Why should you be responsible when installing fence posts? Fence posts are the most important element, the support of the entire structure.

Pay attention to fences in the private sector - there are skewed structures, in some places the posts stick out and become warped.

In order for a fence to retain its geometry for many years, you need to know how to install fence posts correctly - what installation method to use in this or that case, understand why the posts stick out, warp and how to prevent this.

Which fence does not require concrete pillars?

It is quite acceptable to do without strengthening the supports with concrete mortar if the soil on the land plot is sufficiently dense and not subject to heaving. In this case, the fence design should be lightweight, with low windage, and the height of the fence should not be large.

Fences made of polycarbonate, facade mesh, chain-link, wooden or metal picket fences are perfect for the described conditions.

There are also a number of situations when concreting pillars is contraindicated:

- the soil on the site has a low bearing capacity, or is simply loose - sand, peat or silty soils;

- groundwater from the ground surface is so high that the concrete will be susceptible to erosion (for example, in swampy areas);

- the depth of soil freezing below the depth of the fence posts;

- when choosing wooden fence posts.

Separately, it is worth noting that a high groundwater level may require preliminary drainage of the site, as well as ensuring protection of the supports from contact with moisture.

What is better to use?

On heaving soil, do not use mortar, since direct exposure to liquid will lead to destruction.

On heaving soils, you should not concrete the supports - in the spring the earth will bring them to the surface. This is a consequence of a natural phenomenon, like the transition of water from one state of aggregation to another. When soil moisture freezes, it increases in volume. In spring, the water melts and the ground begins to subside. Under the direct influence of liquid, concrete begins to collapse.

On hard ground, it is better to hammer in the supports, but on soil with a sandy or sandy-clay structure, it is more advisable to carry out concreting. Hammering poles is considered a quick and cost-effective method of installation, which is why it is used for the construction of temporary non-permanent fencing.

Choosing supports for a fence without concreting

Based on the requirement for a low weight of the structure, brick, stone, and monolithic concrete supports are not suitable for a fence without reinforcement with concreting. Depending on the material of the fence sections, the choice is made of wooden or metal posts.

Wooden supports

If preference is given to wooden posts, experts recommend choosing timber from coniferous trees, beech, oak, and also from those growing in northern latitudes. It should be remembered that wood requires additional protection from moisture, parasitic insects, mold and mildew.

It is mandatory to treat wooden supports with waterproofing, antiseptic, and fire-fighting compounds.

It is especially important to protect the lower part of the support, which is immersed in the ground. For wood processing they use: tar, resin, copper sulfate, waste machine oil, tar, bitumen.

The standard format for wooden beams is 120×120 or 100×100 mm. The more massive and taller the fence, the larger the diameter of the support. The price/durability ratio is not the most favorable in the case of wood. However, wooden fences are so colorful that their attractiveness is undeniable.

protecting wooden supports from rotting

Metal supports

For the construction of a fence made of polycarbonate, mesh or euro-fence, metal posts are optimal: profile or round pipes, corners, channels. Preference is given to materials with corrosion protection.

Also pay attention to the thickness of the metal wall - it should be at least 3 mm.

For ease of fastening the logs, rectangular pipes are used. The cross-sectional diameter of the support pipes is from 50×30 to 100×100 mm, depending on the weight and height of the structure. Mesh and openwork sections are conveniently mounted on round pipes. Suitable pipe diameter is 60-80 mm.

To prevent moisture from getting inside, the pipes are covered with caps.

Asbestos-cement pipes are also used as an alternative to wood and metal. Most often, a chain-link mesh is attached to them.

Difference based on rock

The butting of fence posts with crushed stone can be done using different building materials.

Granite crushed stone for butting

You can fill different types of fence structures with crushed granite. This building material is a composition of rock mica, quartz and spar. In nature you can find granite of different colors (green, red, blue). The color of the base may vary due to the addition of spar.

Options for installing fence supports

Granite crushed stone for butting pillars can be easily recognized by its tone along with the grainy texture of the building material.

This material can withstand increased loads well when constructing posts for fence structures.

Limestone for pouring fence posts

This building material is made from sedimentary calcite rocks by crushing and sorting by size. The composition of limestone is not characterized by increased strength and is unstable to negative atmospheric influences.

Concreting wooden fence posts

It is not recommended to use it for making pillows for massive structures. This type of crushed stone is used only for organizing foundations for light wooden structures or for structures that do not involve increased loads on the base of the fence.

