Today, few people think about how to build a greenhouse with their own hands from wood and film - it’s easier to buy a ready-made greenhouse made of polycarbonate and metal profiles. But there are situations when such a solution turns out to be the most practical, functional and also economical. In this case, it is advisable to know which wood is best to use, what parameters to choose a film coating for, and how to assemble a strong and durable structure from them.

Film greenhouse for cucumbers Source ogorod.ru

Pros and cons of greenhouses made of film on a wooden frame

When deciding how to build a greenhouse with their own hands from wood and film, land owners are guided primarily by considerations of economy. This is truly the cheapest option available, especially if there is unused lumber left over after building the house and outbuildings. For the construction of a large-scale structure, there are usually few of them, it is a pity to use them for firewood, so it is logical to use them for the construction of a frame for a greenhouse or greenhouse.

Film, compared to other traditional materials - glass and cellular polycarbonate - is also much cheaper. But low cost is not the only advantage of wood and film shelter. There are other reasons in favor of their choice.

- Easy to install.

These materials are easy to work with, and there is no need to buy or rent special tools. A hammer, a hacksaw and scissors can be found in every home.

You don't need complex tools to work with wood Source rubankom.com

- Hassle-free transportation.

Wooden blocks and rolled film can be delivered to the greenhouse construction site by personal vehicle, which cannot be done with heavy metal profiles, bulky polycarbonate and fragile glass.

- Light weight materials.

Facilitates the installation process and eliminates the need for a foundation.

- Maintainability.

A broken stand or a film that has become unusable can be easily replaced.

A common drawback of materials is their fragility. Wood is susceptible to rot and attack by microorganisms and insects, especially in warm and humid conditions. It is highly flammable. But these disadvantages can be partially offset if the lumber prepared for installation is treated with antiseptic and anti-perforation agents.

Antiseptic impregnations will protect wood from rotting Source carrot.com

When thinking about how to build a greenhouse out of wood, you should not forget that to ensure the required strength, the posts and beams must have a fairly large cross-section, so they will cast a shadow.

Film coatings also cannot be compared with glass and polycarbonate in terms of mechanical strength and resistance to the destructive effects of ultraviolet rays. Their elasticity, which is a plus during installation, turns into a minus during operation: the material stretches and sag over time.

Factors such as the ability to accumulate electrostatic discharge and attract dust, which reduces the permeability of the walls to sunlight, are also not in favor of this shelter. As well as the accumulation of condensate on them, which is harmful to most greenhouse crops.

One of the main disadvantages of film greenhouses is the formation of condensation Source krrot.net

However, manufacturers of film materials have managed to create varieties that are devoid of these disadvantages or have them to a small extent. But they also cost more.

Glass

Glass belongs to the category of traditional materials for the construction of greenhouses. This material is durable and has excellent light transmission.

However, despite all its obvious advantages, glass has its drawbacks. It is heavy and fragile, breaks if handled incorrectly, and is also quite difficult to handle.

In addition, glass is an expensive material, but its service life is long; it can retain 1.5 times more heat than conventional polyethylene film.

In terms of its ability to transmit light and heat, glass still remains in first place, but it still retains this heat much worse than new polymer materials.

On a note!

During the construction of greenhouses, single, double and triple glazing is used. Many farmers even build greenhouses from glass bottles, but this looks more exotic.

Single glazing is the cheapest option, but it allows too much sunlight to pass through in the summer and does not provide the necessary thermal insulation in winter. That is why it is better to give preference to double or triple glazing, which filters more “harmful radiation”.

In winter, the greenhouse must create a comfortable microclimate necessary for the crops. The microclimate in the greenhouse is a very important factor because if the growing room is too hot or cold, the process of photosynthesis in the plants stops.

In addition, diffused sunlight resulting from the use of opaque, or “smoky” glass, has a beneficial effect on crops. The latter provides uniform lighting and also activates the process of photosynthesis in plants. This property is characteristic of the so-called milk glass.

With transparent glazing, crops located closer to the outer skin are better illuminated. They, in turn, shade the plants in the depths of the greenhouse. Therefore, the glazing must be of high quality, and when choosing between transparent and milky glass, preference should be given to the latter.

If funds allow, it is best to use safety or even vandal-proof glass. In this case, the structure will last for decades.

When glazing a greenhouse, some installation features of this material should be taken into account: for example, so that the glass roof does not experience overload from heavy rainfall in winter, the roof should be tilted at least 15°. Then the snow will flow freely from the roof without forming large snowdrifts, which are undesirable for a heavy structure.

