Let's start by revealing the concepts of sound and noise insulation. Sound insulation is the ability of walls, ceilings and floors to prevent sounds from traveling outside. And such a characteristic as sound insulation is responsible for the damping of sound waves in building materials by converting sound waves into kinetic heat. High-quality soundproofing material for walls, partitions and other structural elements of a building combines both characteristics, which allows you to achieve maximum peace and quiet in every room.

For city apartments, the values of sound and noise insulation are much more important, since noise sources are intense in number of dB and duration . However, in a country house it is also necessary to strive for comfort, preventing the spread of shock waves from mechanical impact, as well as sound waves transmitted through the air.

Soundproofing materials for walls

Once your walls and interior partitions are installed, it's time to think about soundproofing your home. You will have to choose one of two design systems - frame or frameless cladding . Then you need to decide on soundproofing materials for the walls. In this section we will describe what sound insulation of walls should be by modern standards if you have massive wall structures made of brick, reinforced concrete, gas foam blocks with a surface density above 200 kg/m².

Modern materials for soundproofing walls:

- Sheets of chipboard or plasterboard, rigidly fixed to the wall with nails (screws) by mounting on a wooden sheathing or metal profile. The distance from the sheet to the wall is filled with mineral wool or glass wool; an option with foam insulation is possible. An important point is to prevent the appearance of sound bridges in the frame , due to which all efforts to soundproof the house are neutralized, reducing the sound insulation ability to 3-6 dB.

- The patented ZIPS panel system is a ready-made soundproofing sandwich panel with vibration-isolating fastening units and a finishing plasterboard sheet. First, the sandwich panel is installed directly to the wall, and then the plasterboard is fixed onto the ZIPS panel .

Important numbers

More than fifteen years have passed since the start of production of ZIPS material in the Russian Federation. Over the entire period, more than one million square meters of soundproofing material were produced. Great demand among buyers is due to excellent quality and relatively low cost.

Not many manufacturers of soundproofing materials can boast a thickness of only 53 millimeters. The product range also includes noise insulation that can absorb up to 65 dB. There are many options today, but preference should be given to proven materials that have earned the trust of buyers.

More information about ZIPS panel systems

Thanks to its complete readiness for installation on walls, the ZIPS panel system is recognized as the best material for frameless cladding. In the table we compare soundproofing ZIPS structures of various thicknesses to show what index of additional sound insulation of airborne noise the system can provide.

| Design for soundproofing walls | System Features | Thickness of frameless cladding | Additional sound insulation index |

| ZIPS-Vector | provides an initial level of protection from household noise - voices, dog barking, children's crying, low-power radio and television devices, operating range - from 125 Hz | 5.3 cm | 9-11 dB |

| ZIPS-III-Ultra | shows the highest efficiency in terms of thickness/result ratio, protects against household noise sources at a basic level, operates in the range from 100 Hz | 5.5 cm | 11-13 dB |

| ZIPS-Module | basic level of sound insulation against medium-intensity noise in residential and public buildings, for example, in restaurants, cafes and shops, range from 100 Hz | 8.3 cm | 12-14 dB |

| ZIPS-Cinema | a system that provides high-level sound insulation, used for home theaters and studios, as well as for equipping concert halls, discos, bowling alleys and other rooms with high-intensity noise, the operating range is from 80 Hz | 13.3 cm | 16-18 dB |

Useful: How to build a shed with your own hands

Installation

Installation of ZIPS is possible using vibration isolating units. If you need to attach the panel to a load-bearing wall, you can use six vibration supports, leaving the central nodes unfastened. If the panels are fixed to the ceiling, then it is advisable to use anchor screws for the central units. When laying floors, experts advise using hydro- and vapor barrier layers. Fastening with self-tapping screws through the nodes will minimize the effect of sound waves and vibrations. Installation work with ZIPS panels is easy to do yourself. No technological equipment or tools are required. One has only to take into account that the weight of one slab is about 20 kg, so installation alone is almost impossible.

The installation steps for ZIPS panels are as follows:

- enclosing structures must be treated with a layer of “Vibrostek” type gasket. For fixation, Akulex brand sealant is used;

- To fix the panels, you need dowels with self-tapping screws 5 cm long and 8 mm in diameter. Self-tapping screws must have an addition in the form of cone-type washers;

- ZIPS panels are installed from the bottom up. From each first panel, the ridges are trimmed on both the long and short sides. The next panels of the first row need to be trimmed only on the long side;

- You should place the first panel against the wall and use a hammer drill to make holes in the vibration-isolating units about 6 cm deep. Hammer the prepared fasteners until they stop. Screw a screw with a washer into the vibration unit;

- All panel joints must be treated with Vibrosil sealant.

