The Gilex pumping station is the brainchild of a Russian manufacturer and its calling card. Reliable and easy-to-repair equipment is becoming a leader in demand. Adaptability to domestic conditions and price are of no small importance. Various equipment and materials are used in production. Of the entire line of products, Gilex Jumbo pumping stations of various capacities are in greatest demand.

Operating principle and design of Jumbo pumping stations

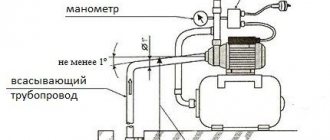

To understand the operating principle of Gilex Jumbo pumping equipment, you should understand its structure. The station has several main nodes:

- hydraulic accumulator, also known as a storage membrane tank, with a capacity of 24 liters or more;

- water pump, for more productive models with a remote ejector;

- a relay that responds to pressure changes in the tank;

- pressure gauge

The pump impeller is always made of durable polymer that is resistant to the mechanical effects of abrasives. The equipment body is made of cast iron (marked with the letter “C” in the name of the device), glass-filled polypropylene (marked “P”) or stainless steel (“N”). The hydraulic accumulator is produced only in steel version.

The pumping station operates according to this principle:

- in the initially filled tank, the pressure is at its maximum;

- as soon as the water supply tap in the house is opened, the liquid leaves the tank through the pipes and enters the plumbing points of the cottage;

- at the same moment, the pressure of the accumulator drops, which leads to the pump turning on;

- the unit pumps water into the tank until the pressure again reaches the set permissible value.

The system always has a sufficient supply of liquid for optimal pressure. The station's operating cycles are repeated.

Membrane wear

Membrane wear factors include:

- friction of the product against the walls of the device body;

- temperature jumps in the hydraulic accumulator;

- continuous process of stretching and compression of the product;

All this leads to wear of the membrane. Its imminent failure can be judged by the following signs:

- the hydraulic accumulator begins to operate jerkily;

- pressure gauge readings are unstable - they increase sharply and quickly fall;

- the tap seems to “spit” water;

- the pump starts more often than usual, at short intervals;

In such situations, it becomes obvious that the accumulator membrane needs to be changed.

Replacing the membrane in the hydraulic accumulator

It is not difficult to replace a worn membrane yourself - just follow these steps sequentially:

- disconnect the hydraulic tank from the water supply system;

- remove air pressure in the unit through the nipple;

- drain the remaining water from the hydraulic tank;

- unscrew the cap with the pressure gauge;

- pull out the used membrane from the special hole in the lower part of the housing;

- install the new membrane in the reverse order;

- put the flange with the valve in its place.

To get a clear idea of the stages of installation work, watch a video about replacing a membrane in a hydraulic accumulator:

Note to the consumer

- If you need to replace the membrane in a hydraulic accumulator, the price of the product is affordable, and you can find it in a plumbing or building materials store, since it is a popular consumable. Check with the hydraulic tank manufacturer or supplier for availability of a suitable membrane.

- When replacing and repairing hydraulic accumulator membranes, it is necessary to take into account that products from different manufacturers are not interchangeable. They often differ in neck diameter.

- The air pressure in the product should be periodically checked and its stability monitored so that the membrane does not have to be changed frequently.

Now you know why a hydraulic accumulator can fail, what the unit consists of, and what the importance of the membrane is for a hydraulic accumulator, and how to replace it.

Using our recommendations, you can easily replace the didrobak membrane if the need arises.

Model range and technical characteristics

All Jumbo pumping equipment from Gilex are labeled in such a way that the user can deduce from the name the main capabilities of the unit. For example, the name of the station NS Jumbo 70/50 N-24 will be deciphered as follows:

- NS - pumping station;

- 70 — unit productivity (l/min);

- 50 - pressure - the maximum distance the unit can transport water, calculated in meters;

- N - body material, in this case stainless steel;

- 24 - volume of the hydraulic accumulator (in liters).

There are several models of Gilex Jumbo pumping stations on the market. With the same technical characteristics, the housings can be made of different materials (steel, cast iron, polymer).

Station Gilex Jumbo 50/28

This model has the following technical characteristics:

- productivity - 50 l/min;

- head - 28 m;

- tank volume - 24 l;

- power - 500 W;

- possibility of transporting water from a depth of up to 9 m.

