Before you calculate the staircase to the porch, you need to decide on its configuration, take a few simple measurements and be sure to decide what the steps and the upper platform will be lined with, which will serve as the basis for the structure. Then this data is used in calculations, of which several can be done, changing the step parameters and choosing the most optimal option. The main requirements for a porch are safety and convenience, for which, if necessary, you can sacrifice your ideas about beauty and style.

For a porch, the most important thing is safety Source pressrelease.com

Calculation of street stairs

The number of steps in a staircase can be very different. This parameter depends on the height of the march, as well as its inclination. It is important to try to make the calculation in such a way that the porch is as comfortable and safe as possible.

How to calculate the height of the porch

After the height of the porch has been measured, you need to determine the angle of inclination of the march.

Important: According to SNiP standards, the slope of the stairs of a residential building cannot be more than 45-50 degrees. The optimal parameter is considered to be 22-37g.

Once the angle of inclination has been selected, you can begin to calculate the stairs. In this case, you need to take into account such a parameter as the most convenient width and height of the porch steps.

Dimensions of treads and risers

The most comfortable steps for movement are considered to be steps with a depth of at least 30 and a height of about 17 cm. Let's look at how to calculate a porch using a simple example.

Let the required height of the staircase be 50 cm. With an inclination angle of 30 degrees, the length of the bowstring or stringer will be equal to C=B/sinB=50/sin30=50/0.5=100 cm. You can roughly imagine that the porch in this case will consist of three steps. Let's perform a more accurate calculation. Each of the steps will have about 33 cm of string length, that is, their depth will be A=C*cosB=33*cos30=33*0.9=29.7cm, and their height H=C*sinB=33*sin30=33*0.5 =16.5cm. Thus, we got the dimensions of the porch steps that were close to optimal.

The width of the flight should not be less than 70 cm. However, the staircase will be comfortable only if the distance between the strings or stringers is at least 110 cm. The minimum number of steps in a flight is two.

Railing posts are installed in different ways: they are embedded in sockets or attached to the ends of the load-bearing elements of the flight. The method of fastening the racks largely depends on the material from which the racks and the marching elements to which they are attached are made, and on the technical ingenuity of the designer.

Types of wood for steps

The aesthetic appearance of a wooden structure depends entirely on the type of wood involved in construction work. For the result to be pleasing to the eye, the tree must meet the following requirements:

- the surface of the elements must be uniform, without defects: cracks, areas damaged by beetles, knots;

- The moisture content of the wood should be no more than 12%. If the indicator is too high, the material should be thoroughly dried.

In this video you will learn how to make wooden steps:

Advice! In places with high loads, it is better to use blanks made from a single piece of wood or take laminated veneer lumber.

The following tree species are involved in the manufacture of products:

- steps made of pine - the hardness is not high, so they can be easily processed. After some time, yellow spots may appear on pine products. But this material can be easily found at an affordable price;

- birch – it produces fairly hard specimens. They serve for a very long time, but, as a rule, large pieces cannot be made from it due to the presence of defects and differences in shades;

- larch – the structure contains tannins, thanks to which larch steps do not deform, but the high cost does not allow the material to get ahead among its competitors;

- beech is a material with a beautiful pattern and color range, susceptible to the influence of ambient humidity. Beech stair treads are recommended for use in interior structures;

- ash - the plates are hard and bright. It is the flashy color that scares off many buyers;

- oak is the most suitable material for steps. Oak stairs are durable, very beautiful, but expensive.

Porch railing

Parameters of the flight of stairs (dimensions in mm): A - the most favorable width; B - permissible width of a flight of stairs

Railing posts are installed in different ways: they are embedded in sockets or attached to the ends of the load-bearing elements of the flight. The method of fastening the racks largely depends on the material from which the racks and the marching elements to which they are attached are made, and on the technical ingenuity of the designer.

The top of the racks is structurally connected to the handrail. Wooden posts are usually attached to the handrail using tenon or sleeve-type joints. Fantasies in the design of handrails, just like the shape of the balusters, are not limited by anything, except for the convenience of grasping them with your hand. Some difficulty is presented by the curved sections of the handrails, which are necessary in the turns of the fences. They are fastened to adjacent straight sections of the handrail using countersunk tightening screws.

Original appearance. A metal porch is a rather rare solution, and it can become one of the important decorative elements of the house.