How to choose material for sound insulation in a frame house

In a wooden house with a frame base, the structure of the wood itself does a good job of dampening sound waves coming from the outside. But shock waves travel noticeably through wooden structures, and they penetrate especially well through voids in the ceilings . If you have built a wooden frame with several floors, footsteps and sounds from falling objects will be clearly heard from above. In this case, to effectively dampen shock waves between floors, a “floating floor” design is used, and more specifically, the floor is placed on a sound insulation layer, which is connected to the walls through elastic gaskets . The floating floor does not come into direct contact with the timber frame.

Manufacturers offer the following soundproofing materials for walls in a frame house:

- fibrous materials of mineral origin - mineral wool, basalt wool;

- fibrous materials of organic origin - felt, ecowool, plasterboard;

- elastic materials - cork, latex, polyurethane foam, synthetic rubber.

If you want to focus on dampening airborne noise, focus on the fibrous structure of the insulation , and to eliminate the predominant influence of structural and impact noise, choose elastic materials .

Application

For low-budget repairs, experts advise using frame panel installation schemes. Frameless technology has shown the best efficiency in soundproofing floors and ceilings. The floor in the apartment is soundproofed using two components: an elastic material and a leveling screed. If the subfloor is level, a finished floor covering can be used over some resilient materials.

Laminate or parquet boards can be laid on the leveling coating “Shumaplast”, “Shumanet-100Hydro”, “Shumanet-100Kombi”, “Shumostop”. At the same time, the thickness of the soundproofing base is only 1 cm, and the structure will have good insulating ability. In this case, impact noise insulation will be up to 43 dB, and airborne noise insulation will be 8–10 dB. To improve performance, special edge slabs are laid around the perimeter of the room, and the seams between the materials are sealed with sealant.

The work can be done faster if you use the ZIPS floor quick-assembled soundproofing panel system. The main elements of the system are as follows:

- ready-made sandwich panels;

- acoustic layer “Soundline”;

- finishing plywood sheet.

Acoustic triplex "Soundline" is a special three-layer material, which consists of interconnected moisture-resistant gypsum fiber sheets. The dimensions of the sheets are 1200x1200x17.5 mm. The material is characterized by high fire safety. ZIPS flooring can be used locally without damage to premises that do not require renovation. The ZIPS floor model range includes systems such as:

- "Vector". This is the thinnest system that provides standard sound insulation;

- "Module". The system is 11 cm thick and provides effective insulation.

For walls, ZIPS wall panels are suitable, which must be selected taking into account the characteristics of the model range. Ceiling materials are usually divided into soundproofing and sound-absorbing. The first option has a decent mass, and the second is usually fibrous. Insulating materials reflect sound waves, while insulating materials inhibit sound waves. It is believed that designs with sound-absorbing material inside and sound-insulating material outside are the most effective. For soundproofing ceilings, ZIPS “Module”, “Vector”, “Cinema” or “Ultra” are used. With a thickness of 5 cm, the design provides additional insulation against airborne noise from 11 to 13 dB.

How to soundproof a wooden floor

Each wooden floor in a wooden house is potentially a source of heat loss and noise propagation. Beams made of wood creak on their own, but they also conduct sound perfectly . Materials for soundproofing a home must cope with impact, structural and acoustic (airborne) noise. For the maximum degree of sound absorption, we recommend choosing basalt, mineral wool or ecowool.

Additional soundproofing functionality will be provided by installing a subfloor made of OSB or chipboard . This structure, based on the principle of a floating floor, is simply supported on beams under its own weight. There is no rigid connection with wooden floors, which means there is also no risk of transmitting unwanted sound. And one more thing: you will need to lay rolled felt insulation in the seam between the floors and load-bearing walls, as well as in the chimney area. The plinth is nailed to the wall and covers the joints. It is advisable to place a foil, cork or polystyrene underlay under the floor covering to reduce vibrations and impact noise .

How to soundproof partitions

The level of noise protection depends on the thickness and density of the soundproofing partition, and increasing sound insulation due to thickness is completely ineffective. It is important to take into account the sound absorption coefficient - the strength of sound is reduced by granular, soft, fleecy or cellular materials, that is, those that create as many barriers as possible for the sound wave. Multilayer panels with a sound-insulating, sound-absorbing layer and an air gap have proven themselves very well , that is, it is necessary to ensure a difference in the environment.

High-quality sound insulation of partitions will reduce sound pressure and reflect the wave from the protected interior. For these purposes, the following materials are actively used:

- GKL (plasterboard sheets). The ideal option is a multi-layer sandwich: gypsum board on both sides, and filler inside. The cladding must be made in compliance with technological standards and mounted on a special profile. Soundproofness indicators are increased by installing soundproofing fasteners for frame partitions , expanding the spaces between the racks, thickening the frame and cladding, and laying high-quality filler. There should be polymer gaskets on metal connections, and a sealing tape under the starting horizontal profiles.

