You can buy any thing in modern stores. With a little imagination, a mouse and keyboard with Internet access, your computer will be flooded with a huge number of offers from social networks and online stores. It also happens that the financial situation is not the best, and purchases in online stores are considered elements of luxury. And sometimes you just want to do something with your own hands, they just itch. Here we have a small selection of examples of how you can make some furniture with your own hands.

Pattern with detailed dimensions for children and adults

To make a pear chair you will need to make a pattern.

You can draw it yourself or find a ready-made version on the Internet. The pattern is drawn on graph paper. And then it is transferred to the fabric. The parts are cut along the contour.

Attention: when transferring the pattern to the fabric, do not forget to leave allowances of a few centimeters on each side.

The pattern of a chair for an adult will consist of the following parts:

- 6 pieces of wedge-shaped parts, 15 cm wide and 40 at the ends, with a diameter of 50 cm and a length of 130 cm;

- diamond-shaped top 15 cm on each side;

- The bottom is diamond-shaped, 40 cm on each side.

The pattern of a chair for a child will consist of the following 6 wedge-shaped parts:

- height – 90 cm;

- diameter – 45 cm;

- width – 40-22 cm.

The bean bag chair consists of:

- Internal zippered cover filled with polystyrene foam. Here you should choose thick cotton or raincoat fabric.

- Outer cover. Suitable for manufacturing: corduroy, leather, velor. You will need to sew a 1 meter long zipper onto the removable cover.

How to weave an original model?

A hanging chair made from a gymnastics hoop, created using macrame, will be an excellent option for a nest chair for the country house. For a chair made using macrame, you need to prepare two hoops with a difference in diameter of at least 30 cm, and more than 3 cm in girth. The hoop must have a metal base. You will also need thick clotheslines, a cord for braiding, two rods (if you need a “nest”, then there will be at least 6 rods, the joint winding of the hoops is replaced by fixing the hoops with a thick braid at the same distance), an awl, a tape measure, PVA glue, gloves, tape measure, weights for the canvas, decorative elements as desired.

The rope for making must be strong and smooth. The ends of the thread can be melted or coated with glue to prevent the edge from unraveling. The seat is made using a hoop of smaller diameter. Cross weaving is used with an upper transition over the 1st and a lower transition under the 2nd main thread, with a further upper transition over the 3rd and a lower transition under the 4th thread.

The finished seat will need to be braided with lace along the ends and tightened with knots. The same cord secures a hoop with a larger diameter, a distance of at least 15 cm.

The backrest is placed opposite the winding; the rise of the backrest is attached with rods. Its height is adjustable as desired. The rods are secured with braid. Next, the hoops are connected with Herculean or square flat knots.

You can use decorative elements to decorate the chair. Fringe is made from loose threads. The finished chair is connected to slings. On the front part the line flow will be wider than on the back.

Step-by-step instructions for reupholstering a chair with your own hands

Reupholstery of upholstered furniture begins with complete disassembly of the product and inspection of existing damage. Afterwards, the soft filler and fabric are measured, cut, and secured. The structure is assembled and decorated at your own discretion. Before starting work, it is recommended to read the instructions on how to disassemble and upholster the chair step by step.

Disassembly

Most old chairs are made of wood or from materials such as chipboard, and the fastenings are made on a tongue-and-groove basis, using steel corners, self-tapping screws, and wood glue. To disassemble the product, place it on its back, unscrew the legs and armrests. Next, disassemble the bottom, removing staples and other fasteners from it. Then the upholstery is removed as carefully as possible, which needs to be detached without damaging it, since it will be needed to cut out a new cover.

Assessment, damage correction

When the product is completely disassembled, all parts are disconnected, the fabric is removed, a thorough examination is carried out for cracks, chips, and joint defects. If such are found, they are dealt with first - broken parts are replaced with similar, homemade ones, loose connections are replaced. You also need to evaluate the condition of the padding - when the soft surface has serious unevenness, the material is torn or crumbles, it is removed, and a new one is nailed into the vacant space with staples. To make the edges look aesthetically pleasing, the corners of the foam rubber are cut off and something like a chamfer is made along the edge.

Cutting and attaching new fabric

The chair must be covered with properly cut material. Its quantity is calculated based on the perimeter of the back, seat, height of the filler, a few centimeters of hem on the back side of the structure. After measuring the product, a piece of fabric of the required size is selected. The standard fabric width is 140-150 cm, the length depends on the size of the chair, the height of the backrest, and the number of parts. If the structure is folding, a small allowance for unfolding is also necessary.

The standard set of elements is something like this:

- the front part of the backrest and seat are sometimes made in the form of a single piece;

- back surface of the back;

- armrests – internal, external parts;

- a narrow strip along the bottom;

- Some designs require the presence of side parts for armrests and backrest.

