Connecting the toilet to the sewer is a simple process. If you want to save on the work of a locksmith, you can try to do it yourself. Fortunately, manufacturers of plumbing fittings offer many adapter options. To conveniently and reliably connect elements located offset from each other, an eccentric is used.

What is a toilet eccentric

An eccentric (cuff) is an element of connecting fittings in the form of a pipe, the edges of which are offset relative to the common axis. This design allows you to have some freedom when installing the toilet if its outlet and the sewer hole do not coincide. Alignment is achieved by turning the cuff placed on the pipe.

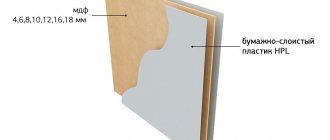

Toilet eccentrics are made in different lengths with a standard diameter of connecting holes. Rubber cuffs have a corrugated surface at the points of connection to the pipes. This ensures a more reliable fastening. And the cuffs, made of plastic, are equipped with special rubber sealing gaskets.

Eccentrics mainly connect pipes located in the same plane. But if the angle of divergence is small, plastic cuffs are used, varying the corrugated part, in the area of which a slight bend can be made.

Criterias of choice

Rubber product

The upcoming installation of a toilet in a bathroom or repair work to eliminate drain leaks requires the selection of high-quality parts. To do this, it is recommended to decide on:

- material;

- length;

- appearance.

Polypropylene eccentrics are a reliable option. The material is durable and moisture resistant. With proper operation, leaks will not form within 3-5 years. Rubber parts are less preferable. This material stretches over time. Its density is disrupted, as a result of which the tightness decreases. However, rubber seals at the ends of the cuff are the main element contributing to high moisture resistance.

Size is the main thing to pay attention to. If the diameters of the inlet and outlet rings meet the standards, then the length is selected depending on the location of the toilet in relation to the sewer pipe. For a non-standard method of placing a plumbing fixture, a stepped option is used. This guarantees a perfect “fit” of the part. A corrugated cuff will also work. Moreover, the corrugation should not be short: if it is tightened, it loses its elasticity. It is recommended that a product that is greatly stretched due to an incorrectly selected length be strengthened in a straightened form with additional fasteners. A corrugation that is too long will sag and the water will not drain completely.

External characteristics - the white color of the material, in harmony with the bowl, the smooth surface of the cylinder without burrs and scratches - are no less important. The overall impression of the aesthetics of the toilet room directly depends on the appearance of the elements.

When is it convenient to use the cuff?

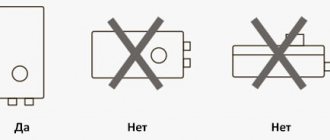

In addition to using a cuff, there are other options for connecting the toilet to the sewer, but there are cases when an offset toilet eccentric is the only available option to make the joint. Typically, this can only happen with two types of toilets: horizontal and slanted. The reasons for the misalignment of the axes may be the following:

- Replacing an old toilet with a new one and the impossibility of choosing a model that is similar in geometric dimensions.

- Changing the floor level when laying tiles, resulting in a discrepancy in heights at the exit and entrance of the plumbing fixtures.

- Inability to maintain alignment with the initially displaced passage of a sewer riser in a multi-story building.

- Miscalculations when designing communications.

In all these cases, the use of an eccentric is relevant, provided that the displacement does not exceed five centimeters.

If the tank is low?

There are also cases when the tank is located too low. This is a problem, but not so strong that it cannot be solved.

- The first step is to put the cuff between the tank and the toilet on the end of the toilet extension shelf.

- Then, using a wire, we fix the eccentric in a stationary state.

- After this, we unscrew the rubber part and attach the attached shelf to the toilet with bolts.

- We pull the eccentric onto the outlet pipe of the sink. Using sealant, we coat the joint with it and, tightening it with wire, fasten the cuff.

- After this, you should perform a test run to make sure there are no leaks. As with any plumbing connections, the bathroom must be installed hermetically.

Toilet eccentric: dimensions

Eccentric-type toilet couplings have a hole diameter of 100 mm. This allows them to be directly inserted into the sewer pipe socket without additional adapters.