This station is the best option for a small summer cottage or a family of 2-3 people.

NS Jumbo 60/35

Features of this model according to the instructions:

- temperature of pumped water - +1-+50 degrees;

- productivity - 60 liters per minute;

- head - 35 m;

- permissible depth of liquid intake - 9 m;

- power - 600 W.

The approximate price of the Jumbo 60/35 model is about 8,500 rubles.

Jumbo Station 70/50

Here the unit is more powerful and productive. Its technical characteristics:

- power - 1100 W;

- productivity - 70 l/min;

- head - 50 m;

- tank volume - 24 l.

All models of Jumbo pumping stations are equipped with a soft start system and protection against dry running (combustion). Automatic control of the unit simplifies its operation.

Options for membrane closed containers

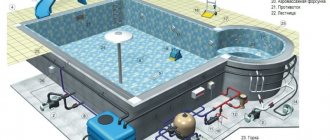

Membrane tanks are used as part of pipelines installed for various purposes, including:

- Cold water supply. The tank is used to accumulate and supply cold water and protects various household appliances from water hammer when the pressure in the system changes. Extends the life of pumps by reducing the number of pump starts.

- Providing hot water. The device used in this case must operate successfully in high-temperature conditions.

- Heating systems. Such tanks are called expansion tanks. They function as part of closed heating systems and are their important components.

Depending on the configuration, hydraulic tanks can be horizontal or vertical. However, the principle of their operation does not depend on the configuration.

Hydraulic accumulators intended for inclusion in the water supply system are painted blue, and those that operate in the heating circuit are painted red. These two types of membrane tanks also have some design distinctive features, which is clearly visible in the presented diagram (+)

A special feature is the presence of a special valve for bleeding air in the upper part of vertical models, the volume of which exceeds 50 liters. This air, as mentioned above, accumulates in the upper part of the chamber as the device operates. Therefore, the presence of a bleed valve in this place is a completely justified measure.

If it is necessary to bleed air masses when operating horizontal models, then a drain or a separate tap located behind the membrane tank is used for this purpose. To remove air from small devices, you will have to completely drain the water from it.

Since vertical and horizontal models are equally effective and functional, you should choose a suitable device based on the dimensions of the room in which it will be located. Whichever model fits best into the room is the one they take.

In addition to design features and different purposes, tanks may also differ in their capacity: this photo shows hydraulic accumulators of various volumes, designs and purposes

How to choose a station for a country house

In order for pumping equipment to operate as efficiently as possible (do not overuse electricity and supply the optimal volume of water), when choosing it, you need to rely on the following criteria:

- Performance. Determined by the number of plumbing points in the house and the number of people living in it. In this case, the productivity of the unit should not be greater than the flow rate of the water intake source. Otherwise, the station will shut down due to the danger of dry running.

- Storage tank volume. For a family of two people, it is enough to take a hydraulic accumulator with a capacity of 24 liters. For 3-5 people living in a house, a volume of 50 liters is already needed, and so on.

- Station pressure. It is calculated simply - the vertical distance from the unit to the highest plumbing point + 1/10 of the total horizontal length of the pipeline + tap pressure (from 4 to 10 m).

- Case material. Here you need to rely on the future operating conditions of the equipment. Steel and cast iron are suitable for more “field” ones. The polymer will be cheaper, but it is better to use it in a warm room.

- Equipment power. It must correspond to the family’s ability to pay for utilities with optimal technical characteristics of the station.

If water will be taken from a depth of more than 10 m, it is worth taking equipment with a remote ejector.

Problems with the hydraulic accumulator

You can check the pressure in the accumulator with a car pressure gauge

The most common malfunction is a decrease in pressure inside the water supply network. There is only one reason - the pressure between the rubber membrane and the steel walls of the accumulator has dropped. In factory conditions, nitrogen is pumped into the hydraulic tank under a pressure of 1.5 atm. It creates pressure inside the water supply network by pressing on the membrane into which water is pumped from a well or borehole.

