There are several ways to ensure an uninterrupted supply of water from a well to your home at any time of the year. The most common is the construction of a caisson, the depth of which allows for laying a water supply from the mouth of the source below the freezing level of the soil. But there is another, less expensive method, which uses a downhole adapter cut into the casing at a selected level. How much better or worse it is than a caisson, in what cases is this method recommended and how installation is performed, find out from this article.

In the caisson, the pressure pipeline from the pump is discharged through the well head Source strojdvor.ru

What is it and how it works

Borehole adapter is a structural unit that connects the pressure hose from the pump to the main water pipe supplying water to the storage tank. The device allows you to change the direction of liquid flow by ninety degrees and hide the source with the water pipeline underground. The design consists of two elements:

- A fixed part in the form of a pipe mounted into a hole in the casing pipe. One side of the element is located in the well string and has a rectangular shape with a wedge slide for mating with the moving part of the adapter. On the other side of the pipe, protruding beyond the casing, a thread is cut for connection to the main water conduit and along which the part is attached to the column using a seal, a shaped washer and a nut.

- A moving part in the form of a tee pipe with internal threads on both sides and a side ebb in the form of a rectangular flange with a rubber seal. The sides of the flange are dovetail shaped for connection to a fixed part in the column. One side of the pipe is connected to the HDPE pipe from the submersible pump, and the other with a blind hole is intended for a rod used to fix the elements of the device together.

The assembled parts of the device represent an angle pipe, but the possibility of disconnecting the structure allows for prompt dismantling of the pump from the casing.

Operating principle

It consists of connecting structural parts that create a common water supply line from a deep-well pump to a storage tank.

- the work is done using a rod with a thread cut on one side and a welded handle on the other. To connect to the moving part of the structure, it is screwed into a threaded hole on the moving part of the device. The size of the rod corresponds to the depth of soil freezing, taking into account the required release from the well string;

- after fixing the rod in the movable nozzle using the handle, the movable part is pulled out of the wedge connection of the stationary part of the nozzle and, together with the hose and the deep-well pump, is removed from the casing;

Unlike a source equipped with a caisson, the operation of removing the pump from the casing with an adapter is completed in a few minutes instead of an hour's work.

§ Adapter device

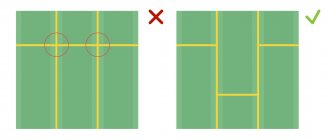

Pittles - the adapter consists of an internal and external part. The first half (shown on the right in the picture) is a threaded pipe with rubber seals on both sides. It will be located outside the well at the level of the drilled round hole and secured with a nut through O-rings.

A correctly secured outer part forms vertically located projections inside the well (in the picture indicated as “sleds”). The second (internal) part is attached to these protrusions.

The method of fastening through such “sleds” is called “dovetail”. Used in hard-to-reach places where it is difficult to work with a wrench.

The inner half (shown in the picture on the left) is a tee. A submersible pump will be connected to the bottom of the tee. The upper “blind” part has a thread for the mounting key. Water will flow into the house through the middle hole. The inner half of the adapter is removable.

Types and characteristics

World adapter manufacturers, including our country, produce designs that are classified according to the material used for manufacturing and dimensions.

The dimensions of the device are determined by the volume of the deep-well pump, the diameter of the casing and hose. Adapters are divided by type of metal:

- Made of bronze alloy.

- Made of brass.

- Made from stainless steel.

- Made from DZR, a special anti-corrosion alloy.

According to the size type used, depending on the diameters of the pipes, the designs are divided into: 4.4 cm, 5.4 cm, 7.3 cm.

One part of the nozzle is fixed at a depth of 1-2 m to the casing and to get to this connection you will have to dig; the pipes for the adapter are best made of stainless steel.

When purchasing an adapter, you need to check with the manufacturer and read the certificate so as not to purchase a product with poor characteristics.

Some tips

Having decided to equip a well with an adapter (in retail chains they are called Pitless adapters), you get a reliable water supply system and save on the timing of the work and the cost of its implementation. However, when purchasing it, you must remember the following:

- In order for the product to maintain its tightness throughout its entire service life and guarantee the possibility of repeated installation and dismantling of the deep-well pump, it must be of high quality. Do not buy adapters from little-known manufacturers that do not have a manufacturer's warranty.