- Acoustic drywall consists of a perforated layer on the front surface, which absorbs noise, and a non-woven fabric on the back, which enhances the effect. Each hole is a mini-resonator that picks up sounds and causes the wave to attenuate. A very good option for a meeting room or recording studio, but not only. Acoustic drywall is relevant wherever you need to provide soundproofing in a room with no echo and reduced background noise .

Useful: We calculate the cost of building a frame house

Questions and answers on ZIPS and sound insulation

What restrictions are there on the use of ZIPS panels?

The only significant limitation for the use of ZIPS panels is that the soundproofed surface must be flat. That is, before installing the ZIPS, it must be leveled if necessary

It is also important to consider the load-bearing capacity of the wall/ceiling. Is it enough to insulate one wall or do you need to soundproof the whole thing?

It happens that after soundproofing that same wall, the noise does not disappear completely, although it becomes quieter

This is due to the fact that sound waves are transmitted through the joints to adjacent surfaces, and you hear noise that comes from other walls, from the ceiling, from the floor. The best sound insulation is sound insulation based on the “room within a room” principle, when absolutely all surfaces (walls, floor, ceiling) are soundproofed. However, this does not mean that soundproofing a single wall will not have an effect. Usually the noise is reduced significantly. At the same time, if achieving an absolute result is really important to you, we strongly recommend that you consult with an acoustic engineer before carrying out work.

Is it possible to hang something on a wall covered with zips?

Can. If we are talking about a painting or a small shelf, no problem at all. If you decide to hang something really heavy, you will need to provide anchors during installation. In this regard, it is better to consult with specialists in advance.

Will I be able to install ZIPS in my apartment myself?

Yes, sure. However, most likely you will need an assistant. It's a bit difficult to hold the panel and screw it on at the same time. This is especially critical when carrying out work on soundproofing the ceiling.

You say that ZIPS is the thinnest sound insulation, but I have seen advertisements for materials that are much thinner!

Unfortunately, many dishonest sellers mislead consumers. No, most often they don’t lie. They just don’t say enough. Remember the fairy tale about the porridge made from an axe? The ax required very little, very little, additional ingredients - cereal, salt and butter. So it is here. Those thin materials are usually just part of the soundproofing structure that you will need to build to achieve real results. For example, weighted vinyl glued to the wall will not have any significant effect. It is used ONLY as part of a sandwich in frame soundproofing structures. In some cases, the sound insulation of walls can be significantly increased using triplex solutions with a thickness of about 25 mm. However, this is only possible for walls with extremely weak initial sound insulation. The total sound insulation indicator will not be very large. But a tangible effect will be achieved thanks to the low base. We can offer you such solutions. But the possibility of their applicability in your particular case must be discussed with acoustic engineers.

What, besides ZIPS panels, will be needed to install soundproofing cladding?

ZIPS panels are attached directly to the surface to be insulated. All necessary fasteners are included in the kit. But you still have to buy something else.

To improve the ZIPS characteristics, as well as to increase the strength of the cladding, the ZIPS panels are sheathed with specialized weighted plasterboard AKU-line. In order to prevent noise from being transmitted to the front surface of the panels along the junctions, it will be necessary to lay the perimeter with a Vibrostek-M soundproofing gasket. The seams at the joints are filled with vibration-isolating sealant Vibrosil. Thus, in addition to the ZIPS panels, you will need AKU-line gypsum boards and self-tapping screws for fastening them, as well as specialized accessories: Vibrostek-M soundproofing gasket and Vibrosil vibration-isolating sealant. Our managers will help you calculate the required amount of materials and the estimate.

What fillers are there in gypsum plasterboard partitions?

Full sound insulation of partitions includes sound-absorbing filler. Typically this is expanded polystyrene with a fire retardant in the form of a foam material with hollow, air-filled granules that are fused together. The flame retardant in the composition prevents combustion . Mineral wool, membranes made of thin fabric with pile, polyurethane foam, polystyrene foam can also be used as a filler.

When you are at the stage of choosing which is better for sound insulation - polystyrene foam or mineral wool - we advise you to pay attention to the following nuances:

- polystyrene foam insulates well, but is not a material for absorbing noise;

- mineral wool is inferior to foam plastic in thermal conductivity, but the sound absorption coefficient of mineral wool is 10 times higher than that of foamed plastic;

- foam will not help at all against airborne noise , however, under a floating screed, foam can achieve a small degree of protection against impact noise;

- polystyrene foam cannot be mounted monolithically, that is, unnecessary voids will certainly appear, but mineral wool can be laid overlapping and in several layers;

- polystyrene foam creaks when vibrating, unlike fibrous material;

- Insects and rodents do not grow in mineral wool.

