If you are choosing a foundation for a building made of timber or logs, then you have probably come across information about screw and reinforced concrete (RC) piles. It is especially beneficial to use such supports if the conditions on the site are far from ideal. Today we will look at several proposals from real companies and, using an example, we will try to figure out which technology is better.

Foundation as the basis for a country house Source www.severecosrub.ru

Description of pile types

Let's first take a look at the definition of each type of pile.

About screw piles

Screw piles are hollow steel pipes with a sharp tip into which a blade is welded. When installed from the inside, they are filled with a cement-sand mixture, which prevents internal corrosion, and a cap is placed on top. To protect them from the effects of the external environment, they are coated with an anti-corrosion coating. As a rule, these are epoxy compounds or galvanization. Relatively recently, manufacturers have appeared on the market that use double corrosion protection. More on this below.

Installation of screw piles Source www.severecosrub.ru

About reinforced concrete piles

Reinforced concrete piles are a concrete rod with a reinforcement cage. For private housing construction, supports with a cross section of 150x150 mm or 200x200 mm are used. When choosing reinforced concrete piles, you need to pay attention to the grade of concrete from which they are cast and its frost resistance class. These characteristics determine how strong and durable the foundation will be.

Let's move on to comparing technologies. To do this, we will take “Standard-1” screw piles from the KKZM plant, screw piles with two-level protection of the HelixZINC series from the HelixPRO company and reinforced concrete driven piles from the manufacturer MONTAZHSVAY.RF. What aspects are we interested in? Firstly, a rational cost ratio for the planned construction, secondly, the convenience and possibility of installation for the site, thirdly, the price of components, labor and delivery.

Advantages of installing a pile foundation

Construction work in winter has a number of advantages. The main advantages of constructing a pile-strip foundation for the winter:

- no preliminary earthworks are required;

- installation of reinforced concrete piles takes on average 1 day;

- sub-zero temperatures down to -25 degrees do not affect the quality of the design;

- after installing the reinforced concrete structures, you can immediately continue construction work;

- Installation of piles is possible in sandy, swampy, peat areas.

The disadvantage is the high financial costs, since in winter the conditions are harsher and require proper operation of the equipment.

Value for money

To begin with, we note that on screw piles, as well as on reinforced concrete, you can build any type of wooden houses (frame-panel, half-timbered, timber, log), baths, garages, gazebos, outbuildings, etc. The main thing is to understand the relationship between price and quality. If you are planning to build a house for permanent or seasonal residence and the conditions on the site are good, then it’s all about the price. Please note that reinforced concrete piles have a greater load-bearing capacity compared to screw piles. But despite this, when designing, they have the same step, that is, it will not be possible to save on quantity.

Continuing my thoughts... If your plans include a bathhouse, garage or some small house, then it is more profitable to use screw piles. Now the question is: which ones? In appearance, most of them look the same, since they have a black coating on top (if we are not talking about galvanization). But coverage is different from coating, as they say. Today the price varies from 70 to 700 rubles per liter. You understand that not everything that is black protects metal from rust. It was not in vain that we paid attention to the proposal of the KKZM plant. “Standard-1” is a budget option for piles with a more or less high-quality protective coating. The manufacturer monitors compliance with technology, does not use used rolled metal, and purchases anticorrosive materials that have been proven over the years. Such piles will last more than 80 years if installed correctly. The main thing is to choose the required size. Typically, supports with a diameter of 108 mm are chosen for construction. The design department will be able to carry out calculations for a specific house.

Speaking about screw piles with double corrosion protection HelixZINC, we note that these supports have an increased service life. The manufacturer specifies 120 years of operation. The meaning of the technology is that the piles are coated with hot zinc, and on top - with an epoxy composition. For what? During installation, the top layer of the coating may be damaged by stones in the ground. At the site of chips and scratches, corrosion will occur first, which will have a detrimental effect on the foundation as a whole. The barrier layer provides a guarantee against premature destruction of the metal. Of course, galvanized piles differ in cost from regular ones. But when it comes to building a family nest, the difference will seem insignificant. But for simpler buildings, ordinary piles are also suitable.