- Having decided to purchase a Pitless adapter, be sure to check with the seller how difficult it is to find spare parts for this product in retail chains, first of all, o-rings and a removable part assembly. What is the probability that in a couple (or better, in five) years this product will still be produced.

- Having settled on this option, you will need to place all the equipment of your water supply system in the house itself and, preferably, in a separate room.

If you also have a main water supply, then it is useful to install an avk flanged valve to be able to shut it off. Depending on the situation, you can choose the source of water supply.

Advantages and disadvantages

By determining the positive and negative qualities, the product is compared with the caisson traditionally installed when constructing a well. The advantages include:

- the ability to operate the source all year round, with water supplied to the house;

- the cost of the structure with installation is 5 times less than when constructing a well with a caisson;

- ease of installation and maintenance of the product and deep-well pump;

- there is no need for additional space on the site;

- tightness of the device;

The disadvantages include the need to dig a pit to replace a failed seal on a non-removable part of the structure attached to the pipe.

Frequently asked questions to our engineers

Why is the choice of pumps limited when using an adapter?

The adapter partially occupies the space inside the casing, and the internal flow area is reduced accordingly. Today there is a large selection of pumps with a diameter of 3 inches in different price categories.

All my neighbors have caissons or wells, but for the cost I’m happy with the adapter. But I doubt my choice because they appeared recently.

Technical progress is inevitable, new mechanisms are replacing old ones. In many cases, modern equipment is technically more advanced. Adapters have been used for many years. They are time-tested and have advantages. But don't forget about the shortcomings. If possible, choose a caisson.

If I choose an adapter, can I make a watering tap next to the well, and not pull it from the house?

Technically, this is possible - a tee is cut into the water pipe at the outlet of the watering tap. But experts do not consider this solution reliable! We warn in advance that such a system will last no more than 2-3 years if you have clay soils on your site. Filling with sand or crushed stone under the drainage system ensures the operation of the system for a limited time, then the crushed stone or sand is mixed with clay. But the warranty period has already expired, and the company that installed the water supply is no longer responsible for the use of unreliable solutions.

Video reviews of our long-time clients, whose services were provided 4-5 years ago. Their impressions of the operation of our systems: Read more

Look at an example of our completed work on the arrangement: Water well in the village of Barybino

Find out what is better to choose when arranging a source - a metal caisson or a well adapter: Read more

What to consider when choosing between an adapter and a caisson

The use of a caisson for arranging a source provides access to the head of the casing and placement of equipment for purification and accumulation of water, as well as a device for monitoring the operation of the pump.

Installing an adapter allows you to supply water to the house if there is a technical room directly from the well, regardless of weather conditions.

The cost of arranging a source with a caisson is 3-5 times more expensive than installing an adapter for water.

When deciding on the construction of a well, we proceed from the following conditions;

The installation of a caisson is justified if:

- there is no technical room in the house;

- the territory of the site allows;

- seasonal well operation;

- no restrictions on funds;

It is advisable to use the adapter when:

- needs for year-round water supply;

- availability of technical premises in the house;

- limited area of the site;

- limited family budget;

Downhole adapter - what is it? Video of adapter installation on a well.

Construction of a well using an adapter or with a caisson, what to choose?

This question is immediately asked by those who install plumbing in a private home. A caisson is a more popular option, but when choosing, you need to evaluate the real conditions and possibilities.

The caisson has its advantages:

But the caisson also has a big drawback - its price with turnkey installation. The caisson itself alone will cost about 40,000 rubles. But to this we must add the costs of anchoring the caisson: a concrete slab, anchoring cables, etc. Installation of the caisson according to the standard estimate will cost approximately 130,000 rubles. This is almost three times more expensive than piping a well through an adapter - about 50,000 rubles. We wrote more about this in the article Construction of a water well with a turnkey adapter.

What tools will you need?

