When constructing any building or structure, from a skyscraper to a fence or utility block, the first thing in order and importance is the construction of the foundation. Pile foundations have proven themselves well for construction on difficult soils. Only specialists can make the correct calculation of a pile foundation, since it is necessary to take into account all the nuances of the foundation for a specific building and type of soil. All other methods will give only approximate results.

There are certain rules for calculating pile foundations and all of them must be taken into account Source fazenda.guru

Video description

In this video we will look at what you need to know about concrete piles:

Piles are used in 3 types:

- Hammers.

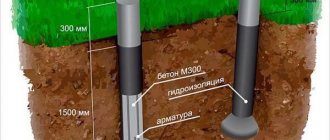

- Bored. As one of the options for bored piles, so-called TISE piles are installed, with a widening at the bottom. This design feature reduces the load on the soil and allows the foundation to effectively withstand the buoyancy forces that arise during frost heaving of the soil.

- Screw.

Driven elements are used extremely rarely in private construction, because... require the use of heavy construction equipment.

Types of pile foundations Source kursremonta.ru

Determining the type of soil

To determine the type of soil it is necessary to dig a well

During the construction of large public and civil facilities, geological and laboratory studies of the soil at the construction site are carried out. Tests are carried out by specialists, their services are quite expensive.

In private construction, you can independently determine the composition of the soil. It is necessary to use a drill to dig wells in several places on the site, the depth of which will be half a meter greater than the length of the pile. We look at what layers of soil are on the drill blades and present inside the well.

The depth of groundwater can be found out from neighbors or determined from existing wells on the site. If a small flooded area is found, we try to position the supports so as to bypass it.

Online foundation calculator

To find out the approximate cost of a “grillage on piles” foundation, use the following calculator:

Pile foundation calculation

To calculate a pile foundation, like any other, you should calculate the load on the foundation F. To do this, add up the weight of the walls, ceilings, roof, snow load and floor load. The first 3 parameters can be calculated independently, or using special construction calculators. The snow load depends on the region in which the building is located and is determined according to SNiP 2.01.07-85 “Loads and Impacts”, the load on the floor is taken to be equal to 180 kg/m2 of the total area of the structure.

Distribution of snow loads depending on climatic zones Source obustroeno.com

Then the load-bearing capacity of the pile is determined by the formula

P= ϒ cr*R0*S+u ϒ cf*fi*hi , where

- R0 – standard soil resistance under the base of the pile

- S – base area

- ϒcr – coefficient of soil operating conditions under the foundation

- u – section perimeter

- ϒcf – coefficient of soil operating conditions on the lateral surface

- fi – soil resistance on the lateral surface

- hi is the depth of the pile below ground level.

The base area S of round piles is calculated by multiplying the square of the pile radius by 3.14, the perimeter by multiplying the section diameter by 3.14. The diameter of the pile is chosen based on the intended formwork material and equipment parameters, usually for private construction - 200-300 mm.

Calculating the grillage

The pile base can be constructed from only supports, on which the lower frame of the building is laid.

To ensure that the load on the supports from the weight of the structure is distributed more evenly, they resort to making a grillage.

A grillage is a beam or reinforced concrete slab that horizontally connects the tops of each screw element. Pile-grillage foundations are equally well suited for the construction of wooden and foam block buildings. The strip grillage can be monolithic or prefabricated, the main thing is that it is cast from concrete, the grade of which is not lower than 150.

In order for the grillage to be properly constructed and create a strong connection between the screw elements, you need to correctly calculate its dimensions. There are a number of special calculations, but we will limit ourselves to the minimum dimensions of the binding tape:

Foundation with reinforced concrete grillage

- Height – 30 cm.

- Width – 40 cm.

To give the grillage the necessary rigidity, it must be reinforced with longitudinal and transverse reinforcement (10-12 mm in diameter). The rods are connected using wire according to the principle of an armored belt. The distance from the reinforcement to the edge of the grillage must be at least 2.5 cm so that the metal rods are completely sealed with concrete mortar and are not subject to corrosive processes.

The connection of the grillage with the supports can be rigid, when its reinforcement is connected to the pile rods, or loose, when the grillage lies on the foundation supports without additional support. In both cases, the load is distributed evenly between the piles.

Video description

What are the features of concrete driven piles?

We will talk about the pile foundation in our video: The immersion depth is chosen arbitrarily, but not less than the soil freezing depth +0.5 m, or according to the depth of the load-bearing soil layer, the groundwater level should also be taken into account.

The standard soil resistance R0, operating conditions coefficients ϒcr and ϒcf are determined from tables from SNiP 2.02.03-85.

Using such tables, experts determine the standard soil resistance, but first you need to find out the type of soil, for which a soil analysis is carried out. Source stroj.umorists.ru

How to calculate the cost of screw piles

Calculations for the cost of foundation construction are simple. Knowing the required number of screw posts, you can easily calculate the total cost. In the example above, there were 12 supports - 8 pieces with a diameter of 108 for the bathhouse frame and 4 with a diameter of 57 mm for the stove.

A pile with a diameter of 108×2500 mm costs 1850 rubles without installation and 3050 rubles with installation. Accordingly, for 8 pieces you will pay 14,800 rubles. or 24400 rub. 4 supports 57×2500 with self-screwing will cost 4200 rubles, with installation from specialists - 8400 rubles.

In our example, the cost of piles will be 19,000 rubles, or 32,800 rubles.

Calculations are carried out similarly with your denominations.

