In the process of designing a staircase, an important step is also the calculation of the staircase opening. The opening for the stairs is a hole made in the ceiling, which is necessary to install the structure. In order to avoid any difficulties when installing a flight of stairs, and to ensure that the descent to the stairs is convenient and safe, it is necessary to make all calculations as accurately as possible. We will look at how to make a staircase opening, as well as what its optimal parameters are, in this article.

What is the place under the stairs called?

A stairwell refers to the area in which the stairs are located. A flight of stairs (flight) is a set of steps between two landings. ... Determines the placement of the staircase and its proportionality to the room. A landing is a platform connecting two flights of stairs.

Interesting materials:

How to disable automatic locking of Windows 10 computer? How to disable automatic computer restart on Windows 7? How to disable automatic reboot on Windows 10? How to disable automatic reboot in Windows 10? How to disable automatic reboot of Windows 7 through BIOS? How to disable automatic restart of Windows 7 when errors occur? How to disable auto-brightness on Windows 10? How to disable auto-update of applications on Windows 10? How to disable auto-update in Windows 7 Ultimate? How to disable auto updates in Windows 10?

Varieties

The opening for the stairs to the second floor can have a different shape. Depending on the design, there are several types of openings for stairs:

- Round shape. This type is used when installing spiral staircases. It looks very neat, original and elegant.

- Rectangular shape. This is the opening that is most often constructed when installing stairs in private houses. This type is the simplest in terms of design and further finishing. The dimensions of the opening must correspond to the parameters of the flight of stairs.

- In the shape of a semicircle or oval. This variety is also perfect for screw structures; it looks great in combination with a spiral staircase, having different speeds.

- Opening of non-standard shape. Typically, such openings are part of unique designer interiors. These can be trapezoidal shapes, polygons or something else. The owners strive to create an unusual, original design in the house, and the flight of designer imagination often has no limits.

Landings and their sizes

Landings are an equally important element of a flight of stairs. It is with the help of such a platform that two levels of the march can be connected. Regarding the platforms, this march has the following structures:

- without platforms;

- with one upper or lower platform;

- with two platforms;

- with an intermediate platform.

Landings located between two consecutive straight flights must have a length of at least sixty-two centimeters. If a turn is expected, then according to GOST the area of the structure in question must be at least one square meter. The width of the installed platform should be the same as this march. The height of the landing should be the same as the riser (the vertical edge of the step, the height of which, according to GOST, ranges from fifteen to eighteen centimeters). This height of the platform is the most comfortable and convenient for going up and down the stairs.

Manufactured platforms , according to GOST, are of several types:

- flat (1 LP). Designed for flat flights of stairs without frieze steps (LM);

- ribbed (2 LP). Designed for flat flights without frieze steps;

- ribbed (LPF). Designed for ribbed marches with frieze steps (LMF);

- ribbed platforms or half-courts (LPP). They are used for ribbed marches (LMP).

These letter symbols mark the marking of both flights of stairs and landings. They mean the type of stair element and talk about its classification. Marking according to GOST begins with these symbols.

Platforms produced in accordance with GOST are manufactured in both left and right versions. That is, both for rising clockwise and counterclockwise.

Stair length

You can calculate the length of a flight of stairs in a fairly simple way. To do this, you will need the previously calculated number of steps in the flight, minus one, and their calculated width (or depth). These indicators are simply multiplied together.

If the length of the staircase turns out to be too long, then it is made to rotate 90 or 180 degrees and is supplemented with intermediate platforms or winder steps.

An important role in the calculation and design of a wooden staircase is played by the height of the clearance between the horizontal plane of the step and the lowest part of the ceiling structure located in front of the staircase opening. The vertical distance here should be more than 1.90-2.00 meters, so that a tall person climbing or descending cannot accidentally injure himself.

The calculation of a wooden staircase should be taken with full responsibility. Competent design and adherence to installation technology will ensure optimal operating conditions.

Features of designing a wooden march in a private house

The staircase design is usually done at the house planning stage. If such a decision is left to the last minute, the march will have to be adapted to the available space.

In the interfloor space of the residential second floor, stairs are installed, which are convenient for moving, carrying loads and evacuating in case of unforeseen situations. In auxiliary rooms, a less convenient design can be designed.