To carry out excavation and installation work yourself, you will need a set of tools:

- bayonet shovel;

- scrap (if there is rock or gravel soil);

- yardstick;

- extension cable;

- electric drill with a core cutter;

- grinder (grinder);

- gas adjustable wrench;

Auxiliary materials required for work:

- sandpaper;

- water-repellent sealant;

- tightening clamps;

- connecting fittings.

The process of constructing a well with a caisson: stages of work

Arranging a water source with a caisson is a complex process that requires equipment and specialists. The work is labor- and time-consuming. There are a number of operations to be performed:

- A hole for the casing is cut in the bottom of the caisson. The diameter is 10 mm larger than the casing size.

- Nipples for supplying pipes and cables are welded into the sidewalls.

- Dig a trench under the camera. The depth is such that the neck of the caisson after installation rises 20 cm above the surface. The length and width of the pit are required to be slightly larger than the chamber for ease of installation.

- The casing pipe is cut off near the ground and a caisson is installed. The position is adjusted and the casing is hermetically sealed. Cables and pipes are introduced.

The process is complex and takes a lot of time.

How to install it yourself

It is advisable to carry out excavation and installation work at above-zero temperatures, without precipitation. The installation of the downhole adapter can be done using step-by-step instructions and the experience of the craftsmen.

In order to quickly install the device and water pipeline, before the main work it is important to carry out the following preparatory work:

- Obtain information about the depth of soil freezing in the area where the source is located.

- Familiarize yourself with the parameters of the well: depth of the aquifer (should not exceed 70 meters), production capacity, casing diameter.

- Based on these well parameters, select a deep-well pump and a pressure food pipe with a diameter corresponding to the dimensions of the holes of the device. Purchase a pump control cable, a well cover and select an adapter.

- Purchase: control and monitoring devices for the operation of the source, a condenser and equipment for water purification.

- For the main water route, purchase a pipe and adapters.

- Prepare the necessary tools and components for assembling the water pipeline structure.

- Around the casing we clear the space required for work from soil to a depth exceeding the freezing level by half a meter, and dig a trench to the house for laying a water pipe.

- Using a grinder, we cut off the casing at ground level, clean the cut edges, install and secure the well cover.

- In the casing, at the bottom of the dug trench, we proceed to install the downhole adapter. Using a hole saw matched to the diameter of the product pipe, we drill a hole in the pipe wall.

- We insert the stationary part of the adapter into the hole on the column and secure it to the pipe with a nut using an open-end wrench. First, we put a rubber seal and a shaped washer on the pipe, ensuring the tightness of the connection.

- After the nut, we screw an adapter onto the pipe, to which we mount a water pipe, laying it in a trench to a storage tank in the technical room.

- We connect the hose, cable and safety rope to the submersible pump, combining them into a single string. We lower the pump into the casing to the required depth.

- We cut off the pressure hose and attach a fitting to the end, using it to connect the pipe to the moving part of the device.

- We insert the power cable into the hole in the well cover and stretch it along the trench to the technical room, connect it to the control panel.

- We screw the rod into the movable branch pipe of the structure and, lowering it into the casing pipe, insert the part into the stationary part of the device.

- We tighten the safety rope and secure it to the column, removing the load from the pump and hose with cable from the adapter. We remove the mounting rod from the shaft.

- We turn on the pump, pass water through the assembled system into a storage tank, and check the tightness.

- We close the well cap and fill the trench. The house's water supply system is prepared for operation.

Design and functions of the adapter for the well

We are talking about a device that connects the water supply that goes to the house with the outlet of the well. The adapter is installed in the casing pipe and, as we just noted, below the soil freezing level, due to which the well will remain operational regardless of the time of year. The design of the adapter is such that the connection is as tight as possible, but at the same time easy to dismantle/repair.

The adapter consists of two parts - external and internal. The outer element is a kind of pipe installed in a hole made in the casing pipe. At the same time, on the part that is located inside, there is a special groove, thanks to which the parts of the device fit tightly and hermetically. There is a thread on the outside to connect to the pipeline, additional seals and a union nut that secures the device in the desired position/place.

As for the second part of the device, it is entirely located in the casing pipe. It is, in fact, a “knee”, slightly modified and modernized, which is connected by leads to the first part of the device (there is a special tenon that connects to the groove mentioned above; together this is a “dovetail” connection, sealed with a rubber ring) and a hose connected to the pump.