Gravel for heaping fence supports

Bulk material, which is obtained by sifting quarry soil, or crushed stone is produced by crushing large stones. This group of building materials also includes large-sized gravel formed in the bottom sediments of reservoirs.

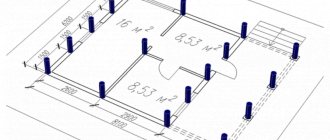

Drawing for butting

Natural gravel for backfilling, unlike crushed stone produced by crushing large blocks, has neat shapes with rounded contours. This determines the low degree of adhesion of all components during the manufacture of sand and gravel mixture (SGM) for organizing the foundation, in contrast to crushed material.

Pole installation methods

When constructing a fence of any design, it is important to thoroughly fix the support posts in the ground. Only in this case will you be able to hide from prying eyes and ensure a high level of security for your family. It is possible to achieve a high-quality result if you install the supports in compliance with the technology provided for the specific case and the chosen design. Installing a fence without concreting involves strengthening the support pillars using the butting or hammering method.

Butting of supports

The bottling method is actually very simple. In order for the fence to be strong, you just need to know how to properly stuff the posts.

The algorithm of actions is as follows: firstly, according to the pre-prepared marking of the site, wells of the required depth are constructed, for this a motor drill is used. Secondly, pillars are mounted in the recesses and secured with spacers, the supports are aligned strictly vertically. Then gravel, crushed stone or ASG is filled in layers.

Please note that every 15-20 cm a layer of crushed stone must be thoroughly compacted in order to be crushed according to the technology. The more densely the crushed stone is compacted, the stronger the pillars will stand.

Driving pillars into the ground

Hammering supports is much more difficult than budding. However, driven posts stand much stronger in the ground.

The method is only suitable for supports made of materials that do not deform from strong impacts from above.

It will also be difficult to cope without help. The driving process is carried out using a sledgehammer, headstock or piledriver:

- A sledgehammer is ideal if you are planning to build a low fence. It is important to monitor using a building level or a regular plumb line so that the post enters the ground strictly vertically after each blow to it;

- The device, which builders call “grandmother,” is made independently by cutting off a steel pipe with a cross-section larger than that of the support being driven in. Its length should not exceed 100 cm. A heavy plate is welded to the pipe, raising and lowering it with force, gradually deepening the support into the ground;

- The hand hammer is an innovative, gasoline-powered tool for driving fence posts. The impact energy of the pile driver is adjustable, which allows you to accurately drive pipes with different wall thicknesses.

To drive a pipe into the ground, shallow holes with a diameter smaller than the supports themselves are drilled for the fence. Then the pillars are hammered with one of the devices described above.

It is effective to “screw” round pipes into the ground, although this is physically very difficult.

Sometimes it is effective to combine butting with driving. In such cases, the supports are placed in prepared holes 40 cm deep, the lower part of the support is driven into the ground to the same depth, the hole is filled with crushed stone and thoroughly compacted.

Alternative option

In search of an alternative, classic screw piles are installed - hollow pipes with threads and/or blades at one end.

Fencing on piles is characterized by high levels of strength and reliability. Ideal for heaving soils, but not suitable for rocky areas.

Installation of the supports involves alternately screwing the piles according to the markings into pre-drilled holes (not forgetting the vertical), then filling the voids of the columns with concrete mortar, and compacting the adjacent soil. To securely fix the screws, a depth of at least 150 cm should be ensured. The procedure is quite labor-intensive, so assistants will be needed.

general description

Crushed stone is a bulk building material that is mined by crushing stones of different origins. This material can also be prepared using secondary raw materials in the form of concrete bases and metallurgical waste with further screening taking into account the resulting fractions.

Among the main indicators of building materials for butting fence posts, the following items can be noted:

- fraction - the minimum diameter of crushed stone or gravel, taking into account GOST 8267-93, must be at least 5 mm;

- manufacturing material - crushed stone - is made from river sediments, various types of rocks, secondary raw materials;

- flakiness - the characteristic is selected taking into account the proportions in the composition of the material of different shapes;

- strength - M1400 indicates the highest density, the lowest grade of crushed stone is M200.

Pattern for backfilling fence posts

When choosing a building material, you need to take into account the purity of the composition and additives that affect the technical performance of dry concreting.

Strength characteristics

Taking into account the strength grade, the following categories are distinguished:

- M1200 – M1400 – bulk composition of increased strength. Butting of the base of multi-storey buildings is carried out with a grade of at least M1200.

- M800 - M1200 - using this composition you can firmly concrete the load-bearing support of the fence.