Site depth

The most important indicator of the site that you need to know before making a porch. The depth primarily depends on the size of the door leaf. It's easy to define. You need to open the door to its maximum reach and measure its length. In addition to the obtained value, one more factor must be taken into account. You not only need to open the door, but also stand on the entrance platform yourself.

So, if the length of the door itself is 900 mm, for the convenience of using the stairs you need to add about 400 mm to this value. This is enough to easily open the door while standing on the landing. Thus, the depth must be at least 1300 mm.

What is more profitable to make a porch from?

All of the materials listed have their advantages and disadvantages, so you will have to choose according to a number of parameters. First of all, this is the cost of the finished structure and the availability of materials. If you work with metal by occupation, it will be much easier to find materials for a metal frame and people who are willing to help with welding the finished structure.

If you have recently completed the construction of a wooden house, there will definitely be some lumber and paintwork materials left on the site that can be used to build a wooden porch. Since wood is the easiest to work with, this is the most common solution.

There are not only those listed, but also many other options. For example, the side parts of the porch can be made of brick, and wooden steps made of boards can be installed on them. Such a structure can be plastered, it will look solid and interesting.

Another solution is a porch on logs: instead of bowstrings and stringers, the steps are laid on treated logs, in which special recesses are made. It is simple and reliable, since no additional fasteners are needed.

- hammer;

- construction level;

- yardstick;

- spatula (trowel);

- wood saw;

- shovel;

- electric grinder with a nozzle for metal.

What are the entrance staircases?

The first thing you need to know when building street stairs and steps is the material that is used for this type of work. Most often used:

- Tree. With proper treatment, some types of wood will last a really long time, especially as steps. Of course, the cost of any wood for the home is now quite high, but we should not forget about the pleasant appearance of this material.

Stylish combination of wood and forging - Stylish combination of wood and forging

- Metal. Street stairs made of metal require welding and proper processing. But the long service life of the metal very often allows you to make a choice in favor of this material.

Massive metal structure - Massive metal structure and original concrete steps

- Concrete. A material that is quite simple to prepare, and its service life is sometimes longer than that of metal structures. If you have a concrete mixer, a concrete (or brick) entrance staircase can be poured in a few days, but finishing work will take much longer.

Example of a concrete entrance staircase with tile trim Example of a concrete entrance staircase with tile trim

Example of a concrete entrance staircase with tile trim

Video from Youtube:

In fact, for the construction of external stairs there is a sufficient variety of building materials (for example, brick); it is enough to choose the one with the most optimal pricing policy and long service life. But this type of stairs also differs in the shape of its design. It can be:

- Screw. Often used in houses with a high base. They can have a classic shape or have more right angles.

- Straightforward. The most common, as they make one row of steps, which does not require a large amount of building materials.

- Street stairs with a platform. Which is mounted to improve the appearance. For the site it is necessary to make more gentle steps.

Of course, there are a large number of modern solutions near the home, but the above examples are the most common.

We cover the porch with our own hands

Finished concrete steps can be faced without the involvement of experienced finishers.

Laying tiles must be done in the following sequence:

- The reinforced concrete base must first be prepared: remove debris, completely remove dust from it.

- The surface of the base is treated with a special impregnation to increase adhesion.

- The surface of the steps and the facing material is lubricated with an adhesive composition.

- The tile is pressed against the base, but it must not be allowed to move.

- An interval must be maintained between separately laid slabs. For this, special spacers are used.

After laying decorative tiles, it is recommended to level the resulting seams with a special grout. And the required volume of the adhesive mixture can be calculated based on the area of the concrete base to be finished.

Another reason for the destruction of the porch cladding can be its shrinkage, and it is impossible to prevent this process. It should be anticipated.

Types of steps

Oak furniture and various wood accessories have never been considered cheap. This is explained by the complex preparatory process (drying and staining) of the workpieces. The result is a high quality product. Not everyone can afford to purchase oak products, however, the price does not count when the splendor and durability of the product are at stake. Therefore, when cladding flights of stairs, oak tiles are often used, guided precisely by their long service life. Oak steps last a long time without changing their positive characteristics.

There are 3 types of steps

Kinds:

- Solid. To create them, a whole piece of wood is used, and the structure of the wood pattern does not change. The main condition before installing the panels is that the wood must be kept for some time in the room where the adaptation work is supposed to be carried out.

- Solid lamella. Products are obtained by superimposing horizontal plates on top of each other. The pattern in this case is not lost.

- Spliced. The method is good if you need to create a very durable wooden structure. The method is based on merging several lamellas with tenons or grooves in the vertical direction. It is in demand when lining the treads of a flight of stairs.

