The question of heating sooner or later arises before every facility, both residential and public, at any stage of construction. Comfortable living conditions in the room are provided by wood, gas or electric systems. Electrode boilers, little known today in Russia, have not yet been able to conquer their niche in the market. Their high cost, a very responsible installation scheme and the lack of a sufficient number of reviews on use raise doubts among many consumers.

Principle of operation

Electrode boilers are closed-type heating devices. The scheme for using electrodes was proposed by N. Tesla, based on heating due to the electrical resistance of the coolant. The efficiency of such equipment is due to the use of low-calorie fuel and a good shock-absorbing system, which negates the need for maintenance and additional operating costs.

The operating diagram of a boiler with a storage tank and heating element is radically different from the version with electrodes. In the first case, the heating element is located at the bottom of the container and ensures heating of the coolant gradually, according to all the laws of physics from bottom to top. The operating principle of an electrode boiler involves using the coolant itself as a heating element. Electrodes are placed in a storage tank with a volume of liquid, a small starting electric current is passed through them, the system is heated to achieve a certain efficiency.

It should be mentioned that the power of such a device is directly proportional to the resistance of the coolant and the temperature of the heated water. Electrode heating boilers are characterized by a longer service life (up to 30 years) and savings on electricity costs, since at the slightest leak or boiling of the liquid, the electrical circuit opens and the machine turns itself off.

Electric convectors and their varieties

Electric convectors and their varieties

No less popular units for electrical heating of a private home are convectors with their many modifications in the form of thermal curtains, “guns” and fan heaters.

Thermal curtains are not used in residential premises. They are usually placed above doorways. When the door is opened, the curtain automatically turns on and prevents cold air from entering the room.

To install, simply mount the device above the doorway and connect it to the network. Depending on the characteristics of a particular design, the order of its connection may have individual characteristics. Therefore, be sure to carefully study the instructions for the curtain you purchased.

Heat guns are also used very rarely in private homes, except for heating basements. They work on an extremely simple principle: the unit is connected to the power supply, the built-in fan begins to pump air, which passes through the built-in heating element and evenly heats the surrounding space. No special installation measures are required; it all comes down to connecting the unit to the network.

Heat guns

Electric fan heaters are usually used as additional heat sources. In small rooms they can be used as the only and main heating. The built-in regulator allows you to easily set the desired fan power and ensure a comfortable microclimate in the room.

Modern models lack the main drawback of their predecessors - fan heaters no longer dry the air. An additional advantage of such heaters is the ease of connection and use - the device is simply placed in a convenient place, connected to the network and set to the required power.

An excellent option for electrical heating is the use of electric oil heaters. They have an attractive design and fit perfectly into the surrounding environment. Typically, such heaters are mounted under a window opening instead of a standard battery, or they are placed on the side of the doorway.

Oil electric heaters

Installation is extremely simple.

First stage. Make marks for installing fasteners. On the body of the oil heater there are special elements with which it will be hung on fasteners. Position the heater body at the installation location and mark these canopies.

Second phase. Drill holes in the wall according to the markings.

Third stage. Attach fasteners to the prepared holes. Typically, hooks for hanging heaters are included in the factory equipment. Otherwise, you will have to purchase these products at a hardware store.

Fourth stage. Connect the electric oil heater to the network and set it to the desired operating mode. Modern models can be equipped with sensors, thanks to which the heating power will be set automatically. If your model can also work in conjunction with such sensors, install them according to the manufacturer's instructions.

Electric household wall heater

Direct electric heating

Oil radiators

The housings of these devices consist of several sections with mineral oil as a coolant, which is heated by powerful heating elements up to 200 degrees, maintaining the radiator temperature no higher than 100 degrees.

Oil radiators are capable of heating any living space; they do not “burn” oxygen during operation, but they are used only in extreme cases due to the high consumption of electrical power.

Convectors

In these devices, a heating element heated by electric current directly heats the air without an intermediate coolant. Therefore, they have higher heat transfer and efficiency, but at the same time some of the oxygen is burned out of the air in contact with the hot metal of the heater.

