Here you will learn:

- Advantages and disadvantages of pumping stations with a hydraulic accumulator

- Operating principle of pumping stations with a hydraulic tank

- Operating principle of a system without a hydraulic tank

- Does it make sense to abandon the hydraulic accumulator?

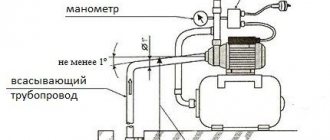

- Diagram of a pumping station without a hydraulic accumulator

- Water supply without accumulator

A pumping station without a hydraulic accumulator is a pump connected by a pipeline to water collection points. The main disadvantage of such a system is the rapid wear of pumping equipment.

Advantages and disadvantages of pumping stations with a hydraulic accumulator

If we talk about the advantages that a pump with a hydraulic accumulator has, the most significant of them usually include the following.

- In water pipelines served by pumping stations with a hydraulic accumulator, which is always filled, a constant availability of water is ensured.

- A hydraulic accumulator for a pumping station, the main structural element of which is a membrane that creates the required pressure of the liquid medium in the system, ensures the supply of water to the pipeline even in cases where the pump is not functioning. However, water will flow into the pipeline when the pump is not working until it runs out in the hydraulic tank.

- The use of a hydraulic accumulator eliminates such a negative phenomenon as water hammer in the pipeline system.

- Water pumps operated in conjunction with a hydraulic tank have a longer service life, as they operate in a more gentle mode, turning on only at those moments when the liquid level in the hydraulic accumulator drops to a critical level.

To ensure efficient operation of a pumping station equipped with a hydraulic accumulator, it is very important that the pressure switch installed on it is correctly adjusted.

For any water supply system you can choose a suitable accumulator

Among the disadvantages of pumping stations with a hydraulic tank are the following:

- It is necessary to allocate a decent area for the installation of such equipment, which is explained by the large dimensions of the accumulator.

- If the pressure switch fails, the site on which such equipment is installed will be flooded with water.

- The design features of the hydraulic tank require regular (once every 2-3 months) bleeding of air from its tank, which ensures the efficient operation of such equipment (the design of the hydraulic accumulator requires the presence of a special valve for this procedure).

What is a hydraulic accumulator

A hydraulic tank (or hydraulic accumulator) is a water container with a rubber elastic membrane (resembling a pear) located inside the container and having a sealed connection to the metal body of the tank. This connection is made using a flange with a threaded connection to connect the device to the water supply. The cavity between the membrane and the metal body of the hydraulic tank is filled with compressed air, usually the pressure is 1.5-2 bar. Hydraulic accumulators are used to maintain constant pressure and create a water reserve in domestic or industrial conditions. It is this unit that provides the required pressure in the system when the pump is turned off.

Fig.1.

Hydraulic accumulator structure 1 – metal body; 2 – rubber membrane; 3 – flange with valve (passes air); 4 – nipple for pumping air into free space; 5 – cavity for compressed air; 6 – supports; 7 – platform for the pump. More details about the design of the hydraulic tank in the video: Return to content

Operating principle of pumping stations with a hydraulic tank

A pumping station with a hydraulic accumulator, used for pumping water from an underground source and further transporting it through a pipeline, is a whole complex of technical devices, the main one of which is a water pump.

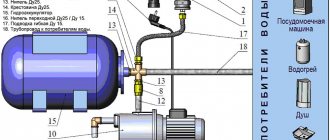

Construction of a pumping station with a hydraulic tank

The operating principle of a pumping station with a hydraulic accumulator is as follows.

- Through a hose placed in a well or well, equipped with a coarse filter and a check valve, water is pumped out from an underground source and sent to a hydraulic accumulator. A hydraulic tank, which is a container with a membrane that separates the liquid and air media in it, is responsible for the cycles of turning pumping equipment on and off.

- Water enters the accumulator until the membrane is fully tensioned, on the other side of which there is half a container with air pumped under a certain pressure.

- As soon as the half of the hydraulic tank into which water flows is filled to capacity, the pump station pressure switch automatically turns off the pump.

- After water from the hydraulic accumulator begins to flow into the pipeline system, the fluid pressure in the hydraulic tank drops to a critical value, and the pressure switch sends a signal to turn on the pump.

Operating principle of the hydraulic accumulator

Depending on the number of people living in the house for which the pumping station is used for water supply, the hydraulic accumulator capacity is selected in the range from 20 to 500 liters or even more.