- M600 - M800 is a medium-strength building material that is used for the construction of lightweight structures.

- M300 – M400 is a material of low strength. As a rule, this is crushed concrete or limestone. The building material is not used for backfilling the foundation of reinforced concrete structures.

- M200 is the minimum strength indicator.

Drawing for bottling

Granite occupies the first position in terms of its strength characteristics. After it there is crushed gravel, which is produced by crushing monolithic products. Limestone types of building materials, as well as recycled compositions, have the lowest reliability indicator.

Installation with and without butting

Frost resistance

Before hammering fence posts, it is necessary to consider such an indicator as frost resistance. This characteristic is marked with the letter F (translated from English Frost - cold):

- gravel is characterized by an index of F200 – F300;

- loose gravel is highly resistant to freezing and defrosting cycles, has an index of F300 - F400;

- limestone has little resistance to seasonal temperature changes, is marked F25 - F100;

- slag, taking into account the composition of recyclable materials, has frost resistance within the range of F75 - F200;

- Crushed stone from recycled materials has a frost resistance degree of F50.

Installing a fence support

Fence posts are backfilled with building materials with a frost resistance rating of at least F250.

How to strengthen rickety fence posts

During the operation of the fence, pillars without concreting may sag or lose their reliability. To restore the fence and return the supports to “slenderness,” reinforcement is carried out using time-tested methods:

- You can connect the supports to each other by arranging a strip-type foundation;

- Properly compact the soil around the pillars themselves. For this purpose, specialized tampers are used;

- Add and compact gravel or crushed stone to increase the stability of the supports of the fence structure.

You can take an ordinary bayonet shovel and build a shallow trench exactly to the depth of its bayonet between two or three adjacent posts. To strengthen metal supports, you can weld a profile pipe or a round one.

For other pillars, only a shallow strip foundation will help. To create it, you need to dig a trench and make formwork. Then lay a special mesh for reinforcement in it and fill it with high-quality concrete. First you need to make sure that all supports are strictly vertical. This is the best option for strengthening already installed fence posts.

If the situation is not too critical, then you can remove the soil around the rickety pole. Then carefully pour water into the hole. Next, the recess is filled layer by layer with crushed stone or ASG. Tamping should be done as tightly as possible.

In order for your fence to last longer without repair, you will need to build it according to all the rules of construction technology and from high-quality materials.

Stage 1. Measurements and calculations

Make the necessary measurements, determine the dimensions of the future fence and the distance between the posts. Draw a drawing of the fence and calculate the number of supports and materials from which you will build the sections.

Note! Don't make the sections too long or tall. The optimal distance between fence posts installed without concreting the supports is 2 m. This design will be strong and reliable. The most suitable height is 1.8 m. In this case, two logs per section will be enough.

Buy everything you need at the construction base and begin installation work.

Preparing for backfilling

First you need to stock up on materials and tools for work. After everything has been purchased, you can begin preparatory work.

- Site marking. It is necessary to mark the places where the corners will be located, as well as all other columns. Usually the distance between them is 2.5-3 m. It is important not to forget about wickets and gates.

- Making holes in the ground. According to the marking plan, holes need to be made in the ground. Their depth varies from 1.2 to 1.5 m, but not less than a third of the height of the pillar. In this case, the hole must be dug so that its bottom is just below the soil freezing depth mark characteristic of the region. For example, in the Moscow region, the value of this parameter is from 130 to 160 cm. The width is 150-200 mm, which should exceed the diameter of the support pipe by 12 cm. You can use any drill. It is better to refuse a shovel, since a wide hole will subsequently be more difficult to compact.

Butting

Like any work, butting requires work. The installation of pillars begins with the preparation of holes.

Digging holes

Before you begin preparing holes for installing support pillars, you need to make markings indicating the location of the supports.

In the place where the support will stand, you need to drill a hole. Its depth should be 200-300 mm below the soil freezing level.

To dig a hole, it makes sense to use a mechanical device, such as a mechanical drill. The use of a shovel will lead to the expansion of the hole and compaction of crushed stone will be difficult.

Peculiarities

The difference between the described method and concreting is that the compacted layer is permeable to water, that is, a drainage layer is formed at the base of the fence support, which allows moisture to pass through it. This property is the main one when determining the method of installing racks in heaving soils.

During the onset of frost, the water in the ground freezes and begins to expand. After backfilling, the support layer does not contain any extraneous moisture, and therefore it does not expand. Another difference is the plasticity of the base, made of crushed stone and sand.

The buffer zone smoothes out the pressure of the lower layers of soil.