With the radiator and convector method, cold air from below the room, after heating, rushes upward and collects near the ceiling, and from there it is distributed throughout the entire volume of the room.

Therefore, when the temperature at the top of the room reaches +22°C, the air near the floor will warm up to +17°C, which is quite acceptable, but not entirely comfortable.

Convectors use temperature sensors with automatic temperature control systems, which can significantly save energy costs.

Attention! The convector located below the window protects the room from the penetration of cold air through cracks from the street, preventing drafts.

Design and operating principle

Electric boilers have a fairly simple design. All devices are equipped with a heating element and a container for heat conduction. According to the type of heating element, electric boilers are divided into:

- devices with heating elements (tubular heaters);

- induction boilers;

- devices with electrode heaters.

Electric boilers are classified into 3 types Read more: DIY induction heating boiler.

The coolant can be forced to move through the system by installing additional equipment (pumps). Also for this purpose, the elementary laws of physics and the force of earth's gravity can be used. With automatic circulation, the pump is installed at the return inlet.

Device with thermal electric heater

Such devices are considered the most popular due to their simple design and low cost. The heating element (heating element) is installed in a container, where the heat conductor is heated to the desired temperature. When current passes through the heating element’s spiral, it heats up to a high temperature, due to which the liquid is heated.

The heating element is protected from overheating, as water constantly circulates and cools it. To maintain a constant temperature level of the heat conductor, a thermostat is installed that turns off the heating element if the set temperature is exceeded. The device turns on again when the indicators are reduced to the minimum.

It is not difficult to make an electric boiler for heating with your own hands, if you compare its production with other types of heating equipment. It will not have the advantages of purchased analogues, but it will still perform the function assigned to it.

To make your own device, you only need heating tubular elements and a container. But such a boiler should not be considered ideal, since its efficiency will be below 80%. Much also depends on the quality of heating elements, on which scale forms due to salts dissolved in water. It often leads to equipment failure due to overheating. As practice shows, scale with a layer of 1 mm reduces efficiency by 10-15%. But even taking this into account, electrical designs for heating rooms are very popular.

The efficiency of such a device will be far from 100%

Induction devices

Such devices, unlike heating element models, have an efficiency close to 100%. Plus they are durable. Their service life is about 25-35 years, and in addition they can serve as a boiler, heating water. Thanks to energy conversion with virtually no losses, induction boilers have the highest energy efficiency.

However, this type of equipment has not become popular among home craftsmen, since it is very difficult to make a homemade induction electric boiler for heating a home. This is due to the need to use electronic voltage converters.

The design of such a device consists of a coil (inductor) that is mounted on a metal core. The latter is a coil of pipes through which the coolant moves.

An induction boiler differs from heating element devices in that the area of contact of water or antifreeze with the heating element is several times higher. Therefore, the efficiency of induction units is 99-100%. There is several times less scale formation in them, since microvibrations are created that prevent such a process. Electric boilers also have protection against overheating of the electrical element, since water is constantly circulating.

Electrode unit

The electrode-based design is somewhat reminiscent of an “army” boiler. It consists of two blades, between which there is a gap of 1-2 mm. Water with dissolved salt is used as a coolant.

The electrode boiler includes a piece of metal pipe. There is an electrode inside, which is closed with bushings. There must be a good grounding to the pipe, which is connected to the boiler body.

This boiler has a simple design

When preparing a heat conductor, it is necessary to correctly calculate the amount of salt, since the current strength in the circuit, that is, the power of the device, will depend on this indicator. A thermostat is used to adjust the temperature. The device is also equipped with an automatic shut-off system.

Tips on what to consider when choosing heating

When choosing heating systems for a house made of timber, in addition to their cost, it is necessary to take into account the complexity of installation and operating costs. It is necessary to analyze the efficiency of the equipment, as well as the ease of operating the system and monitoring the temperature in the premises. It is worth considering the level of complexity of carrying out preventive measures and repair work, operational safety and environmental characteristics.

