Despite the possibility of installing a variety of compact metal stoves, brick heating devices are still very popular among homeowners. Their design is constantly being improved. The classic option is a bell furnace. Read and find out what it is, the principle of its operation, its varieties, design features and advantages. Let's talk about the nuances of determining the thermal power and ordering of such a two-bell stove with a single-burner stove.

Option of a bell-type furnace design Source mtdata.ru

Basic general information

Throughout history, a large number of different models of brick kilns have been created. Among them, the lion's share consists of structures in the construction of which the bell-type principle is used. It is used to create massive stoves that can have a fireplace compartment and a bench. This construction principle is also used in the construction of compact structures. These structures are ideal for small houses.

One of the options for a miniature but effective device is the Kuznetsov furnace. The design got its name in honor of the famous stove maker. This inventor thoroughly refined the furnace design of the bell-type operating principle. Thanks to Igor Viktorovich Kuznetsov, this type of stove became popular in Russia and numerous other countries.

Laying stoves for home drawings and diagrams

Classic Russian wood stoves for the home have characteristic advantages.

Instead of outdated, imperfect devices, new, more modern models of heating stoves are being introduced today.

A competent master who introduces new types of similar structures into life must be well aware of all the shortcomings of the old models that have survived. He must be able to repair or alter them. To do this, he must be familiar with the most common examples of not only new, but also outdated devices, as well as know their drawings and be able to apply his knowledge in practice.

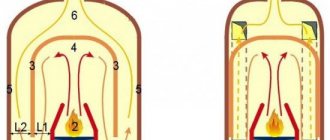

Operating principle

The compact bell-type furnace design is simply called “Kuznetsovaya”. In it, combustion products move without obstacles. The heating structure also has other special design differences. It was they who influenced the great popularity of Kuznetsovka.

In Kuznetsovka, combustion products move freely Source remontnik.ru

In the vast majority of brick stoves, the masonry is directly heated from the energy generated as a result of fuel combustion. In other models, heat is transferred to the walls from the smoke, which passes through channels with a complex configuration.

In furnace structures with direct heating of the walls, the heat transfer value is affected by the thickness of the masonry. As it decreases, the heat capacity increases. However, this version of the furnace design constantly needs a large amount of fuel. Otherwise, the large stove will not warm up properly. When the fuel stops burning in it, the structure gradually cools. At this moment, heat is transferred from it to the room atmosphere.

If the stove has a complex configuration of smoke exhaust channels, the structure is heated more evenly. However, more requirements are placed on such a structure. This applies in particular to the height of the chimney. It must provide good traction

A stove with a complex internal structure Source stroyfora.ru

On a note! In stoves with a complex configuration of narrow channels, more soot accumulates. Therefore, they have to be cleaned more thoroughly. In this case, it is necessary to constantly monitor the permeability. Most often, traffic jams form at the turns of smoke exhaust ducts. If they are not constantly removed, then traction worsens significantly. At the same time, there are a lot of turns in such furnace structures.

A bell-type stove for heating a home is almost completely devoid of the listed disadvantages. After all, its design implies the presence of two smoke exhaust channels. At the same time, they are connected to each other. Thanks to their presence, the efficiency of the furnace structure increases. Two connected channels accumulate thermal energy much better.

One of the chimneys is an internal circuit. It is created next to the firebox or even laid out around it. Such a channel remains hot longer because there is also an external circuit in the design. It is through this that the smoke comes out.

Important! The furnace design with internal and external channels cools down more slowly. After all, combustion products move along a complex trajectory before entering the chimney.

Diagram and principle of gas movement in Kuznetsovka Source stroyfora.ru

The two-bell furnace is also distinguished by the presence of 2 chambers, which are heated as a result of the operation of the structure. They are called the lower and upper caps. In the first of them, heated combustion products circulate. The same thing happens in an ordinary bell-type furnace design.

After circulation in the lower hood, the smoke moves to the upper part, where it fills all the free space. As a result, this part of the furnace structure is heated. Only after this the combustion products enter the chimney.

Types of bell-type stoves

The Kuznetsov bell furnace can have different designs. After all, the engineer has developed a huge number of variants of such designs. Today there are more than 150 models. With their help, various rooms are heated.