Depth and height

The depth of the pile is determined based on the location of the solid bearing layer, as well as the seasonal freezing point of the soil. The level of soil freezing is found using the formula:

Where:

- Mt – the total value of average monthly negative temperatures during the winter;

- d0 – coefficient (assumed equal to: for coarse soils – 0.34, medium-sized sands – 0.3, sandy loams – 0.28, clays – 0.23).

According to regulatory requirements, the minimum height of the base is 20 cm, but experts recommend sticking to a value of 30–45 cm. For wooden houses, the lower floor can be raised 50 cm from ground level, and for regions with high snow cover - by 90 cm or more.

Weight of building structures

When calculating loads, the weight of the following structures must be taken into account:

- foundation;

- walls;

- floors;

- flights of stairs;

- partitions;

- roof.

The weight of standard fillings of window and door openings can be ignored when designing a private house, since it will not exceed the weight of the walls and partitions.

When calculating, it is necessary to multiply the resulting value by the reliability factor ϒϝ.

| Structures of buildings: | reliability factor ϒϝ |

| 1. metal | 1,05 |

| 2. concrete (with an average density of more than 1600 kg/cubic m), reinforced concrete, stone, reinforced stone, wood | 1,10 |

| 3. concrete (with an average density of 1600 kg/cubic m or less), insulating, leveling, finishing layers (slabs, rolled materials, backfill, screeds, etc.) | 1,30 |

Foundation

Since in the future the magnitude of the load will be used to calculate the area of the foundation base, it is necessary to take into account its weight, since it also exerts pressure on the ground. To determine the weight of the foundation, you simply multiply the volume of the structure by the volumetric weight of the material

Most often, the foundation is made of prefabricated or monolithic reinforced concrete. The volumetric weight of the material of a strip or columnar foundation is 2000-2100 kg/cubic. m. For a solid (slab) foundation, this value will already be 2500 kg/cubic. m, since in such a structure there is much more steel reinforcement

To determine the weight of the foundation, you simply need to multiply the volume of the structure by the volumetric weight of the material. Most often, the foundation is made of precast or monolithic reinforced concrete. The volumetric weight of the material of a strip or columnar foundation is 2000-2100 kg/cubic. m. For a solid (slab) foundation, this value will already be 2500 kg/cubic. m, since in such a structure there is much more steel reinforcement.

Walls

Walls are the structural elements of a building that enclose or divide it along its entire height, regardless of the number of floors. The floors and roof rest on load-bearing walls. The load produced by the walls depends on their thickness, height and volumetric weight of the material. To determine the weight of the walls, you need to calculate the volume of the material and multiply it by its volumetric weight (density). In addition to the main structural material, you also need to take into account the weight of the insulation, as well as facing materials.

| Name of building materials: | Volumetric weight, kg/cubic. m |

| 1. concrete | up to 2400 |

| 2. high-strength concrete | 2000-2800 |

| 3. concrete is porous | 350-1000 |

| 4. gas silicate block | 200-600 |

| 5. expanded clay concrete block, foam concrete | 500-1200 |

| 6. reinforced concrete | up to 2500 |

| 7. vinyl siding | 800-1550 |

| 8. natural stone | 800-2500 |

| 9. building brick | 1000-2200 |

| 10. foam | 10-25 |

| 11. extruded polystyrene | 15-30 |

| 12. tree | 420-1200 |

Floors

The weight of the floors can be determined by multiplying the volume of the material by the density. If the floors are made of reinforced concrete hollow slabs, then their weight will be 30% less than that of monolithic reinforced concrete. The weight of floors made using wooden beams can be determined by knowing the volume of lumber required and the density of the wood. When calculating the load created by the ceiling, it is necessary to take into account the weight of the floor coverings, as well as the weight of thermal insulation if the ceiling is insulated.

Flights of stairs

Staircases and flights of stairs rest on walls and ceilings. Their weight also needs to be taken into account. To simply determine what load the stairs produce, it is enough to multiply the area of the stairs and the height of the riser, and then take into account the slope of the flight, that is, divide the resulting value by cos α, where α is the angle of inclination. By multiplying the resulting value by the number of floors of the building, you can obtain the volume of staircase material. Next, everything is as usual, the volume is multiplied by the density of the material and the weight is obtained. If both the floors and the stairs are made of the same material, for example, reinforced concrete, then the weight of the stairs can not be taken into account separately. At the same time, when calculating the foundation, the area of the floors must be taken without deducting the area of the stairs.

Roof

To calculate the weight of the roof, you need to know the weight of the materials used in its manufacture, including insulation and vapor barrier. In individual construction, pitched roofs made on wooden rafters are usually used. Asbestos-cement sheets (slate), ceramic tiles, and profiled steel sheets are used as roofing.

| Name of building materials: | Volumetric weight, kg/cubic. m |

| 1. ceramic or cement roofing tiles | up to 2200 |

| 2. slate | up to 2800 |

| 3. profiled metal sheets (metal tiles) | 5-10 |

| 4. extruded polystyrene | 15-30 |

| 5. glass wool, mineral wool | 15-250 |

| 6. foam | 10-25 |

| 7. tree | 420-1200 |

Object Parameters Settings Manager

The Object Parameters Settings Manager is designed to create a drawing template.

Used to solve the following problems:

- managing the settings of parameters of all program elements (Fig. 1−3);

- using standard and creating custom layers with setting their properties (Fig. 4);

- saving settings in a file for later use in other projects.

| Rice. 1. Settings Manager Menu | ||