Conclusion: when posing the question - is foam plastic or mineral wool better for sound insulation - we choose the second option. And if the budget allows, we install acoustic slabs using noise and vibration mounts .

What it is?

ZIPS panels are a frameless soundproofing structure. When there is no need to make panels without a frame, it becomes possible to quickly install sound insulation. The panel fastening system is unique and patented. The vibration units built into the panels not only allow you to secure the plane, but also prevent the transmission of sound vibrations to the external part of the structure.

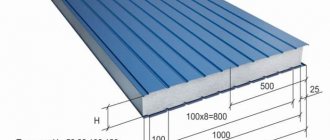

The structures are multilayer panels, which are currently widely used in the modernization of structures and buildings, and also make it possible to increase the sound insulation of surfaces. The sound insulation characteristics are affected by the composition of the panel, which includes alternating soft and dense layers, and a facing coating on top of them. The number of layers may vary due to modification of the panel type. The panels can be mounted to all surfaces: walls, ceilings, floors. You can use 5 cm long dowels and screws with cone washers. The ends of the panels are glued to special elastic gaskets, and a vibroacoustic sealant is used as an adhesive.

The professional soundproofing system ZIPS is suitable for soundproofing load-bearing walls and partitions in rooms for various purposes. Using the system, standard sound insulation values are achieved. The panels can easily cope with household noise and reduce the impact of intense noise in the range from 80 to 125 Hz. The soft base of the soundproofing material is fiberglass, the hard layer is gypsum fiber. The system comes into contact with the surfaces of brick, concrete, as well as gypsum board partitions and ceilings through tape-type gaskets made of fiberglass “vibrostek”. The system preserves the basic acoustic principles laid down in building regulations. Currently, ZIPS is sold in several modifications, which differ in acoustic efficiency.

How to soundproof a ceiling

In order to reduce sound pressure and prevent the spread of noise, specialists provide sound insulation of the ceiling along with partitions, ceilings and walls. Soundproofing methods include:

- soundproofing plasterboards;

- liquid sound and heat insulating compounds;

- acoustic suspended ceilings.

In terms of popularity among affordable ceiling sound insulation, the leaders are practical and easy-to-install plasterboard boards with polyurethane foam blocks, foam glass, reed tiles or cotton wool . If you choose an environmentally friendly sound-absorbing material, give preference to cork or coconut fiber.

We suggest you familiarize yourself with the stages of installing a plasterboard ceiling with sound insulation function.

- Along the perimeter of the walls, using a level, you need to mark where the frame will be located.

- Brackets are fixed to the ceiling, onto which frame partitions will later be mounted. The pitch of the frame depends on the thickness and quantity of gypsum plasterboard.

- The membrane is glued to the ceiling.

- If plasterboard sheets are laid perpendicularly, the frame pitch is chosen from half a meter to 60 cm, and if parallel, the pitch is 40 cm.

- Sound insulation is glued to the membrane between the frame profiles.

- GKL is fixed to profiles, and sound-reinforcing tape is laid in the joints.

- Moisture-resistant mastic or plaster covers the joints between sheets of drywall.

Choose the appropriate soundproofing method and strictly follow the technology, since even a small mistake can affect the final result.

Characteristics

The frameless system is suitable for soundproofing interior partitions, which are known to have extremely low insulation. Gypsum blocks with a frame system are not suitable for such partitions, since the thickness of these walls is usually small. Low insulation of partitions up to 75 cm thick is due to low surface density. The partitions also retain a pronounced resonance phenomenon. The wave phenomenon at critical frequencies affects the insulation efficiency of all building structures. If you install ZIPS soundproofing panels on either side of the partition, they will significantly reduce the sound radiation of the partition in the operating frequency range.

The operating principle of the panels is based on anti-resonance resistance. The panels do not require the additional use of gaskets and elastic sealants. The fastening points of soundproofing panels can be sealed with any putties suitable for gypsum fiber sheets. For example, placing a panel increases the noise insulation of a structure by 6 to 10 dB. Moreover, the less insulation the partitions initially have, the more significantly it can be increased.

Installation of the panels is very simple, the event is quite effective. ZIPS panels were launched under the corresponding brand, and therefore have this name. The produced panel is ready for use without any modifications. To fasten the panel, special vibration units are provided, which are performed at the production stage. The panel itself is a combination of dense and light materials that vary in thickness. The range offered by the manufacturer includes several types with which it is possible to soundproof walls with different characteristics.