On a note! Existing versions of Kuznetsovok differ in technical characteristics. They also have different functionality. The location of heating hoods has a great influence on all parameters.

Sections of a functional “Kuznetsovka” Source stroyfora.ru

A popular model is the Kuznetsov two-bell furnace, characterized by the location of one bell above the other. This type of heating brick structure has small dimensions, which allows it to be created even in small houses.

"Kuznetsovka" may have one of the following abbreviated names:

- IOK is a stove exclusively for heating.

- HOVIC is a heating structure with a hob. This structure is made of ceramic bricks. At the same time, fire-resistant blocks are not used for laying the firebox.

- OVIK BK is a Kuznetsov brick stove for a wood-burning home, a cooking and heating stove, the design of which includes a side fireplace compartment.

- OVIC L is a heating stove equipped with a hob and a stove bench.

- OVIC ZK is a heating structure with a cooking compartment and a fireplace, which is located in the rear part of the structure.

- PKIK1K – stove with heater.

- RTIK is a Russian traditional bell-type stove design.

- BIC is a heating structure for a bathhouse.

Construction of “Kuznetsovka” in the bathhouse Source ekomeistras.files.wordpress.com

This design can also have an oven. To designate such a structure, an abbreviation is used that contains the letter “D.” Abbreviated names allow you to quickly understand the purpose of a specific structure. Each abbreviation is used to designate a whole model range in which heating structures have similar sizes, shapes, and technical characteristics.

Preparatory work

First of all, you need to choose a place to build a furnace.

The easiest way to do this is before building a house - then both the stove and the building are designed together so that three or at least two rooms are heated. With a ready-made house, the situation is more complicated. In this case, they tend to build the stove into an interior partition, since installing it into a load-bearing wall requires complex calculations and dangerous, time-consuming work (part of the wall will have to be dismantled, keeping the load from being blocked by a system of lintels and columns). You can, of course, limit yourself to a simple wall-mounted arrangement, but then only one room will be heated.

A reinforced concrete foundation must be built at the selected location. Its dimensions must exceed the dimensions of the oven by at least 100 mm on each side. It is not allowed to combine the foundation of the furnace with the foundation of the building - both structures give different settlements and one of the foundations will pull the other along with it, causing it to skew.

A reinforced concrete foundation must be installed under the furnace.

The depth of the foundation depends on the bearing capacity of the soil, the depth of its freezing, and the method of operation of the building (periodically/continuously). Typically, in buildings with year-round habitation of people located on stable ground, the foundation is deepened by 400–600 mm. Crushed stone should be poured onto the bottom of the excavation as a reinforcing layer, and a sand cushion should be placed on top of it.

Then everything is done using traditional technology - they install the formwork, fix the reinforcement frame and fill it with concrete. You should proceed to the construction of the furnace only after the concrete has fully matured and gained sufficient strength - this usually takes about a month.

Determination of the thermal power of bell-type stoves

The operational parameters of a furnace structure are always determined at the first stage of its development. This allows you to design an efficient heating structure that will heat the house well.

In addition to the dimensions, the thermal power of the furnace is always determined. The parameter represents heat transfer. This characteristic must correspond to the dimensions of one or more rooms that will be provided with heat from the stove. During the calculation, heat loss must also be taken into account. They are present even if the building is very well insulated.

Experts also take into account the thickness of the brickwork. This parameter affects the degree of thermal energy accumulation.

The thickness of the oven walls affects heat accumulation Source susaninclub.ru

Only specialists can accurately calculate all the parameters of the furnace structure. Calculations are carried out taking into account the following rules:

- to heat 10 m² of house area, which has high-quality insulation, 0.5 kW of the power of a brick heating structure is consumed;

- in residential buildings built in cold regions, 0.75 kW of furnace power is spent on heating 10 m².

Experts often recommend using ready-made designs for furnace structures. This speeds up the process of building a structure in the house. Although, when turning to professionals, a regular or two-bell heating and cooking stove will be designed in a minimum period of time. After all, the specialists have experience and are well aware of all the nuances of the development of each Kuznetsovka model.