When designing a house made of timber for permanent residence, you should pay attention to heating systems that use liquid or electric current as a coolant. This is precisely the conclusion that arises after comparing the advantages and disadvantages of different heating options. The same result will be obtained when comparing the cost of heating a house using different systems.

If you plan to build a country house from timber for seasonal living, then networks with a liquid coolant turn out to be completely ineffective. For such a house it is better to equip a fireplace or electric heating.

General aspects of electric heating

With the exception of boilers, all types of electric heating do not require external heating and auxiliary devices (heating circuits and radiators, chimneys), which is their undoubted advantage. They are quite easy to operate and install, and have low inertia. It is often possible to connect electronic control units and operate them remotely.

Again, most of the considered types of electric heating are quite expensive to operate. The power of almost all devices required to heat a room of a certain area is approximately the same, and it is quite large. It is generally accepted that for heating 100 sq. meters with a ceiling height of 2.5-3 m, 12-16 kW of electrical appliance power is required.

The geographical location of the heated house also plays a role here. In the southern regions of the country, the cost of electric heating will be much lower than in the northern regions. The design and insulation of the house also play an important role. The warmer and smaller the house itself, the less electricity will be required to heat it. Typically, electricity is used to heat small one-story houses or apartments in urban buildings with powerful wiring. In other cases, electric heating is used as auxiliary heating.

And most importantly, this type of heating makes you completely dependent on the availability of electricity itself, i.e. it makes the system energy-dependent.

Great savings come from the use of electrode boilers, warm infrared heaters and devices with automatic mode and temperature regulators (the so-called smart home).

An electric boiler with three heating elements mounted in the basement of my house (see photo) was used initially, from the design stage, as a backup option. I almost never turn it on. The total boiler power is 6 kW (3*2 kW).

This power is for a well-insulated house (interior decoration, foam blocks, insulating foam layer, brick cladding) with an area of 95 square meters. meters in the Urals are only enough to maintain the temperature in the rooms within 15-18 degrees, and in severe frosts it is only enough to keep the water heating circuit from defrosting.

The situation is also the same with my neighbors: one of them used the same boiler for heating a new house with an area of 64 square meters for one month. meters, which cost him 6 thousand rubles. Later (and now), after connecting the gas, he spends 1-1.5 thousand rubles per month on heating. The difference is noticeable.

At the same time, common electrode boilers with automatic adjustment and non-freezing liquid in our area “consume” 2-3 thousand rubles per month, which is comparable to the cost of gas heating.

From the author.

Device

Structurally, the electrode boiler is an all-metal pipe with polyamide insulating coating. On the case there are power terminals and coolant input/output (water or other liquid). At one end of the cylinder, electrodes are inserted into the boiler, and the other has an outlet into the heating system.

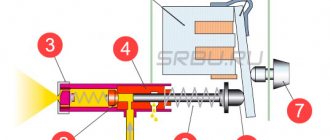

On the picture:

- 1 - pipe for supplying hot coolant to the external system;

- 2 — steel body;

- 3 - layer of electrically insulating material;

- 4 - coolant heated by current;

- 5 — electrode block;

- 6 - pipe for introducing cold liquid for subsequent heating;

- 7 - insulation and seal;

- 8 - power input.

The composition also usually includes an electronic control unit. There are samples of ready-made automation units for factory boilers on the market; they can also be adapted to a homemade “water heater”.

These boilers received the name “electrode” precisely because of the two electrodes located inside - the anode and the cathode. “Minus” goes to the cathode, and “plus” goes to the anode. When current is applied to the electrodes, the heat-carrying medium heats up and enters external systems. The electrical charge passes directly through the liquid, causing it to quickly become hot.

In industrial boilers, the following device diagram is usually used:

- cylindrical body with a round electrode inside;

- “zero” is connected to this electrode;

- the second contact is the housing itself - the phase is connected to it.