If we are talking about building a huge wooden house with a large number of rooms, then it is better to give preference to reinforced concrete driven piles. One support can withstand loads from 9 to 60 tons depending on the section, while a screw pile has a load-bearing capacity of up to 10 tons depending on the diameter.

Reinforced concrete piles are a concrete rod with a reinforcement cage Source kkzm.ru

How to fill piles with concrete yourself

Concrete foundations on screw piles are durable, strong, reliable, resistant to various influences and allow you to create high-quality foundations on different types of soil. But before you start work and decide whether it is necessary to pour concrete into screw piles at all, you need to carefully study all the nuances.

General concepts about piles filled with concrete

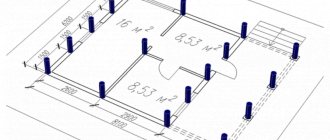

Concrete is poured into cast-in-place piles, which come in different types - reinforced concrete, concrete, metal, synthetic, asbestos-cement, screw, etc. First, the locations of the piles are calculated and marked at the site, which can be installed either individually or in bushes or strips. Typically the base is rectangular in shape.

Installation and pouring of cast-in-place piles

For cast-in-place supports, wells are first made - by conventional soil drilling, drilling with the introduction of a clay solution under pressure, drilling using vibro-mechanical equipment, or explosion. The process can be carried out manually or using special equipment, tools, or equipment.

After drilling, a mixture of sand and gravel in equal volumes (or only sand) is poured into the bottom of the well, with mandatory compaction and a final layer thickness of 10-20 centimeters. A layer of waterproofing is laid on this pillow.

It is imperative to take care of covering the surface of the well inside with a saturated clay mixture in water-logged soil (using special equipment). In this way, it is possible to create a waterproof layer that protects the walls from collapse.

A frame made of steel reinforcement is installed strictly vertically into the prepared well. Concreting needs to be done in stages, pouring the solution in a layer 20-25 centimeters thick. Next, the poured mixture is compacted with a hand vibrator.

Pouring piles using casing pipes

For soils with not very high bearing capacity, cast-in-place piles for buildings are made using casing pipes. Before the screw piles are filled with concrete, everything needs to be prepared. First, they drill wells, then lower the pipe segments inside; if necessary, use jacks.

If it is necessary to arrange a pile support with an expanded base, you need to cut off the soil layer with a special mechanical knife or expand the bottom with an explosion. In this way, it is possible to significantly increase the bearing capacity of piles.

The assembled steel frame is installed on a bed of gravel and sand and a layer of waterproofing. Concreting is carried out in layers, with each layer being compacted with a vibrator. As the concrete hardens, part of the casing is dismantled.

Pouring cast-in-place piles with concrete using pneumatic equipment

If the pile foundation is installed on water-saturated soil, the base is built on cast-in-place piles and concrete is poured using pneumatic equipment. First, according to the general principle, a cushion is filled in, then waterproofing is laid, and the pile is formed from concrete with compressed air supplied by a compressor. The support is filled in layers throughout its entire volume using injection equipment.

Pouring bored piles with a widened heel

When dealing with the question of whether it is necessary to fill screw piles with concrete, it is advisable to study all the technologies for creating a structure. One option is to construct piles with an expanded base.

How to arrange an expanded well base:

- Filling in layers

the bottom of the well with a layer of concrete of 20-30 centimeters and squeezing the mixture under pressure into the surrounding soil to create an expanded base.

- Creating a heel

with a special cutting tool - a folding element, which is attached to the drill head and is capable of opening at the required depth. During rotation, the knife expands the width of the base to 2-3 meters in diameter. The knife activates a hydraulic mechanism controlled remotely.

- Explosion Expansion

– a remotely located device causes the explosive to detonate, which creates a spherical depression.

Then the well cavity is reinforced with a steel frame and concrete is poured.

Drilling piles with a mixture of soil and concrete

To make a driven soil pile, special drilling rigs are used that mix soil and liquid concrete. The blades of the mechanism mix the concrete solution and cut soil, the entire volume goes under pressure into the hole for support, as a result, a pile with a sufficiently high load-bearing capacity is created. Thus, the soil is not removed from the well, since it is the soil and concrete that form a solid foundation. Typically, such piles are made on weak sandy soils.