When making calculations, please note:

There are many programs that will make calculations, produce a drawing, a 3D image of the future structure based on your measurements - SolidWorks. ArchiCad, AutoCad and others. Staircase manufacturers also provide design services. From them you can not only order a drawing, but also the production of wooden elements for self-assembly of the march.

Decoration of staircases and landings

Stair elements are made of reinforced concrete blocks. However, stairs can serve not only the main function, but also perform an aesthetic role. That is why such elements can be made with decorative finishing. Today, construction stores are filled with all kinds of finishing materials. Therefore, with the proper imagination and a small financial outlay, you can install a reinforced concrete staircase even in your private home and not be afraid that it will look too bulky and unpresentable.

Flights of stairs can acquire a smooth surface , which can be obtained using heavy concrete and cement. Or the surface of the structure will receive a polished, mosaic finish. Such a decorative layer can be created using concrete, as well as white and colored cement and crushed marble. And if you cover the surface of a private flight with ceramic tiles, this will make the staircase royally majestic.

Of course, it is not advisable to create such decorated and unique spans in a residential apartment building. However, such staircases will become a true decoration in office buildings, hotels, restaurants, shopping centers, and educational institutions.

If all vital structural elements were manufactured in accordance with GOST, and no violations were committed during the installation of the staircase structure, then such stairs guarantee a long service life and safety in operation.

Basic requirements for staircase openings

- Cutting staircase openings in ceilings necessarily requires the presence of free space below. The platform must be at least 1 m in length. And if there is more than one door next to it, then its area should be even larger so that it is possible to simultaneously open the doors and safely move a person along the stairs.

- When designing a staircase opening, they are guided by the average human height. When climbing the stairs, he should not touch his head to the ceiling on any of the steps. The more spacious the staircase opening, the more convenient it will be to use.

- The staircase opening must be well reinforced so that the ceiling does not collapse during operation of the stairs.

- The opening for a straight staircase must have a rectangular shape; screw designs require the creation of a round opening.

Making a staircase

- Having calculated the basic parameters of the future staircase and opening, draw up a detailed project. Put all the available values on it. When designing the width of the staircase opening, do not forget to add to the width of the steps the distance required for installing the railings.

- Draw a contour with the dimensions of the staircase opening on the ceiling. Remove the floor covering within the existing markings.

- Next, part of the beams is dismantled. They are removed by connecting the remaining elements together. Be sure to strengthen the structure by adding cross beams that have the same cross-section as the main ones. Fasten them to metal corners along the entire length of the opening.

- Securely fix the installed bars on all sides.

How to make a reinforced staircase opening in a concrete floor, watch the video.

Fashion trends of our time

Today, the interior design of private houses is distinguished by a wide range of materials, a huge palette of color shades and a wealth of style solutions. However, the fact remains that in order for a building to be not just beautiful, but comfortable and cozy for living, it must have a convenient design.

An important element in this aspect is the staircase that leads to the second floor. Careful attention has always been paid to its construction and decoration. Especially if the cottage has rather narrow spans between floors.

Look at the following photo to see a similar design for small corridors with your own eyes. It really amazes people with its sophistication and original appearance, despite the limited free space between the bays of the house.

You shouldn’t be upset at all if the corridors of your home are not particularly wide. You can design the structure leading to the second floor of the cottage so that it is very convenient and at the same time beautiful.

In this case, the average protrusion should not exceed 4 cm. The optimal number of them in one flight of stairs is considered to be 15 pieces.

For finished floors

You can achieve comfortable movement by increasing the angle of elevation or reducing the size of the tread (in modular designs this value can be 16 cm).

In order for the staircase to fit optimally into the existing opening, it is necessary to consider:

Before building a staircase, it is useful to have an idea in your head of how it will fit into the environment. This makes it easier to choose the material and type of fencing. You can be inspired by photos of designers or contact our company. Our experts will help you make your staircase beautiful and functional. Our catalog of wooden stairs is here.

Source

If you can only get into the attic by placing a stool on a chair, or if you have to tiptoe through the bedroom to get to the study on the second floor, if in order to get to the basement you have to run through the rain and cold, then you need new staircase. The first stage of creating a staircase is making a hole in the ceiling and installing new beams along its boundaries. Due to the fact that when installing a new staircase, the floor area on two floors changes greatly, it is necessary to carefully consider the location of the hole for the staircase. Try to position the stairs so that existing walls do not have to be moved or removed. For a normal turn on the stairs when entering and exiting it, there must be a space between the upper or lower step and the wall that is at least as wide as the width of the stairs. Also try to position the new staircase so that it does not interfere with electrical wiring or plumbing or heating pipes. And if you can plan the staircase so that the hole in the ceiling is located along the beams, you will simplify the job of installing the beams framing the hole, since if the hole is transverse to the beams, you will have to install six new beams.