The length of the cuffs varies. The shortest rubber eccentrics are limited to 150 mm. Plastic cuffs can reach a size of 250 mm. It is not advisable to make longer couplings, since you can always extend the sewer pipe to the desired condition using a plastic outlet.

Corner release

In old houses where the pipes have never been changed, the toilet is installed using a rubber cuff. This is most often a conical toilet cuff. It is connected to a cast iron pipe. If the input/output axis is shifted, then an eccentric is purchased. Suitable for smooth or corrugated tube. If there is a significant distance to the pipe, you can use corrugation, stretching it to the desired length. An eccentric is also needed to obtain a more tight connection.

The principle of installation of products made of rubber or plastic, corrugated or smooth parts is very similar. But there are some nuances. Next we will look at three options for connecting a toilet.

Other connecting adapters

Along with eccentrics, there are other connection elements:

- Plastic adapters, bends and pipes. They are used mainly for coaxial jointing of fittings, or at different divergence angles of pipes. Using a different combination of bends, for example two 45-degree angles, you can make a homemade eccentric for the toilet. It will be inferior to the factory model only in an aesthetic sense. In terms of reliability and durability, this is the most practical option.

- Corrugations, corrugated cuffs. These connections are used in difficult situations, with sharp divergences in joint angles of up to 90 degrees and above. Corrugation can be used to bypass any interfering element. The disadvantage of the connection is its fragility. Thin walls in the bend area can break through, and sediment easily accumulates on the inner surface due to the ribs.

- Fan pipes. These shaped elbows are suitable for straight joints. They benefit aesthetically due to the material from which they are made: earthenware, porcelain, piece porcelain. This product must be handled with extreme care due to its fragility.

- Straight rubber or plastic cuffs.

Customer Reviews

Vanya, Moscow : “The cascade eccentric came to the rescue when we bought a toilet, not taking into account the height of the drain hole: it was 6 cm higher than the sewerage inlet. Installed without problems, looks aesthetically pleasing, does not leak. No sealant was used."

Roma, Moscow : “After the expiration date, the cuff had to be urgently replaced. Previously there was a rubber one, I took a combined eccentric one with corrugation at the ends. The flexible corrugation helped to quickly deal with the problem. I protected myself with silicone sealant, no leaks were observed.”

Zhenya, Moscow : “Some are afraid that flushed solid waste may get stuck in the eccentrics due to the bends. I can say for sure that their statements are baseless. A year of using this cuff did not reveal any complaints: the flush is good, there are no blockages. Maybe they flushed something that doesn’t dissolve down the toilet?”

Step-by-step installation of a toilet on an eccentric

For example, you can consider installing a toilet in a newly renovated toilet, where the tiles on the floor and walls have been completely changed and there is only an exit from the sewer pipe. In the source data - the presence of an axis offset between the connected elements.

The process is divided into several steps:

- Place the toilet in its permanent position and outline the leg with a black marker directly on the floor tiles. Mark the mounting holes.

- Measure the distance between the pipes, plus add 5 cm on each side to put on the eccentric for the toilet.

- Buy an eccentric of the required length and automotive sealant (it does a better job of sealing the seam than silicone).

- Move the toilet to the side, insert the eccentric into the socket of the sewer pipe. Return the toilet to its place and, turning the eccentric in a circle, ensure that the toilet outlet fits exactly into it.

- A marker is used to make a general notch on the eccentric and the socket of the sewer pipe in order to have a reference point for the position of the element.

- Remove the toilet, remove the coupling from the pipe, drill the mounting holes and install plastic dowels in them.

- A layer of sealant is applied along the inner circumference of the sewer pipe (where the eccentric fits) and the coupling is inserted, aligning the marks.

- Apply a layer of sealant to the toilet drain outlet and install the latter in a permanent place, inserting the toilet eccentric 100 mm.

- Let the sealant sit for 30 minutes and check the drain by pouring several buckets of water into the toilet. To control leakage, place a sheet of white paper on the floor under the cuff.

- If everything is successful and there are no leaks, screw the toilet to the floor and wipe the marker line with alcohol.

It is important to consider that you can achieve a reliable seam by applying sealant only to a dry surface.

