A split system is a rather complex device. For its normal operation, compliance with operating rules, as well as regular maintenance, is required. One of the obvious signals of a violation is the appearance of frost or ice on the air conditioner, that is, freezing.

Materials and tools

For work you will need the following tools and materials:

- Slotted screwdriver

- Flashlight

- Medium short bristle brush

- Antibacterial cleanser

- Freon for refilling

- Tester for "ringing"

- Soldering iron

- Capillary copper tube

- High pressure compressor

Ice forms on the indoor unit of an operating air conditioner

Over time, all components of the air conditioner wear out, malfunctions and breakdowns occur. No one is safe from them. Here is a list of reasons why the indoor unit of a properly working split system may freeze:

- Large temperature difference between indoors and outdoors;

- The filter drier is clogged;

- There is a refrigerant leak;

- Air filters clogged;

- The evaporator in the indoor unit is clogged;

- The capacitor in the external unit is clogged;

- There is high air humidity in the room;

- One of the sensors has failed;

- The fan is not working well;

- The filter drier is clogged;

- The air conditioner controller is faulty.

Timely service is a guarantee of serviceability

When buying an air conditioner, many people do not seriously think about carrying out regular maintenance of this equipment. Why carry it out?

Firstly, this must be done so that the split system maintains its service life and has to be repaired as rarely as possible.

Secondly, periodic maintenance of the equipment is necessary to maintain the power of the unit, since over time its loss is inevitable and, as a result, warm air will come out of the air conditioner.

Thirdly, if due to poor inspection the unit fails, then this will not be a warranty case and you will have to pay for repairs.

Obviously, without systematic maintenance, the operating period is reduced, and this is due to the fact that:

1.When the fans operate, dust is sucked into the air conditioner. And without regular cleaning of the split system, it will cover all the components of the air conditioner with a layer: radiator, heat exchanger, drainage outlets and, first of all, air filters. When the condenser becomes dirty and, as a consequence, due to a decrease in the refrigerant supply, the load on the compressor increases, which directly affects the service life of this unit.

2. Another important factor for regular maintenance is that warranty repairs exist only for factory defects or poor-quality installation of equipment. The consumer rights law clearly states that “defects caused by improper use of the product are not subject to free repair.” And prevention of climate control equipment is a necessary condition for the operation of this equipment.

What should specialists from the service center do during maintenance? After all, it is common knowledge that the user is only allowed to clean or change the air filters.

Maintenance of the indoor module includes:

- Cleaning the heat exchanger.

- Cleaning the drainage system.

- Diagnostics and inspection of electrical communications.

- Fan cleaning.

Preventive inspection and repair of the external unit includes:

- Cleaning the fan.

- Refilling with refrigerant.

- Cleaning dirt from the air conditioner.

- External inspection and control of electrical devices and connections.

In some service centers, servicing of climate control equipment occurs as planned twice a year: in the spring before the onset of heat and in the fall after the end of the summer season. But even if they do not make rounds, it is recommended that the user of the split system call specialists from the service department at least once a year. And then the climate control equipment will serve you for many years, maintaining comfort and coziness in your apartment.

Source

What causes the evaporator to freeze in a new air conditioner?

It happens that after installing the air conditioner, the evaporator becomes covered with ice. This can happen in the first hours of work, and sometimes after weeks or months. There are several reasons for the appearance of ice in the indoor unit of a split system:

- Incorrectly selected power;

- Pipe collapse during installation;

- Didn't refill freon for a long line;

- The air conditioner is installed in a room with high humidity;

- Installation standards are not followed;

- Service valves are not fully open;

- The freon pipeline is poorly evacuated.

What is condensate?

The risk of harm to health from improper removal of evaporated moisture is much more dangerous than the threat of a split system breakdown. Although, in terms of its chemical composition, condensate is just ordinary water. But the fact is that pathogenic microbes accumulate in stagnant warm moisture.

The consequences of not draining condensate can be:

- unpleasant musty smell from the air conditioner;

- reproduction of Legionella pathogens;

- formation of various forms of mold.

It is a mistake to consider air conditioning to be the main cause of severe Legionnaires' disease. A dangerous microorganism lives in the soil, swimming pools, and decorative fountains. Wherever there is stagnant water, even in medical physiotherapy equipment, there is a risk of encountering Legionella.

Removing excess moisture from the split system is necessary for the health of your family. Constantly draining condensate will not give a chance for water stagnation to develop

The drainage system is designed to drain excess moisture. Correctly performed condensate drainage and timely maintenance make air conditioning equipment completely safe.

Wrong selection

Ice in the indoor unit of the air conditioner is formed due to the low temperature of the gas in the evaporator. One of the reasons is incorrect selection of cooling capacity. When choosing a model you need to consider:

- Volume of the refrigerated room;

- Indoor temperature;

- Temperature outside the room;

- Heat influx from other sources.