Pouring screw piles with concrete mortar

The screw concrete pile is filled with mortar in layers, each layer should be approximately 20-30 centimeters. The layers must be compacted with a special vibrator. If a small building is being built, the concrete can be compacted with a bayonet made from ordinary reinforcement or something suitable.

Screw piles demonstrate excellent load-bearing capacity, but usually these types of foundations are not used for buildings made of heavy materials.

Priming

Much depends on the conditions at the site. If the soil is highly acidic, then installing screw piles is dangerous, as they will quickly rot. Therefore, it is worth doing a soil test before starting construction to avoid risk.

There are areas with a large difference in ground level or water-logged soil. In this case, on the contrary, it is worth giving preference to screw piles, because during installation they can be increased until the blade reaches dense soil. In addition, due to the wide base, the screw pile will be more stable in this type of soil, where a concrete pile can simply fall deep into the ground.

Features of installing reinforced concrete piles in winter

The foundation of a construction project makes up 25-35% of the total cost. Various technologies force customers to choose the basis and time of year to begin work. The question arises whether to give preference to a pile-grillage foundation in winter, whether piles are driven in during this period. Construction requires a large amount of special equipment, time and financial investments. The posts are installed in the frozen ground using a diesel hammer. If the ground is frozen to 30 centimeters, heating is required using special electrical equipment.

Construction work begins with the development of a project and calculations for the location of reinforced concrete piles and immersion depth. Preliminary geological surveys of the soil are carried out to determine the category. It can definitely be said that it is possible to install piles in winter, you just need to correctly assess the possibilities in a given area. The work consists of several stages:

- Preparatory: clearing the construction site of debris and last year's grass.

- Marking the territory: marks are installed for the outer and inner perimeters of the walls. The pitch value is 2-2.5 m, the drilling depth is from 1.5 to 2 meters.

- Installation of reinforced concrete structures: special equipment is used to install supports. If for some reason the work is suspended, conservation of the pile foundation for the winter is not required. The supports are made from the appropriate type of concrete and are properly treated before immersion.

Is it possible to make a pile foundation in winter? It is definitely necessary if the soil has high humidity. For example, in summer the construction of berths, piers and bathhouses is difficult due to water. A reinforced concrete base is suitable for difficult soil conditions, and foundation blocks will make the future structure even more stable.

Delivery and installation process

Reinforced concrete piles are installed using a mini-pile driving machine. That's what they're called - driven ones. The crawler-mounted machine moves independently around the site, operates at high and low temperatures, and installs supports quite quickly. But delivering it to the site requires special equipment. However, in one shift it is possible to install about 40 reinforced concrete piles, that is, the foundation for a house.

Mini-pile driving machine drives reinforced concrete piles Source kkzm.ru

Screw piles are installed manually, electromechanically or, if absolutely necessary, using a hole drill. The best option is electromechanical installation. Today, any serious company offers it. How does this happen? Screw piles are installed using manual hydraulic machines. That is, the mounting hole is inserted into the gearbox, which creates torque. Compared to the manual method, the electromechanical method has advantages in terms of penetration and installation speed.

If the area where it is necessary to install the foundation is difficult to access for one reason or another, the only possible way is manual installation of screw piles.

The futility of concreting screw piles - justification

Many people believe that there is no need to concrete screw piles - both contractors and customers think so. It is believed that the main danger due to which screw piles can fail is contact between metal and concrete; they simply have a different coefficient of thermal expansion. Due to this feature of the materials, microcracks form inside the concrete mass - that is, a place appears for the accumulation of air and moisture. Due to this, the corrosion process is activated - the slow but sure destruction of the pile begins.

Bottom line

| Technology / Structure: | Bathhouse / Terrace / Garage | Wooden house (timber/log/frame) | Aerated concrete house (foam block, aerated concrete) | Stone house (brick, monolith) |

| Screw piles | 5 | 5 | 3 | X |

| RCC driven piles | X* | 3 | 5 | 5 |

* irrational costs

Small buildings and wooden houses made of timber or logs

Speaking about garages, bathhouses, terraces, gazebos, fences, cabins and other small and light buildings, we note that it is not rational to use reinforced concrete piles. For an ordinary timber or log house with a residential attic, screw piles are often also more preferable. But if we are talking about a large house, and you are betting on durability, then you can consider the option of a reinforced concrete driven foundation, because in the ground concrete practically does not collapse and does not deteriorate.