Connection technology

After a certain period of operation, the eccentric may fail. Therefore, in addition to the initial installation of the toilet, after a while you will need to replace the cuff.

Damaged and burst elements are unable to cope with their functions, which leads to leaks.

Easy connection

If the system is old, a straight or tapered piece will do in most cases.

The work is easy to do with your own hands, in several stages, including preparation:

- Cleaning the outlet pipe and outlet. You can use special products designed for thorough treatment of plumbing fixtures and its internal parts. It is better to choose soft compositions, without aggressive substances that can corrode the material. All devices must be degreased.

- The prepared devices must be allowed to dry, otherwise it will be difficult to achieve high-quality sealing.

- After preliminary measurements, a suitable cuff is purchased. If the pipes are old, cast iron, it is recommended to additionally treat the internal and external surfaces of the adapter with silicone acriplast.

- One part of the eccentric is put on the bowl drain. There is no need to apply force, as the seal will automatically create a maximum seal. If a sealant is used, you need to give it time to harden.

- The second end is inserted into the drain.

With correctly selected parameters and modification of the cuff, a fixed position is quite easy to achieve.

Connection for multi-level releases

If the outlet from the equipment and the entrance to the riser are at different distances from the floor, only an eccentric corrugation is suitable, since it can easily combine the two elements due to its flexibility.

Also interesting: Plumbing repair: water is leaking from the tank, what should I do?

The installation principle is identical to connecting a straight cuff. Involves preparation, cleaning of internal surfaces and fastening.

In this case, you will need to handle the adapter carefully. When inserting, you need to bend the device carefully so as not to damage it.

Work is carried out before attaching additional elements. This will help you install the device quickly and without interference.

Connection for low tank height

In modifications of the toilet with the location of the flush equipment at a short distance from the floor, installing the eccentric will be difficult. But if you wish, you can also do it yourself.

The adapter is put on the front part of the tank attachment plate from the end of the smaller diameter, approximately a third of the length. The remaining cavity will include the neck of the bowl and the inter-end step.

In this place, careful fixation is required, for which steel wire is usually used. The corrugation must be slowly rotated and bent to the specified position.

The shelf is mounted to the toilet using fasteners.

The device is combined with the sewer outlet pipe. Despite the tightness of the internal seals, it is recommended to additionally tighten them with wire for reliability.

Replacing the rubber cuff

During operation, eccentrics sometimes fail and begin to leak moisture. This can happen due to rubber aging and loss of elasticity. To replace the cuff with a new one, work in the following order:

- Rinse the toilet elbow with several buckets of water and remove any remaining liquid in the elbow.

- Using a metal file, cut the cuff in half, unscrew the screws securing the toilet leg to the floor and the pipe from the cistern (after turning off the tap). The toilet is moved to the side.

- Remove the remains of the used cuff from the toilet and the sewer pipe. Carefully remove the layer of old sealant and salt deposits formed during the operation of the sewer.

- Install a new eccentric for the toilet with an offset of 100 mm as described in the previous chapter of the article.

Silicone sealants

silicone sealant

Silicone sealants are used to fill cracks and cavities to seal and protect against various environmental factors, as well as to glue different surfaces together.

At room temperature, the sealant hardens and turns into rubber. This sealant is waterproof!

What kind of sealant is needed for a toilet?

If the toilet is white, then it is better to use white sealant rather than transparent. The sanitary sealant contains special anti-fungal additives that prevent the appearance of fungus, mold and other microorganisms on its surface.

How long does it take for silicone to dry?

Silicone sealants are neutral and acidic. The most common are neutral, they dry for about 24 hours at a temperature of 5-40 degrees Celsius and at normal humidity. Acid sealants are cheaper and dry faster (4-6 hours).

How to remove old sealant?

The cleaner will soften the sealant and its residue can be removed either with a spatula (plastic) or a glass scraper. Instead of Soudal cleaner, you can use pure gasoline (Galosh), white spirit, vinegar + warm water. After removing the sealant, wash off its remains with soapy water and finish with clean rags + water.