With such a scheme, the case is certainly grounded, for which a ground contact is placed on it. Homemade samples also adhere to this method of manufacturing electrode boilers.

Average parameters of factory products:

- pipe length - up to 60 centimeters, diameter - up to 32 centimeters;

- power - from 2 to 50 kW. The most powerful ones heat rooms up to 1500 square meters. m.;

- the current used is three- or single-phase. The latter operates relatively low-power household appliances, and three-phase current powers productive high-power boilers in commercial buildings, workshops and industrial facilities;

- The ideal temperature of the working fluid is 75 degrees. At this level, optimal energy consumption is established. At a higher temperature, the boiler consumes too much current, and at a low temperature it drops, since as it cools, the thermal conductivity of the medium decreases.

Boilers are divided according to the method of supplying water or other liquid:

- open - the movement of the working fluid is carried out naturally: it leaves the heat generator, transfers heat to the environment and returns back;

- closed - equipped with an expansion pump and tank. The pump provides circulation, and the tank serves for initial heating of the coolant.

Interesting: modern industrial boilers not only have advanced control automation, but are also often equipped with remote control systems and GSM communication modules. Such a device can be controlled via an application from anywhere in the world with Internet access.

Water heating with electric boiler

Almost the most common option for using electricity to heat a house is water heating in combination with an electric boiler. One of the significant advantages of this approach is the fact that you are not tied only to electricity. If you wish, you can install a backup boiler and also make full use of water heating.

The range of prices for electric boilers is quite large. Therefore, you can always choose the option that will be more comfortable for you.

The main advantages of this approach:

- Possibility of connecting an alternative heat source

- High efficiency of electric boilers

- Safe, non-explosive heating system

- They don't spoil the atmosphere. Eco-friendly

- Possibility of using additional equipment

- Instant temperature change and adjustment

- Silent operation

The disadvantages include:

- The short service life of heating elements in most boilers. Especially budget ones

- Formation of plaque, which reduces the service life of the heating element

- High heating bills

- Requires high electrical power

- Depends on the network voltage. If it falls, then the boiler’s performance also drops.

- Large houses require three-phase wiring

Electric boilers are also not only heating elements, but also induction and electrode. They essentially differ only in the principle of operation, but in terms of energy consumption they are absolutely comparable

Induction boilers

Every technician knows the fact that everything that enters a magnetic field tends to heat up. An induction boiler is a large coil through which current passes, and the water inside the coil is heated as it passes through it.

Assembling a heating boiler on electrodes

Devices of this type have become actively used only in the last 10-15 years. These are more technologically advanced devices compared to heating elements.

Design

In electronic electric boilers, the liquid plays the role of a heating element. A self-assembled electric boiler of this type is a metal casing, inside of which there is an insulated steel electrode.

0 is supplied to the housing, and phase is supplied to the electrode. When voltage is applied, water ions begin to vibrate with a frequency of 50 hertz. In this case, the liquid gradually heats up. Due to this property, such boilers are also called ion boilers.

Advantages:

- small dimensions, thanks to which the ion boiler can be placed even in a small apartment;

- the absence of the so-called “dry running”, which guarantees the serviceability of the boiler, since without liquid inside it will not work;

- resistance to voltage surges;

- high heating and cooling speed, which means ease of adjustment;

- efficiency in energy consumption compared to devices using heating elements.

Among the disadvantages of such boilers are the following:

An important condition for the effective functioning of an electrode boiler is the level of thermal conductivity and the quality of the coolant; the device must be reliably grounded, since there is a high risk of electric shock; It is important to exclude the possibility of air getting inside the system, otherwise the electrodes will become unusable due to corrosion.

About the advantages

Electrode boiler ROMSTAR 2 smart (set)

- The main advantage of ion boilers is their high efficiency (up to 98%), which is explained by the relative simplicity of the device’s operation.

- Their small size allows them to be used even in small houses.