Operating principle of the well adapter

To facilitate installation, there is a blind thread on top of the internal part. The installation pipe is screwed in there, thanks to which the device is lowered. In the well, it is installed in the groove of the second part, then the installation pipe is simply unscrewed and removed. It is not difficult to make such a tool with your own hands.

Here you can see the blind threaded hole for mounting the internal part of the well adapter

Table. The main materials from which a downhole adapter can be made.

| "Stainless steel" | Stainless steel devices are durable, lightweight, and can last approximately 30-40 years. The price of such adapters corresponds to their quality. |

| Bronze | High quality bronze adapters are very expensive. But at the same time they serve for a long time - about 25 years. |

| DZR-alloy | This brass-based material is good because it does not emit any harmful substances, which cannot be said about the next option. |

| Brass | Cheap brass adapters last no more than 8-10 years. During this time, they release zinc/copper oxides into the water, and therefore it is recommended to additionally install a filter. |

On a note! The material from which the well casing is made deserves special attention. It is advisable to give preference to steel products - they will withstand the loads encountered during operation for a long time. The same applies to adapters. As a result, the entire structure will be more reliable and last longer.

Maintenance and service

Technical inspection of the product is combined with maintenance of the well pump.

- when lifting the deep unit from the casing pipe, together with the pressure hose, the moving part of the device is removed;

- The main wear and tear on the product is the seals. Rubber rings lose elasticity and are damaged by fine abrasives in water. If defects are detected, the seals are replaced with new ones;

- The threaded connection of the removable pipe of the product with the fitting on the pressure hose is checked. If a thread leaks, the seal or fitting must be replaced;

- if during operation the fixing ridge of a moving part of a device with a stationary element on a pipe is damaged, the moving part of the product will have to be replaced;

- To replace the damaged seal of the stationary part of the device, it is necessary to dig out the casing before inserting the product, disconnect the water line and remove the nut from the pipe.

Installation

To install the adapter in the well, you will need a mounting rod, which is a piece of steel pipe about 2 m long of the appropriate diameter with an external thread. To drill holes in the steel casing pipe, select a bit with a diameter greater than 1 ¼ inches.

Do-it-yourself installation is carried out, guided by the operating instructions for the device, in the following sequence:

- Before installation, be sure to make a vertical mark with a file at the end of the stationary part - this is important for accurate vertical installation of the part, the placement of which is difficult to check from inside the casing.

- A trench is dug near the well string to the required depth to protect against freezing, usually this distance is in the range of 1.5 - 2 m, and to a width that ensures ease of installation work.

- Drill a through hole at the intended point of the casing pipe with a metal drill, replace it with a bimetallic crown and make a through mounting hole of the appropriate diameter of at least 32 mm (for a 1 ¼ inch unit).

- Screw the tee part to the installation pipe in an inverted position and put a fixed unit on it, which will be attached to the casing pipe. This is done in order to prevent the accidental fall of a part, which, with this installation method, will rest against the stop.

If the fixed part has a small mounting hole on the protrusion or in the body, a safety line is tied to it and connected to a tee screwed to the mounting rod not in an inverted, but in a straight working position.

- Push the parts on the pipe into the borehole channel and then install the stationary part into the cut hole, highlighting it with a flashlight, lightly fix it with an external nut and remove the mounting rod along with the mating part.

- Turn the part in the socket 180 degrees and screw it tightly with a union nut using an adjustable wrench. Then a transitional compression fitting is screwed in to secure the underground HDPE pipeline.

- The submersible pump is lowered into the well; to do this, a pressure pipeline is first connected to it, a cable is tied, if necessary, the cable is extended and they are tied together with ties. Cut the pressure pipe at a pre-marked distance, connect its end through an adapter compression fitting to the mating part of the adapter, and screw a pipe wrench to the part.

- Lower the installation pipe into the well channel and place the moving part in the dovetail socket using a flashlight, unscrew the key, place a special protective cover on the top of the casing and tie the electric pump cable to it.