At the very beginning of planning the location of the stairs, consult with a specialist supervising the quality of construction. Building codes specify the minimum width and clearance of stairs. It is these dimensions that determine the dimensions of the hole in the ceiling. If the staircase leads to one room (other than the kitchen or living room), it can be only 600mm wide. In most other cases, the minimum width is 800 mm. The length of a standard stair opening should provide sufficient space between the ceiling and the steps. Building regulations require a height of at least 2 m, but remember that the greater the clearance, the more comfortable it will be for tall people to walk and the easier it will be to move furniture. The dimensions of the opening in the ceiling depend on the type of staircase being installed. The rules for constructing an opening are basically the same for any type of staircase and are described on these pages for the case of installing a staircase in a basement. Once you have determined the dimensions of the opening, add at least 50mm on all sides for finishing once the stairs are installed. To cut an opening, you need to remove part of the floor, cut the beams and remove part of the ceiling (this does not apply to the basement shown here, which has no ceiling). For subsequent finishing of the opening, use pieces of boards removed from the ceiling, which can be used to cover the protruding additional longitudinal and transverse beams. Cover the edges of the plaster and the ends of the floor boards with boards or plywood that are nailed to the joists of the opening. To create a more attractive appearance, cover the gaps with platbands. An unguarded opening for stairs is dangerous and is not permitted by building codes. Your job is not finished until you enclose it with a balustrade or simple railing.

Anatomy of a staircase. If the opening is along joists, remove parts of two joists and connect the hanging ends of the joists to the remaining joists using two short crossbeams. The cross beams must have a thickness and height equal to the corresponding parameters of the main beams, and are attached with angles to additional beams installed along the long sides of the opening. In the example shown here, the right longitudinal beam of the opening consists of an existing beam attached to a new beam. On the left, in order to obtain the required opening width, two new beams were installed between the existing floor beams. If the opening is located next to a stone wall, the cross beams can be embedded at one end into the wall.

1. Installation of jack stands. Mark the planned opening on the lower surface of the floor, adding 50 mm on all sides for finishing. For most stairs, mark out as described on the following pages. Add reinforcement beams to each long side of the opening and then install support beams and adjustable jack stands outside the narrow sides of the opening about 500mm away. At each corner, drill holes in the floor from bottom to top.

2. Cut out the holes. Go to the top and locate the holes drilled in the corners of the opening. Measure 100 mm from each hole along the opening to install the cross beams. Mark four chalk lines to mark the elongated hole. Make cuts along the two sides of the hole, at right angles to the floor boards, then make cuts parallel to the floor boards.

3. Removing floor boards. Knock out the sawn pieces of floor boards by hitting them from below with a piece of board. Finish the top with a claw crowbar.

4. Removing beams in the opening. Saw the beams flush with the opening, having a helper support the beam from below so that it does not jam the saw. The cut parts of the beams can be used to make double cross beams, which are needed to strengthen the opening. Cut two pieces of beam to fit the hole and fasten them together with 100mm bolts or nails, driven in a staggered pattern.

5. Installation of cross beams. Nail 100mm wide brackets to each end of the double cross beam. Press the cross beam against the sawn ends of the beams, aligning their top edges. Nail the brackets to the longitudinal beams, driving nails into all holes in the brackets. Place 50mm wide brackets into the joints between the sawn beams and the cross beam and nail them in place. Finally, nail the cross beam to the ends of the sawn beams using two 150mm nails. Install the second cross beam in the same way.

Staircase next to a stone wall

Embedding the ends of cross beams into the wall. If the stairs in the basement are located next to a wall, then the cross beams can be embedded at one end into the wall. Using a wide chisel and sledgehammer, make 100mm deep holes in the wall to accommodate the ends of the double cross beams. Insert the beams into the holes. Nail them to the sawn ends of the beams and attach them to the longitudinal beams of the opening with brackets. Drive wedges of tiles or bricks under the beam and seal the hole with mortar and pieces of tiles or bricks.