Nitrogen pressure decreases for various reasons, but more often due to the weak holding capacity of the nipple. It is not difficult to solve this problem yourself. To do this, use a car pressure gauge, which checks the pressure by installing it on the nipple. The latter is located on the opposite side of the hydraulic tank inlet pipe.

- Remove the nipple protective cover made of plastic.

- Install a pressure gauge and check the pressure inside the container.

- If the parameter is underestimated, air is pumped through the same nipple using a conventional automobile pump to the desired value.

- Close the nipple with a lid.

Even if after this the pressure in the used hydraulic accumulator quickly drops, the reason must be sought elsewhere. More often these are leaks at the joints of the plumbing system. Therefore, it is necessary to first examine the entire water supply system. Usually they check the joints between pipes, connections with fittings, with shut-off valves, with filters for various purposes, with consumers and other products installed in the water supply system of a private home. If leaks have been identified, they must be eliminated.

There are two more reasons why the accumulator does not hold the required pressure. This also applies to reducing the nitrogen pressure inside the tank.

- Over time, areas of leakage appear at the flange-nipple junction. Gas leaks through them. To solve this problem, you need to unscrew the nipple, remove the old flange and install a new one in its place. Spare parts and parts for hydraulic tanks are sold in all hardware stores.

- The same applies to the junction of the flange and the rubber pear-shaped membrane. Sometimes this problem is solved by simply tightening the mounting bolts (there are six of them in the tank design).

If the pressure is set incorrectly, the membrane wears out quickly

Sometimes the membrane in a hydraulic accumulator simply breaks due to wear. To replace the rubber bulb, you need to disassemble the device:

- the pump is disconnected from the power supply;

- one of the consumers opens, water is drained from the water supply network;

- the flexible hoses connecting the hydraulic accumulator to the water supply are unscrewed;

- unscrew the six bolts connecting the flange to the membrane with a wrench;

- the flange is removed, the pear is pulled out;

- the container is washed and dried;

- a new membrane is installed;

- a flange is mounted, which is tightened with mounting bolts;

- from the nipple side, air is pumped into the container using a car pump to a pressure of 1.5 atm;

- the hydraulic accumulator is connected to the water supply using flexible hoses;

- The pressure relay is configured to turn the pump unit on and off, taking into account the nominal pressure of the hydraulic tank.

This repair process may take several hours. The service center will do this in half an hour. But since the procedures are simple, you can do them yourself.

Advantages and disadvantages

Users note the following positive aspects of Jumbo stations:

- smooth start;

- no water hammer in the system when turned on;

- constant water pressure in a country house;

- compactness of the unit;

- ease of installation and connection;

- protection against voltage surges, dry running.

The only disadvantage mentioned is the increased noise level of the station. But this problem can be solved if you install the equipment in a soundproofed room.

Major pump failures

The exact cause of the malfunction can only be determined through a detailed inspection of the equipment.

But for an approximate diagnosis, the characteristic signs accompanying the breakdown are sufficient.

Similar symptoms include:

- When turned on, the pump shows no signs of life.

- The body of the device produces an electric shock when touched.

- The supply water pressure has decreased significantly.

- The equipment operates unevenly or makes strange noises during operation.

The most common reasons for such “abnormal behavior” are the following problems:

- The pump motor winding burned out.

- The power supply wire of the mechanism is broken.

- The electrical contact has come loose.

- The seal of the pump housing is broken.

- The moving working elements of the mechanism are worn out, and the pump is unable to maintain the original pressure.

The listed malfunctions are usually caused by factory defects or severe operating conditions. Thus, wear of the impellers can occur due to the presence of a significant amount of mechanical impurities in the water, most often fine sand. But defects in electrical equipment may well arise through the fault of factory assemblers. For a more detailed examination and repair of the Vodomet pump, you will need to remove it from the well and disassemble it.

Customer Reviews

According to reviews, the Jumbo pumping station is ideal for installing an autonomous water supply system in a country house or country house.

Nikolai, 38 years old: I bought the Jumbo 70/50 station three years ago, when I finished building the house. For a family of four, I took equipment with a 50-liter tank. From the house to the well there are 20 meters plus a water surface of 6 meters. Additionally, I have a plot of 5 acres. All this is supplied with water by the hard-working Jumbo. In summer it pumps continuously for watering for 3-4 hours. It still works fine. The station was installed in the basement. It's true that it's noisy, but I put a thick rubber mat on it. They are thinking about isolating the basement from the house to prevent noise.

