flat, sharp object - a spatula or knife.

- Carefully remove the old glass unit. Make sure that the linings that spread it out and on which it rests are not lost.

- Install a new double glazed window. Spread it open with pads. How to do this correctly - see GOST 30674 Window blocks made of PVC profiles.

- Install the glazing bead in place: first the short ones, then the long ones. Use a hammer with a special “soft” tip to avoid accidentally damaging the glass.

- Dispose of the old glass unit.

How to install the bead back

After the new panel has been installed in the window frame, you can begin fixing it with glazing beads. The first thing you need to do is secure the bag from below, and then from above and on the sides.

It is worth noting that, even without any experience in such a matter as replacing a double-glazed window in a window, all the work is completed in 20-25 minutes.

Dismantling

In order to remove the old double-glazed window, use a sharp knife. Use a sharp edge to pry up the glazing bead where the bag adheres to the plastic structure.

Next, moving along the perimeter, carefully tap the knife with a hammer. Eventually the beads will come away from the frame.

It is too difficult to remove the clamps yourself and at the same time hold it, and to dismantle a heavy glass structure.

Therefore, experts, answering the question of whether it is possible to change the glass in plastic windows on your own, say no. Help is needed.

It is worth noting that specialists use special suction cup handles for their work. But in private use it is expensive to find such devices. Therefore, when replacing, even when a double-glazed window is inserted, two people need to act.

Installation

After the old glass surface is removed, a new one is installed. To ensure that it is installed correctly and without distortions, additional elements are used. These are special gaskets.

People call them bridges. Thanks to such bridges, glass structures are quickly fixed inside the window and, easily installed in them, perform their functions.

Window adjustment

Over time, it happens that the windows are not pressed as tightly against the frame as before. There is no need to even say that this damages the thermal insulation and requires repair. Now we will figure out what to do in such situations.

All plastic windows have a clamping device. It is an elastic band that can fail due to gradual loss of elasticity or shrinkage.

Fortunately, window manufacturers are aware of this problem. In particular, for such cases, the windows are provided with a system for adjusting the clamping tension.

To adjust the mechanism on the windows there are special mechanisms - trunnions. These are the same metal “barrels” that move along the rails when you turn the handle. Usually they are mounted three or four per window. You can turn them using a hexagon or a regular flat-head screwdriver.

Each trunnion has two slots, a long one and a shorter one. It is their position that indicates how to rotate the mechanism. So, in order to increase the tension (this is exactly what is needed in case of problems with the elastic band), you should turn the trunnion so that the long slot looks inside the apartment, and the short one looks out. If it turns out that the window has become difficult to close, it means that the tension should be slightly eased by a slight turn in the other direction. You need to turn all the mechanisms, otherwise you will only get a partial effect.

Different windows may have slightly different mechanisms that are adjusted slightly differently. There are three options:

- the axle is turned using a screwdriver, which is inserted into the groove in the center of the eccentric;

- the trunnion is slightly pulled towards itself with pliers and only then turned;

- the pin is simply turned with pliers, without pulling.

Before you start making adjustments, you should carefully check which method works.

On the windows of some manufacturers, this operation has to be carried out every season. The fact is that due to the characteristics of the material, the elastic band contracts slightly in winter and expands in summer. As a result, the clamping stress changes. This effect is not always noticeable, but if it happens, you will know what to do.

Is it possible to change?

You can increase the number of chambers in a sheet structure if the features of the system allow and the structure can withstand the increase in load.

Single-chamber to double-chamber

This can be done if two conditions are met:

- The width of the rebate is sufficient for a double-glazed window. If a package of several glasses is similar in width to a single-chamber one, then there will be no problems with installation. If it is slightly wider, the glazing beads may need to be replaced.

- The aluminum window structure can withstand the weight of the sash. It is possible to strengthen the plates and hinges.

Before making a decision, it is advisable to consult with a specialist.

With a rubber hammer: remove the old coating

You should only begin removing the old blade to replace it when the new glass has been delivered to you. Otherwise, you should be careful about the safety of your home. It is unlikely that cellophane film or wooden boards will keep uninvited guests away.

If the new glass is already waiting in the wings, you can start replacing it. You should not remove the old glass until the new one is delivered, so as not to provoke robbers

To remove the glass to replace it, you will need a rubber mallet and a regular knife. How to remove double glazed windows? Follow the instructions carefully:

- remove the window frame from its hinges and place it horizontally on a soft cloth;

- gently tapping with a hammer, break the canvas into small pieces;

- remove the remains from the glazing beads.

Beads are an important element of the plastic system and do not need to be replaced. Thanks to the small element, the glass sits tightly in the frame. Glazing beads are rectangular, rounded and curly. Without them, the window cannot function properly.

When carrying out work, take care of your own safety. Glass can break into hundreds of small fragments, which can cause significant harm to health. Therefore, work only in overalls and gloves, and do not forget about safety glasses. If the glass sheet is very large, call for help.

You will learn how to remove damaged glass from the video below.

Checking the sash geometry

The easiest way to check the geometry of the sash is to measure its diagonals and compare them with each other, since the diagonals of a regular rectangle are always equal.

At the same time, for sashes it is allowed to increase the diagonal from the bottom hinge to 2 mm in relation to the other diagonal. If it is smaller, then the sash is probably not wedged, and there is a risk of its further sagging. It is wrong to measure the geometry of the sash relative to the frame, because the frame itself can also be skewed.

4-02-2021

Report an error (Ctrl+Enter)