Links to other pages of the site on the topic “construction, home improvement”:

Source

Completion

In order not to delve into the details of calculating the size of the opening for the stairs and to avoid annoying mistakes, contact ours. An experienced specialist will come to you free of charge, calculate absolutely all the parameters of the opening, taking into account the nuances, configuration of the staircase, available space and other criteria.

Source

The design of any structure begins with determining the parameters of the opening in the interfloor ceiling - the staircase opening. The comfort of movement and safety of all residents of the house depend on the correct selection.

The parameters of the staircase opening depend on its type:

Manufacturing of high-quality spans according to GOST

The use of high-quality material in construction guarantees strength, resistance to any type of load and reliability of the staircase structure. First of all, this applies to reinforced concrete products. And it is they who are subject to GOST requirements.

In the manufacture of stair sections, heavy concrete (GOST 26633) and lightweight concrete (GOST 25820) with a density of 1600 to 2000 kilograms per cubic meter are used.

Stepped spans are installed using reinforcement, for the manufacture of which the following are used:

- rod hot-rolled reinforcing steel class AI-AIII (GOST 5781);

- rod thermomechanical strengthened reinforcing steel class At-IIIC, IVC (GOST 10884);

- wire of class BP-I (GOST 6727).

Also, all flights of stairs and platforms that are used for the installation of stairs must withstand certain loads in accordance with GOST during operation. For residential structures, such a load should be 360 kgf/sq.m., and for industrial, public and industrial buildings 480 kgf/sq.m. is allowed .

Stair treads are also provided for by GOST. 1 LN are intended for laying on the ordinary and lower steps of manufactured flights. 2 LN are intended for installation on the upper steps of such flights, as well as on the upper and lower landings.

Types of stair railings by material and method of execution and fastening

The staircase railing can be made of wood, plastic, or metal. The technological process of creating and installing the stairs depends on the selected material. Fastening and assembly methods will also differ. Recently, a combination of different components has been increasingly used in interiors. Wooden or metal stairs and vertical railings can easily be reinforced and decorated with plastic and glass parts in the form of infill.

Wooden

Manufacture of stair railings from wood has long been used by man. The natural material lends itself well to processing and has different textures and patterns. This has led to the widespread use of wood for the construction of stairs of any style and design. Railings can be painted, sanded and varnished, thereby extending their service life. Using wooden railings for stairs¸ you can decorate the room in any style - from classic to modern.

The most important advantage of wood is that, even without much carpentry experience, you can build a staircase to your house with your own hands by choosing a material with a suitable texture. For work, you need to give preference to hardwoods such as beech or oak. Of the coniferous trees, pine lends itself well to processing, but its fibers are very soft. Spruce is more difficult to process - it is even more pliable and knotty.

To make various parts of the future staircase, different types of wood are used. Balusters that bear the main load should be made of hard wood: beech, ash, oak. The cut of these trees is beautiful and original in itself. Softwoods do not last long, dry out and crack, and very soon require replacement. The optimal wood moisture content when making balusters should be 12–18%.

Glass railings for modern interiors

The use of glass to decorate and fill fences has taken interior design to new levels. In the generally accepted understanding, glass as a material is fragile, short-lived and unreliable. However, modern technologies make it possible to widely use laminated glass for interior stairs. This material is glued with a polymer, which does not affect its transparency and significantly increases its strength. In a critical situation, such glass, unable to withstand the loads, will not shatter into small fragments, but will be fixed on the film. When talking about glass railings, two types should be distinguished:

- railings without a frame, consisting exclusively of glass;

- glass is a filling component.

The use of glass as filling makes the structure light and airy. You can make drawings like stained glass. With this type of work, the filling is continuous, and therefore safe. The tempered glass used for such railings is made differently than ordinary glass. During production, the material is “heated”. It is heated at high temperature and then brought to its original temperature state. The material is unusually strong, can withstand heavy shock loads and, when broken, disintegrates into non-sharp, safe edges. To build stair railings, you can use tinted and multi-colored glass, achieving an ideal combination with the interior. Duplex and triplex with a thickness of 10 mm can be used to make a structure made of solid glass, which is inappropriate for homes where there are children. Despite the strength of the material, you should still avoid beating it.