Pavel, 33 years old: At my dacha there is a Jumbo 60/35 in a cast iron body. Initially I bought it for watering the garden. Now he has built a three-room house on the site. For my wife and I, such a unit (shower, toilet, kitchen sink) is enough. The noise of the station was neutralized by a special insulated caisson. For two years there are no complaints about the unit.

Yura, 29 years old: I bought a Jumbo 50/28 station in a steel case for watering my garden. To prevent the unit from jumping during operation, it was additionally fixed (there are special fastening legs). The equipment works properly and supplies water with good pressure. In two hours of continuous work we water 6 acres of garden. Normal, I think, for a Russian apparatus.

Automation mechanisms for the pump are used to ensure autonomous operation of devices with the setting of a suitable mode. In addition, high-quality automation protects pumps from dry running and saves energy consumption. This approach allows you to extend the life of expensive pumping equipment.

A special feature of automation from the Gilex company is the ability to use devices both with branded models and with devices from other manufacturers. In addition, inexpensive equipment has a number of other useful properties.

Selecting a membrane tank wisely

A hydraulic tank is a container whose main working body is a membrane. Its quality determines how long the device will last from the moment of connection to the first repair.

Products made from food-grade (isobutane) rubber are considered the best. The metal of the product body is important only for expansion tanks. Where water is contained in the pear, the characteristics of the metal are not decisive.

If you don’t pay special attention to the thickness of the flange of your purchase, then in a year and a half, and not in 10-15 years, as you plan, you will have to buy a completely new device or, at best, change the flange itself

When choosing a device, special attention should be focused on the flange, which is usually made of galvanized metal. The thickness of this metal is very important

With a thickness of only 1 mm, the service life of the product will be no more than 1.5 years, since a hole will certainly form in the metal of the flange, which will damage the entire device.

Moreover, the warranty on the tank is only a year with a stated service life of 10-15 years. So the hole will appear just after the warranty period expires. And it will be impossible to solder or weld thin metal. You can, of course, try to find a new flange, but most likely you will need a new tank.

To avoid such misfortunes, you should look for a tank whose flange is made of stainless steel or thick galvanized steel.

Instructions for the Jumbo pumping station

Instructions for the Jumbo pumping station

Instructions for the Jumbo pumping station

You can download the instructions for the Jumbo pumping station HERE

. Or by clicking on the picture.

You can buy a Jumbo pumping station at a low price HERE

.

One of the advantages of such pumping equipment is its automatic operation. Switching on occurs at the moment when the user needs water (the tap is open), which is extremely convenient.

However, in order to ensure correct operation of the equipment, the correct connection diagram for the Gilex Jumbo pumping station must be observed.

Kinds

A membrane tank is a special container in which a certain amount of water accumulates. The main function of the expansion membrane tank is to collect water and supply it under a set pressure.

Manufacturers produce several types of rubber membranes:

- pear;

- ball;

- diaphragm;

- balloon.

Small types of membranes up to 100 L are similar to a rubber heating pad or glass jar. Models with a volume of more than 100 liters resemble a pear or bottle.

On the shelves of specialized stores you can purchase two types of expansion membrane devices:

- with a replaceable membrane - has a high price, it is possible to timely replace the part if ruptures and deformation occur;

- with a stationary membrane - has a low price range, there is no possibility of replacing damaged elements and restoring the operation of the water supply system.

Modern manufacturers produce a wide range of membranes for hydraulic accumulators, the volume of which starts from 10 liters. For home water supply systems, the most popular tanks are 24, 50, 60 and 80 liters. In residential cottages with a large number of people, membranes with a volume of 100, 150 and 300 liters are installed.

For uninterrupted operation of heating systems in rooms of various types and purposes, experts recommend installing Wester expansion tanks that monitor the pressure in the pipes and, if necessary, automatically reduce it to an acceptable level.

Material

One of the main criteria when choosing the required membrane is the type of material from which the part is made. Due to the fact that the rubber element is in constant contact with water, the material from which the membrane is made must comply with all sanitary standards and requirements.