Balloon or membrane

Hydraulic accumulators are divided into two main types - membrane and balloon. The principle of operation of both types is similar - an elastic film of rubber expands or contracts under pressure from water and compressed air. The main difference is that in a membrane tank, water coming from the well comes into contact with the metal walls of the tank, which can potentially lead to corrosion. In a tank with a rubber cylinder, water comes into contact only with the cylinder itself, without touching the metal walls. The absence of conditions for the development of corrosion extends the life of the balloon accumulator.

An additional convenience is that the cylinder, unlike the membrane, is a replaceable part. Carrying out the replacement will not cause any difficulties - even a non-specialist can do it. As a result, servicing a hydraulic accumulator with a cylinder will be cheaper. Taking into account the above factors of practicality and reliability, cylinder accumulators are the optimal solution for individual water supply.

An important factor when choosing a hydraulic accumulator is the cost of spare parts

Please note that some manufacturers may unreasonably inflate the price of components. For example, a rubber cylinder can cost half or even more of the cost of the entire hydraulic accumulator

Operating principle of a system without a hydraulic tank

Equipment pumping water works the same way: it takes liquid from a source - a well, a well - and pumps it into the house, to water collection points. The pump can be either submersible or surface pump.

The role of connecting lines is performed by pipelines made of polypropylene pipes or flexible hoses. In the same way, water is supplied to the bathhouse, garage, summer kitchen, and swimming pool.

So that water can be used in autumn or early spring, it is recommended to insulate the well and bury the pipes to a depth of 70-80 cm - then the liquid will not freeze even during frosts

The difference concerns the use of additional devices, such as a hydraulic accumulator, pressure switch, etc. Installing pumping equipment without means of control and adjustment is extremely dangerous - primarily for the equipment itself.

The simplest example of equipment for providing dacha residents with water in the summer is the AL-KO garden pump. You can use it to water plants, organize a shower, or fill a pool with water.

If a large amount of water or a more stable supply is needed, another important element is included in the scheme - a storage tank. First, the water flows into it, and only then to consumers.

When using household pumps, the liquid volume is usually from 2 to 6 m³/h. This amount is usually enough if the station is connected to a well or borehole and serves a country house.

When choosing a unit, it should be taken into account that the absence of a hydraulic tank accelerates the wear of parts, so the equipment must be durable - with a steel or cast iron body coated with anti-corrosion paint.

The pump functions are controlled using a pressure switch, which is responsible for regulating the pressure. For control, the easiest way is to install a pressure gauge, which is usually equipped with automatic pumping stations.

In the absence of a hydraulic accumulator, the pressure switch is connected directly to the pumping station or integrated together with a dry-running relay into the pipeline

In addition to equipment for pumping water, you will need an electrical cable, a connection point to the network and grounding terminals. If the ready-made solution does not satisfy your needs, the station parts can be purchased separately and then assembled at the installation site. The main condition is the compliance of the system elements with characteristics.

Positive and negative feedback

How good a system without a hydraulic accumulator is in practice is best judged by the reviews of users - owners who have been using it in their homes for a year or more.

One of the advantages is the compact size and ergonomics of the pumping station. There is no hydraulic accumulator that takes up a lot of space, making it much easier to find a small corner to install the pump.

You can use different types of pumps with equal success, including submersible units - then only the pipeline and control devices will appear on the surface.

The cost of a unit without a hydraulic tank is lower, and installation is simpler.

An example of a pumping station that can be used for domestic servicing of a dacha. The pump is equipped with a pressure switch and dry-running protection

There are also disadvantages, the main one being insufficient power. A system without a hydraulic accumulator has minimal performance, and pumping equipment is constantly at risk of failure.

It is not protected from water hammer, and from frequent switching on/off it simply wears out earlier than stated by the manufacturer.

Today, when there are many models on the market with a hydraulic accumulator costing from 8,000 rubles, the system with a storage tank is considered outdated and irrational.

Does it make sense to abandon the hydraulic accumulator?

When designing a water supply system for a house, it is necessary to take into account factors such as the number of consumers, the volume of pumped liquid, and the resource of a well or borehole. If water is required on an ongoing basis and in large quantities, then you simply cannot do without a hydraulic accumulator.