If the air conditioner is chosen incorrectly, it will not have time to cool the room. Because of this, it will work more intensely and turn on more often. The refrigerant is greatly supercooled. Accordingly, moisture from the surrounding air condenses and freezes on the evaporator. This most often happens with non-inverter systems.

To check if your system has enough cooling capacity, use an online air conditioner capacity calculator. Compare the obtained values with the parameters of your model.

The documentation for the air conditioner or the nameplate on the indoor or outdoor unit (see photo) may indicate the capacity in kW or BTU (British Thermal Units). It is necessarily present in the model name. For example, the Daikin FTXB20C model has a cooling capacity of 2.0 kW. And Neoclima Alaska 2.0 NS-09AHTIw – 9000 BTU.

This is how the power of the air conditioner is shown in BTU on the nameplate of the indoor or outdoor unit.

To convert kilowatts to BTU, multiply the value by 3412. To convert BTU to kW, divide it by 3412. Or use this table:

| kW | BTU | BTU | kW |

| 1 | 3412 | 5000 | 1,47 |

| 1,25 | 4265 | 6000 | 1,76 |

| 1,5 | 5118 | 7000 | 2,05 |

| 1,75 | 5971 | 8000 | 2,34 |

| 2 | 6824 | 9000 | 2,64 |

| 2,25 | 7677 | 10000 | 2,93 |

| 2,5 | 8530 | 11000 | 3,22 |

| 2,75 | 9383 | 12000 | 3,52 |

| 3 | 10236 | 13000 | 3,81 |

| 3,25 | 11089 | 14000 | 4,10 |

| 3,5 | 11942 | 15000 | 4,40 |

| 3,75 | 12795 | 16000 | 4,69 |

| 4 | 13648 | 17000 | 4,98 |

| 4,25 | 14501 | 18000 | 5,28 |

| 4,5 | 15354 | 19000 | 5,57 |

| 4,75 | 16207 | 20000 | 5,86 |

| 5 | 17060 | 21000 | 6,15 |

| 5,25 | 17913 | 22000 | 6,45 |

| 5,5 | 18766 | 23000 | 6,74 |

| 5,75 | 19619 | 24000 | 7,03 |

| 6 | 20472 | 25000 | 7,33 |

If the installed air conditioner is weaker than necessary, there are three options:

- Set the temperature to a higher temperature;

- Install additional air conditioning;

- Replace the existing one with a more powerful one.

Working in the heat

Every air cooling system has a temperature limit at which it can operate. The greater the temperature difference between the indoor and outdoor units, the worse the performance of the air conditioner. To compensate, it will turn on more intensely.

In normal mode, water droplets in the indoor unit of the air conditioner turn into frost. But when the compressor does not work, it thaws and goes into the drain. If it’s hot outside and the air conditioner is set to the minimum temperature, the frost will not thaw. Ice will build up on the evaporator.

The minimum and maximum temperatures are indicated in the documentation for the air conditioner. Check with him. Please note: if the external unit is on the sunny side, it heats up more and dissipates heat less well. To solve the problem:

- Turn off the air conditioner;

- Wait until the ice on the evaporator melts (to speed it up, you can turn it on for heating);

- Set the temperature 2-3 degrees higher;

- If ice forms on the evaporator again, raise the temperature further.

Important

The most common illness among office workers in the summer is the common cold. Do not set the air conditioner temperature too low. This way you will not only prevent the formation of ice on the indoor unit, but also maintain your health.

Compressor

Signs of a compressor malfunction may include:

- air conditioning delay;

- work cycle disruptions;

- presence of a characteristic hum (the air conditioner does not turn on).

The reasons may be breakdown and breakage of conductors, failure of capacitors in AC devices, failure of valves (TRV or four-way), filling the crankcase with freon, etc.

It is not recommended to carry out problem diagnosis and repairs on your own, even when there is complete confidence in the need to replace parts and assemblies. After replacing them, you will most likely need to adjust the sensors, which is difficult to do without full access to the capabilities, primarily of the electronic unit.

Clogged filter

The indoor unit of any model has one or two mesh filters. They are located above the evaporator heat exchanger. Over time, dust accumulates on them, and if the unit is installed in the kitchen, grease and soot. They block access to the air drawn in.

If the filter is heavily clogged, the air flow rate will decrease. It cools more slowly, the freon does not have time to pick up heat and heat up. Due to its low temperature, more moisture accumulates and freezes on the evaporator than it has time to thaw. This is one of the common reasons for ice freezing in the indoor unit of the air conditioner.

How to open the air conditioner cover to clean the filter and clean it, see this video:

Why do you need to drain into the sewer?

Connecting the drainage system with the sewer system is the most expensive option for removing condensate from a split system. But experts recommend choosing this method, despite the costs. Because he is the most correct in all respects.

The feasibility of a complex option

The first air conditioners were installed without much thought for the environment. But today environmental issues come to the fore in the technical development of society.

Expensive climate control equipment is purchased for a long service life. Your caring care will prolong his life

The health of humans and their smaller pet friends requires care. Illnesses take away energy and money for medicine. Therefore, the most expensive method of diverting the drainage line into the sewer will pay off over time due to savings on treatment.