- Electrode boilers do not have a “dry run”. The liquid is a full-fledged “participant” in the working process, so its absence will not cause overheating of the system - only the circuit will open.

- Voltage drops in this case are not dangerous - if it drops, the device will not turn off, it will simply work with less power.

- Cost-effectiveness is another advantage of electrode boilers.

- Finally, they reach the set temperature quickly and cool down just as quickly, allowing for more efficient use of automatic control. Operating principle Drawing of an ion electric boiler

Heating system options

So, let's look at existing equipment that will make electric heating in the house economical and cheap.

Using the boiler

Installing an electric boiler, which will heat water in the home heating system, warming up the room, is the first, least effective option. Of course, on the Internet you can see a bunch of information that talks about economical boilers that can reduce consumption by up to 80%, but all this is nonsense. The only option to reduce costs is to install thermostats and various automation systems, which will turn on only when the temperature in the room drops, as well as at certain times of the day. All other talk about new product designs or reduced power is just a publicity stunt. If you buy a small-power boiler, it will take more time to heat the water for heating the house, so that’s what it will do.

Using IR Panels

Installing infrared heaters is a more reasonable solution and, most likely, the most profitable. The fact is that these products do not heat the air in the room, but certain objects (floor, walls, closet), from which heat is subsequently transferred. If in the previous version the hot air will rise to the ceiling and immediately cool down, then in this case the heat is directed to the floor, which is more reasonable (people do not walk on the ceiling).

This diagram shows the efficiency of an economical heating system for a private home:

You see everything for yourself, so there is nothing more to prove. It should only be noted that IR devices can work more efficiently if you add thermostats to them. One regulator is enough to control three heaters in an economical heating system for a private home. We talked about how to connect a thermostat to an infrared heater in a separate article.

Using convectors

Many manufacturers convince us that an electric convector effectively heats a room and at the same time consumes a small amount of electricity. The issue is of course controversial, because, in fact, the principle of operation of the products is similar to the option with radiators (the air rises upward). The advantage of convectors is that their installation and connection are not difficult. In addition, heating of the heating element takes about one minute, which is undoubtedly faster than in the case of water radiators.

Other advantages of electric convectors include:

- low cost (from 2 to 10 thousand rubles);

- fire safety (which is especially important when installing heating in a wooden house);

- you can gradually increase the heating system (one convector for a room is not enough, buy another one and connect it to the network without any problems);

- attractive appearance;

- trouble-free operation during power surges (also important in the private sector);

- compact sizes.

Separately, I would like to recommend that you explore a heating option such as electric heated floors. You can find out a review of this heating system by watching the video:

Application of heated floors

We analyzed reviews from customers who used this option and saw that most people were satisfied with the purchase. The main thing is to additionally install a temperature regulator in order to make economical electric heating in the house with your own hands.

Infrared heating system

This circuit uses an electric heater to generate infrared radiation that is directed in all directions, usually from top to bottom. Heat waves affect not so much the air in the room, but rather the solid objects in the room: the floor, furniture, fabrics...

Such electric heating of a wooden house is considered beneficial for the human body. Infrared rays are directed at objects and the human body, heating them first.

The efficiency of existing IR system heaters reaches ≈90%, which indicates their high efficiency. However, you need to carefully analyze the financial costs: the price of infrared equipment is quite high.

For comparison with convector heating: the thermal radiation method allows you to create a temperature of +22°C near the floor, while near the ceiling it will only reach +17°C.

Air conditioners

An air conditioner is often perceived as a device for cooling air.

It is important to understand that any such device is a type of heat pump operating on an air-to-air cycle. If you start it for heating, it demonstrates no less efficiency than similar direct heating equipment

The ratio of thermal power to consumed energy for modern inverter air conditioners is in the range of 3.6 - 5.

Heating functions can be effectively performed at a lower operating temperature of -25 degrees. In regions located in central Russia, air conditioners often serve as an auxiliary heat source, regardless of the time of year. Installation of equipment can be carried out either independently or by numerous companies. The most convenient in this regard are considered to be window models, the installation location of which is often an open sash.