A pumping station with a hydraulic tank ensures a continuous supply of water to the house, and if a power outage suddenly occurs, the supply of liquid is enough to finish your business. The volume of the tank is selected based on needs.

The average volume for domestic use is 25-50 liters, but for frequent use it is better to immediately purchase a 100-200 liter tank or include a storage tank as an addition to the circuit.

The hydraulic accumulator performs several important functions: it stabilizes the water pressure in the system, protects equipment from water hammer, and increases the service life of the pump.

The water supply system can operate without a hydraulic accumulator. In essence, it is a pump connected by a pipeline to water collection points. The main disadvantage of such a system is the rapid wear of pumping equipment.

In a system with a hydraulic tank, the pump is turned on only when necessary, but here it will turn on every time someone opens a water tap or wants to water the flowers. Due to frequent activation, the engine fails faster, and the pump has to be repaired or replaced more often than usual.

Connection diagram for a pumping station without a hydraulic tank. A surface pump is installed in the basement, water is supplied through a suction pipeline lowered into a well (well) (+)

However, manufacturers have not abandoned models without a hydraulic tank, because they are in demand. Most often they are of interest to owners of summer cottages who use the water supply system only in the summer - for recreation, growing vegetables or flowers.

Let's consider situations in which you can get by with one pump, without a hydraulic accumulator:

The pump can be used to transport liquid from a well, well, and even a pond or swimming pool. The pressure and degree of water purification do not matter much. If daily watering of large areas is required, in order to save money, it is recommended to use a storage tank in addition to water from the well. To fill the tank from which water is supplied to the hoses of the drip irrigation system, it is enough to install a conventional pump - submersible or surface. When water is used only for one tap serving a small country house, it is not necessary to install a pumping station.

Thus, if there is no need for a large amount of water, which must be supplied stably, constantly and have a reserve, you can get by with an ordinary automatic pump. In other cases, a hydraulic accumulator is required.

Correct selection

An interesting nuance: the name of this equipment does not depend on its design, but on the area of application.

When it comes to water supply, the tank is called a hydraulic accumulator. A container built into the heating with the same structural characteristics will be called a membrane or expansion tank. But it is important to take into account the information provided by the manufacturer. Each product has its own operating temperature and pressure:

- up to 4 atmospheres and up to 120 degrees Celsius - for heating;

- up to 12 atmospheres and up to 80 degrees – for water supply.

It is not the cheapest tank that is selected based on volume, but one that corresponds to the system parameters.

To normalize the pressure in the heating system, a number of devices are used. But the most important of them is the hydraulic accumulator. Its design makes it possible to automatically stabilize the coolant pressure when the temperature changes.

Purpose

The hydraulic accumulator is installed only for closed-type heating systems. They are characterized by high water pressure, which occurs due to its heating. Therefore, if the permissible value is exceeded, a compensation system is necessary. This is what the hydraulic accumulator is designed for.

It is a steel structure, which is internally divided into two chambers. One of them is designed to be filled with water from the heating system, and the second serves as an air compensator. To set the optimal pressure in the air chamber, a valve is provided in the accumulator. With its help, the degree of air injection is changed, thereby adapting the device to the parameters of a specific heating system.

The chambers are separated by an elastic membrane or rubber balloon. When the water temperature in the pipes rises above critical, a pressure surge occurs. The liquid, expanding, begins to press on the walls of the separation membrane. She, in turn, under the influence of this force, increases the filling volume of the water chamber. This leads to normalization of pressure within the entire system.

Connection rules, diagram

When installing a hydraulic accumulator, certain rules should be followed. First of all, you need to select an area in the heating main where it will be installed. Experts recommend installing the expansion tank in the return pipe with chilled water. But at the same time, it must be installed before the pumping equipment. The general installation diagram is as follows.

As you can see, a safety valve is installed at the outlet of the heating equipment to protect the line from differences in liquid pressure. It performs the same functions as a hydraulic accumulator, but is designed for higher pressure surges. An expansion tank is necessary to normalize heating operation at small pressure drops.

Before starting installation, please consider the following:

- Selecting an installation location. The main requirement for it is free access to the device. This is especially true for the air chamber control valve.

- There should be no other shut-off or control valves in the area between and the expansion tank. It can make significant changes in hydraulic resistance.

- The temperature in the room where the accumulator is installed should not be below 0°C.

- Its surface should not experience mechanical stress or external influences.