- Through a previously installed transitional compression fitting, a HDPE water pipe is screwed to the tee, which is placed in a trench with a certain slope to organize self-discharge into the well. At the end of the work, the ditches are covered with earth.

Main stages of installation work

Which is better

The construction market offers adapters installed on the well, produced by domestic and foreign manufacturers. The popularity of devices depends on environmental friendliness, reliability, precision of execution and durability:

- Products made from bronze and brass alloys oxidize and negatively affect water quality. Therefore, the use of devices made of these alloys is limited to wells for technical purposes.

- DZR alloy fixtures provide corrosion resistance at the expense of zinc loss during manufacture. The material has a positive effect on the quality of drinking water and is classified as a food alloy.

- Stainless steel adapters meet these requirements in all respects.

Among the companies whose products are in demand on the market are:

- American company Baker - manufactures from bronze alloys;

- European manufacturer Debe Pumpar - devices made of DZR alloys;

- American company Granby Harvard - stainless steel devices.

The average cost of products, depending on the material used and the manufacturing company, is from 2 to 6 thousand rubles per piece. The cost of installation with excavation works ranges from 8 to 10 thousand rubles.

Photos and video materials, in which the authors show in practice how to carry out installation work correctly and what mistakes should not be made, help to install the downhole adapter efficiently and quickly.

Popular adapter manufacturers

Similar devices are produced today by many companies, but we will highlight several brands that are most popular among buyers.

- DebePumpur . Adapters from this manufacturer comply with all European requirements and standards. The body of the device can withstand corrosion processes for a long time, but the most important thing is the built-in heating (thermal protection), thanks to which such adapters can be installed above the ground freezing level. All you need to do is simply connect it to the electrical network and that’s it – you don’t have to worry about the water supply freezing.

- Vinkell. The manufacturer produces high-quality borehole adapters made of bronze. They are characterized by the fact that they can be connected even to small casing pipes (diameter 120 mm). According to customer reviews, Vinkell adapters are of such high quality that they can be installed even in the most unstable and dirty soil layers (for example, next to a sewer or foundation).

Downhole adapter Vinkell - Baker . The adapters from this manufacturer are mostly made of steel, designed for the circulation of drinking water. Such devices can work with systems that can withstand up to 8 atmospheres of pressure and pipes up to 8 m long. According to customers, Baker products are one of the best for home plumbing systems.

Note! Do not buy devices from unverified manufacturers in an effort to save money, because in this case you risk buying a low-quality adapter, which, in turn, will cause serious problems with the water supply in the future.

Also note that the adapters in general are almost no different from each other in terms of design features. The key difference is only the material that was used in manufacturing, as you have already seen for yourself by reading the above classification of the devices described.

Video - What to install: caisson or adapter?

Video - How to install a well adapter

Construction of houses

0 votes

+

Vote for!

—

Vote against!

An important step in preparing for the operation of a suburban area or house is the water supply wiring. In the absence of central communications, a well would be an excellent solution, and if one is already available, then we can consider that half the battle is done. Now all that remains is to properly organize the water supply. The article will discuss installing an adapter on a well.

- Method one

There are four main methods of arrangement for year-round water use: well, pavilion, caisson or adapter. Of course, each option differs in cost, complexity and reliability.

As for the well, it is not particularly reliable, the pavilion is expensive. The metal caisson is susceptible to corrosion, and the plastic model has a number of “contraindications” for installation. Recently, a borehole adapter has been an excellent alternative to all of the above devices.

Well adapter

This device makes it possible to hermetically connect the well column with a horizontal water pipe. It is advisable to use it if there is a technical room (basement, boiler room), in which you can place: a hydraulic accumulator, automation, etc.

Well adapter device

- Hermetic fixation of the pipes is ensured by two parts, where one is mounted directly to the casing, and the second is screwed to the hose with the pump.

- The connection of these parts is carried out according to the “dovetail” principle. Such fasteners are used mainly on highly loaded components of mechanisms.