Clean air without harmful vapors from dripping condensation is useful both in a country house and in local areas in multi-storey urban areas.

What do the rules dictate?

Discharging liquid into the sewer is only recommended, but is not prohibited by the instructions for climate control equipment. It’s just that this method is the most gentle for proper long-term operation of the device. It eliminates the dangerous consequences of the accumulation of large amounts of moisture on the air conditioner evaporator.

Constantly slipping statements about the legal requirements to install a condensate drain only in the sewer system are unfounded. Those interested can verify this by reviewing the judicial practice on claims against owners of air conditioners with gravity street condensate drains. The courts refuse to satisfy such claims as they are not justified by legislative norms.

There are local bans on the release of condensate into the atmosphere as part of decisions made by housing developments. We will not discuss the legality of such documents. As they say, the collective farm is a voluntary matter.

Building codes require condensate to be discharged into the sewer system. But compliance with SNiPs is mandatory only for new premium-class residential buildings put into operation with an installed air conditioning system

And yet there is one general prohibition that applies to any condensate drainage systems. Do not drain moisture from the air conditioner into a storm drain. This is dangerous for the equipment. Due to increased pressure during rain, water may flood the air conditioner through the drain pipe.

Disadvantages of gravity drainage to the street

A simple accessible method is used for reasons of saving time on installation and money on paying for the services of craftsmen. However, this method of removing condensate has a number of unpleasant nuances.

Water flowing out of the drain pipe:

- pollutes the facade, windows, and sometimes gets on passers-by;

- disrupts the silence of the night, spreads dangerous germs;

- slowly but surely destroys the structural elements of the building.

The sight of dirty puddles under the module does not cause aesthetic delight. The sound of drops at night may not bother you at all. But it is unknown how your sensitive neighbors in an apartment building or townhouse will react to noise.

In a private house, a hose with dripping water hanging on the wall spoils the appearance with its sloppiness. Steam particles carry organic harmful components of condensate throughout the local area

The water itself, formed from collecting condensate, is an undesirable product and requires disposal. From the point of view of hygiene, ethics, and the safety of people and pets, it is best to dispose of such waste liquid into the sewer system.

Freon shortage

Another possible reason why the air conditioner evaporator freezes is a lack of refrigerant. Freon performs the main role - it takes heat from the room and transfers it to the street. If there is not enough of it, it will not be able to effectively cool the room.

Determining a lack of refrigerant is simple: inspect the service valves on the outdoor unit. They are usually located on the side wall at the bottom right. In some models, the valves are protected from precipitation by a plastic or metal cover. If there is frost on the service valve, there is not enough refrigerant in the system.

There are two reasons for a lack of refrigerant:

- There is a leak in the system;

- After service, little freon was added;

- The permissible length of the freon line has been exceeded.

Results

Now you know why your air conditioner may become covered with frost or ice. In some cases, this is absolutely normal, but if water begins to flow down the walls, or ice is clearly visible without removing the decorative cover, then it’s time to sound the alarm.

This situation can only be corrected by an experienced specialist from the service center, so we do not recommend performing repairs yourself. Entrust this task to a professional. He will conduct a complete diagnosis of not only the indoor unit, but also the outdoor unit.

If you have encountered this problem before, please share your experience in the comments below. It will be useful for both users and novice craftsmen. Good luck!

Pipe crease

If the indoor unit of the air conditioner freezes, the cause may be damage to the copper freon tubes. They connect the external unit and the internal one, and refrigerant circulates through them. They can be “broken” during maintenance or installation of the air conditioner.

If there is a crease in the tube, the throughput in this area is reduced. When it is located in front of the evaporator, too little refrigerant enters it. As it expands and boils, its temperature drops below normal.

When the refrigerant in the evaporator is supercooled, the moisture condenses and freezes much faster. In defrost mode, the ice does not have time to turn into water and go into the drain. Gradually it accumulates and the evaporator radiator freezes more and more.

You can determine the tubing crease yourself only visually. For this:

- Turn off the air conditioner and let it stand for 10 minutes;

- Remove the thermal insulation from the tubes;

- Inspect the freon line for kinks (see photo).

A hole in the copper tube through which freon circulates during the installation of the air conditioner.

Important

Even a small leak has a negative impact on the compressor. He has to work under increased load. And this leads to premature wear and reduced service life. Repair and replacement of the compressor is comparable to the price of a new air conditioner!

You will not be able to fix a crease in a copper tube on your own. The damaged area must be completely replaced. Before repairs, it will be necessary to drain the freon, and then evacuate the system and pump new one into it.

Automatic diagnostics

Factory defects, poor installation and improper operation are the main reasons why the internal parts of the air conditioner fail prematurely. There is practically nothing that can be done about a manufacturing defect; in the other two cases there is a chance to improve.

Inscriptions on the display and blinking lights will help you find out in time that certain problems have arisen.