- The response of the pressure reducer to release air from the chambers must be set according to the parameters of the heating system.

Guided by these rules, you can install the expansion tank yourself. But at the same time, you should follow the connection rules, use products made of high-quality material and calculate the optimal tank volume.

To make the calculation, you need to know the total volume of the heating system, the optimal and maximum pressure in it, as well as the expansion coefficient of water. Formula for calculating the size of a membrane-type hydraulic accumulator:

- e – water expansion coefficient – 0.04318;

- C – total volume of the heating system;

- Pi – initial pressure;

- Pf – maximum pressure.

Let's consider an example of a calculation for heating with a total volume of 500 liters, an optimal pressure of 1.5 bar, and a maximum of 3 bar.

This technique will allow you to correctly select and connect an expansion tank for a closed heating system.

Diagram of a pumping station without a hydraulic accumulator

In principle, the scheme is quite simple. Regardless of which pump will be used in the home water supply system (submersible or surface), first of all it must be protected from silt and dirt from the water intake source. Therefore, a mesh filter is installed at the very bottom, which will trap large suspended particles.

Next according to the diagram is either the pump itself, if it is deep, or a pipeline that will connect the filter to a pump installed on the surface. In the first case, the same water supply will be extended from the pump in the form of a pipe or hose. That is, the route will start right at the hydraulic structure. Therefore, it is very important to determine the level of soil freezing in the area where the well or borehole is located. Starting from this level, the pipeline will have to be thermally insulated.

Scheme with an additional pump

Now for the internal plumbing. Firstly, it is necessary to consider the water treatment system. Unfortunately, the water coming into the house from wells and shallow wells will not be very clean. Therefore, the simplest option is to install two filters: coarse and fine. They easily cope with the responsibilities assigned to them for purifying water, but require that their filter cartridges be changed more often.

The next element is a storage tank with a float. It is connected to the pump through a pipe and installed filters. After this, the pipe is routed to consumers.

Scheme with a tank in the attic

Peculiarities

The hydraulic tank is called a hydraulic accumulator or membrane tank. It is used to maintain a stable pressure level in the water supply system. The product also protects the pump from wear and the drainage system itself from water hammer. Thanks to the hydraulic tank, you can use water even in the absence of voltage.

Advantages of vertical hydraulic tanks:

- Protection of the pump from early wear.

- Maintaining stable pressure in the water supply system.

- Protection against water hammer that may occur during the start-up of alluvial equipment. Water hammer can damage the pipeline.

- Maintaining water reserves in the system.

Vertical type hydraulic accumulators have disadvantages, which include complex installation. Installation will require effort and some skill.

Water supply without accumulator

If you exclude the hydraulic accumulator from the water supply scheme, then two options are possible:

- using a pump to supply water directly to water collection points;

- connecting a storage tank.

Both options are actively used, but the first is optimal for irrigation systems with a small volume of liquid, and the second is most appropriate when you need to provide water to a shower, kitchen faucet - that is, consumers inside the house.

Connecting the pump directly

There are many interesting solutions, but the most practical and economical are automated irrigation systems. They work only during periods when there is no rain, and are installed wherever regular watering is necessary - in the garden, near flower beds, on lawns.

One of the options is an expanded irrigation system for a personal plot. It is fully automated. To set the on/off time, connect the controller. Solenoid valves can be installed on each individual line so that they can be operated separately.

Approximate scheme of automatic watering of a summer cottage. Transportation of liquid from a well or well is carried out through pipes with a diameter of 19 mm (central) and 16 mm (branches) (+)

The rain sensor makes the irrigation system more efficient: during rainfall, the pump does not function.

The procedure for installing the irrigation system:

- we place the pipes on the surface of the earth according to a pre-designed diagram and connect them with fittings;

- we install sprinklers, drip systems, watering hoses;

- we equip a pumping group - a surface unit and a pressure switch;

- connect the water supply, test the system for leaks;

- if all is well, we dig trenches 30 cm deep, build a drainage cushion from crushed stone and sand, lay the pipeline and fill it up;

- We carry out repeated testing to check the tightness, check the performance of all lines;

- connect the controller and rain sensor;

- We check the operation of all elements of the system.

If the throughput is small, we set up alternate operation of the lines. This is a complex circuit that requires knowledge of how to configure the equipment. The simplest is a regular “Baby” type pump with watering hoses connected to it.