All fabric parts are pinned together, tried on a chair, and if necessary, the patterns are slightly adjusted. Next, the elements are sewn down on a sewing machine, the finished cover is put on the chair, pulled tightly, and secured with staples in inconspicuous places. If the work is done manually, use a “sail” or “denim” seam. If you have an overlocker, all seams are sewn over it - this will make the upholstery denser and prevent the joints from unraveling.

Assembly, decor of the updated product

The most difficult thing to assemble is a folding chair, since you will have to carefully fasten the moving mechanisms without losing the bolts or putting the part upside down. If the mechanism creaks or jams, lubricate it with machine oil. At the same stage, wooden parts are processed - they are sanded, tinted with stain, and varnished. The legs and wooden armrests are screwed in at the very end.

Pillows are most often used as decoration. They are sewn from the same fabric as the upholstery, made contrasting, decorated with embroidery and appliqué. If a product has many wooden parts, they are hand-painted and patinated.

Features of a shell-type chair

When making a shell, you will need skill in using a jigsaw, the ability to transfer the dimensions of parts from drawings to the material, and experience in deforming plywood in order to bend it in the correct shapes and directions.

Note! When cutting out parts, it is important to achieve smooth movements of the jigsaw, which is quite difficult for an untrained person.

When making a shell chair without experience working with bent plywood, you can use pieces of scrap wood to train your hand for practice. To fasten the parts of such a chair, wood glue is mainly used, and clamps are used for fixation. You can use self-tapping screws as fasteners, but in this case you will have to drown their heads in the wood fibers.

Once the bent plywood shell chair is fully assembled, all bumps and chips are sanded, after which the surface is cleaned of dirt and dust. To give the product an aesthetic appearance, it is coated with several layers of varnish.

Advantages and disadvantages

Hand-made reupholstery of home and office furniture has many advantages:

- significant budget savings - it’s easier to buy a couple of meters of textiles and a piece of foam rubber than a whole new chair;

- creative process - independently remaking even the simplest, nondescript chair will help you feel like a real master;

- the possibility of updating the interior - a freshly redesigned chair will be designed exactly as its owner intended;

- A quality restored product will last for many years.

There are also several negative points:

- the product will be very different from the store one - this matters if you want to create a specific model, but the skills are not yet enough;

- the labor-intensive process - if the chair is badly damaged, not only the fabric is replaced, but also the “filling” - foam rubber, springs, while completely disassembling it;

- For work you will need some tools that are not available in every home;

- You will need to organize a workspace, which will then have to be thoroughly cleaned, since the restoration process is quite dusty.

Finally about the unusual

However, cardboard is very useful in creating chairs. For example, for modeling unique chairs, pos. 1 in Fig. Sheets of cardboard are glued together to the thickness of the chosen plywood or board, cut into blanks and assembled from them into a model, which, of course, cannot be sat on. After fitting, the model is disassembled and a set of templates for cutting the base material is obtained. True, although it is not difficult to fill the gaps of the skeleton with polystyrene foam or polystyrene foam, in order to cover such a chair with soft material and trim it with decorative fabric, you need to be a cutter and an ace seamstress.

Unusual homemade chairs

Armchairs made of felt or overcoat cloth, pos. 2, covered with foam cubes (the seat is supported by a hidden plywood insert), pos. 3, or water pipes, pos. 4, already require more invention than high skill. Felt and tubular, of course, will cost a pretty penny. But a chair made from cubes can be made even by less than adult craftsmen and craftswomen. And a hand-made chair for my mother’s birthday – it really couldn’t be cooler.

In general, the chairs, even without reaching complex representative ones, give scope for creative self-expression like few other pieces of furniture and homemade products in general. So, since the chairs are on the way, create, invent, try!

Styles

Any piece of furniture should not only be practical, comfortable and safe, but also harmonize with the surrounding interior. You can make a chair with your own hands in any style. But the most popular directions are:

- Loft. This style refers to industrial and industrial. It is characterized by the use of natural and safe materials.

Therefore, the chair must be made of wood, metal or textile. For upholstery, it is recommended to use coarse fabric, such as linen or burlap in gray, white or bright colors.In this direction, chairs made from pallets will look harmonious, as they are distinguished by speed of production, minimal costs and exclusive appearance. Furniture made from profiled pipes also looks good in the interior.

- Provence.

This direction came to us from sunny France. Provence is associated with wheat, poppies, and lavender fields. Natural and safe materials and simple designs are appropriate here. The frame of the chairs is made of natural solid wood. Suitable upholstery options include linen, cotton, and chintz. Their color scheme should be colorful and bright, for example green, turquoise, red, purple, or soft and neutral - the color of fresh milk, golden fields, sandy beaches. A good choice for Provence would be wicker chairs made of rattan or wicker. Forged furniture items will also look beautiful here.

Attention: in the Provence style the use of modern furniture is not allowed. It should have an aged appearance, which can be achieved with patina.