How to make steps for a porch: technology for proper tiling

In order to more fully understand the seriousness of the approach to the matter, we will cover the question of how to lay tiles on a porch, point by point. Naturally, special attention will have to be paid to the nuances.

Steps for the porch photo

- We upholster the porch with a metal mesh with a large mesh - maximum 50x50mm. We fasten it with a Berbach dowel, but it is better not to use plastic plugs. The advantage of this dowel is its flat, wide head, which does not interfere with the use of the comb. We install them at the intersection of the mesh rods.

- We prime the surface of the porch with the standard composition ST17.

- We prepare glue for the tiles and putty the porch with it. The task is to fill all the cells with glue and place the mesh inside it. Particular attention should be paid to the inner corners of the steps - there should be no voids there.

- We leave the porch puttied with glue to dry - we say goodbye to it until tomorrow.

- We prime the surface. During the drying time, it was sure to be covered with street dust, which needed to be neutralized.

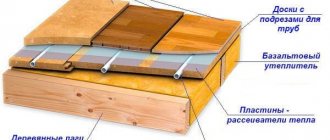

- Laying the tiles. In order to qualitatively veneer the steps for the porch with your own hands, at this stage of the work you will need to observe some nuances. Firstly, you need to apply glue to both the porch and the tiles themselves. If you noticed, the back side of the tile has a corrugated surface - this may sound strange, but it is intended to increase the gluing surface. All this corrugation must first be filled with glue, and then only applied with a comb. Secondly, when laying the tile, it must be carefully nailed to the base with a rubber hammer - if glue comes out from under it on all sides, this is very good and indicates that there are no voids under the tile. Thirdly, this is grout. There is no question of any colored seams on the porch - the seams are rubbed down with the same glue on which the tiles are laid. It is better to do this immediately during the installation process - in this way you can get a monolithic structure of the seam and the base (that is, glue).

Laying tiles on the porch photo

DIY porch steps

And finally, one little piece of advice - when tiling steps for the porch, try to lay the tiles so that they have a slope directed away from the entrance to the house - then water will not leak under the door and disturb it with its presence. In addition, it will not spoil the facade of the building - mold and fungus will not grow on it.

Crushed stone is often used to reduce cement costs and increase the strength of the mortar.

Accepted Standards

It is for the comfort of movement that there are standard sizes accepted by builders all over the world. Whatever the landscape conditions, the ideal proportion of the porch is considered to be 1/2. In other options, it may be inconvenient and unsafe to move around.

The width of the steps of the external porches must correspond to the average width of the foot, that is, from 25 cm, but not more than 30 cm. The height of the stair riser varies between 14cm and 20cm, but not higher (the difference between a step and a riser is shown in the photo). Compliance with standards during any construction work is a guarantee of the harmony and reliability of the constructed facility.

The exact definition of what is a riser, step or tread

Concrete steps for porch

To build concrete steps you will need: cement, water, crushed stone and sand. The solution will need to be made in a sand to cement ratio of 3:1.

Crushed stone is often used to reduce cement costs and increase the strength of the mortar.

We begin the construction of concrete steps:

In principle, building a small number of steps will only take you one full day and will not take much effort from you. The main thing is to calculate everything clearly and in detail in advance so that no shortcomings arise.

Concrete steps do not have to be gloomy, gray and straight. Add a little imagination, change the shape, make them semicircular and make each step a different shape. Finish gray concrete with style. And then your porch will sparkle with new colors.

In addition to “longevity” and strength, there are several more advantages - the steps can be given any, most incredible, shape, and there is a huge selection of materials for their finishing.

In addition to “longevity” and strength, there are several more advantages - the steps can be given any, most incredible, shape, and there is a huge selection of materials for their finishing.

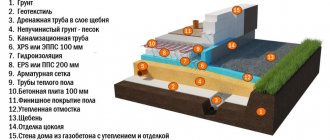

Such a heavy structure cannot exist without a foundation, so the area should be thoroughly cleaned and then a pit should be dug; its depth should be 70 cm, this is the minimum. A sand cushion is poured into it, a frame made of reinforcement is placed on top, then the formwork is made. The operation is completed by pouring concrete. After 3 days, you can begin further work.

A layer of waterproofing is laid on the dried foundation, most often it is roofing felt. The formwork is made of boards or plywood, with additional stiffening ribs and vertical supports attached to its sides. This design must exactly repeat the drawing of the staircase.

After the formwork is ready, the main work begins.