A bell-type stove is often built according to a ready-made and proven design Source baniwood.ru

See also: Catalog of companies that specialize in the design and installation of fireplaces and stoves

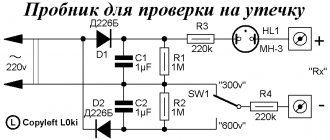

Kitchen stove with oven and hot water box

To lay a kitchen stove with an oven and a hot water box measuring 1290x640 mm, the same materials are required as for the previous stove. Additionally, you should purchase a water heating box measuring 510x280x120 mm.

The figure below shows a general view, a horizontal section along A-A and a vertical section along B-B of the slab.

Kitchen stove with oven and hot water box: a - general view; b - cuts. Definitions: 1 - firebox; 2 - cast iron plate; 3 - oven; 4 - water heating box; 5 - smoke valve; 6 - ash chamber; 7 - angle steel trim

A kitchen stove with an oven and a hot water box is placed in the same order as a kitchen stove with an oven. The only difference is that after laying the third row, instead of a brick partition, a water-heating box in a case is installed on the edge between the oven and the vertical channel. The height of the hot water box should correspond to the height of four rows of flat brickwork. The rest of the masonry is completely similar to the masonry of a kitchen stove with an oven.

The main distinctive features of bell-type stoves

The right choice cannot be made if you do not know the main features of the heating structure. Thus, a bell-type heating stove, the construction of which is often carried out in private homes, differs:

- Almost complete isolation of the firebox from the hood . This is one of the main distinguishing features of Kuznetsovka. The combustion chamber is lined with fire-resistant fireclay bricks. After all, this chamber heats up to 1000 ℃ or even 1200 ℃.

Construction of a stove with fireclay brick firebox Source master-off.net

On a note! Regular and fireclay blocks differ in density. For this reason, a 5mm gap must be created between them, which prevents cracks from forming in the bricks when they heat up and expand. In this case, they do not leave empty space, but fill it with asbestos. Typically this material comes in the form of sheets.

- Lack of direct contact of the water tank and oven chamber with the flame and heated combustion products . The bell-type stove with water heating boiler and oven is a well-thought-out design. After all, the water container and additional compartment are located in the top hood. This type of heating structure was chosen because at the top the maximum temperature is 400 ℃. It prevents the metal from overheating. Therefore, its integrity is not violated. At the same time, this temperature is enough for the entire structure to function fully.

“Kuznetsovka” option with oven Source stovekiv.com

- A shorter chimney than other similar heating structures . A bell-type stove for a bathhouse or residential building must have a chimney, which, first of all, allows combustion products to be removed without violating current rules. This is its main purpose in such a heating design. Only secondarily should it provide the required traction.

- High efficiency, the value of which reaches 80%. Compared to other similar heating structures, this is a good technical characteristic. After all, for similar furnace structures for the same purpose, the efficiency does not exceed 65%.

Important! A bell-type stove with a water heating boiler, the arrangement of which allows you to create a compact firebox, helps to save wood. Thanks to a well-thought-out design, fuel consumption can be reduced by up to 40% compared to stoves in which combustion products are removed directly.

Construction of Kuznetsovka with a water circuit Source build-experts.ru

- The presence of a so-called dry gap in the firebox . Its width usually varies from 2 to 3 cm. The seam is created to improve traction. At the same time, the gap allows you to maintain the required temperature in the combustion chamber. This becomes possible due to the gradual removal of combustion products.

Important! The so-called dry gap can be located anywhere in the brick walls of the heating structure. In this case, the seam must be created in such a way that it represents a channel that is connected to the stove hood.

Operating the device

After the structure is laid out, it is dried. In summer it will take 2 weeks. If the masonry was carried out in the autumn-winter period, they begin to heat the stove with small wood chips for 30 minutes once or twice a day. For additional ventilation, all cleaning doors and latches are opened (if it rains, they are not opened).

Photo 2. Finished 3 by 3 brick oven. The device is installed near the wall and has a very compact size.

When wet spots disappear from the surface and condensation stops falling on the metal elements, the structure is dry. After this, a control fire is carried out - the furnace is heated at full strength for several hours at maximum draft. If no cracks have formed in the masonry in the area of the firebox (small spiderweb cracks are acceptable), then the stove is ready for use.