Regular stool

Before the invention of stools, people sat on the ground. It was the first piece of furniture that Homo Sapiens invented.

An ordinary stool has a simple structure. Consists of four legs of equal length and the seat itself. Sometimes, for reliability, closer to the bottom, the legs of the stool are connected to each other with wooden slats. The stool has no back and armrests. Includes seating for only one person.

If you rarely cut plywood, practice on an unnecessary piece, so you will not only get used to the jigsaw, but also decide on the cutting speed.

There are also stools with three legs. One of the most famous three-legged specimens is considered to be Alvar Aalto's stool.

In Moscow there is a museum dedicated to the history of furniture, in front of which there is a monument to a stool, which is considered the ancestor of all furniture art.

To make furniture with your own hands for the first time, you need to put in maximum effort, endurance and patience.

Tools and materials

You can make good and comfortable chairs with your own hands using different materials.

The chair can be built not only from profile boards, bars or metal, but also from barrels, tires, tires, polypropylene and PVC pipes.

The most commonly used materials for the manufacture of the frame base of chairs are:

willow vine is a beautiful material that is afraid of moisture;

To make a chair yourself, you need to stock up on all the necessary materials and tools. If you plan to make a frame-type structure, you will need the following devices:

- drill;

- a sheet of sandpaper;

- jigsaw;

- pencil and ruler.

Materials that will be useful:

- lumber (most craftsmen prefer 20 mm plywood);

- screws;

- thin nails;

- foam rubber and upholstery material for furniture structures;

- special wood glue;

- stain;

- high quality glossy paint.

They also require different tools and materials.

Tools that will be useful:

- chalk, pencil and ruler;

- sewing machine;

- pins and scissors;

- thread and needle.

The materials you will need are:

- material that will be used for the internal and external covers of the chair;

- suitable filler (home craftsmen often turn to inexpensive foam rubber);

- 2 zippers: with a length of 40 cm and 1 m.

Also, to carry out various works you will need the following tools:

- drill;

- hammer;

- compass;

- meter;

- screwdriver;

- self-tapping screws

Let's consider what types of upholstery are the most popular and relevant.

Faux suede. A beautiful looking material that does not require complex and constant maintenance. The main advantage of artificial suede is its breathability, wear resistance and durability - it is not so easy to tear. In addition, such upholstery will not fade from light.

Preparing for work

The main component in the preparatory stage is the presence of a list of tools and materials that should be in the master’s arsenal.

Necessary materials:

- “Dowel” (24x60 mm) made of cedar – 30 pcs.;

- Brass screws - 4.5x50 mm and 4.5x32 mm, 20 pcs.;

- Sandpaper;

- Thermostatic glue;

- Furniture varnish for coatings;

- Drying oil;

- Masking tape;

- Cardboard for stencil.

After preparing the materials for the wooden chair, you can begin directly assembling the product.

Required tools:

- Saw (circular);

- Plane;

- Manual frezer;

- Wood hacksaw;

- Screwdriver;

- Drill;

- Clamps;

- Ruler, tape measure, pencil.

Tools for work.

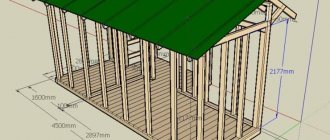

A preliminary calculation of measurements for the components of a cedar wooden chair is as follows. Dimensions are indicated in millimeters.

- Legs 4 pcs. (rear 2 pcs., front 2 pcs.)

- Two front legs – 20x254x787;

- Two rear legs – 20x76x533.

- The back of the chair is 20x279x914.

- Chair armrest:

- Support - 2 pcs., (20x127x406);

- Rear support – 1 pc., (20x76x610).

- Jumper – 1 pc., (20x51x589).

- Insert strips – 2 pcs., (12x20x254).

The parts that make up a garden chair.

Features of the material

The features of making furniture from natural wood include:

- Naturalness and safety. Wood does not emit toxins that are harmful to human health and does not cause allergic reactions or irritations.

- Resistance to mechanical damage. Wood products do not deform during use. They are quite difficult to damage, deform and scratch.

- Long service life. Solid wood furniture will serve its owners for several decades, delighting them with high technical characteristics and original appearance.

- Maintainability. If the product is damaged during operation, it can be restored, and the unusable part can be replaced with a new one.

- Versatility. A wooden chair will harmoniously fit into any interior, both classic and modern.

But in order for natural wood furniture to really be of high quality, you need to be able to choose the right consumables. The most popular types of wood are:

- Pine.

It is distinguished by a pleasant light shade, ease of use, and beautiful texture. Its aroma has a beneficial and relaxing effect on people. The advantages of pine include its lightness and flexibility in processing. Furniture products can be given absolutely any shape and design. The only drawback of pine is its fragility. But with proper care, a pine chair will last for decades. - Oak. This material is considered elite. Products made from it are massive, wear-resistant, and durable. Oak comes in red and white. The first option looks very elegant and exclusive. The disadvantages of this type of wood include high cost and difficulty in processing. Without certain skills in making furniture, you are unlikely to be able to make a chair from solid oak.