In an air conditioner, they usually talk about breakdowns of the following nature:

- Broken thermistor, resulting in no additional temperature control.

- Problems with the directional valve.

- Problems inside the fan.

- Voltage surges at the outdoor unit.

- Exceeded parameters related to energy consumption.

- Problems with the cable or circuitry due to communication.

- Lack of overvoltage protection.

- The work goes on both heat and cold at the same time.

- Malfunction in the thermistor of the external part.

- Faulty internal thermistor.

The instructions provide a precise definition for those who are interested in deciphering the appearing codes and designations. This allows you to quickly determine what exactly happened.

But not every code has a decryption for users. Most of the information is handled by technicians belonging to a particular service center.

Compressor and clutch problems

If the radiator on the external unit is clogged with dirt, this part of the structure may overheat. Heat removal becomes more difficult and the load on the device increases. The pressure level in the lines requires a separate check. Excess refrigerant must be released if the reading is higher than normal.

Never rule out the possibility that the fan on the external unit has become faulty. Clogged capillary tubes are another common cause of later problems. Replacing one of the tubes often solves the problem.

There are other signs that indicate breakdowns in this part:

- Compressor failure to start when .

- Presence of oil leaks on the compressor.

- Compressor drive belt creaking.

- Extraneous noise.

- Decreased performance.

Complete compressor replacement and repair are complex operations, so it is recommended to immediately contact specialists.

But noise can indicate both problems in the compressor and malfunctions in the drive. The pulley bearing is most likely the source if the noise is heard even when the device is turned off.

If the compressor refuses to start, they also look closely at several parts of the mechanism:

- Clutch.

- Relay.

- Fuse.

A blown fuse is the easiest to deal with; in case of breakdowns, it is simply replaced with a new one. The electromagnetic clutch is studied next if the previous steps did not produce any result.

As for the compressor itself, there are several reasons for its breakdown:

- Reduced refrigerant level.

- System clogged.

- Complete blockage.

Repairing and replacing a compressor is quite an expensive undertaking, so it is recommended to treat the part with as much care as possible during operation.

When the device turns on and turns off immediately, the reason most likely lies in the sensors - evaporation or temperature. Data from temperature sensors is associated with the operation of the control board. If the system is faulty, there is no information. And the device believes that the current operating mode does not need adjustment for this indicator.

Compressor overheating and shutdown often occur due to fan malfunctions. This usually happens if the rotation speed of the device is less than certain specified parameters.

Dirt and dust may appear in some other parts:

- Dryer filter.

- External radiator.

- Capillary tubes.

In such situations, the compressor stops turning on and working normally.

Freon line length

Each air conditioner has a refrigerant charge rate based on weight. But it depends not only on the model. The length of the freon line plays a big role. As a rule, 5 meters of copper pipes are supplied with the split system. If the distance between the blocks is greater, you will have to increase them.

The longer the freon pipeline between the blocks, the greater its volume. If air conditioners with different line lengths are filled with the same amount of gas, the pressure in the system will be different. Amateur air conditioners do not know about this or forget.

If ice forms on the indoor unit of the air conditioner after installation, the reason may be a lack of refrigerant. You won't be able to determine this on your own. Testing for freon deficiency requires special equipment and skills.

Why does the air conditioner blow warm air instead of cold air?

The next step will be to check the external and internal units for contamination. It is necessary to open the front cover and check the filter, as well as the evaporator radiator of the indoor unit of the air conditioner. You should also check the evaporator of the outdoor unit for the presence of a layer of dust or poplar fluff. The filters are easily removable and can be washed under running water, and the outdoor unit can be cleaned with a high-pressure washer, or, in extreme cases, with a vacuum cleaner or steam generator. If a layer of dirt has formed on the filters, wash it, dry it, put it back in place and try to start it again.

Did not help? So it's all about the refrigerant. You won’t be able to fix the following problems yourself without the intervention of a specialist. But we will show you how to accurately identify the cause.

On average, up to 10% of the refrigerant is lost per year of using an air conditioner, even with a sealed system. There may be insufficient refrigerant in two cases:

- The air conditioner has not been serviced for more than two years

- Air conditioner has a refrigerant leak

If the air conditioner has not been serviced for a long time, then you should contact specialists for further technical service.

Refrigerant leaks often occur. It is caused by the negligence and inexperience of installers. Due to a poor rolling connection, the freon simply comes out. If your air conditioner has run for more than one full season without problems, there is most likely no leak. If the operating life of the split system is shorter, then you should contact the installer. As a rule, experienced companies provide a guarantee for work for more than two years. If there is freon in the system, but there is simply not enough of it:

Pay attention to the radiator of the indoor unit. It freezes and becomes covered with an ice crust. A characteristic cracking sound is also possible when the air conditioner is operating.

A characteristic cracking sound is also possible when the air conditioner is operating.

Also pay attention to the radiator of the outdoor unit. It can also become covered with a fur coat of snow. Pay attention to the service taps of the street block. They can also become covered with frost.