Functions, purpose, types

Installation location - in a pit or in a house

In the water supply system of a private house without a hydraulic accumulator, the pump turns on whenever water flows somewhere. These frequent starts lead to wear and tear on the equipment. And not only the pump, but the entire system as a whole. After all, every time there is an abrupt increase in pressure, and this is a water hammer. To reduce the number of pump starts and smooth out water hammer, a hydraulic accumulator is used. The same device is called an expansion or membrane tank, a hydraulic tank.

Purpose

We found out that one of the functions of hydraulic accumulators is to smooth out water hammer. But there are others:

- Reducing the number of pump starts. There is some water in the tank. With a small flow rate - wash your hands, wash yourself - water flows from the tank, the pump does not turn on. It will turn on only when there is very little left.

- Maintaining stable pressure. This function requires one more element - a water pressure switch, but they maintain the pressure within the required limits.

- Create a small supply of water in case of power outage.

It is not surprising that most private water supply systems have this device - there are many advantages from its use.

Kinds

The hydraulic accumulator is a tank made of sheet metal divided into two parts by an elastic membrane. There are two types of membrane - diaphragm and balloon (bulb). The diaphragm is attached across the tank, a pear-shaped cylinder is secured at the inlet around the inlet pipe.

According to their purpose, they are of three types:

- for cold water;

- for hot water;

- for heating systems.

Hydraulic tanks for heating are painted red, tanks for water supply are painted blue. Expansion tanks for heating are usually smaller in size and lower in price. This is due to the membrane material - for water supply it must be neutral, because the water in the pipeline is potable.

Two types of hydraulic accumulators

Depending on the type of arrangement, hydraulic accumulators can be horizontal or vertical. Vertical ones are equipped with legs; some models have plates for hanging on the wall. It is the elongated upward models that are most often used when independently creating water supply systems for a private home - they take up less space. The connection of a hydraulic accumulator of this type is standard - through a 1-inch outlet.

Horizontal models are usually equipped with pumping stations with surface-type pumps. Then the pump is placed on top of the tank. It turns out compact.

Principle of operation

Radial membranes (in the form of a plate) are used mainly in gyroaccumulators for heating systems. For water supply, a rubber bulb is usually installed inside. How does such a system work? As long as there is only air inside, the pressure inside is standard - the one that was set at the factory (1.5 atm) or that you set yourself. The pump turns on, begins to pump water into the tank, and the pear begins to increase in size. Water gradually fills an increasingly larger volume, increasingly compressing the air that is located between the wall of the tank and the membrane. When a certain pressure is reached (usually for one-story houses it is 2.8 - 3 atm), the pump is turned off, and the pressure in the system stabilizes. When you open a tap or other water flow, it comes from the accumulator. It flows until the pressure in the tank drops below a certain level (usually about 1.6-1.8 atm). After which the pump turns on, the cycle repeats again.

The operating principle of a gyroaccumulator with a pear-shaped membrane

If the flow rate is large and constant - you are filling a bathtub, for example - the pump pumps water in transit, without pumping it into the tank. The tank begins to fill after all the taps are closed.

A water pressure switch is responsible for turning the pump on and off at a certain pressure. In most hydraulic accumulator piping schemes, this device is present - such a system operates in optimal mode. We’ll look at connecting the hydraulic accumulator a little lower, but for now let’s talk about the tank itself and its parameters.

Large tanks

The internal structure of hydraulic accumulators with a volume of 100 liters and above is slightly different. The pear is different - it is attached to the body both at the top and at the bottom. With this structure, it becomes possible to fight the air that is present in the water. To do this, there is an outlet in the upper part into which you can connect a valve for automatic air release.

The structure of a large hydraulic accumulator

How to organize your workflow

Let us immediately note that in order to install a central water supply in a private house, you will have to spend a lot of time not only on work, but also on drawing up documentation and getting it approved by the competent supervisory authorities. Let us begin our consideration with this part of the work.

Paperwork

In order to explain the procedure for obtaining permits, developing technical specifications and designing a project, you will need a whole instruction:

- First of all, you should contact the water utility to develop technical conditions for connection. To do this, you will need documents on ownership of the land and building, and an application in the prescribed form. The period for issuing the conclusion is 1 month.

- Ready specifications are provided to the SES, which gives an opinion on the possibility of inserting into communications. At the same time, design and estimate documentation is ordered from the competent organization, which provides for all the main features of the system and reflects the location of each of the elements.