Benefits of a well adapter

In addition to the low cost of the adapter itself (10 times cheaper than a caisson) and the ease of installation, this device has other very significant advantages:

- O-rings provide reliable protection of the well from groundwater penetration;

- hidden installation prevents the pump from being stolen;

- saving space on the site; installing an adapter is especially important if there are other underground utilities nearby;

- allows you to install water pipes below the freezing depth of the soil;

- the equipment can be used at high groundwater levels;

- Easy dismantling makes it possible to remove the pump to replace it or, if necessary, drain the water supply system for the winter.

Despite a rather impressive list of advantages, there are also negative aspects of constructing a well with an adapter:

- the choice of pumping equipment is limited;

- carrying out repair or maintenance work is difficult due to inaccessibility;

- the impossibility of connecting additional sources of water intake, for example, for a bathhouse, watering a garden, although this statement is controversial - a tee will be the solution;

- placing related equipment in large country cottages is not a problem, but for country houses this idea is not very successful.

What material is the well adapter made of?

There are 4 main types of alloys from which adapters are made:

- bronze alloy – guarantee up to 25 years of device service;

- brass alloy - service life about 7 years;

- iron-carbon alloy (stainless steel) - will last 20-50 years;

- DZR alloy – 25 years warranty.

The first two materials used for production are gradually leaving their positions. The reason for this is non-compliance with drinking water standards, which have recently become more stringent. After all, such alloys oxidize, thereby releasing harmful substances into the water supply system.

Today, preference is given to a more modern solution from manufacturers that use a special alloy - DR (Dezincification resistant - the literal translation is: “resistant to zinc loss”). High corrosion resistance ensures long-term operation of the downhole adapter.

Well adapter price and manufacturers

The trouble-free operation of this device is ensured by its precise manufacturing from high-quality materials. Therefore, before you buy an adapter for a well, you need to carefully read the reviews about the most popular models.

The most famous manufacturers of downhole adapters are:

- Baker and American Granby Harvard (USA);

- Debe (Sweden);

- Unipump (Russia).

Using these examples, a mini-review of adapters for wells will be made, where the material of manufacture, the presence of safety holes for ease of installation, cost and other equally important criteria were taken into account.

| trademark | manufacturer | material (alloy) | safety hole | pipe diameter (mm) | average cost rub./piece |

| Baker well adapter | USA | bronze | No | 100-200 | 3 300 |

| American Granby Harvard well adapter | USA | stainless steel | No | 110-130 | 5 000 |

| Taiwan | bronze | No | 110-130 | 4 500 | |

| Debe well adapter | Sweden | DZR | There is | 125-195 | 4 500 |

| Unipump well adapter | Russia | Brass | No | 110-160 | 2 000 |

| Vinkell well adapter | unknown | bronze | There is | 127-158 | 3 000 |

To sum it up, we get the following:

- the average cost of a downhole adapter is 3,700 rubles;

- installation will cost approximately 8,000 rubles;

- excavation work will cost about 1,500 rubles.

As a result, organizing a water supply system in this way will require an average of 13 thousand rubles. Undoubtedly, you can save a lot if you install the equipment yourself.

Adapter for well installation

It should be immediately noted that the choice of column diameter must be calculated taking into account the size of the adapter for the well. This auxiliary element occupies about 30 mm on the inside. Therefore, the selection of pumping equipment is also carried out on the basis of these parameters. Otherwise, the pump may simply not pass by the stationary part of the device or may become stuck at a given point.

The well passport indicates all the required indicators and recommendations for the selection of devices. These characteristics will help you select and install all equipment correctly.

Do-it-yourself installation of a well adapter can be done in 2 ways.

Method one

- For this option you will need a T-shaped key made by yourself. This could be a plastic pipe with a tee soldered on the end. Before lowering one of the adapter parts into the pipe, you must secure the O-ring included in the kit with silicone. Otherwise, its “irretrievable” fall into the well cannot be avoided, and purchasing a spare rubber product can sometimes be very difficult (depending on the manufacturer).

- And one more trick: on the counter part, to which the water pipe will be subsequently mounted, a risk is made. This is necessary in order to install the element in the correct position.

- A hole is drilled in the casing pipe below the freezing depth of the soil; for this, a bimetallic bit mounted on an electric drill is used. The diameter of the hole corresponds to the diameter of the adapter.