Plastic in handrails for stairs

The use of PVC (polyvinyl chloride) for the construction of fences allows you to significantly save on the purchase of materials for building stairs. This is a practical and budget material. Railings made of plastic will last a long time and will not lose their appearance for a long time. They do not require any special care. The option of creating balusters from plastic involves the introduction of a metal core, which will take on the entire load. In this case, the plastic plays a decorative role, decorating the supports. PVC is not natural, but over the years it does not deteriorate, rot or lose its shape.

Metal railings

Metal is the strongest basis for the manufacture of staircases. This is a typical staircase fencing used in the construction of multi-storey residential areas. Durability and ease of maintenance, the ability to give the railings a stylish look, this is just a short list of the advantages of metal. When constructing stair railings, many metals can be used.

Some cottage owners, in pursuit of style, prefer aluminum for its lightness, elegance and brilliant appearance. At trade counters, entire aluminum kits are sold for those interested, which owners can assemble at home without much effort. This is a huge advantage of aluminum railings. But at the same time, the metal does not tolerate shock loads, bends and quickly loses its shape. Over time, scratches form on the surface of the railings and they are affected by corrosion.

Chrome-plated railings also look good, which can also be purchased at retail outlets as an assembled structure. The elegant appearance and stylish shine negates one big disadvantage - they wear out quickly.

There are three ways to manufacture metal fences: welding, forging, assembly (fittings and pipes).

Welded metal

Metal railings made by welding are considered the most economical.

For the manufacture of railings using welded technology, a metal beam of 10x10 mm is used, for the posts - a profile pipe of 15x15 mm (or 20x20 mm). A 40x4 mm strip is suitable for the handrail. During assembly, electric arc welding is used with further cleaning. Welded structures are widely used for equipping administrative buildings, office premises, private cottages and summer cottages.

Forged

It is quite difficult to make forged railings with your own hands, especially if hot forging is planned. But the forging process can also be done cold. There are special bending machines that are available for rental. Using such equipment, you can prepare a variety of twisted and bent elements for your stairs. When working, you have the opportunity to choose various metals and rolled products. The material itself is quite expensive, which is a significant obstacle for “home” craftsmen.

The design of the railings during forging can consist of:

- round or square rod;

- profile pipes (round, square, rectangular).

For manufacturing, simple structural steel can be used, which is subsequently painted in any color that matches the interior.

Cast fences and railings

The main difference between this type of railing is the manufacturing feature. The technological components of the process are:

- pouring mold;

- molten metal to fill the mold.

For the production of such railings, brass, bronze and cast iron are usually used. Forms are developed according to customer sketches in accordance with the interior being created. Cooled products can have various configurations. The railings are distinguished by high strength of element joints and long service life. Significant disadvantages are the high cost and complexity of the manufacturing process. Molded railings are a great option for installing outdoor stairs in an open space to decorate the exterior.

Combined stair railings

Combined fencing is a combination of metal, plastic, wood and other materials. In such fences, crossbars and glass are used for filling. The possibility of improvisation when using railings of this type allows you to decorate any type of interior with them - from classic to ultra-modern. Internal fences of the combined type are beautiful, original and safe. Their use is acceptable in both private cottages and administrative buildings.

Stainless steel is the main option for railings, which goes well with other materials. When creating this structural element, tempered glass and triplex are used. Such glass, like stainless steel, is resistant to temperature changes and can withstand shock loads. Handrails can be made of hard wood, impregnated with a special composition against dampness and temperature loads. Another option is PVC handrails, which do not fade or collapse for a long time.

When constructing combined fences, simple black steel can be used, which is painted to protect it from external factors. It is also possible to introduce decorative elements made of bronze and copper.

Made of metal

A metal staircase is suitable for many room designs. The price of materials is rather high, but this is compensated by the advantages of the design. A metal staircase has the following advantages:

- strength, durability and reliability;

- withstands heavy weight and loads;

- long service life;

- fire resistance;

- can be given any look (especially with forged elements it looks chic);

- quick installation;

- variety of shapes, varieties and colors.

But metal models also have some disadvantages:

- if you attach wooden steps on top, they will begin to creak over time;

- it is necessary to periodically combat rust when the structure is located near the kitchen or bathroom;

- high cost of manufacturing components;

- unprofessional execution will be noticeable in crooked seams and irregularities.

On a note!

When choosing such a staircase, you need to carefully inspect the structure after purchase for cracks in the seams, in order to avoid problems with further operation.