- Walnut.

This wood has a unique texture. The dark brown shade of wood will harmoniously fit into classic motifs. Despite the roughness of the material, working with wood is quite easy. Its advantages include durability, strength and reliability. - Ash.

Externally, this type of wood is similar to oak. But it is easier to process and has an affordable price. Its color can be pale or rich yellow-brown. A distinctive feature of ash is its flexibility. Keep in mind that ash furniture is not suitable for outdoor use. Since its surface is practically impossible to treat with an antiseptic, and it reacts poorly to negative environmental factors. - Alder. It is quite common and in demand in the manufacture of armchairs and chairs. This wood is resistant to moisture. Alder furniture lends itself well to processing, sanding and painting.

Advice: professional furniture makers note that the ideal materials for making a chair are: oak, birch, ash and alder. Since these materials are unique and have a unique texture. They do not crack, do not creak during operation and are distinguished by high technical qualities.

What type of wood to choose is up to you. When choosing a material for making a chair, it is worth considering that the working surface should be free of knots, cracks, visible chips, rotten spots, and traces of pests. In addition, the selected lumber must be well dried.

What is undesirable

Simple homemade chairs are enough; as you can see, there are many. But there are structures that it is better not to tackle, no matter how much desire or skill you have. This is, firstly, an office chair. The requirements for its ergonomics are radically different from those for a home for relaxation: it should create comfort that is not relaxing, but maintains performance for a long time. Technologically, this is achieved by using complex-shaped parts made from high-quality materials. And their production, in turn, requires industrial conditions with equipment for pressing and stamping, for plastic casting, TIG/MIG welding, etc. In addition, a gas lift, when purchased individually at retail, can be more expensive than a finished chair; Gas lifts are already made by machine-building enterprises with equipment for precision metalworking.

Note: a computer chair differs from an office chair essentially only in name, and everything said above applies to it in full.

Secondly, the chairs are made of cardboard. Packaging cardboard with internal corrugation is a wonderful material in many respects and finds the widest application. But not for chairs. In principle, building a chair from cardboard is not so difficult, see figure, and its overall strength will be very high. But - alas! – even cardboard reinforced in any way easily crumples at the end and the seat of the chair will sag very soon. And a push with anything hard, even a vacuum cleaner, will leave an irremovable dent.

Stages of making a chair from cardboard

Model selection

Furniture products made of wood differ in design solutions, design style, the presence of additional elements and functionality.

Products are divided into models:

- with frame and solid elements;

- with fabric upholstery and filling.

Models with a rigid structure are durable, reliable, and optimal for everyday use. Wood products of various configurations are placed in guest rooms, bedrooms, and work rooms. A handmade antique chair will highlight the interior. The armrests and backrest can be decorated with gilding, carving, aging and decoupage techniques.

Wooden upholstered chairs are comfortable and aesthetically pleasing, but require regular maintenance. Products are placed in recreation areas, dining rooms, and children's areas. The models are equipped with a durable frame; the upholstery can hide the product completely or individual elements (armrests, backrest, seat). For teenagers, it is optimal to make the back and armrests hard, leaving the seat soft. The height of the filler varies; for soft flooring it is necessary up to 3-5 cm, for medium density – 2-4 cm.

According to their design, the chairs are divided into:

- folding;

- sliding;

- Kentucky;

- with a high back;

- rocking chairs, etc.

Folding structures are ergonomic, easy to move, and multifunctional. The products are equipped with a folding system, metal brackets, and springs. Furniture can be easily transported to a country house or to outdoor events.

The configuration of the Kentucky chair is original and easy to manufacture. The product is made of durable wood and metal brackets and does not have fabric inserts. The lightweight design is optimal for installation under trees in the country.

Designs with high back support are made solid or padded. A throne chair made of wood looks harmonious in classical and Gothic interiors, Rococo and Baroque styles.

Types of chairs

If we talk about the types of chairs, they are usually:

- With solid construction;

- Soft;

- Semi-soft quality;

- In the form of rocking chairs.

In the first case, all elements are first manufactured separately. Then they are processed by making holes and applying paint or varnish. What is noteworthy is that chairs with a solid structure do not require upholstery material.

The soft type is completely upholstered in material and looks good in a home interior.

The version of the semi-soft chair must be made with a pair of armrests. They should have upholstery fabric, as well as internal padding where the back, seat and possibly armrests are located. Such models are convenient to use for the garden.

A universal option is a swinging chair, which can be placed both in the room and in the garden or on the terrace.