Eccentric repair without replacement

A malfunction of the connecting cuff can occur at a time when it is difficult or impossible to replace it. To eliminate the leak and continue to use the bathroom painlessly, several methods are used:

- Sealing with fabric. Take a piece of dense cotton fabric and cut it into strips 5 cm wide. The pipes and eccentric are well wiped from moisture, dust and dirt. Starting from the toilet pipe, wrap the fabric (similar to winding insulation) over the entire area up to the sewer pipe pipe, making a couple of turns on it. Secure the edges with insulating tape. The entire surface of the material is painted with oil paint. The paint is allowed to dry.

- Repair with an elastic rubber bandage. They use the same winding principle, without subsequent painting.

- Putty with automotive sealant. The method is used if the eccentric cuff for the toilet leaks at the joint. The joint is cleaned and dried. The sealant is filled into the treated area and allowed to dry for half an hour.

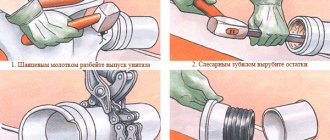

Dismantling old elements

Before connecting the toilet to the sewer pipe, the installation site should be cleared of elements of the previous structures. The procedure is carried out using a hammer, screwdriver and pry bar.

In most cases, the outlet of old products is built into a cast iron structure (“elbow”), which requires breaking the pipe with a hammer. When performing this procedure, be sure to wear safety glasses. Otherwise, sharp ceramic shards will get into your eyes, causing injury.

After the old plumbing fixture is dismantled, you need to knock on all sides of the cast iron pipe, then begin to remove the cement layer and other deposits from the walls.

To remove small parts, a screwdriver and a hammer are enough, but for large elements you will need to use a pry bar. When tapping with a hammer, it is important not to overdo it, because... strong impacts will lead to the splitting of the cast iron socket.

In this case, you will need to break the floor to get to the sewer riser. Then you will need to connect the new outlet to the riser.

When the main deposits have been removed, you can begin the final stage of cleaning the pipeline. To do this, you need to coat them with a special chemical for cleaning the toilet, and then scrape off the residue using a wire brush.

Finish cleaning with a rag. The first 5-6 cm of the cast iron socket must be completely smooth from the inside, because the absence of leaks in the future and the tightness of the joint depend on this. The entire procedure must be carried out wearing protective gloves.

Advantages and disadvantages

Corrugated toilet flush is in demand among consumers due to a number of positive qualities:

- easy installation: no special tools are needed, as well as extensive experience in performing such work;

- light weight of the product: installation is done by hand;

- low price;

- when displaced or in an area of complex configuration, a flexible pipe makes it possible to connect the sewer riser and the toilet outlet;

- corrugation helps to join elements of the sewerage system that do not match in diameter;

- resistance to corrosion;

- no need to dismantle the toilet;

- significant permeability due to the device: when stretched, the stiffening rings that make up the walls of the flexible pipe acquire a certain volume, which slightly increases the diameter of the product in the area between the cuffs.

Corrugation for the toilet: advantages and disadvantages.

This product also has disadvantages:

- low strength: when a sharp object, a splinter, gets into the pipe, the risk of damage to the walls increases, which may result in a leak that cannot be eliminated;

- Do not use a pipe that is too small or large, as it will sag under the weight of the contents;

- installation errors (installation at an inappropriate angle, significant bending) can lead to clogging;

- rapid clogging is also determined by the ability of the pipe to retain contaminants on the walls;

- insufficiently long service life;

- In terms of attractiveness, such a product is inferior to smooth-walled analogues;

- installation restrictions: it is impossible to cover the toilet outlet with plasterboard, as well as install it inside the floor.

The prohibition on installation in the thickness of the wall is due to the high probability of leakage. It is difficult to detect damage in time; as a result, sewage will enter the premises.

Important parameters

All parts that are commercially available today differ from each other in materials, shape, and diameter. Before purchasing, you should know important nuances. So, pay attention to the diameter of the sewer pipe to which one end will be attached. The standard diameter is considered to be 110 millimeters. However, the dimensions may vary in some homes.

Also, before choosing, you should clarify what type of outlet the particular toilet has and the diameter of this hole. The second end of the cuff will be attached to it. It may happen that the sizes will not match. Then you will have to purchase a non-standard model.