Placement of equipment in staircases

Also, when installing staircases, you should take into account the requirements of clauses 4.4.9 and 4.4.10 SP 1.13130.2020, which determine what is permissible to be placed in staircases and what is not allowed.

Table 5

| Allowed to be placed in staircases cells | Not allowed in stairwells |

| Ordinary staircases | |

| heating radiators at a height of less than 2.2 m while maintaining the standard width of the escape route and fencing them to prevent injury to people | pipelines with flammable gases and liquids |

| built-in cabinets for communications and fire hydrants | built-in wardrobes, except for communications and fire hydrants |

| hidden electrical wiring for room lighting (in buildings up to 28 m high, inclusive in ordinary staircases) | openly laid electrical cables and wires (with the exception of electrical wiring for low-current devices and for lighting corridors and staircases) |

| garbage chutes (in buildings up to 28 m high, inclusive, in ordinary stairwells) | equipment protruding from the plane of the walls at a height of up to 2.2 m from the surface of the treads and landings of stairs |

| no more than two passenger elevators descending no lower than the first floor, with enclosing structures of elevator shafts made of non-combustible materials with non-standardized fire resistance limits | exits from freight elevators and freight elevators |

| security premises | premises for any purpose, except for security premises |

| rooms for central heating control units and water metering units, fenced off with partitions made of non-combustible materials | |

| water metering units (under the flights of the first, ground or basement floors) | |

| heating control units (under the flights of the first, ground or basement floors) | |

| electrical input and distribution devices (under the flights of the first, ground or basement floors) | |

| bathroom premises with an area of no more than 5 m2 (in buildings of preschool institutions) | |

| Smoke-free stairwells | |

| heating radiators, pipelines (risers) (made of non-combustible materials, with the exception of cases of using fire-fighting couplings when crossing fire barriers) water supply, sewerage, water heating systems while maintaining the standard width of the evacuation route and taking measures to prevent injury to people | |

Important!

Voids when pipelines cross building structures of staircases must be filled with non-combustible materials that do not reduce the fire-technical characteristics of the structures (clause 4.4.9 of SP 1.13130.2020).

Calculation of system elements

The layout of the straight and rotary march structure is carried out according to the general principle. To calculate the stairs to the second floor, you need to measure:

- height (H) from the floor of the first floor to the floor of the second floor. If the finished floor is not finished, add the thickness of the screed, underlay, or floor covering to the resulting number;

- the length of the opening is from the end of the ceiling to the outer wall. Double-check from different angles. If the values are different, take the smaller one;

- opening width - the distance between the right and left walls. We double-check again on both sides and take the minimum size.

Let's calculate the angle of inclination

The slope depends on the area of the house and the height of its ceilings. A staircase with a slope of 30-36 degrees will be compact, but it will be difficult to go down it. For a slope of 40-45 degrees, you need a large room, since such a wooden staircase is quite bulky. The lower the inclination, the more dangerous it is to move along the march; the higher it is, the more space the structure takes up.

Correct calculation of the width and height of the step will ensure ease of movement up and down. The average human step is 63 cm, the step height is 2 times less (31.5 cm). The standard value is 30 and 15 cm, respectively.

We calculate the slope using the formula:

- 2x + y, where

- X - riser height;

- Y - tread width.

If the size of the steps is less than 14.5 cm, X does not need to be doubled. The lower the step, the wider it should be.

Ratio of inclination angle (in degrees) / tread size (w/h, cm):

- 30/ 28/16

- 33/ 26/17

- 37/ 24/18

- 41/ 22/19

- 45/ 20/20.

How to correctly calculate the slope in a simple way:

On a piece of paper, draw a right triangle in which:

- horizontal leg - horizontal projection of the base of the future staircase;

- vertical - height from floor to floor between floors;

- hypotenuse - the length of the march.

The acute angle at the bottom of the projection is the elevation angle. If its value is within the norms, you can begin to calculate the steps.

Let's count the steps

The slope of the march is 40-45º. Let's calculate the number of steps using the formula:

- 2A + B=60-64 cm, where

- A - riser height;

- B - tread width;

- 60-64 is the average human step.

Let's say A=14-17. We calculate the width of the tread B:

- 60-15x2 or 64-15x2 = 30 or 34 cm.

The lack of width can be compensated for by a protrusion.