They can also become covered with frost.

The installers came for scheduled maintenance of the split system in cold weather. Cleaned it and measured the pressure. It showed below. We decided to refuel. When tested, the air conditioner was working properly. But in the heat, the pressure increases, and the compressor simply choke. An overdose also happens when refueling without a pressure gauge, so to speak by eye. In such cases, independent repair is not recommended.

Reason #6. The air conditioner blows warm air. Complete absence of refrigerant

Everything is very simple here. Either there is a refrigerant leak or there is no refrigerant to begin with. Full filling of the unit must be done using scales (the exact weight is indicated on the cover of the outdoor unit), in order to avoid shortages and overdoses. Often, a lack of refrigerant in an air conditioner occurs when a company or installers try to pass off a used air conditioner as a new one. Very often such a story is found in chain stores of household appliances.

Also, the air conditioner may simply not cope with the given quadrature due to low power. But in any case, the temperature should drop, at least not by much.

| As a rule, the proper operation of an air conditioner depends 80% on proper installation, and only 20% is allocated for warranty cases. If your split system still does not cool the room, it does not matter! Just call us and we will advise you free of charge. | ________ |

| Name of works | Cost of work |

| 3'500 rubles | |

| 2'000 rubles | |

| from 1'000 rubles | |

| from 3'000 rubles | |

| from 4'900 rubles | |

| from 1'000 rubles |

Unfortunately, this type of malfunction is most often the result of improper care of the air conditioner. You need to regularly clean it of dust and dirt yourself, and also invite a professional to carry out a deeper and more complete cleaning, preferably once a year.

Cleaning your air conditioner in a timely manner is not too time-consuming or costly. But if this is not done, more complex and expensive repairs will be required.

Dirt in the indoor unit

The filter cannot completely protect the filling of the indoor unit from dirt and dust. Over time, they accumulate on the evaporator grille, fan, and walls. Because of this, the heat exchange between the freon and the air deteriorates. The compressor has to work harder to maintain the desired temperature.

Due to more frequent switching on and higher speeds, the refrigerant cools more strongly when boiling in the evaporator. Moisture condenses on dirty deposits and crystallizes. The resulting layer of ice is constantly increasing.

It is easy to determine that the evaporator grilles are dirty. To do this, you need to open the panel of the indoor unit and remove the mesh filters. You can wash the internal block of the split system yourself. The process is well described in this video:

The main reasons why an air conditioner does not cool the air well

- The air conditioner may not work well due to a dirty heat exchanger in the unit. Air conditioner parts become especially dirty during the poplar flowering period, when there is a lot of poplar fluff in the air. The air conditioner can also be damaged by street air that is too saturated with gases from vehicles, factories and factories. You can fix the problem by vacuuming the dirty parts with a special vacuum cleaner. You can also use a Karcher and wash the filters with water pressure.

- The fan of the indoor unit may become very dirty. The fan is also removed from the air conditioner and washed in soapy warm water. It dries and returns to its place.

- The air conditioner may not work well due to the lack or absence of freon. This problem can be eliminated by filling the device with a special product. This procedure should only be carried out by an experienced specialist who will select the most suitable method of refilling freon from the three existing ones.

- One of the air conditioner fans may fail due to a breakdown of the additional board or electric motor.

- The air conditioner does not cool the room well due to a breakdown of the four-way valve, which switches from cooling to heating mode. If it really fails, it needs to be replaced. Specialists can diagnose and replace it.

- The air conditioner may not perform its functions well due to a compressor failure. It may jam or short out. A relay or capacitor may also break. If there is a breakdown in the capacitor or relay, they can be replaced. If the compressor shorted, you will have to change the entire indoor unit. However, if such a breakdown occurs, the device simply will not turn on.

- Temperature sensors may begin to malfunction. They may show incorrect data. Because of this, the control board will not signal the system to turn on the compressor. If the cause is broken sensors, they should be replaced.

- Also, sensors may not work due to high or low pressure.

- The air conditioner may not work well due to a clogged capillary tube. To eliminate this malfunction, the capillary tube is cleaned using a press or a new one is soldered in. If the tube is clogged with condensation, it is cleaned by vacuuming. A characteristic sign of this malfunction is water dripping from the air conditioner (indoor unit) or suspiciously not dripping from the external one.

Now you know what causes low cooling efficiency of an air conditioner.

If the equipment is fully operational, but the room is as hot as always and the humidity is high, it means you have chosen the wrong model, and the air conditioner does not have enough power to cool a large room.

The most important thing to remember is that before you start repairing the air conditioner, it is important to diagnose its operation and determine the actual cause of the malfunction. Any climate system is designed to cool the interior of buildings in the summer heat, but service centers for such equipment quite often receive calls from users with the same question: why doesn’t the air conditioner cool? There are many reasons why a split system may not function properly, but in this case there are no more than a dozen of them, and we will try to talk about each in detail. Any climate system is designed to cool the interior of buildings in the summer heat, but service centers for such equipment quite often receive calls from users with the same question: why doesn’t the air conditioner cool? There are many reasons why a split system may not function properly, but in this case there are no more than a dozen of them, and we will try to talk about each one in detail.