The correct position of the glass greenhouse in relation to the movement of the sun will protect crops from overheating and burns.

Selection and preparation of materials

Both wood and film are different. Which material to choose depends on the budget of the building, its design and the desired service life. Since you can build a greenhouse with your own hands from wood for one season or for several years.

Simple designs are intended to protect young seedlings from spring frosts or to root cuttings. They are made small, light and mobile, and disassembled when the need for them passes.

Greenhouse for growing seedlings Source plodovie.ru

Such temporary shelters can be assembled from any remnants of bars and boards and installed directly on the ground - in a short time they will not have time to rot and collapse. But if you need a full-fledged greenhouse in which you can arrange beds, provide water for irrigation and even heating, then you need to use high-quality materials.

Lumber

You can get a strong and reliable building that will last for several years without repair if you use dense wood that is resistant to rotting. The most suitable species are larch, oak, beech, and teak. But their use will destroy the idea of creating a cheap greenhouse, since such wood is not cheap, and it is difficult to work with.

Therefore, the best option would be lumber from coniferous species - spruce and pine. Moreover, pine is preferable - it contains more resin, so it resists putrefactive processes better and longer.

Regardless of the type of wood, it is advisable to choose lumber that meets the following requirements:

- absence of visible traces of rotting and damage by microorganisms;

- absence of deep cracks and a large number of knots;

- maximum wood moisture content is 20%.

The reliability of the frame depends on the quality of the lumber Source jsm.lt

Advice! For load-bearing elements of a greenhouse frame up to 3 meters wide, pine beams with a cross-section of 50x50 mm are suitable. Beams and racks of more massive structures must have a cross-section of at least 80x80 mm.

Before making a greenhouse with your own hands at home from wood, all elements must be treated with antiseptics and dried.

Film

The cheapest and most popular material for creating temporary shelter for plants is plastic film. It is not durable and breaks easily, and the break instantly spreads, which requires replacement of the coating. But even if you managed to install it without tears or cuts, it will still not last long - a maximum of one season before the onset of cold weather.

The heat-saving properties of polyethylene shelters are also not at a high level: during night frosts, they release all the heat accumulated during the day.

Polyethylene film is produced in the form of a single-layer sheet or sleeve with a width of 120 to 300 cm Source vdom36.ru

See also: Catalog of companies that specialize in the design and installation of greenhouses and winter gardens

Until recently, there was practically no alternative to it. But now you can buy materials whose performance has been improved by introducing special additives into polyethylene.

- Stabilized film is several times more resistant to ultraviolet radiation than regular film. Outwardly, they are indistinguishable; such material can be identified by its markings and higher cost.

- the heat-retaining film retains heat much better, has hydrophilic properties, and does not attract dust. But it doesn’t last longer than regular polyethylene.

- The hydrophilic film does not allow drops of condensation to form on the surface - moisture settles on it in a continuous thin layer. In addition, it has high light transmittance.

- Light-converting film with phosphor additives converts ultraviolet radiation into red and infrared radiation that is beneficial for plants.

When ultraviolet rays hit the material, the light-converting film changes its color to reddish Source insales.ru

Advice! When deciding how to build a wooden greenhouse to get the earliest harvest, you can cover it with plastic bubble wrap. Due to the air-filled cells, it retains heat perfectly, practically not inferior in this characteristic to cellular polycarbonate.

All of the materials listed are not strong enough to withstand severe mechanical and wind loads and sub-zero temperatures. They are good for seasonal structures. For the winter they are removed from the frame, and in the spring they are covered with a new film.

Reinforced and polyvinyl chloride films are more resistant to the listed influences. They can last 2-3 years without replacement or removal for the winter.

- Reinforced films.

They are also made from polyethylene, but they are stitched with a kind of frame made of fiberglass or polymer threads, which can withstand significant snow loads and resist wind and hail well. In the event of a rupture, it is limited to the walls of the cell and does not spread further, which makes it possible to repair the coating by sealing the hole with tape.

Reinforced film for greenhouses Source td-set.ru

Dense material in not too harsh climatic conditions can last 5 years if the greenhouse design is designed correctly and snow does not linger on the roof slopes. But its light transmission is low, and it is more difficult to wash off dust from the surface due to the relief created by the frame.

- PVC films.

This is the most expensive, but also the best material in terms of durability, light transmission and heat conservation. It contains stabilizing additives and light transformers. Can last more than 5 years if properly installed and well maintained. Disadvantages include an increased ability to attract dust and instability to frost. But any contaminants from such a surface are easily washed off, and frosty fragility can be leveled out by heating. Therefore, PVC film is usually used to equip winter heated greenhouses.