Attention! You cannot immediately heat the stove too much - this will cause cracking of the masonry and render the structure unusable even before operation begins. As a result, the entire construction phase will take an average of 1 month:

As a result, the entire construction phase will take an average of 1 month:

- foundation preparation - 10 days;

- laying the stove and chimney - 1-2 days;

- drying of the structure - 14-21 days, depending on the time of year.

After this period, if no shortcomings have been identified, you can start heating the stove at full capacity.

Advantages of bell-type brick kilns

Compared with other similar structures for the same purpose, the bell-type stove has a number of advantages:

- Construction is carried out using less mortar and bricks.

- Construction is faster and easier, because the structure has the optimal number of internal channels for the movement of combustion products. For this reason, a conventional or two-bell Kuznetsov heating and cooking stove, the order of which is understandable even to craftsmen with little experience, has become widespread in private homes.

- Light weight due to fewer building materials required. Therefore, the lightweight structure is built on a small foundation.

Arrangement of a small foundation for Kuznetsov’s stove Source ad-cd.net

- Intensive combustion of fuel in a firebox that is almost completely insulated. For this reason, after burning wood, a minimal amount of solid waste is generated. As a result, the surfaces in the combustion chamber and smoke channels are less covered with soot.

- Easy maintenance. After all, a stove structure of this type is easier to clean from soot due to wider smoke exhaust channels.

- It is not difficult to modernize the selected project if it is necessary to build a heating structure with an oven or a tank for heating water. After all, almost any Kuznetsov brick stove for a wood-burning home has a hood of impressive size.

- Fast heating, which allows you to heat the air in the room to the desired value in a short period of time.

- Uniform heating of all walls. Therefore, the furnace design has high heat transfer.

Any of the Kuznetsov stove options heats up evenly Source brandstove.ru

Usually in bell-type stoves the oven is located at the top. When the oven is located at the bottom, then it is necessarily separated from the firebox by a wall. It protects the metal oven box from excessive heat. The temperature around it does not exceed 400℃. At the same time, inside the oven box it reaches a value of no more than 250℃.

On a note! The hood circulates air around the oven. Therefore, the metal box is heated evenly. This contributes to better baking of the prepared dishes.

Peculiarities

The bold decorative element looks lively and modern despite its ancient origins. Sometimes brick is exposed during repairs during the dismantling of old finishing - wallpaper or plaster. Don’t rush to get rid of such “gifts” of fate. If a brick wall is handled correctly, it will become a source of pride for the owners and will arouse general interest and admiration. Sometimes, in order to restore the beauty of natural masonry, you have to tinker a lot. Cleaning a wall from pieces of plaster, dust and dirt is not so easy. In some cases, simply removing residues is not enough and you have to restore the surface.

When developing a future design project, it is necessary to take into account the following features of this type of finishing:

- it can easily fit into almost any style - ethnic, classic, Provence, pop art, grunge, loft. It will also be very appropriate in an eclectic design;

- the shade of the accent part of the wall does not have to match the color of the base. It may be slightly lighter or darker than other surfaces;

- the material, coated with a special varnish, is able to add light to the room due to its good reflectivity;

- real brick can be successfully replaced with imitation made from various materials;

- the tiled wall will be an excellent backdrop for decoration - photographs, paintings;

- The most successful are considered to be alliances of light brick and finishing with a red or peach tint. Coffee-colored elements go well with gray and beige surfaces;

- Long-term service of a brick is impossible without treating its surface with antiseptic agents that protect against mold and mildew.

Preparation before construction of the stove

After choosing a model of the furnace structure, the master carries out preparatory processes before starting installation of the heating structure. At this stage, a place for the construction of the stove is selected, and individual elements are purchased.

Cast iron parts for the stove Source glavspec.ru

The efficiency of a heating brick structure largely depends on the location of the structure. When choosing it, they are guided by existing fire safety requirements. If the walls of the house are built of wood, then the following rules are observed:

- The minimum distance from the stove to the wooden walls should be 10 cm.

- A heat-resistant basalt or asbestos layer is created between the wall of the building and the stove structure when the heating structure is built into a previously prepared niche.

