In small apartments, it is necessary to correctly place furniture and things for a comfortable arrangement of the room. Multifunctional systems will help you cope with the task, many of which can be assembled at home. For example, an original bed with a lifting mechanism is made with your own hands based on ready-made drawings. By spending a little time and effort assembling a creative piece of furniture, you can save free space without depriving the room of comfort and coziness.

What are the advantages and disadvantages of handmade furniture?

Buying a new piece of furniture is an expensive option, despite the fact that it is not necessarily of high quality, strong and durable. In this case, many resort to independent production and collection of interior items. Let's consider the advantages and disadvantages of hand-made furniture.

If you don’t have enough money to buy such a ready-made bed, you can try making it yourself. First let's look at the disadvantages:

- Lack of experience can affect the quality of work. If you want to save on your purchase, you can pay twice as much. Lack of experience, inability to work, incorrect calculations can lead to serious mistakes.

- There is some danger in the work. Failure to operate certain tools can cause serious injury.

- You can't always save money. Sometimes it is much cheaper to purchase a ready-made product than to assemble it yourself, since the purchase of some materials can cost an impressive amount.

- Difficulty of the process. Despite the excellent end result, the process itself is quite exhausting. You need to be as focused and attentive as possible.

- You'll have to spend a lot of time. Making parts yourself and assembling them is a long and labor-intensive process.

Making such furniture yourself will require time and certain skills.

It is worth considering that there is a possibility that the final result may not turn out as expected. You need to be prepared for this. Considering all the disadvantages, you need to be sure that this process is necessary. Let's consider the advantages of making furniture with your own hands:

- There is an opportunity to take into account all your wishes. Finished products do not always fully satisfy consumer desires.

- Confidence in quality. When making furniture yourself, you can use the highest quality materials and have full control over the process.

- Pleasure from the final result. This point should not be overlooked, since pride in one’s creation is of great importance.

- Opportunity to save. It is not recommended to make this item a priority, but still the opportunity to reduce costs pleases many.

Making your own will help you make a bed taking into account all your wishes. Knowledge of negative and positive factors will help resolve the issue of making a lifting bed with your own hands.

Only by understanding all the intricacies of the process can you draw a conclusion about whether or not it is worth making such a bed yourself.

Wooden double bed project

List of required materials

The list of materials below assumes they are all of good quality. In fact, you should purchase more lumber than is listed in order to be able to reject pieces with defects (knots, bends, cracks, etc.). Those who buy lumber of a larger width than required and cut blanks of the required size from them turn out to be right.

As a general rule, the wider the board/block, the higher the quality of the wood (narrow boards are cut from the trunks of thin, low-grade trees and often end up warped).

| Lumber size | Quantity | Place of application |

| 5x20x240 cm | 2 * | bed side rails |

| 5x20x360 cm | 1 * | bottom of the headboards |

| 5x25x240 cm | 3 * | bottom of the headboards |

| 5×7.5×240 cm | 3 * | for making legs |

| 4x4x240 cm | 2 | slatted bottom supports |

| 5x10x240 cm | 13 | slatted bottom (you can also use 5x7.5 cm boards) |

| 60mm wood screws | 24 | for attaching bed side rails |

| * Instead of boards marked with an asterisk, it is better to buy six 5x25x240 cm boards and cut blanks of the desired size from them. | ||

General form

Cross section

Notice how the bottom slats rest on the bars supporting them.

Cutouts at the ends of the slats ensure that the slats do not add too much height.

Headboard

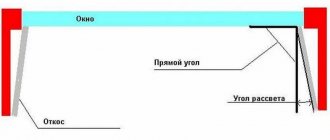

It is better to make holes for dowels by clamping the horizontal fragment of the headboard and the leg together with clamps. The hole should be drilled through both parts at once, as shown in the figure.

Foothills

Bed side rails

Each side rail of the bed has a row of bars on the support bar. The purpose of these bars is to prevent displacement of the bottom slats.

4x4 cm bars, which will support the weight of the slatted bottom, are best secured with both glue and screws.

Final assembly

The side rails are attached when the bed is installed in its permanent location. They must be removed to move the bed frame.