We calculate the number of elements in a march:

height H/step height (riser) = quantity

The optimal riser height, recommended by SNiP, is 15-19 cm. If the result is a fraction, round to the nearest whole.

Let's assume H=280 cm. Let's calculate:

- 280/15 =18, 6

- 280/16= 17,5

- 280/17=16,4

- 280/18=15,5

- 280/19=14,7

In a march you can do from 14 to 19 steps (a larger value is rounded up, a smaller value - rounded down).

If there is an interfloor staircase with a landing, we plan a landing for the entire width of the opening, 1 m long, and place it on the drawing. Let's calculate the exact number of steps on one flight:

shaft length minus platform length / tread width

In our example it turns out:

200/25 (tread width according to SNiP) = 8

Given the existing dimensions, there are 8 steps each on the lower and upper flight and the ninth is a platform, which is considered as a step. In total, the staircase consists of 17 steps.

Let's calculate the step using the formula:

interfloor height (H) / number of steps = step height (riser)

Let's calculate using our example - 280/17 = 16.47. Round to 16.5 cm.

We got a comfortable staircase of 17 steps, with a step height of 16.5 cm and a tread 25 cm wide.

Since we rounded fractions during the calculations, we need to put the deviations somewhere. For example, an error of 0.03 cm in the height of the riser will go to the bottom step, which we will make shorter than the others by 5.1 mm (17x0.3).

We check the correctness of the calculations on the spot - we draw a projection of the steps with the given dimensions on the wall with a pencil. You will be able to find out if a window, door, or radiator is bothering you and adjust the calculations.

In the process of designing a staircase, an important step is also the calculation of the staircase opening. The opening for the stairs is a hole made in the ceiling, which is necessary to install the structure. In order to avoid any difficulties when installing a flight of stairs, and to ensure that the descent to the stairs is convenient and safe, it is necessary to make all calculations as accurately as possible. We will look at how to make a staircase opening, as well as what its optimal parameters are, in this article.

Frame and support post

First, our user made a frame for the winder steps and a support post.

For the frame, YaRo used 40x50 mm timber. The dimensions of the support column are 100x100.

For the second support of the march, I screwed in the rest of the professional timber measuring 100x150. On the support pillar, the craftsman made cuts for the second, third and fourth winder steps.

First, I screwed the platform for the winder step to the post, and then secured the support to the floor through it.

Next, our participant varnished the stringer that will stand against the wall in two layers. This is so as not to waste time.

*The thickness of the overlap in this example is 205 mm; if the overlap is larger, then this project may not be suitable.

Spiral staircases to the second floor, examples of optimal sizes, calculation formulas

A promising view are spiral staircases to the second floor, in the form of a regular segment, a spiral-shaped hyperbola and curvilinear ones. They are classified according to the fastening of the steps into options:

- the wide end of the wedge-shaped steps rests on the wall, and the narrow end on the rod;

- on the central support with the stairs indented from the walls;

- to the string (stringer), turning into supports - railings (post and string or both strings - spirals). When making the string of such a ladder, the use of metal or wood is very expensive. Spiral concrete stairs have become a popular economical solution. They are durable, but visually light.

Optimal generally accepted parameters

An easy-to-use spiral staircase with dimensions in accordance with generally accepted parameters assumes the presence of:

- span, width from 800 mm;

- structures with a diameter of 2000 mm;

- lifting height 3000 mm;

- steps from 200 mm deep in the middle;

- D diameter of the support is 100mm, with D the location of the steps from the center is 150mm;

- D of the wide edge near the edge is 400 mm or less;

- D (total) of the entire staircase is not less than 1300 mm, but not more than 3300 mm;

- D – railings on the inside 1200-3200 mm;

- Opening in the ceiling D from 1300 to 3300 mm;

- march, width 530 mm - 1430 mm.

Existing types and types of stairs

Types of stairs

As a rule, the owners of an apartment or house think about how to calculate the stairs to the 2nd floor after purchasing a home. It is usually believed that there is nothing complicated in the design and installation, since it is typical for all buildings. In fact, there are several options for ergonomic, beautiful and safe stairs, and the chosen type depends on the room itself, its dimensions, the location of the rooms and the space allocated for the future stairwell.

The type and design of the staircase can be determined in two ways. The first is more expensive, namely: trust the professionals and pay the designers and builders a certain amount, in addition to the purchase of materials. The second is more labor-intensive, but less expensive: do not involve a construction team, but figure out all the intricacies yourself.