- The minimum distance from the chimney to the floor beams and rafters should be 15 cm.

Preparatory work also includes the construction of a foundation for the furnace structure. The durability of the entire heating structure depends on its strength.

Important! The reinforced concrete base of the stove should not be monolithically connected to the foundation of the house. After all, the shrinkage of these two structures may differ, because unequal loads will act on them. When they are combined, it is possible that cracks will appear on the walls of the stove and the house due to mutual influence.

The stove foundation is not connected to the base of the house Source ad-cd.net

A bell-type heating structure is a dome stove. Regardless of the name, a building for heating premises can be built in a house that has long been put into operation. However, in this case, the floor is dismantled to construct a pit in which the foundation will be poured.

Important! The perimeter of a monolithic concrete foundation should be 0.5-0.8 cm larger than the base of the furnace.

Sometimes houses are built on a slab foundation. Therefore, the furnace structure also has to be built on the same foundation. To minimize the likelihood of deformation of structures, experts recommend building a lightweight stove. This is exactly what “Kuznetsovka” is.

On a note! It is recommended to bury the reinforced concrete base of the stove structure at least 30-50 cm into the soil.

Necessary materials

Before starting construction, you need to buy all the required materials and prepare the necessary tools in order to stop construction.

Fire brick

Materials for the construction of the furnace:

- refractory bricks - for the construction of a firebox,

- fireproof mastic - for the firebox,

- ceramic brick (grade minimum m150),

- cement, sand and clay - to create the base and brickwork,

- wooden material - for formwork,

- wooden blocks 50x50 - installed in the corners for even masonry,

- metal corners, fittings, wire, plates,

- special foil for the base,

Tools for the construction of “Kuznetsovka”:

- drill with a whisk for mixing the solution,

- shovel and bayonet,

- Master OK,

- big or small grinder,

- large building level,

- roulette,

- bushhammer,

- solution container,

- saw (hand or electric saw).

This is what the minimum set of tools will look like, without which it will not be possible to achieve the desired result.

Ordering of Kuznetsov's furnace design

One of Kuznetsov’s popular furnace structures is a design with two hoods. Its frequently encountered modified version is a stove called the “Big Little One.”

This model is a 2-bell Kuznetsov stove with a hob, which has one burner. Although there may be 2 of them. The presence of one burner allows you to build a stove that will have a larger lower hood. Thanks to this modernization, a structure with increased heat transfer is obtained. Therefore, the room in the house will heat up faster.

When erecting a two-bell structure with one burner, 32 rows of bricks are laid. The heating structure is an effective Kuznetsov stove, the order of which is as follows:

- 1 row of 18 bricks. The laying is carried out on a waterproofing layer laid on a prepared concrete base. The first continuous row is created strictly along the horizon and the level of the finished floor.

The first continuous row of a brick stove Source tproekt.com

Important! The seams between the bricks are made identical with a width of 5 mm.

- 2 row of 11 bricks. When installing the blocks, the base of the lower bell is formed and the ash compartment begins to be laid out. At the same stage, a door for cleaning the lower area of the hood and a similar design of the ash chamber are secured.

- 3 row of 11.5 bricks. When laying the blocks, the corners of 2 brick fragments are pressed together to form an opening under the door, which will allow for further cleaning of the hood.

- 4 row of 14 bricks. Mounted blocks cover the openings under the door of the lower hood and the ash compartment. The smoke exhaust channel, which is located behind the ash pan, is also partially closed in front and behind. In this case, a hole of 26*26 cm is left above the blower chamber.

- 5 row of 14.5 bricks. When laying 2 blocks, the upper surface is cut off at an angle so that the grate can be laid later. At the same time, it will be removed onto the protruding brick blocks of the previous row.

When laying a furnace, it is necessary to change the shape of some bricks Source pvsm.ru

At this stage, the top of the lower cap is divided into 2 channels by the brick. The near passage is necessary to connect this part of the furnace with the upper hood, and the distant channel is subsequently equipped with a valve, which will allow the heating structure to be used in the summer. The dividing brick at the front and bottom is cut diagonally so that the smoke can freely escape into the channel.