The slats that make up the slatted bottom are not secured. Small wooden blocks prevent them from slipping along the support bars.

Next, we give the floor to the author of this material.

Selecting a bed model and lifting mechanism

Initially, you need to choose a bed model with a lifting device.

Among the models of bedroom furniture are:

- single;

- one and a half sleepers;

- double.

It is better to install such single beds in the corner of the room. Doubles are used in the bedrooms of teenagers or adults; they take up more space and are best placed in the middle of the room.

Large beds with such a mechanism are best placed in the middle of the room. Consider the models of the lifting mechanism:

- Manual lift. It requires physical effort, so it is not particularly convenient to use. But it is this type that has the longest service life, reliability and durability.

- Spiral springs. A simple and reliable method, but not durable - their service life is about five years. The big advantage is the low cost.

- Gas shock absorbers. With their help, raising the bed is easy and silent. Service life more than ten years, capable of lifting bulky mattresses.

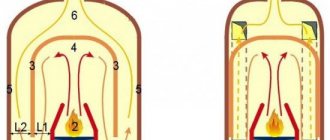

Lifting mechanisms can be manual, with springs or with gas shock absorbers. It is also necessary to consider the type of bed itself. If the structure is light, then it is better to use springs or manual lifting, and if it is heavy, it is recommended to give preference to gas shock absorbers. You can select a vertical or horizontal rise.

Lifting mechanisms can be either horizontal or vertical.

How to choose the right one

When choosing a bed for the bedroom, it is recommended to take an integrated approach. To ensure that furniture meets all requirements, you should pay attention to a number of basic criteria.

Company manufacturer

The furniture market offers a wide range of beds from different manufacturers. It is better to give preference to well-known brands whose product quality has been tested in practice. Since the bed is purchased for a long time, you should not experiment with products from little-known manufacturers.

Color

When deciding on the decorative characteristics of a bed, you must first take into account individual preferences. It is also important that the color of the furniture fits harmoniously into the existing style.

Load

Depending on the person for whom the bed is intended, the load indicator is determined. For children with low body weight, beds that can withstand minor loads are suitable, while adults should choose among more durable structures,

Type of operation of a gas lift to a bed

There are direct action mechanisms, when lifting is carried out by compressing the retractable rod, and reverse mechanisms. The result of the operation of gas lifts is the same, so this parameter is not particularly important and depends on the manufacturer.

Drawing up a drawing and sketch

The second stage of preparation for making a bed with a lifting mechanism with your own hands is drawing up a drawing or sketch. It is necessary to work out in detail all the nuances and order of work. The drawing details the dimensions, shapes, constituent fragments, fasteners, components and much more.

One of the options for a simple sketch of a bed with a lifting mechanism. The bed is a box of 4 rectangular fragments and 4 transverse ones that form the bottom. The correct sketch must include the parameters of the mattress, since the dimensions of the structure will be developed on their basis. Standard sizes: length from 1.8 meters and width from 0.8 to 1.8 meters. If additional built-in elements are planned - shelves, drawers - they must also be described in detail on the drawing and the methods of their fastening.

If the bed has shelves and drawers, they also need to be described in detail in the sketch. You also need to create three drawings: the first sketches the general appearance of the future structure, the second contains detailed information about materials and dimensions, and the third describes the procedure for carrying out all the work. Thus, in the end you will get a ready-made plan for the manufacture of the structure.

If you have no experience in drawing up such a drawing, you should resort to the help of the Internet. Here you can find a variety of sketch options that can be changed and supplemented at your discretion.

Possible difficulties during work

Without practical experience in assembling furniture or making minor mistakes, you may encounter difficulties. The following installation difficulties are common:

- Need to drill additional holes. Recesses for fasteners are required in many parts of the structure, and if third-party elements are used, then new holes must be made on the body, having previously made markings.

- Gas lift installation. The process of installing the lifting mechanism is the most difficult step, so it is important to be careful and follow the exact sequence of actions.

- Incorrect markings on the furniture frame. If you make a mistake in the markings, you will not be able to assemble the bed correctly, so you need to check the measurements several times.