On a note! Any film becomes cloudy over time and transmits light less well. Therefore, it is recommended to change it at least once every 3 years, even in the absence of mechanical damage.

PVC films are stronger and more elastic than polyethylene films Source tdk-minsk.by

Film

This material is easy to use, quite durable, has a low cost, but, unfortunately, is short-lived. There are several types of film that is used to cover greenhouses and greenhouses.

Polyethylene film

This film is often used to cover cultivation areas due to its low cost, ease of handling and high light transmission. However, ultraviolet radiation and solar heat, as well as exposure to wind, rain or hail, significantly reduce its service life. Such a coating can last no more than 4 months. Recently, higher quality analogues of conventional film have appeared - with polymer additives.

Expert advice

When choosing a suitable polyethylene film, in most cases preference should be given to reinforced film - light, durable, easy to use and not requiring large material costs.

Hydrophilic film

The surface of such a film is much less contaminated than the surface of a regular polyethylene film. However, the main difference between this material and a simple film is that all the water that evaporates eventually accumulates on its surface and flows down again, creating a humid microclimate in the greenhouse. Such conditions are beneficial for some plant species. The service life of the hydrophilic film is 2-3 years.

Light stabilized film

This is a polyethylene film with the addition of a light stabilizer concentrate. It is much more resistant to ultraviolet rays and converts them into infrared. Thanks to this, its energy efficiency increases. The service life of such film is significantly longer and ranges from 2 to 5 years. Light-stabilized film can be painted in any color and even left for the winter.

Heat retention film

Such a film, unlike conventional polyethylene film, allows you to increase the temperature inside the cultivation room by 1-2 °C. Heat-retaining films include multi-layer air bubble and foam films, which are able to regulate the air temperature in an enclosed space, increasing it at night and decreasing it during the day.

PVC film

This material is smooth, transparent and thermoplastic. It is very strong, micro-permeable, heat-resistant and durable. The service life of PVC film is usually 4-5 years.

Design selection

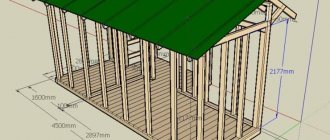

The first thing they do before building a greenhouse with their own hands from wood and film is drawings of the future structure. To build them, you need to choose the shape of the structure and its dimensions.

To optimize costs and not waste money on unnecessary materials, sizes are selected in accordance with the standard length of lumber and the width of the film. As a rule, bars and boards are 6 meters long, so the optimal dimensions for a wooden greenhouse will be:

- 2x4 m;

- 2x6 m;

- 3x6 m;

- 3x12 m, etc.

The height of the side walls is 1.5 or 2 meters.

How to make frames, doors, transoms

Transoms, frames and doors that are used for service and ventilation can be glazed or covered with film. They may consist of one or more cross bars, crossed slats or cells.

The design and size of doors and frames depend on the type of greenhouse and its size. It is important that frames with a large number of cells are quite difficult to manufacture, and they do not have high strength. The optimal frame size is 130-150 x 70-80 cm with cells measuring 60-80 x 30-50 cm. The size is selected in accordance with the overall size of the greenhouse frame. An example of making a transom for a greenhouse is shown in Figure 8.

Frames, doors and transoms are made from square-section wooden slats, which are additionally processed with a planer. The corners are tied or connected with nails, screws or glue. Metal corners provide additional strength to the structure.

Figure 8. Drawing and example of manufacturing a transom for a greenhouse

Frame bonding with glue will be very strong if you use synthetic resin glue. They are not susceptible to fungus and moisture. However, it is important to consider that when gluing the parts, they must be dry.

When making frames, you need to determine in advance what type of coating you will use. For glazed greenhouses, grooves need to be made in the frames, but if the structure is covered with film, they will not be needed. In order not to make grooves, you can simply attach slats of a smaller cross-section to the finished frame.

It is also necessary to mark places for attaching the hinges. Try to drill the holes for the hinges to the same depth so that the greenhouse can be tightly closed.

Video description

For example, you can take the project from this video, which shows how to build a greenhouse with your own hands from wood - the drawing illustrates all the dimensions step by step:

The characteristics of wood do not allow the construction of arched structures from it, although this is possible if desired, but it will require more time and effort. However, preference is given to direct forms. Single-slope and gable greenhouses with vertical or inclined walls are built from this material.

- Single-pitch structures can be free-standing, but most often they are attached to the wall of an existing permanent structure. This makes it possible to save space on the site and conduct water and heat from the house into the greenhouse, minimizing communication costs.