How to make a rocking chair with your own hands

The selection of high-quality material determines how high-quality and durable the chair you make will be. After all, the material should be light and durable, since the owner of this chair may get used to carrying it around. Those who do not want to pay a lot of money for such a thing ask themselves how to make a rocking chair with their own hands at home, choosing the most suitable and high-quality materials. Therefore, when selecting materials, we recommend making a rocking chair from wood, reed, or wicker. Also, sometimes the chair is made from light metals.

A rocking chair is the perfect way to create an atmosphere of comfort and tranquility.

Plywood rocking chair

Plywood - Can fall apart due to water, but is an excellent option for creating a chair. Because of this, many are interested in how to make a rocking chair with their own hands, drawings from plywood. We recommend making such chairs for your home or apartment. Therefore, if you want to make such a chair, then you should carefully monitor it if it is in the yard.

A rocking chair made by yourself in a classic style with curved runners will be an excellent option for your first experience in making furniture.

To create a simple and comfortable rocking chair, you need to prepare:

- For the sides: plywood sheets (1200x1400 mm, a moisture-resistant type of plywood would be an excellent option) 30 milliliters thick;

- For the base: 3 boards (20x150x800 mm);

- For sitting: 32 small boards (15x39x1200);

- Portable router;

- Screwdriver;

- Electric jigsaw;

- Portable electric grinding machine;

- Self-tapping screws (20 pieces);

- Wood glue;

- Putty;

- Varnish.

Making a rocking chair with your own hands is not at all difficult; a minimal set of tools and a great desire are enough.

Sidewalls

To begin with, the side parts are prepared, which are also the runners, as well as the base for the chair. Two parts are cut out with a jigsaw.

To begin with, let's draw out 2 sides of the chair using the template and carefully cut them out according to the markings with a jigsaw.

Frames

With this action, they are created with markings on the sidewalls, which are drilled (20x150x800 mm). One of the main conditions for this operation is its accuracy. After this, grooves are made that correspond to the grooves of the jumpers. They are 5 mm deep. Before installing the frames, coat these holes with glue. To prevent the material from bursting, holes are made in advance.

All edges of the parts must be sanded with sandpaper.

Boarding

Mark the holes in the planks (15x39x1200) that make up the seat. Mark 20 cm from each edge, draw lines where the screws will be fixed. The distance between parts is 1 cm.

We glue the supports to the side walls with wood glue and, for reliability, secure each of the bars with a self-tapping screw.

Finishing elements

It is made with putty dissolved with sawdust, the holes where the boards were attached are hidden, and the surface is leveled. Sand after the putty has dried. Then they are varnished with water, after which a mattress or carpet can be placed on the chair for comfort. It is better to do this, because a stationary mattress will be wet from the rain.

The ends of the sidewalls can be varnished or painted with glossy paint.

How to make a rocking chair out of wood

When starting to create a chair, many people ask the question: how to make a rocking chair with your own hands from wood, while finding suitable drawings and sizes? They search for a long time on various sites, ask on forums, and so on. In this section we will tell you how to make it high-quality, reliable, convenient and modern.

These rocking chairs are beautiful and can decorate your interior in your apartment, on the balcony or in the courtyard.

In order to create a chair, you will need:

- hacksaw with fine teeth;

- a plane to process the structure;

- belt machine for grinding parts;

- folding milling machine;

- plumb line;

- screwdriver;

- hammer;

- portable ruler and pencil;

- clamp;

- brush.

You can create a drawing at your own discretion and to your own size, or you can find it on the Internet.

To begin, make 1 meter grooves in a wooden board measuring 4.5 by 4.5 centimeters. Grind the ends of the boards to fit into the slots of the runners. Place the runner boards in hot water until the wood is pliable for bending. Using the jig, bend the board to a suitable radius and set it aside until it is completely dry. Place the dried runners on the legs, treating the grooves with glue in advance.

Anyone can make a new homemade rocking chair at homePreparation of the drawing

Surely, the diagram of the chair you like is freely available on the Internet. It specifies the exact dimensions, necessary materials, and tools for manufacturing. If you are not satisfied with the presented models, you can study several of the most attractive ones and model your own circuit.

By making a chair from plywood, you can not only create a high-quality piece of furniture, save money, but also get great pleasure from the work.

In order to make a drawing correctly, design your chair on paper, ideally from several angles. Visually divide it into main parts and draw them. You may need patterns, a pencil or marker, a ruler, a tape measure, a corner, and scissors. Select sizes based on your own needs.

A rocking chair made of plywood with your own hands is an excellent option for relaxing in the country, in a country house, or just in nature.

Step-by-step manufacturing instructions:

- Transfer your drawing from paper to a sheet of plywood;

- Saw the parts of your chair;

- Sand the cut areas;

- Pre-assemble your chair without using fastening parts. Use helpers. This is necessary to deliberately eliminate shortcomings.

- Glue the necessary parts;

- Drill holes for self-tapping screws.

- Connect all the parts together.

Don’t be afraid to experiment; as a result, you will get a comfortable, beautiful and original piece of furniture.