Electric heating of the house - the basic principle of operation

Manufacturers offer a wide range of heating systems that run on electricity. Their work is based on the Joule principle. When current is connected, it flows to the heating element. Additionally, resistance arises in the system. However, some of the energy manages to create heat. In this case, it is also possible to achieve a partial reduction in voltage. By making changes to the connection diagram, it is possible to take control of the level of heat transfer. A conductor is a spiral or thread that consists of a refractory metal.

The heating level directly depends on the current strength in the network. However, you will additionally need to take into account the resistance value and operating time of the device.

Experimental heating method with high efficiency

Smart Heart specialists have developed autonomous heating modules and devices of different types and different power levels that can be used to heat both industrial premises and private houses, greenhouses, swimming pools, and paths. You purchase the device itself, install it yourself or with the help of specialists, and connect it to the Internet.

In the future, you use it like a regular electric heater or boiler, paying your own bills for electricity consumption, and the company compensates you daily via e-wallet for the use of the computing power of your device.

Currently produced heating modules of this type can be divided into two types:

- Air heating - in them, processors are cooled using air supply. They work on the principle of conventional electric fan heaters, only instead of a spiral, the heating elements in them are working chips (processors). Such devices can be used for air heating or drying areas of the house and for creating separate comfortable zones in the room.

- Water heating - in them the heat of the chips is transferred to water. They work like electric boilers - water heated in them to a temperature of 42-45ºС is forced into the heating or hot water supply system of the house. To do this, they can be easily installed into an existing water heating system or installed specifically for this heating module. Such devices are the best option for a thermal energy generator for water-heated floors in a house, underground heating of greenhouses, paths, swimming pools or other places where heating with a low-temperature coolant is required.

Currently, Smart Heart produces the following heating modules: Air heating units:

- A1 (“Veterok”) with a thermal power of 450 W, can be used to heat small rooms at home or create a comfortable zone, compensation for computing power for this module (as of 2015) is 40 rubles per day;

- 4A1 - thermal power 1.85 kW, can be used for round-the-clock air heating or drying of house premises, compensation payments - 200 rubles per day.

Hot water installations:

- W1 - thermal power 950 W, with a nominal water temperature at the outlet of the module - 45ºС, is a good solution as a water heater for a home hot water supply system. Compensation for computing power for this block is 100 rubles/day;

- W3 - power up to 1500 W (adjustable in the range of 1-1.5 kW), with water heating temperature up to 75°C. It may be the best option for heating water in the hot water supply system of a private home. Compensation payments (in 2015) - 200 rubles/day;

- C3SS5 - with a rated power of 3 kW (adjustable within 2.5 - 4.2 kW) and an output temperature of 42ºС, is the optimal solution as a low-temperature heat generator for installing water heated floors in the house.

Of course, to heat a large house, one such device will clearly not be enough, but in this case, you can use several of these heating modules (for example, separately for each floor) or use one, but in parallel with other heat generators (gas, solid fuel, heat pump) .

Efficient methods of heating with electricity

Heating with electricity in a private house has the main advantages over all others - these are simple and accurate methods for monitoring and regulating the operation of all components and elements. Even the sensors and display of information about operating modes are more accurate than those of equipment using other types of energy carriers.

When we are talking not just about local heating, but about the heating SYSTEM, this means the following:

- Heating works not only when there is someone in the house (therefore, a wood stove is not a system).

- You can manage the system (set up, regulate), including remotely. Therefore, an oil radiator or fan heater simply plugged into an outlet is not a heating system.

Individual electric heating of a private house has four options for heating systems:

- autonomous water heating systems based on electric boilers:

- use of infrared ceramic heaters;

- electric convectors with electronic thermostats;

- electrical converters with inverter thermostats.

All these systems can be adapted into a smart home system and controlled remotely.