It is recommended to attach a wall-mounted lean-to greenhouse to the southern wall of the house Source 7dach.ru

- The gable structure with straight side walls looks like a house. This is the most popular and easy-to-make option for making a wooden greenhouse with your own hands.

- Structures with inclined side walls diverging outward are closer in their characteristics to arched greenhouses. They have more space for growing plants than a rectangular structure.

- Round-shaped buildings are less common - they serve a decorative rather than a utilitarian function.

Types of wooden greenhouses Source ibb.co

Video description

This video explains how to build a Mittleider greenhouse:

If you are planning to acquire a year-round heated greenhouse, you can take as a basis a project whose feature is to be buried in the ground to the full height of the walls. Only the gable roof of the structure rises above the ground.

In-depth greenhouse-thermos Source teplica-exp.ru

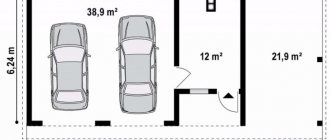

At the design stage, it is advisable to think not only about how to make a wooden greenhouse, but also about its internal contents. The number and width of the beds depend on the dimensions of the building. If it is up to 3 meters wide, you will only get two side beds and one central passage. With a width of more than 3-3.5 meters or more, you can arrange two aisles and an additional bed in the center for the tallest plants.

Main stages of construction

Like any other building, a greenhouse consists of a base on which rests a frame lined with covering material. The design provides openings - a door to enter the interior and vents for ventilation in hot weather.

We'll tell you how to make a greenhouse with your own hands at home from wood step by step.

Base

Wood is very susceptible to rotting in a humid environment, so you cannot install the frame directly on the ground. This is only permissible when constructing small temporary greenhouses. In all other cases, a foundation is required.

This can be a strip or column foundation, as well as metal supports driven into the ground, to which racks or horizontal piping are attached.

- Strip foundation.

Foundation made of concrete blocks Source mosteplitsy.rf

Why is it beneficial to use wood?

If you choose the right treated wood, then it is no worse than other materials. Its advantages:

- Environmentally friendly material;

- As a result of exposure to high temperature or ultraviolet radiation, it does not emit toxic substances;

- Installation is carried out using carpentry tools;

- The design is lightweight but sufficiently durable;

- It is easy to replace any damaged part;

- Usually you can add new rooms or shelving, shelves for tools, placement of seedlings;

- It features reduced costs compared to agrofibre, metal, and double-glazed windows.

Video description

How to assemble a wooden frame is shown in the following video:

- To build a “house”, vertical posts are installed on the base or lower frame along the entire perimeter in increments of 1-1.2 m. They are secured by cutting or using metal corners.

- The racks are fastened to each other with an upper frame, and to give rigidity, the corner racks are supported with struts.

- Rafters are mounted above each pair of racks, choosing a slope in accordance with the snow load of the region.

- Door and window frames are assembled separately and hung on hinges.

Coating

When covering the frame with film, it is secured through overlays - thin wooden slats, strips of rubber, linoleum, packing tape, etc.

The film on the roof is fixed through shingles Source maja-dacha.ru

The material is stretched well, and if there is insufficient width, an overlap is made, fixing both canvases on one frame bar.

Briefly about the main thing

Wooden film greenhouses are gradually being replaced by polycarbonate structures, but are still used by many summer residents as the most economical and easy-to-make shelters for heat-loving plants.

In order for them to serve for a long time, you need to know how to make a greenhouse out of wood correctly. To do this, choose high-quality lumber and protect it from rotting with special means. The choice of film also matters: polyethylene is used as a temporary seasonal shelter, and winter greenhouses are covered with reinforced or polyvinyl chloride films.

Construction begins with the construction of a base, on which the frame is installed and covered with film, taking precautions and preventing breaks.

Features of greenhouse finishing

If you want to make the greenhouse beautiful, then it is recommended to treat its wooden elements on the outside with breathable facade paint. We are talking about a water-dispersed color emulsion.

Paint can be applied at temperatures above three degrees Celsius. Only under such conditions does the coloring composition dry within two days, and then crystallize within three days.

However, many gardeners say that there is no particular need for paint. It will not improve the functionality of the greenhouse, but will only give the building an attractive appearance.

As a result of special processing, the wood is covered with a protective film

When you want to achieve both attractiveness and durability of the greenhouse frame, you should use wood impregnation. This product has a pleasant color, protects the wood from damage by bacteria and insures it from rotting.

It is recommended to treat wooden elements both outside and inside the greenhouse with impregnation. In order for the product to be useful, it must be applied to the surface in 2 or 3 layers, which depends on the financial capabilities of the owner of the building.