Manufacturing options

There are many ways to make beautiful and comfortable chairs.

Let's take a step-by-step look at what options there are for making such pieces of furniture.

Soft

You can make an excellent soft chair at home. To do this you will need a plywood sheet and all the necessary tools. Let's take a step-by-step look at how you can make such a furniture design yourself.

- First you need to draw up an accurate drawing of the future product indicating all dimensional parameters - based on the diagram, it will be easier and more convenient to work.

- You need to cut out cardboard templates. In the future, they will be used to prepare the plywood parts of the future chair. It will be necessary to make crossbars; their inclination, bend and size should be determined in advance.

- All wood parts must be thoroughly sanded. The sides should be painted, and the end parts should be further strengthened with special metal rims.

- Foam cushions need to be glued to the seat and back of the product. If desired, the procedure should be repeated for the armrests. At the top, the foam rubber is strengthened with a stapler.

- To sheathe the structure, you need to make holes and secure the rims with screws. First of all, you will need to stretch the upholstery fabric over the back of the furniture, after which you can move to the remaining areas.

- Install all parts in their places and among themselves using a screwdriver and self-tapping screws. All joints, connections and fastenings must be coated with glue.

Bag chair

Modern chairs that resemble a large, soft bag in appearance are very popular today. Such things can also be done with your own hands, and there is nothing complicated in such work.

Excellent products can be obtained from 3 meters of satin, 1 m of woven material for the cover. You also need to prepare 1 m of zipper, scissors, padding polyester. The following tools will be useful: needle, pins, thread, scissors. The scheme of action here will be as follows.

- Using patterns, prepare fabric parts. You need to cut out a large bottom bottom, a small top one and 6 wedges. The latter will need to be stitched and sewn on both bottom parts. The top cover of furniture is sewn in a similar way.

- The zipper in the resulting workpiece will need to be carefully sewn into one of the wedges. To make the cover easy and convenient to take off and put on, 2/3 of the bag needs to be filled with filler, and then put it into the outer cover and simply fasten it.

Frameless

Many people like soft frameless chairs. They are comfortable and pleasant to the touch. They are often made for young users. Let's take a step-by-step look at how to properly make such interesting furniture using the example of a child's chair.

A similar structure can be made from timber or inexpensive chipboard. The front part is usually made of plywood. The rear component can be constructed from hardboard. In the interior of the furniture structure, all bends and uneven parts should be glued with cardboard. When the adhesive has completely dried and set, the unevenness will need to be carefully smoothed out using a special construction knife. You can safely glue a piece of foam rubber on top of the structure. After this, the homemade structure can be sheathed with the selected material.

Chair-bed

Modern chairs that can serve as a bed have long won the love of consumers.

The backs and seats of this furniture design can be constructed from simple plywood sheets. The action plan here will be as follows.

- All components will need to be firmly secured using self-tapping screws. The latter on the upper part will need to be properly fixed using a high-quality adhesive composition.

- All surfaces made of wood will need to be thoroughly sanded using a sheet of sandpaper.

- The side backs can be made from bars. Their design must include legs, a handrail and 5 racks.

- The seat is made of 3 main parts. Each of them must be equipped with a timber frame.

- The sliding mechanism operates due to special metal hinges. In order for it to work without jamming or malfunctioning, it is imperative to leave small gaps.

- The seats must be connected using self-tapping screws on a plywood sheet with bars. All 3 required seats must have the same dimensions.

- The seats should be attached using high-quality iron hinges. The right half will need to be securely attached to the side parts with bolts to make the structure as stable and reliable as possible. The parts must be held in one position when the chair is moved apart.

- The furniture structure will need to be coated with a good varnish or painted. A foam pillow in a nice case would be a nice decoration.

Decorating wooden furniture

An equally important stage in furniture manufacturing is decor. At the same time, it is not necessary to purchase expensive accessories for such purposes, because you can even use old, unnecessary things, pillows.

You can cover the back and seat with padding polyester, and stretch decorative fabric on top. Fasten the upholstery to a wooden structure using a furniture stapler. In addition, the back is sometimes decorated with buttons, which are covered with the same fabric. You can hide the marks from the staples with decorative edging or various laces.

Example of garden furniture design

At this stage you will have to show your imagination. You can decorate the surface using paint of different colors - this will allow you to get a unique product that suits your interior specifically.

How to sew chair covers

To prevent the furniture upholstery from being wiped out or damaged by children and pets, a cover is sewn on it. It is advisable that within the same room all objects are decorated with the same material - this way the decor will not be disjointed. Fabrics used are cotton, velor, as well as flock, chenille, and microfiber.

Design solutions for capes are very different - they are country and loft, Provence and shabby chic, high-tech and baroque. Usually the cover completely covers the product, reaching the floor. Parts List:

- back – front, back, side;

- seat – upper, front part;

- armrests – two side, two end parts.