House made of lightweight concrete (foam blocks or aerated concrete)

For this type of building, both screw piles and reinforced reinforced concrete piles are suitable. In the first case, it is worth choosing supports of large diameter and further strengthening the foundation. In the second, it is enough to choose the right section. In addition, on reinforced concrete piles paired with a shallow grillage of 600x400 mm, you can safely build even a three-story brick house.

Do screw piles need to be concreted?

Concreting screw piles is a fairly simple technological process, but the feasibility of its implementation is questioned by some experts.

Competent opinions of supporters of this technology

The method of increasing the load-bearing capacity of screw piles and ensuring their corrosion resistance was born from the method of installing drilled injection piles. This technology is used in construction in densely built-up areas and eliminates the destruction of the foundations of neighboring buildings that occurs when using cast-in-place piles.

Video shows concrete pouring of the iron frame of the pile

Construction of a foundation using drilled injection piles involves the use of auger drilling units. A reinforcement cage is installed into a well drilled with a hole drill, which is filled with sand or water-cement solutions, then the pile is pressurized.

The technology of using solution injection into the shaft of a screw pile increases its load-bearing capacity by a third, which is achieved by increasing rigidity and strength, and the elasticity of the pile to deflection also increases. The use of sand-concrete mixture diluted with water is recommended in warm seasons; in winter, special additives are needed to prevent freezing.

Some competent experts believe that concrete, when filling piles, can leave cavities due to its density, i.e., air is not removed. The best solution is to backfill with TsPS or M-300 sand concrete; the condensate that appears over time will concrete the mixture.

The required amount of mixture is calculated using the formula:

where: π = 3.14; r – trunk radius (m); h – pile length (m).

Calculations determined that 16 kg of mixture is required for 1 meter of pile shaft D=108 mm.

Justification of the futility of concreting screw piles

The feasibility of using concreting technology for screw piles is questioned by some customers and contractors. They believe that the main danger for the possible destruction of a screw pile is the presence of contact between concrete and metal, which have different coefficients of thermal expansion.

This feature of materials leads to the formation of microcracks inside the concrete mass. Thus, it becomes possible for moisture and air to accumulate, which activates the corrosion process, i.e. the pile begins to collapse.

Typically, water-gas seam pipes with a wall up to 4 mm thick are used to make the pile shaft. They are designed to operate at a maximum pressure of 24 atmospheres. The new thick-walled (up to 7 mm) pipe D = 108 mm will withstand the destructive impact of greater force, while the cost of its acquisition is comparable to the cost of concreting.

Or, for example, for a screw pile you can use seamless pump and compressor pipes designed for a pressure of 450 atmospheres or more. They have a wall thickness of up to 8 mm. Concreting such a pipe is impractical.

Concreting technology

The first step is to make level marks, along which all sections are subsequently trimmed. The sand-concrete mixture is poured slightly below the edges. The mixture is prepared in a ratio of 1 to 3 cement and sand, respectively. Dry ingredients are mixed with water to form thick sour cream. The solution is poured into the sealed pipe manually using a rod. It sags in the pipe, so after a short period of time the top of the pile is again filled with cement or powdered concrete, which helps eliminate residual excess moisture, level the mixture and ensure high-quality pouring.

The mixture is poured dry, because over time it will become saturated with moisture, turning into stone. The pile filled with concrete solution is tied with a channel or a steel cap is placed on it for further fastening of the structure of the structure. The grillage connects the base elements, combining with the piles, adding them to its thickness. This relative arrangement of parts is used to construct the foundation of structures from any type of material. The base with a grillage does not need to be monolithic, because it is welded and secured to the heads of the elements.

At temperatures above 0ºC, the mixture can be diluted with water, but at sub-zero temperatures, an additive must be added to prevent the solution from freezing, since the pile can break due to the pressure difference when water expands in the mixture. Table salt serves as a budget additive, preventing water from changing to another state until the cement sets.

If the air temperature is quite low (-5ºC or more), then anti-frost liquids should be used to prevent the pile from collapsing and the poured solution from leaking out.

Necessary materials and tools for installation

Materials for installing this type of foundation include:

- screw type piles;

- heads;

- wooden sticks for marking the territory;

- fine sand;

- cement and mixing tank;

- water;

- anti-corrosion agents for treating joints and seams.