How to veneer concrete steps?

To finish staircases, paving or porcelain tiles, stone or clinker are often used. First, they line the porch, then the treads, then move on to the risers and the side of the stairs.

After the concrete has fully gained strength, finishing begins. First, the surface is sanded to remove all irregularities and bulges.

Treatment of steps with protective agents

Steps made of larch or oak are quite resistant to external influences. But there are several techniques that can further improve the protective properties of the material. Oak steps can be varnished. This adds shine and prevents minor scratches on the surface. Temperature changes and humidity have a negative impact on wooden steps; they can become deformed. Varnishing the surface eliminates such a nuisance.

It is better to use polyurethane mixtures as varnish, which can withstand significant damage. The varnish is applied in three layers, but first a primer is applied.

The next operation to extend the life of the product is wood impregnation. At the stage of selling wooden products, no one can say for sure in what conditions they will be used: in dry places with high loads or wet conditions.

Positive effects of impregnation:

- creates a surface wear-resistant layer and improves the performance of wood (not so important for steps made of larch and oak);

- reduces the sensitivity of the material to ultraviolet radiation - paints and varnishes last a long time and do not fade;

- improves the moisture resistance of wood.

Advice! A board treated with paint and varnish coatings and various impregnations does not allow air to pass through it well, so unpleasant odors will accumulate in the room more quickly. This drawback can be eliminated by good ventilation of the room.

Some useful tips

If every owner of a private house adheres to certain simple rules, then he does not have to worry about comfortable and completely safe movement along his entrance staircase. Here are some of them:

- If the staircase has a steep climb, then it should have strong and wide railings.

- The steps should not be made of slippery finishing materials, and on their surface it is better to install linings made of material with a high coefficient of friction.

- It is desirable that the external aesthetics of the staircase match the architectural appearance of the house.

Strong railings are a necessary element of a steep staircase Source homeli.ru

It is worth remembering that the entrance staircase is, first of all, necessary for the safe movement of people. Competent selection of materials and performers for its installation will help save time during its construction, as well as avoid problems during further operation. You should not skimp on the quality of the stairs being built.

Why is the structure needed?

The adjacent structure performs both protective and decorative functions.

A porch is a structure erected near the entrance to a private house, which consists of a platform and stairs. It is erected to perform the following functions:

- Provide safe and convenient access to the house in cases where the entrance to it is located above ground level (in buildings with a basement)

- Protect the door from precipitation, exposure to ultraviolet radiation, and mechanical wear

- Serve as a decoration element for the façade of a residential building

The advantages of the structure include:

- additional sound insulation and heat retention

- the ability to leave outdoor shoes and ensure that the house is kept clean

- additional space for rest and placement of necessary utensils and household items

Despite all the advantages of the design, this element is not always necessary in the building.

Porch with railings

So, a porch with stairs and railings:

- They are not included in the plan when building a house due to possible difficulties with uniform shrinkage of the building

- Do not build if the door threshold coincides in level with the ground surface

Material selection

The choice of porch material depends on the needs of the residents of the house and the overall design of the site

Depending on what material is chosen for construction, the porch can be:

- concrete

- wooden

- metal

- stone

- brick

For a low porch, concrete or stone is chosen, while railings are not needed for such a structure. Tall structures are best made of metal or wood.

The advantages of a concrete porch include durability, high resistance to wear and temperature changes, and strength. The weakness of the material is its tendency to absorb moisture.

Porch options with railings

Brick platforms are not as durable, but they are cheaper than concrete ones. It is important not to use old brick, which can freeze and collapse. The surface can be tiled or finished at the request of the owners.

A metal porch is durable and able to fit into structures of any design . However, such structures are expensive, require protection from corrosion, and are prone to icing in winter.

Wooden structures are the most common, they look solid, they are easy to install and convenient to use . However, the wood must be additionally impregnated or coated with protective solutions against moisture, fire, and insect pests.

Necessary tools for work

To make a metal frame, you will need a welding machine

. Use plank formwork to fill the concrete treads. The mold is made by hand or purchased a ready-made, repeatedly wrapped structure.

Prepare the tool:

- building level, iron hammer, 5 meter tape measure;

- wide and cap spatula, ironing board, trowel (trowel);

- shovel and bayonet shovel, pliers, crochet hook for wire knots;

- grinder, diamond disc and iron circle;

- container for preparing concrete or electric concrete mixer, electric vibrator.

All devices must be at hand in order to concrete the steps without delay.