Any climate system is designed to cool the interior of buildings in the summer heat, but service centers for such equipment quite often receive calls from users with the same question: why doesn’t the air conditioner cool? There are many reasons why a split system may not function properly, but in this case there are no more than a dozen of them, and we will try to talk about each in detail.

Condenser contamination

There is a capacitor on the back and side walls of the outdoor unit. Over time, its grates become clogged with dust, leaves, poplar fluff, etc. Because of the “coat” that has formed, the refrigerant in the condenser does not have time to cool down from the flow of external air.

To maintain the temperature you set, the compressor starts to turn on more often or increase its operating speed (depending on the model). When evaporating in the evaporator, it cools more than usual. Condensation freezes on the grates in large quantities. The defrost system does not have time to cope with it.

Important

If you are cleaning one of the blocks, do not forget about the second. This will not take much time, but will improve the efficiency of the air conditioner. The cleaner the evaporator and condenser, the less load on the compressor. And accordingly, its service life is longer.

Dirty condenser in the outdoor unit of the air conditioner, before and after cleaning.

A fur coat in summer is bad

In order for an air conditioner to work effectively, it must dissipate heat well through the outdoor unit.

A radiator is used for these purposes. Over time, it becomes dirty, dirt, dust, and poplar fluff settle on it. They create a kind of “fur coat”. Because of it, the radiator does not give off heat well and the air conditioner begins to cool the room poorly. The easiest way is to wash the radiator of the outdoor unit using regular dishwashing detergent.

Be sure to check if the fan is working. If it spins slowly or even stands still, then even a clean radiator will not be able to transfer heat. You can replace the fan motor, but it is better to call a specialist. You can find a good master on the portal for selecting private specialists.

High humidity

High humidity in the room is another reason for freezing of the evaporator in the indoor unit. The more water in the air, the more it condenses on the cooled metal. Accordingly, ice forms faster.

Most often, ice forms on the evaporator due to high humidity:

- In damp, basement areas;

- In the kitchen while preparing dishes;

- In rooms where air humidifiers operate.

It is difficult to determine what exactly high humidity caused the ice to form. Here is one check option:

- Turn off the air conditioner;

- Wait until the ice on the evaporator melts;

- Turn on the air conditioner in dehumidifying mode (Dry, Dehum, Dehumidify);

- Let it work for 5-10 minutes;

- Turn the air conditioner on cold.

If ice has stopped forming or is growing more slowly, the problem is high air humidity. There are three ways to solve this:

- Increase the temperature of the air conditioner;

- Eliminate sources of moisture;

- Use an additional dehumidifier.

If it blows cold

So, the air conditioner is configured and turned on to heating mode. After 5-10 minutes, warm air should blow from its indoor unit. But this doesn’t happen, what’s the matter? There are two reasons:

- The setup was carried out incorrectly, so try again to repeat everything that was done the first time.

- There is something wrong with the air conditioner itself.

If, after trying again to set the device for heating, nothing has changed, then you need to call a technician. The most common breakdown is a lack of refrigerant, that is, freon. This means that there is a place in the system through which freon leaks. It needs to be found and soldered. After that, refrigerant is poured into the air conditioner. It is impossible to do this with your own hands, because first of all, this requires special devices, plus the freon itself, which is located in the cylinder.

Not enough air

Insufficient air flow is one of the common reasons for the formation of frost and ice inside the wall unit of a split system. In addition to internal reasons, there are external ones. Namely, the wrong choice of installation location.

In any operating mode, the air conditioner draws air in at the top and blows it out at the bottom. To avoid obstacles, it is not recommended to hang the indoor unit close to the ceiling. There should also be no obstructions to the outgoing flow.

You will find the permissible distances in the documentation for your model. But experts recommend taking into account the power of the air conditioner and the height of the room’s ceilings. Below is the minimum distance from the ceiling to the indoor unit:

| Ceiling height | up to 12 thousand BTU | 12-18 thousand BTU | 18-30 thousand BTU |

| up to 2.7 meters | 7 cm | 10 cm | 15 cm |

| 2.7-3.0 meters | 10 cm | 15 cm | 20 cm |

| 3.0-3.7 meters | 15 cm | 15 cm | 20 cm |

| 3.7+ meters | 30 cm | 30 cm | 30 cm |

Using a screen for an air conditioner also creates problems for the distribution of cooled air. With a screen, the indoor unit should be located 5 cm lower than without it.

System clogged

Deposits may appear in the copper tubes of the freon line. They narrow their diameter in certain places, which causes pressure drops. Because of this, frost appears on the evaporator, the load on the compressor increases, and electricity consumption increases. Possible causes of clogged copper pipes of the air conditioner:

- Low-quality freon with foreign impurities is poured;

- Filled with cheap oil;

- Compressor oil mismatch with refrigerant;

- During repair or installation, foreign substances entered the system.