List of necessary tools to complete the work:

- measuring tape 20 m;

- a marker that is applied to a metal surface;

- water building level and magnetic;

- discs for grinders that can handle metal;

- welding equipment;

- backup power supply;

- earth drill with removable cutters of suitable diameter.

Trimming piles

It is better to apply cutting marks with a permanent silver felt-tip pen, because this color is well reflected by the laser beams. The line along which the cutting is carried out is wrapped with a clamp for the correct cut. Next, a grinder with a thin disk performs the cutting process. This is a long and labor-intensive process; in 1 working day, a professional master can cut only 20 piles. It is imperative to wear headphones, glasses and thick gloves when performing work.

Reinforcement

The cutting of rods is carried out in accordance with the reinforcement diagram of the project. The reinforcement is assembled into a frame of a given shape, to which clamps are attached and fixed at their intersections. The grillage structure itself, if provided, is assembled according to the following principle:

The grillage also needs to be properly reinforced.

- The clamps are laid out every 400 mm.

- Longitudinal reinforcement is threaded inside.

- The crossing points are tied together with knitting wire.

- L-shaped rods are tied to the grille for fastening to the grillage.

Pouring concrete

Roofing material and a reinforced frame are inserted into the prepared recesses. The pile is filled with sand-cement mortar. This is necessary to block the flow of oxygen and water into the pile and to provide additional resistance to horizontal loads. The process of filling a well is carried out layer by layer. Each layer is 200 mm. The volume of the poured mixture is compacted with a hand vibrator or improvised means. All that remains is to weld the heads, channel or something similar as the base of the crowns.

Sources:

https://svaigermes.ru/news/nuzhno-li-betonirovat-vintovye-svai-iznutri/ https://glavfundament.ru/articles/obosnovanie_neobkhodimosti_betonirovaniya_stvola_vintovoy_svai/ https://svaisad.ru/articles/stoit-li-zalivat- vintovye-svai-betonom/ https://radosvai.ru/o-kompanii/stati/betonirovanie-vintovye-svai/ https://znaybeton.ru/rabota-s-betonom/zalivka/betonirovanie-vintovyh-svay.html

Departments

Accounting

The accounting department has all the necessary information about the receipt of payments from Clients for services provided by GlavFundament (sale of screw piles, construction of foundations on screw piles, express geology, design of foundations on screw piles, civil and industrial facilities). Each Client has the opportunity to promptly receive information about the receipt of his payment to the organization’s account. The department's tasks also include issuing invoices and documents closing the reporting period.

Vasiliev Denis Alexandrovich

Corporate department

The Corporate Department is responsible for fulfilling contractual obligations to Partners for the supply of screw piles to the GlavFundament company (quantity, nomenclature, assortment, timing and other terms of delivery). The department provides assistance in working with other departments and separate divisions of the company, providing the Partner with marketing, technical and logistics support, and promptly compiles financial estimates and other documents.

Head of Corporate Department

Kopev Evgeniy Sergeevich

Human Resources Department

The HR department of the GlavFundament company occupies a responsible position in the development of the organization's plans in terms of providing it with labor resources, carrying out selection, admission, official employment, adaptation, accounting and dismissal of employees.

The tasks of the department include carrying out work on the formation and preparation of a reserve of personnel for appointment to appropriate positions, advising senior management and heads of departments on personnel policy issues in the development of projects, the production of screw piles, and construction. The department evaluates the performance of each employee of the organization.

Head of HR Department

Dubovik Elvira Gizetdinovna

R&D department

The Research and Development Department (R&D) is engaged in research into the nature of the joint work of screw piles with soil, development and implementation of innovations in the field of pile foundation construction.

The department’s specialists create technological solutions that make it possible to reduce work time and reduce costs without compromising quality.

The department’s tasks also include organizing scientific cooperation with departments of construction universities dealing with foundation engineering problems, providing consulting and information assistance to employees of the company’s structural divisions.

Head of R&D Department

Glazachev Anton Olegovich

Sales department

The sales department is the link between the company and the Client, carrying out the interaction process from the first contact to the end of the contractual relationship.