- 6 row of 12 bricks. At this stage, the firebox door is secured. The gaps between it and the bricks are sealed with heat-resistant material. Wire is used to secure the door.

- 7 and 8 row of 11.5 bricks. When installing blocks, a 20mm gap is left in the area of the far right corner of the firebox.

- 9 row of 12 bricks. Block elements cover the firebox door. The blocks above it are cut at an angle. When installing this row, maintain a gap in the far corner. To complete this stage of work, take 1 more brick, the right side of which is cut off from above and below so that it fits the previously laid blocks.

When laying the 9th row, the firebox opening is blocked Source otopimdom.ru

- 10 row of 12.5 bricks. When laying blocks in the slab area, elements with cutouts are used. They will allow you to secure a 5 mm thick metal hob and a 3 mm asbestos gasket. In this case, the level of the slab should be 4 mm below the surface of the bricks. When laying the 10th row, a 6 cm wide passage is also made. It is created in the right corner of the firebox. It is needed to connect to the channel of the lower cap.

- 11 row of 12 bricks. Construction of the stove continues by forming a cooking compartment.

- 12-15 row of 12 bricks. They continue to lay out the cooking chamber and chimney channels.

- 16 row of 17 bricks. During installation, cover the lower hood and the right and left walls of the cooking compartment with blocks cut from the ends. Only smoke exhaust channels are not blocked. The valve for summer use of the stove is also attached here. This stage ends with the installation of 2 additional bricks above the slab.

- 17 row of 17 bricks. The stove area is covered with entire brick blocks.

- 18 row of 11.5 bricks. Form a base for further construction of the upper cap. Two doors are also installed here for cleaning it.

During installation, the 18th row forms the basis for the upper cap. Source stroimpech.rus

- 19 rows of 11.5 bricks. Raise the walls of the upper part of the structure.

- 20 row of 11.5 bricks. Close the doors for cleaning the oven.

- 21-27 row of 13 bricks. Lay out the main smoke exhaust channel. The lowest bricks of the 21st row are trimmed so that combustion products can smoothly turn into the chimney.

- 28 row with 13 bricks. They continue to form the main smoke exhaust channel and prepare a place with cutouts for installing the valve.

- 29 row of 19 bricks. The entire area of the furnace structure is covered with blocks. The corners of some of them are trimmed to increase the strength of the structure. Only the smoke hole is left open.

- 30 row of 17 bricks. The stove area is covered with entire blocks, with the exception of the smoke exhaust duct.

- 31 and 32 row of 5 bricks. They create the basis for a mounted chimney.

Video description

You can clearly see one of the options for arranging a Swedish stove without a fireplace compartment in the following video:

- The next, tenth row is created with bricks in the amount of 17.5 pieces.

They cover the front part of the place where the oven will be. The blocks are mounted directly on metal strips. Their installation allows you to combine the space above the firebox and oven. In this case, cutouts are first made at the top of the bricks used. They will allow you to subsequently lay the cast iron hob.

On a note! At the same stage, a place is designed where in the future a small door will be installed, allowing the upper part of the fireplace chamber to be cleaned.

- For the next, eleventh row, use 18.5 bricks.

From these they begin to build the walls of the brewing compartment, where there is already a cast iron panel. The brick blocks laid on the right should close the gap between the fixed cooking plate and the already created wall. At the same time, the blocks that are used to create the back wall of the fireplace chamber are pushed forward 4 cm and then pulled together. This allows you to continue creating the inclined surface.

Briefly about the main thing

The bell-type stove was thoroughly developed by engineer Kuznetsov. It has two connected smoke channels. One of them is an internal circuit, and the other is used to remove combustion products outside the structure. The two-channel system allows the stove to cool more slowly.

A design scheme with two caps has also been developed - a lower and an upper chamber. In each of them, combustion products heat the furnace structure and only then go outside.

There are designs of bell-type stoves only for heating a house or bathhouse, with a fireplace, hob, stove bench, and air heater. All of them have high efficiency - approximately 80%. They are quickly erected by professionals. The thermal power of these stoves is 0.5-0.75 kW per 10 m².

Structures are erected on a monolithic concrete foundation. Their ordering is carried out strictly according to schemes that have proven their effectiveness.