The patterns are traced on the fabric with allowances for a loose fit and seams, one or two cm. The parts are sewn on the wrong side, the cover is turned inside out and tried on. If the model provides for it, a valance skirt is sewn to the bottom. The latter is made multi-layered, lace, contrasting (the color matches the sides of the back and armrests), it will require a lot of fabric.

Progress

Manufacturing of frame and armrests

The process of making a wooden chair is not as complicated as it might seem at first glance. The detailed manufacturing process will look like this:

We prepare the main elements in advance

At this stage, it is important to check all work with the drawing. This will prevent the risk of errors occurring during the production of individual parts. Now let's move on to manufacturing the main parts

The most difficult parts of making a chair are the side supports and the seat. To facilitate the workflow, you need to make a full-size template of the parts on cardboard. To cut straight sections of parts, it is better to use an electric saw, and shaped sections are processed with a jigsaw. Next we proceed to making the armrests. It is better to cut them according to pre-prepared patterns. We move on to making wedge-shaped supports for the armrests, and screw them to the front legs. We process all cut parts with sandpaper.

Attention: the chair assembly process must begin after treating the product with an antiseptic

Assembling a wooden “throne”

The chair assembly looks like this:

- We install the rear legs perpendicular to the bevel of the support.

- We connect the side parts of the backrest with the first seat bar. To do this, you need to make holes for the bolts.

- We install supports and secure them with clamps.

- We fasten the upper part of the back with screws. The planks are cut according to the markings, taking into account the radius of curvature.

- At the end of assembly, all surfaces are sanded, and the screw heads are hidden with wooden plugs.

Preparation of materials and tools

In order to make a chair with your own hands, you need to do everything in stages. In accordance with the selected drawing, it is necessary to prepare materials. If the base is wooden, then you should purchase or select from available raw materials: plywood, timber, boards, chipboard.

Use quality materials for furniture.

Wood for the frame is the best option, environmentally friendly and inexpensive. You need to choose wood carefully. The presence of bark, splits, cracks, and uneven texture on the boards is not welcome.

The work will require certain tools.

Additionally, you may need fastening elements, wood glue, varnish or paint for application to the surface of the product, foam rubber, filler, textile fabric: velor, jacquard, tapestry, flock, leather (natural, artificial).

For the job you will need some construction tools.

Tools to prepare in advance:

- Screwdriver;

- Furniture stapler;

- Jigsaw, grinder, necessary attachments;

- Machine for sanding boards;

- Staples or screws;

- Chalk;

- Hammer;

- Scissors, upholstery sewing machine.

You can make a chair from wooden slats.

You can prepare the components of a wooden chair yourself or order it from a special enterprise, which can produce blanks according to the samples presented.

Preparing for work

When choosing a specific model, it is important to take into account the maximum load on the supporting elements of the products. For example, with a weight of 95 kg, the owner can try to combine wood and forging in his work. This will increase the durability of outdoor furniture, suitable for passive rest, eating and sleeping

In the absence of a foundation, it is better to use pendulum products that swing equally well on the ground, sand and grass

This will increase the durability of outdoor furniture, suitable for passive relaxation, eating and sleeping. In the absence of a foundation, it is better to use pendulum products that swing equally well on the ground, sand and grass.

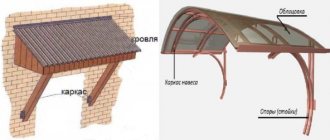

Wicker chairs have a sophisticated look, but do not tolerate heat and moisture well. Therefore, they are often made for closed-type extensions. Maximum comfort is provided by hanging furniture in the shape of a basket or hemisphere. Here, in addition to wood, a novice craftsman will need a pipe hoop, rings, carabiners, thick fabric and several zippers.

To avoid technical errors, before work, it would not hurt to familiarize yourself with various drawings of wooden chairs. We are talking about detailed graphic images, which can indicate the features of the connection and fastening of most parts.

Material selection

Hardwood is the best raw material for garden furniture. Oak, for example, is characterized by high strength and hardness. It lends itself well to dry processing and almost does not absorb moisture. Beech is more suitable for implementing original design ideas. This wood is famous for its uniform texture, and the variety of natural shades creates unlimited possibilities in choosing style solutions. The only drawback of the material is its high hygroscopicity. For this reason, it requires pre-treatment with protective compounds.

You can also use rowan, ash, elm and sycamore in your work. Softwoods, particularly pine, cherry, cedar and maple, are more suitable for decorating finished products.

Model selection

Folding chairs are often called transformers. With one movement of the hand, they turn into sleeping places designed for adults and children. This is the best option for outdoors and small spaces. If the area of the terrace exceeds 15 square meters, and the furniture has to be rearranged from time to time, it is better to take a closer look at functional models on wheels.