Modern manufacturers offer five types of material:

- natural rubber;

- artificial butyl rubber;

- artificial material EPDM;

- material for heating systems type SBR;

- Nitril type material for oil and flammable substances.

Repair "Dzhileks"

After disassembly, we inspect the components and equipment assemblies. Weak pressure is often the result of worn-out wheels. In this situation, you should purchase new impellers from a repair and service center and install them to replace the old ones. It will be more difficult to deal with a burnt winding. It is almost impossible to rewind an electric motor at home, but it is also unprofitable to send it to a specialized workshop for rewinding. It’s easier and faster to purchase and install a new motor.

In case of cable damage or loss of contact in the network, repair is not so difficult. It is enough to replace the power cord or solder the contacts. It will be more difficult to cope with a leak due to depressurization of the housing. In this case, water entering the pump usually damages the capacitor. Therefore, repairing the Gilex pump here will come down not only to replacing this part, but also to ensuring the tightness of the housing in order to avoid repeated leakage.

At the same time, the lubricating fluid is drained and replaced. In this capacity, you should never use motor oil, but only pure glycerin. Otherwise, during the next depressurization, engine oil will run out into the well, making the water in it unfit for drinking for a long time.

Gilex pumps are pressure equipment for water supply, heating, drainage and sewerage, which has come into use since 1993, when the Gileks plant was founded in the Russian city of Klimovsk, Moscow region. Pressure equipment for wells and boreholes, for use in open reservoirs and sewers, smart water supply systems and hydraulic accumulators, expansion tanks, pipes and fittings - the plant’s product line is expanding and improving every year.

Decoding the markings of various models

Marking of water pump models Vodomet.

Pumping mechanisms are available in several modifications; you can choose a unit with characteristics suitable for both domestic needs and industrial purposes. Design features are reflected in the markings of the models.

Example of designation: “Water cannon” 55/35, where

- "Water cannon" - serial name;

- the number 55 indicates the maximum water flow, indicated in l/min;

- 35 - highest pressure.

The marking may contain additional letter designations:

- “A” - the pump is equipped with a float switch;

- “BK” - a unit with a 1 m long cable without an electrical plug;

- "PROF" - pump without an automatic shut-off mechanism;

- “M” - main unit;

- “HOUSE” - for automatic water supply systems in private homes;

- “Ch” - automatic control mechanism;

- “DF” - with a bottom filter.

Major pump failures

The exact cause of the malfunction can only be determined through a detailed inspection of the equipment.

But for an approximate diagnosis, the characteristic signs accompanying the breakdown are sufficient.

Similar symptoms include:

- When turned on, the pump shows no signs of life.

- The body of the device produces an electric shock when touched.

- The supply water pressure has decreased significantly.

- The equipment operates unevenly or makes strange noises during operation.

The most common reasons for such “abnormal behavior” are the following problems:

- The pump motor winding burned out.

- The power supply wire of the mechanism is broken.

- The electrical contact has come loose.

- The seal of the pump housing is broken.

- The moving working elements of the mechanism are worn out, and the pump is unable to maintain the original pressure.

The listed malfunctions are usually caused by factory defects or severe operating conditions. Thus, wear of the impellers can occur due to the presence of a significant amount of mechanical impurities in the water, most often fine sand. But defects in electrical equipment may well arise through the fault of factory assemblers. For a more detailed examination and repair of the Vodomet pump, you will need to remove it from the well and disassemble it.

Do-it-yourself Gilex Vodomet pump repair

Let's consider the most common models of Vodomet pressure equipment, which have a similar apparatus structure. This is a model range of submersible pumps labeled Pro - improved specifically for working in wells with sandy walls and bottom.

Models 40/50 (75), 55/35 (50/75/90), 110/110 (75H/110H) practically do not fail from overheating, because they are equipped with an annular slot for cooling the engine with water . In addition, their design eliminates the valve and pistons system, which contributes to greater durability, and adds a filter system that does not clog the inlets as often. And two seals for insulating and sealing the electric motor and a remote thermal switch greatly facilitate the diagnostic and repair process.