- Using a T-key, the non-removable part is lowered into the well, a rubber seal is put on it, and then an o-ring. These sealing elements are secured with a nut; for reliability, it is tightened with a wrench.

- A coupling (adapter) is screwed onto the outside of the adapter (threaded connection), from which the water supply system will begin.

- Then the pump is lowered to a certain depth with a connected hose-pipe, cable and safety rope. The moving part of the adapter is installed on the required segment using a fitting.

- Water will be supplied through the lower hole of the device at an angle of 90°, and the upper hole is plugged, but has a special threaded connection intended for installation.

- A key is screwed into the working hole (essentially a metal pipe with a thread) and is used to fix it into a fixed element. After installation, the mounting rod is simply unscrewed and removed from the well.

Second way

- The second option is simpler, since the installation of the adapter is carried out practically in a non-disassembled form, so the loss or jamming of the sealing rubber bands will not occur. In addition, there is no need to perform “blind” manipulations to join parts at a depth of 2 meters.

- In this case, only the sealing rings are removed from the adapter and the nut is unscrewed. And in the same semi-collapsible state, it is lowered into the casing using a metal pipe, which is screwed into the mounting hole of the device.

- For ease of maintenance, the pipe is cut to the required length, that is, to the end of the casing, and left in it. Here, when installing the adapter, it is necessary to calculate in advance with extreme accuracy the depth of the pump, the length of the supply pipe, and the power cable, since installation is carried out with full connection of all necessary equipment.

Adapter for well video

Bottom line. All the pros and cons of the well adapter

The low cost of installation, as well as the cost of the well adapter itself, sometimes makes owners of suburban areas think and wonder about the “presence of pitfalls.” Therefore, it is necessary to briefly consider all the features and nuances of this system arrangement.

- Tightness . Many consumers are confused by the “unsteady” connection between the two parts of the device. But as mentioned above, the dovetail connection is reliable and resistant to stress. In addition, it can easily withstand pressure up to 8 bar, which is quite enough to provide water to a cottage.

- Even if the pumping equipment creates more pressure and thus the adapter leaks, this has virtually no effect on the operation of the water supply system as a whole.

- As for replacing the O-rings, this is quite easy to do on the removable part, but if it needs to be done on the frame, you will have to dig a trench to get to the leak. As a rule, such work is carried out every 5-7 years.

- Durability . This characteristic directly depends on the material from which this device is made. Any material reacts differently to external influences (temperature, humidity), has its own natural wear and tear period, and is susceptible to corrosion. Therefore, saving several thousand rubles is not practical here.

- Strength. As you can see, the pumping equipment hangs on the adapter itself and, of course, creates a load on the threaded connection. Many manufacturers indicate in the specifications the weight that it can withstand; the figures can be 200, 600, 900 kg or more.

- If in doubt, you should not refuse to install a safety rope, which fulfills its direct duty - providing protection from possible damage.

- Of course, it does not help the adapter keep the pump suspended, but, nevertheless, it will greatly facilitate lifting the pumping equipment in the event of an emergency.

- Casing diameter . This value is calculated from the diameter of the pump plus 2-3 cm for installing the adapter. It is clear here that the larger the diameter, the higher the cost of drilling work. But these costs are not comparable to the difficulties that may arise during the installation of pumping equipment in a small well.

- Dismantling . Many have encountered problems when trying to spin elements that have been exposed to water for years. They often just “stick” to each other. In this regard, it is recommended to dismantle the removable adapter element at least once a year.

So, the pitless adapter as a system has positive characteristics. And all this thanks to the reasonable price of the device itself, the possibility of self-installation, and saving on land.

Adviсe.

Before purchasing, you need to find out what material the device is made of. In the end, its service life will depend on this. It is not recommended to purchase models from unknown companies, otherwise replacing it, read unearthing the entire system, and accordingly purchasing a new adapter will result in additional costs.

It is important to know whether the manufacturer offers spare parts for the device (O-rings or the entire removable element); they may be needed many years later.

Proper arrangement of the well by installing a pitless adapter will ensure a continuous supply of water to the house, maintain the tightness of the casing, make it possible to quickly drain and, if necessary, dismantle the pumping equipment.