- After the project is received, it must be registered with the SES. At this point, the design work can be considered completed.

- Another important point that should never be overlooked is the coordination of excavation work with utility services. Only having the appropriate permit in hand can you begin work.

Only with a warrant in hand can you begin digging trenches for pipes

Carrying out work

Let’s break this process down into separate steps to make it easier for you to understand their features:

Water supply to a private house from a central water supply involves laying a pipeline at a certain depth, which should be greater than the freezing level of the soil.

This table indicates the depth of soil freezing in some regions depending on the type of soil

If the soil is very complex or a highly located aquifer prevents you from going deeper to the required level, then the pipe can be laid at a shallower depth. But in this case, you will need to use insulation, which is segments of a certain diameter; another option is a heating cable, which can be laid both outside and inside the pipe.

Insulation for pipes allows you to protect them from the cold at a shallow installation depth

- Digging a trench can be done either using special equipment or manually. The second option is very labor-intensive, but in some situations, when access to equipment is difficult, it will be the only possible one.

- The depth of the trench should be slightly greater than necessary, this is due to the fact that a gravel or crushed stone cushion must be poured onto the bottom. This provides additional support to the pipes and reduces stress on them.

- First of all, a pipe coupling is connected or a valve is cut in to connect the pipe. After this, you can install the system all the way to your home.

- It is easier to enter the house in the following way: the pipe is laid under the foundation of the building or through it and is discharged into some room at a distance of 1-2 meters from the outer wall. The vertical section is additionally insulated to prevent the possibility of freezing. A shut-off valve and a meter are installed at the entrance, and then wiring is done throughout the house.

This is what the entrance to the house looks like; if you install the pipe yourself, make sure that its location is as convenient as possible

- When winter water supply is carried out at the dacha from the central water supply, the pipe can be routed both inside and outside the building, this is due to the fact that in the summer a watering hose will be connected.

- If the water pressure in the system is insufficient, then the issue can be solved by installing pumping equipment, with its help the quality of water supply will significantly improve.

In the photo: connecting the pumping station to the central water supply will not cause any particular difficulties, the instructions for carrying out the work are simple and clear

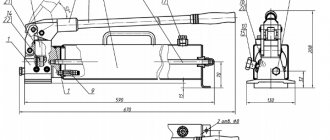

DIY drilling equipment

Water supply to a private house from a well; of all types of work, drilling is perhaps the most specific and unusual process, although this requires little: a drilling rig, a winch, a drill column and a drill head.

A drilling derrick is an ordinary tripod made of a wooden beam or a metal pipe (round or profile).

A winch is attached to it to lift the drill column - a system of rods that are attached to each other using couplings or threads.

The height of the drilling rig depends on the length of the drill rods, which for manual drilling are limited in size to 1.5-3 meters. Short ones will have to be connected and disconnected more often during drilling, and long ones are more difficult to work with.

At the end of the column there is a drill or bailer.

For each type of soil, a different type of drill is used:

spiral (or coil);

spoon drill for soft soil and large diameter wells;

spoon drill for soft soil and small wells;

drill bit for rocky.

The bailer is used to lift liquid fractions when they reach the high water and aquifer. It is also used to extract crushed hard rocks, which are filled with water and raised to the top as slurry.

The choice of working diameter of the drill depends on the diameter of the casing pipe. And here there may be options depending on the depth of the aquifer on the sand (which is of the non-pressure type) and the type of pump.

Surface pumps are capable of lifting water to a height of no more than 8 meters (self-priming models). Taking into account the depth of the caisson or basement, you can calculate no more than 10 meters. For such a well, casing pipes with a small diameter are used (slightly larger than for lifting water), and for an Abyssinian well, a metal pipe is used, which performs both functions.

Water supply to a private house from a well

Submersible pumps operate at significant depths (depending on power). They cost much more and the casing pipe must be selected taking into account that there is at least 4 mm between the walls and the pump casing.

The cost of a large-diameter drill is quite high, and there will be no need to use it further. You can rent it (if there is an enterprise nearby that offers such a service), but it is not difficult to make it yourself. For example, such a homemade sample that combines two types of drill for loose soil - a coil and a spoon.

The coil does not affect the size of the well - it serves to loosen the passable formation. And for the body of the spoon, an old gas cylinder is used; its steel has high strength values.