See also

Properties of acrylic paint for furniture and instructions for working at home

Preparing the necessary materials and tools

The third stage of preparation is the selection of materials and tools. You need to understand that it is impossible to predict everything that may be needed in the process. Therefore, you need to be prepared for the fact that something additional may be needed during work.

Among the materials for making a bed, you should give preference to wood. They are affordable, easy to process and reliable. It is better to take solid natural wood, it will be much more expensive, but its advantages are difficult to overestimate.

To make furniture yourself, you will need a set of special carpentry tools. You will need the following tools: self-tapping screws, electric drill, screwdriver and screws, confirmats, angles, edge tape, bolts, nuts and washers, lifting device, screwdrivers, tape measure, level, furniture stapler, welding machine, hacksaw, sandpaper, foam rubber, pencils or markers , clamps, hair dryer.

Design

Hanging bed - an unusual design solution in the bedroom interior

Any bed, regardless of shape and configuration, consists of the following components:

- Frame

- Base

- Side and support panels

- Optional design elements (legs, hanging backrests, headboard, storage drawers, lifting mechanism)

A home-made sleeping place usually consists of a frame on which a base is installed - a mattress support. The supporting structure is made from:

- wooden slats (slats)

- metal mesh

- spring mechanism

Furniture for sleeping and relaxation can:

- have legs (most often no more than 20 cm high)

- be floor-standing (the frame is located directly on the floor)

- be suspended (fixed to the ceiling)

Original headboard for bed

The headboard is a decorative element that:

- carved from wood

- sawn from chipboard

- forged from metal

- upholstered with foam rubber and fabric

- can be carved and solid, straight and curved

In addition to the main functionality - a place to rest, the bed also serves as:

- closet

- stand

- sofa

- podium

In these cases, the mattress is hidden in the shell of the body during the day, and at night it is unfolded using a “book” mechanism or a gas lift.

Swimming pool at the dacha: device, step-by-step instructions for arranging it yourself | 65+ Photos & Videos

Step-by-step description of making a bed with a lifting mechanism

Having prepared everything you need, you can proceed directly to making the lifting bed. Let's look at all the stages in detail.

Making a lifting frame

The lifting frame is the basis for the main function of such a structure - the ability to lift. Let's take a closer look.

First you will need to make a lifting frame.

Pay attention to the strength and reliability of the structure, as it will support the entire bed.

The work includes two stages: manufacturing and processing. The first ones mean:

- Prepare the frame parts.

- Assemble the bases using calibrated boards. It is best to do this on a flat surface.

- Screed the resulting structure with metal corners and furniture glue. All cuts need to be sanded, making sure that the heads of the screws are slightly buried in the wood.

- If you plan to make a large bed, then you need to make a central partition for greater strength.

- Attach the slats with self-tapping screws on the inside of the sidewall and align them with the bottom edge. The slats should be approximately 20*80 centimeters.

- You can use slats as slats, the length of which should be equal to the width of the future bed. Attach them to the slats for support, about 15 centimeters apart.

The frame is ready, now it needs to be processed. To do this, you need to sand the boards and then coat them with wood varnish.

Installation of an inset frame under a mattress

After making the lifting frame, you need to start installing the mattress insert. It will increase the reliability of the structure and extend its service life, so this step should not be skipped when making a double bed.

For installation you will need wooden planks and a steel profile. For installation you will need a steel profile and wooden planks. It is necessary to act in accordance with the drawing made earlier. To begin, cut the profile using a grinder and connect the parts together using a welding machine. Fasten the racks between the transverse and longitudinal fragments, this will increase strength and avoid arbitrary lifting of the structure. Finish the ends and attach legs if necessary.

Headboard manufacturing process

Any material can serve as the base: plywood or natural wood. Apply markings, and then use a jigsaw to carefully cut out the shape of the back. This element can be given any shape you like.

The headboard of the bed can be given any shape you like.

The simpler the shape of the headboard, the easier it is to cover it.

Take a furniture stapler, finishing material and a foam sheet. The sheathing should be soft and airy; to do this, place two sheets of foam rubber between the plywood.