The department provides consultation, preliminary calculation of the cost of screw piles purchased by the Client, technical support, and conclusion of contracts.

Head of Regional Sales Department

Akatiev Sergey Nikolaevich

Advertising and PR Department

The advertising department is a structural unit tasked with determining the direction, planning and organizing advertising campaigns, as well as developing advertising and information materials.

The advertising department of the GlavFundament company carries out work on advertising its products (screw piles) and services provided (installation of foundations on screw piles, design and redesign of foundations and buildings/structures), and is working on concluding agreements for advertising products and/or services with third-party organizations.

In addition, advertising department specialists promptly notify Clients about various promotions and advertising campaigns, plan participation in exhibitions, and enter into agreements with organizing committees of fairs and construction forums.

Sergin Roman Petrovich

Purchase department

The purchasing department makes decisions regarding the purchase of raw materials required for the production of screw piles, being responsible for concluding product supply contracts and selecting suppliers.

Department employees provide information on the purchase of materials necessary for construction, advise on price categories, and also quickly calculate the cost and delivery time of screw piles to a particular region to organize the delivery of cargo to any point in Russia or the CIS countries.

Head of Procurement Department

Nurgaliev Rinat Razitovich

Planning and Economic Department

The economic planning department calculates the cost of any types of construction and installation work, materials for building a foundation for an individual customer project, as well as the cost of special equipment. orders for screw piles and metal structures that are not included in the company’s standard product line.

The department assists the accounting department in collecting the necessary reporting documents.

Head of Planning and Economic Department

Shushpanova Maria Alekseevna

Project department

The architectural bureau of the GlavFundament company provides a full range of services for the design of buildings and/or structures in modern calculation software systems, regardless of the level of complexity of the object. The department carries out concept development and architectural design, providing for the reconstruction of residential and public buildings; interior design, designer's supervision, preparation and coordination of project documentation, furnishing with furniture, equipment and decorative finishing materials. If necessary, the specialists of the architectural bureau can select a ready-made building/structure project for the Client from an extensive database of ready-made projects.

Head of Project Department

Busygina Ekaterina Alexandrovna

Technical Supervision Service

The Technical Control Department carries out independent quality control of products and completed construction work for compliance with the requirements of building regulations, state standards, technical specifications and technical documentation, guaranteeing this compliance to the consumer.

The department conducts field tests to determine the load-bearing capacity of piles in certain soil conditions, identifies inconsistencies in product quality with building regulations, and resolves emerging technical issues when installing screw piles at the construction site.

Khamitov Ruslan Fanirovich

Legal department

The legal department of the GlavFundament company represents the legal protection of the interests of the organization and mandatory checks for compliance with the legislation of the Russian Federation of agreements concluded by the Company when purchasing raw materials for the production of screw piles and supplying products.

The department provides advice to heads of structural divisions and employees of the enterprise on legal issues. Also, in case of any claims, any Client can seek advice from a company lawyer.

The legal department is called upon to resolve any disagreements during the conclusion and execution of contracts, choosing the best option for developing the relationship between the Company and the Client.

What are the conditions on the site?

If the site is more or less flat, then both screw and driven piles can be used as a foundation. Installation will take a day depending on the project. In some cases, screw piles can be dealt with faster. But if the site has waterlogged soil or a large drop, then screw piles are ideal. The point is that the supports must reach a dense layer of soil, otherwise they will not be able to withstand the force of frost heaving. Screw piles can be extended during installation, but reinforced concrete ones cannot, since their standard length is 3 meters. In addition, in the case of a large difference, it will not be possible to use a mini-pile driving machine - there will simply be no place for it to stand. In terms of convenience, screw supports win.

In any case, if you want to build a house on a pile foundation, you must take into account that setting up a basement will be problematic, and sometimes it becomes impossible.

Drilling piles with a mixture of soil and concrete

A cast-in-place pile is formed by mixing soil with liquid concrete using a special drilling rig. The drill blades mix the cut soil with the solution. The entire volume of concrete mixture is fed into the well under pressure.

When mixed, the resulting mixture forms a trunk with a high load-bearing capacity.

When constructing a driven soil pile, there is no need to remove soil from the cavity of the drilled shaft. Such supports are intended mainly for the foundation of a house on sandy, soft soil.