If you choose the second, cheaper option, then first of all you should familiarize yourself with the types of stairs possible for installation . This:

Ratio of inclination angle (in degrees) / tread size (w/h, cm):

Useful tips

Any type of staircase located in the house must be provided with the necessary care. The most “capricious” in this regard is wooden. The owners who use protective compounds to treat the structure do not know that this is far from sufficient to ensure the beauty and reliability of the staircase. After the coating has dried, the following layers can be applied:

- dye. For indoor painting, only outdoor paint is suitable. The main thing is that, without disturbing the design of the site, you can choose the required color;

- wood oil You should only choose special oil for terraces. It does not create a protective layer, but penetrates deep into the material and provides protection inside, which does not need to be removed when re-applied. The oil is expensive, but the effect is good;

- varnish Applied to existing protective coatings.

The use of grinding is allowed as a last resort if partial damage has occurred over time.

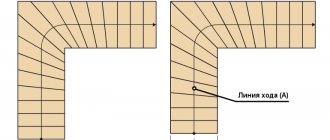

Features of the calculation of turning stairs

There are a number of methods for calculating rotary structures. The calculation of a U-shaped staircase is practically no different from the calculation of a staircase with a 90° turn.

Methods for calculating corner stairs:

- proportions;

- graphic method;

- scans;

- moving the line up.

The simplest method of calculation is the method of proportions; you can find calculation options using other methods on our website. You can also use the construction calculator on our website to calculate U-shaped and L-shaped stairs.

Graphical method

The method is based on the proportional placement of steps at the turning point; the calculation of stairs with a turn of 90 and 180° is identical. Let's look at the example of calculating a U-shaped staircase:

The main parameters that determine the dimensions of the stairs:

Stair railings

Protective fences made in accordance with GOST marches consist of support posts, intermediate balusters and railings. Such marches, which are located along the walls, are equipped with such a structure only on one side. For convenience, you can make handrails on the walls.

However, GOST assumes the presence of handrails and fences on both sides if their width is more than ninety centimeters. For wide staircases measuring two meters or more, it is also necessary to install an additional central handrail. To ensure that children can safely move up the stairs, additional handrails should be installed at their height level.

The height of the fence should be ninety or one hundred centimeters . This height allows you to move quite comfortably along a correctly installed flight of steps, and also prevents falls from the steps. The railing should be fifteen centimeters longer than the fence itself and reach the next landing. If the manufactured flight is rotated ninety degrees, the railing should not be torn apart.

To achieve maximum comfort and safety when going up and down the stairs, the railings must have a smooth and solid surface.

Calculations

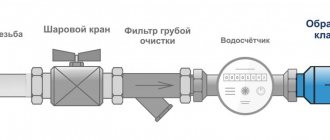

When installing an opening for a staircase to the second floor, it is necessary to calculate the dimensions of the opening. If the staircase consists of one flight, then the width of the staircase opening will be equal to the width of the steps, taking into account the distance required to install the railing. Double-flight designs assume double the value of this parameter.

The length of the opening is directly determined by the slope of the stairs. On average, the distance between each step and the ceiling should be at least 2 m. At the point where the height drops below this mark, the staircase opening should begin.

Now let's look at how to calculate the opening for the stairs to the second floor. To do this, you will first need to determine the length, width of the stairs, depth and height of the steps, as well as the height of the flight of stairs.

The recommended height of the steps is an interval of 15-18 cm. In order to determine their number, the distance from the floor to the ceiling is divided by the height of the step. The result obtained is rounded. As a rule, the number of steps of one flight of stairs ranges from 3 to 18. If there are more steps, then the staircase is divided into several flights, separating them with intermediate platforms.

If you are planning a staircase to the attic, then an opening width of 60-70 cm is sufficient. A regularly used staircase descending into a room combining several rooms requires an opening width of at least 80 cm.

The starting point of the staircase opening is determined as follows:

- The height of the room from floor to ceiling is calculated.

- The height at which each of the steps of the staircase will be located is subtracted from this parameter in turn.

- The calculation stops when the resulting number is less than 200 cm. It is at this point that you need to start cutting the opening.

After determining the dimensions of the opening for the stairs, you need to add 5 cm on each side. This is necessary so that after installation of the structure it will be more convenient to finish it.