Making the main frame

An integral part of any bed is its main frame, which consists of:

- side drawer, front and back back, bottom of boxes;

- mattress covering made from slats or boards.

Be sure to focus on ensuring that all elements are securely fastened.

Making the main frame

Let's take the standard dimensions 2*1.8 meters as a basis. Take 2 boards of 2 meters each for the side edges. For the end, take two 1.8-meter boards, connect them with screws and corners. All boards must be fastened at right angles.

When assembling the main frame, it is important that all boards are fastened strictly at right angles. Install a rigid rib through the longitudinal axis, fix the legs (if they are needed). Cover the structure with varnish.

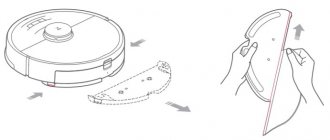

We install lifting mechanisms and supports

To install the lifting mechanism, you should secure the top bar and the bed frame with rolled steel, then attach the two bases of the mechanism to the bar to lift the structure. Fix the bottom bar so that it is located on the main box and check the strength of the structure, as well as its operation. Installing the mechanism is the simplest step, so even a beginner can handle it.

Sheathing and finishing

The last and final stage of making a raised bed is decoration. You can do without it altogether and simply varnish the wood, but if you want to finish it, you need to choose a material for this. The most commonly used are the following:

- textile;

- leather or leather substitute.

Upholster the bed frame and headboard with your chosen material. In order for the upholstery to be airy and soft, you should use foam rubber. A stapler and glue will help you carry out all the operations.

You can make a canopy. To do this, you need to install beams under the ceiling and secure the fabric.

The final stage is covering and decorating the bed.

To begin, glue the foam to the surface, wrap it into the inside of the bed and trim off any excess. When attaching leather or fabric, it is better to use a stapler rather than glue. Smooth the material over the surface and secure the edges with staples. You can use metal corners at the corners for added strength. To make a double bed with a lifting mechanism with your own hands, you need to strictly follow the instructions, take careful measurements and be patient. As a result, you will get a chic homemade bed that will help you successfully save space in a small room.

Final finishing

After the manufacture and assembly of the bed is completed, they move on to its design. The frame is processed using sandpaper, paying attention to all irregularities. For decoration, stain is used, and after it has dried, a special furniture varnish is used. It is recommended to choose quick-drying paints and varnishes that contain polyurethane or acrylic resins.

Design of canopy beds, main advantages of furniture

The headboards of double beds can be made more attractive in appearance by decorating them, installing foam rubber and creating fabric upholstery. If upholstery is not provided for furniture, the back should be thoroughly polished, removing nicks. The treated surface is painted or varnished to increase the protective properties of the wood.

The following materials can be used to decorate the headboard:

- Suede or leather. Not cheap options, suitable for luxurious interiors.

- Eco leather. It has good performance characteristics, relatively affordable cost, practicality and aesthetics.

- Velor or velvet. The advantage of such textiles is their stylish look. The downside is the accumulation of dust, which means you will have to take care of the headboard more often.

The selected material is used to upholster the wooden backrest, securing it with a construction stapler. On a large headboard, the fabric is also fixed on the front side. It is advisable to hide the staples with the help of decorative elements - for example, buttons.

Leather

Suede

Velvet

Mattress base options

Having decided on the dimensions, you can move on to choosing such an important part of the bed as the base for the mattress. Yes, of course, you can do without a mattress, replacing it with a non-removable filler from the same chair-beds and similar furniture, but at home this is extremely difficult to do, so most often beds are made for a mattress

They are like this:

Today it is already considered a relic of the past, but in some places you can still see a flat base. It consists of boards knocked together to form a wooden shield on which the mattress is placed. There are practically no advantages to this design (compared to more modern options), but there are a lot of disadvantages.

Firstly, the mattress deforms very quickly and loses its useful properties. Secondly, a dream with such a reason is not the most pleasant. Thirdly, the mattress is not ventilated, which is why it can become damp, which will lead to the appearance of various parasites in it or the onset of rotting, which is also not very pleasant.