Video description

Connecting the pump to the hydraulic tank is shown in the video:

- The hydraulic tank is filled with water and checked for leaks. If necessary, additional sealing of threaded connections is carried out.

Water must be poured into the tank very slowly to avoid rupture of the membrane. During long-term storage, the “pear” may stick together; with gradual filling, the flexible form will smoothly straighten out.

- The power supply is connected and the pressure switch is adjusted according to the instructions for the equipment.

When using a submersible pump, a check valve must be installed. It prevents water from flowing back into the well.

Connection diagram of the hydraulic accumulator to the elements of the water supply network Source gkyzyl.ru

Removing noise effect

To eliminate noise, it is better to locate the pumping station outside the living space

The unit will create less noise discomfort if it is placed in a coffered chamber near the well. This is a niche with sides 1.5 m by 1.5 m, depth 2-2.5 m, the bottom and walls of which are concreted and plastered. The room is equipped with your own hands like a cellar and equipped with a lid. The water supply from the well is led into the caisson at floor level; for this, a hole is made in the well ring at the required height. If a caisson is installed next to a well, the casing is cut off at a given level.

The caisson is connected to the house by a trench, the depth of which is below the freezing point. In the wall at the entrance to the house, it is advisable to make a case from a larger diameter pipe. This device will increase the service life of the water supply system and facilitate labor during its possible disassembly. The cavity between the walls of the pipes is sealed with heat-insulating padding.

Specifications

| Specifications | |||

| Capacity in liters | Water pressure | Length Width Height | Connector size, inches |

| 14 | 8 | 373x240x261 | 3 x 4 |

| 18 | 403x260x282.2 | ||

| 24 | 450x270x290 | 1 | |

| 50 | 540x350x375 | ||

| 100 | 10 | 450x450x840 | |

| 200 | 600x600x1020 | 1 by 1/2 | |

| 300 | 650x650x1110 | ||

| 500 | 650x650x1715 | ||

| 750 | 800x800x1920 | 1 to 1/4 | |

The company provides competitive prices for its products.

| Products | |

| Model | Price, rub. |

| 6 VP | 700.00 |

| 6 V | 700.00 |

| VP 80 | 4700.00 |

| At 80 | 4700.00 |

| 10 VP | 800.00 |

| 10 V | 800.00 |

| 14 GP | 950.00 |

| 14 G | 950.00 |

| 18 G | 1050.00 |

| 24 GP | 1300.00 |

| 24 G | 1300.00 |

| 35 G | 2300.00 |

| 35 GP | 2300.00 |

| 50 G | 3300.00 |

| 50 GP | 3300.00 |

| 150 VP | 9000.00 |

| 150 V | 9000.00 |

| 50 V | 3300.00 |

| 50 VP | 3300.00 |

| 100 V | 6000.00 |

| 100 VP | 6000.00 |

| 200 V | 12500.00 |

| 200 VP | 12500.00 |

| 300 V | 15500.00 |

| 300 VP | 15500.00 |

| 400 V | 17500.00 |

| 400 VP | 17500.00 |

| 500 V | 23000.00 |

| 500 VP | 23000.00 |

| 750 V | 65000.00 |

Correctly setting up a new device

The new hydraulic tank should be checked to see what its internal pressure level is. It is assumed that it should be 1.5 atm. But during transportation of the product from the place of production to the warehouse and during storage, a leak could occur, which reduced this important indicator at the time of sale. You can check the pressure by removing the cap on the spool and taking measurements.

To measure pressure, you can use different types of pressure gauges.

Inexpensive pumping stations and automatic pumps are most often equipped with pressure gauges in a plastic case. The error in the readings of such Chinese models is too great.

If there is less air in the tank than needed, water will take its place. This will affect the water pressure in the water supply. At high pressure, the pressure will always be high. Higher pressure will provide less water in the membrane bulb, so the pump will have to turn on more often. If there is no light, the water supply may not be enough for all needs.

That's why sometimes it makes more sense to sacrifice pressure to achieve other important goals. However, it is better not to reduce the pressure below the recommended values, nor to exceed the maximum characteristics. Lack of pressure can lead to contact of the bulb surface with the tank body, which is undesirable.

You can use different devices to measure pressure, but the optimal one is a relatively inexpensive automobile pressure gauge with a metal body and a fairly comprehensive scale of measurement results.