Advantages and disadvantages

Although different types of electric boilers differ in design and principle of operation, they have a number of common advantages and disadvantages. The advantages of electric boilers over fuel boilers are as follows:

- simplicity of design;

- high level of security;

- do not need to install a chimney;

- high efficiency;

- electricity is one of the most affordable and environmentally friendly forms of energy;

- there is no need to provide a separate room for the boiler room, and the installation can be carried out in any room of the house;

- much less materials will be required for production;

- long service life;

- electric boilers are silent and automated.

If we talk about the disadvantages of electric boilers, then today we can only point out one. Despite the fact that electricity is an affordable and environmentally friendly form of energy, it is not the most expensive source of heat. Although, on the other hand, if you use electric boilers as additional equipment, then this option will be economically feasible.

Reviews

“I retired, took up dacha chores, and it’s cool in the spring and autumn. I wondered how to heat the dacha. I recently purchased an electrode boiler. My house is insulated, protected from wind blowing, the option suited me. The boiler doesn’t work all the time, everything is fine.”

Nadezhda, Stary Oskol.

“My wife and I purchased the device specifically for our summer cottage. Guys, the boiler is working well. I have not tried it in large rooms. You can install it in a room without bothering with allocating a separate room for a boiler room. I advise."

Vladimir, Krasnodar.

How to properly connect an electric boiler to the heating system

Briefly about how to properly install an electric heating boiler in a private house. To begin installation work, we list the basic safety rules that must be observed:

- When connecting the equipment, the power must be turned off.

- The following distances must be maintained between the boiler and the nearest structural elements of the house: to the wall - at least 5 cm, to the ceiling - at least 80 cm, to the floor at least 50 cm, to the nearest pipe - at least 50 cm.

- The front panel must be freely accessible for maintenance.

- The connection network must be three-phase (380 V) to avoid spontaneous combustion and short-circuiting of the wiring.

- Wire connections must be protected from water and sealed. It is better to protect the cable with corrugation or a cable duct made of self-extinguishing material.

Step 1 - installation of an electric boiler

The floor-standing boiler is installed on a special stand, which is sold complete with the unit. The wall-mounted one is attached to the wall with anchors and dowels. The vertical and horizontal position of the boiler must be accurate - misalignments can lead to failure or premature wear of the equipment.

Step 2 - connecting the boiler to the electrical network

- An electric boiler usually has more power, so it needs to be connected not from an outlet, but from the mains. From the distribution box in the room you need to lay a separate line to the boiler installation site. It is better to hide the cable to protect it from accidental damage.

- The cable cross-section must be selected so that it can reliably withstand high loads. Electric boilers up to 7 kW can be connected to a single-phase network, which, as a rule, was preserved in old Soviet apartments. For small boilers up to 3.5 kW, a separate line is not needed; they can be connected directly to the outlet.

Step 3 - install protection

- A residual current circuit breaker (RCD) and a circuit breaker must be installed on the main panel after connecting the wires to the electric boiler. The purpose of RCDs and circuit breakers is to protect against short circuits and wiring overloads.

- A voltage stabilizer will be needed to prevent the boiler from failing in the event of voltage fluctuations. It is strictly forbidden to use the equipment without grounding. The grounding wire must go from the bus to the boiler body.

Step 4 - starting the boiler

After the wiring is connected, you need to make sure that there are no exposed contacts. All taps, couplings, joints, etc. must be inspected and verified. First, the valves and valves are opened, and then the power supply to the boiler is turned on. Temperature and pressure sensors must operate according to the instructions. In case of obvious deviations from the norm, turn off the boiler and call a licensed specialist.

Tags: automatic, beat, boiler, sconce, view, water heater, switch, generator, house, , grounding, ground, cable, like, oscillation, convector, design, circuit, , magnet, installation, power, nominal, heating, skew , connection, permanent, rule, principle, wire, project, manufacturer, start, , work, size, regulator, row, homemade, network, system, resistance, means, term, circuit, ten, type, current, , smart, installation , phase, photo, shield, electricity, electric convector, electronic, effect