You won’t be able to check the condition of the freon pipeline yourself. You need to call a specialist. If there is a blockage, you can blow out the tubes or replace them with new ones. In this case, you need to replace the old oil and refrigerant.

Cooling circuit

Perhaps the only emergency situation in the cooling circuit should be considered depressurization, causing a refrigerant leak.

Since all elements of the system are connected by metal pipelines, it is almost impossible to ensure complete tightness of the circuit. At the junctions the so-called “normal” freon leak, due to which the air conditioner loses about 8% of refrigerant during the year. This situation does not pose a problem and only requires periodic refilling of the system with freon during regular maintenance.

In case of poor-quality installation, destruction of sealing and mounting parts (for example, when a crack appears in the nut fixing the pipe), or corrosion of lines, additional leak points appear. Freon consumption exceeds standard values, the air conditioner loses performance and temperature rise, parts freeze, etc.

It is difficult for the end user to clearly diagnose a refrigerant leak:

- He does not have the necessary equipment to assess the amount of freon remaining in the system. Indicators by which he can judge the condition of the circuit are the temperature of pipelines and radiators, pressure in the system. However, these measurements also require special instruments - at a minimum, thermometers and a pressure gauge assembly (manifold) attached to the surface, and skills in handling them.

- In some cases, the location of the leak can be judged by oil drips and dust accumulation, but this method cannot be considered reliable and works in all cases.

- Even if the loss of tightness is not in doubt, there is a problem with finding the specific location of the leak.

Various methods are used for this:

- Immersion in water;

- Using soap solution;

- Application of ultraviolet dyes and lamps;

- Work with leak detectors of various designs.

Eliminate refrigerant leaks in the following order:

Disconnect the split system from the network.- Conduct a visual inspection of the lines, paying special attention to joints, the quality of rolling and the integrity of the reinforcement.

- If necessary, search for places of depressurization (it may be necessary to remove freon from the system and pump it with nitrogen).

- Leaks are eliminated by replacing parts, soldering problem areas, cutting pipes at joints and re-rolling them. Work is carried out on a system without refrigerant.

- The circuit is tested.

- Perform vacuuming.

- Charge the system with freon.

If you have the necessary equipment, you can do all the work yourself. However, in the service center the repairs will be performed better and faster.

All necessary materials can be purchased at the same service center. They also provide equipment (vacuum stations, pressure manifolds, etc.) for rent.

Sensor (thermistor) failure

The temperature sensor in the split system regulates its operation. In inverter versions, it affects the speed of the compressor; in conventional ones, it affects the frequency and duration of its activation. In different air conditioner models there can be from 2 to 5 in each block. They measure temperature:

- Refrigerant;

- Air;

- Fan electric motors;

- Evaporator;

- Capacitor;

- Outside air;

- Compressor;

- Freon line.

To check the condition and performance of the sensors yourself, you need to measure their resistance at different temperatures. It must correspond to what is specified in the documentation. If there is no such data, you will have to look for the characteristics of the thermistor of the same model. You can also focus on similar air conditioners in the model range.

If you do not understand electronics and the workings of an air conditioner, it is better to call a professional. Checking temperature sensors is quite a troublesome task. A small mistake will result in unwanted costs for a new sensor.

How does drainage occur in practice?

A small sociological survey conducted among air conditioner users showed interesting statistics.

To the question where do you drain the condensate, the following answers were received:

- Just going outside – 68%;

- To the sewer by gravity - 16%;

- To a special drainage system – 8%;

- What kind of condensate is this? - 8%.

Let us explain the essence of liquid discharge for the unenlightened last category of owners of split systems. For those who do not know where the condensate formed in the air conditioner goes, it is useful to read the instructions for the device. It gives clear instructions for installing the drain outlet from the air conditioner unit.

The problem requires special attention in large private houses with several air conditioners in different rooms. An organized solution for condensate collection should be made at the design stage of the climate system

You should remember the peculiarities of climate control equipment that produces liquid not only during design and installation. It is also necessary to monitor the process of moisture removal when operating the air conditioner.

Covered valves

There are service valves on the outdoor unit of the air conditioner. Usually they are located at the bottom right, on the side wall (see photo). Through them, copper tubes are connected to the outdoor unit. Service valves are needed for any operations related to:

- Freon evacuation;

- Replacing the refrigerant;

- Disabling the external or internal unit;

- Operations with the freon line.

Location of service valves on the outdoor unit of the split system.

Sometimes after installation, repair or diagnostics, air conditioning technicians do not fully open the valves for maintenance. Because of this, the cross-section of the pipeline changes. Pressure drops result and freon cools greatly as it evaporates. Because of this, moisture freezes faster on the air conditioner evaporator. How to check that the cause of evaporator icing is in the service valves:

- Turn off the air conditioner;

- Wait until the ice in the indoor unit melts;

- Unscrew the service valves 2-3 turns counterclockwise;

- Turn on the air conditioner to cool.

If it has stopped freezing, the problem is solved. If it forms, but more slowly, unscrew the valves another 1-2 turns. Repeat the process until ice formation stops or slows down. If the evaporator still freezes, look for another reason.

general information

When users see frost or icing on the indoor unit, they often panic. Still would! Ice forms on the air conditioner right in their apartment or office, and then melts and flows down the walls.

We will surprise you if we say that sometimes a light veil of frost can form when the air conditioner is working normally. Of course, ice and water flowing down the wallpaper do not mean anything good, but light traces of frost do not always signal a breakdown.

Frost may form in the summer if the device is operating at full capacity. Defrosting will begin naturally when you turn off the air conditioner.

Light icing may also occur if you use the air conditioner in heating mode. If the frost is almost invisible and quickly thaws, and the condensate is easily removed through the drainage pipe to the street, then everything is in order and you do not need to worry.

Note! Frost or light icing can only be seen if you open the decorative cover of the indoor unit. In this case, frost forms on the evaporator. If you notice heavy icing and it is noticeable without removing the decorative cover, immediately call a technician from the service center!

Poor vacuum

When installing a split system, replacing the refrigerant and other operations with the freon line, it is necessary to evacuate it. This is necessary to remove air from the system into which freon will be pumped. If the line is not evacuated, air and moisture remain in it. This leads to a decrease in cooling capacity.

Refrigerant mixed with air is less able to remove heat from the room and releases it through the condenser. The compressor has to work more intensely, the temperature in the evaporator drops and ice appears on it.

The moisture contained in the air crystallizes into ice during operation. It settles on the walls of the system and reduces their cross-section. Ice flakes also damage connections and compressor parts. This leads to microcracks and shortens the service life of the air conditioner.

Reason. Are we in a hurry?

All air conditioners wait a very long time when the heating mode is turned on. Most models start the fan after 10-20 minutes. This feature is called "warm start". That is, the air conditioner first warms up the freon, and only then disperses it through the system. In models without this addition, things happen a little differently. Their startup time is approximately 0 to 15 minutes. The air is supplied, first cool, and then warmed up in the process. In simple words - turn it on, wait up to 20 minutes. If the air conditioner does not blow warm air or does not blow at all, move on to the next step.

Fan malfunction

The split system has two fans, in the outdoor and indoor units. The first is responsible for cooling the refrigerant in the condenser by driving a flow of air through its grille. The second provides cold air to the room.

The faster the fans run, the more efficiently the refrigerant cools the room. If the impeller in the outdoor unit does not rotate, or does it slowly, the freon transfers heat worse. The compressor has to work faster, the refrigerant in the evaporator is supercooled, which leads to icing of the indoor unit.

The fan in the wall-mounted air conditioner unit is responsible for airflow. It can cause ice to appear in two cases:

- When the air conditioner is in a humid room and the fan rotates quickly, a lot of air passes through the evaporator grille. Moisture settles on the surface of the grate and turns into ice.

- If the air conditioner is in a room with normal humidity and the fan rotates slowly, the air flow is too weak. The evaporator gets very cold and the condensate on it freezes faster than it can thaw.

You can determine the rotation speed visually. If the fan is spinning slowly, there are three possible problems:

- Insufficient voltage is supplied to the motor;

- The bearing is worn out;

- A blockage has formed at the junction of the shaft and the motor.

You can solve the problem yourself. You need to remove the unit panel and fan. Then assess the condition of the shaft and bearing. If necessary, clean them, lubricate or replace them. If this does not help, there are problems with nutrition. In this case, it is better to contact a specialist.

When freezing of the pipes of the outdoor unit of the air conditioner is not a breakdown

- Turning on the air conditioner for the first time after winter. Pipes often freeze when the split system is started for the first time after a long period of inactivity. Let the air conditioner run for an hour or two. Perhaps the tubes will thaw and will no longer freeze.

- A light layer of frost on the pipes. Let’s assume that the split system is working properly in all modes and there is no “fur coat” in the outdoor unit. A small layer of frost turns into weak condensation on the pipes during the “rest” of the air conditioner.

If you see a lot of ice in the external unit, or the presence of frost on the pipes is combined with poor cooling of the air conditioner, most likely it is a breakdown.

Clogged filter drier

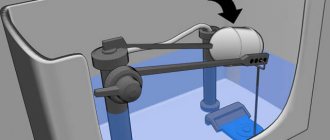

The filter drier is located between the condenser and the capillary tube. Its task is to draw moisture from the refrigerant and absorb it. It also traps impurities contained in the refrigerant and oil.

A clogged filter drier reduces the system's capacity. Because of this, freon circulates through it more intensively. The evaporator temperature drops and it becomes covered with ice. It is impossible to determine that the filter is clogged without dismantling it.

Important

Whenever working on the freon line, you need to check the condition of the filter drier. If you are refilling, replacing refrigerant or oil, you must change the filter.