Tools

An inexperienced carpenter will definitely need a circular saw. With its help, wood can be cut at a convenient angle in the longitudinal or transverse direction. Particularly popular are units with protective covers and a built-in engine braking function. Other tools you will need are clamps, drills, a drill and a hand saw.

When choosing a miter box, it is more logical to give preference to a device with a small amount of play. This way you will be able to ensure convenient trimming of basic and decorative elements with millimeter precision.

Recommendations

Here are some useful tips that will make it even easier to make a chair from wood with your own hands. To begin with, let's say that before creating any structure made of wood, you should carefully think about how it will roughly look and what you want to see it as. This will allow you to at least approximately determine how much of a particular material you need.

Another important aspect is that you should not neglect such a thing as drawings. For some reason, many people do not pay enough attention to them, which is why they end up with crooked chairs and armchairs. In this matter, everything should be thought through to the smallest detail and the parameters of each detail should be checked. It would not be superfluous to say that it would be better to use a circular saw for cutting longitudinal parts, and a jigsaw for transverse parts.

Another important issue concerns the connection of the chair elements. Everything is quite simple here. In connections where the main load occurs, it is better to use self-tapping screws or self-tapping screws. But in other cases, you can use adhesive or chopsticks made of wood. Choppers can also be used to secure the upper parts.

An important point will be the selection of materials for processing. But here everything will depend on how high-quality the wood is used. If it is “clean” and has no defects, then it will be enough to treat it with stain and apply varnish. But if there are stains on it and there are some defects, then you should putty them, then cover them with a primer and only then paint. Another important point is that you should not paint the wood right away. It must be pre-treated with drying oil. Otherwise, it will quickly be absorbed into the surface. Then there will be bald spots, which will ruin the appearance of the chair.

Schemes and drawings

When making garden furniture, the following recommendations regarding its dimensions must be observed.

- The sizes of stainless steel screws are 51*8 (similar ones can be used).

- Dovetail nest, in which the armrests rest on the front and rear legs - 10*19*102 mm.

- A 3 mm chamfer is removed on the edges of all parts.

- The hole into the center of which the self-tapping screw is screwed widens to 19 mm at the surface of the part, turning into a narrow part and deepened to 5-10 mm. It will be easier to tighten the screws and cover these places with varnish (if plugs are not used).

- Rear legs: 2 pieces, 20*254*787 mm each. Front – 20*76*533 mm.

- Chair back: 20*279*914 mm.

- Armrest supports: 2 front 20*127*406 mm, rear 20*76*610 mm.

- Jumper: 20*51*589 mm.

- Insertion strips: 2 pieces, 12*20*254 mm each.

Different design options - folding or regular, differ in the size of the parts. The chair must be reliable, not break or squash under tens of kilograms of weight, which account for a significant part of the body weight of a large person.

How to make a chair with your own hands

Before starting work, you need to decide on the dimensions of the finished product and think about the inclination of the slats. To make patterns, you will need cardboard: the template will be useful for cutting out frame parts, preparing the foam filling and drawing up a pattern for the cover. How to make a children's and adult chair from foam rubber with your own hands?

Based on the drawings, a template of the chair parts is made.

The standard height of a child seat is no more than 60 cm, diameters are 25 and 11 cm.

A child seat has its own parameters.

Preparing all the details

Based on calculations and drawings, it is necessary to create templates for parts on cardboard. Wooden elements are cut out with a jigsaw. Even wooden parts hidden under filling and upholstery should be sanded and treated with stain so that the furniture lasts longer.

Wooden parts are cut out with a jigsaw.

Particular attention should be paid to the end parts: they are impregnated with drying oil. If bends are provided, they can be achieved by splitting the fibers with a hammer

Foam rubber and fabric parts must be cut according to the template.

Assembling the frame

The main parts of the frame are connected to each other (starting with the side slats and the back), and then additionally fastened with a metal rim or furniture ties. Screws are used to secure the rims.

When making the frame, all parts are connected to each other.

The finished base must be covered. Any wear-resistant fabric is suitable for finishing the back panel. (secure with wide-headed wallpaper nails).

The upholstery must be secured to the base.

The interior of the chair (seat, backrests, armrests) is lined with foam rubber. It can be secured with furniture glue, but for greater reliability it should be riveted along the contour with nails or ties. The upholstery is fastened along the edge, along the transverse parts.

The inner part is lined with foam rubber.

The finished chair is covered with furniture fabric.

Making a case

Before sewing the cover, you need to take measurements of the width and height of all structural elements: seat, armrests, borders, backrest. Using ready-made measurements, based on the remaining templates, prepare the details: transfer the patterns to graph paper, attach to the fabric with safety pins and trace. Add allowances of 15-20 cm.

Before sewing a cover, you need to measure all design parameters.

For the armrests you will need two patterns: external and internal. The fragments are connected on fabric folded in half. The seam lines of the longitudinal thread should be marked with chalk.

For the armrests you will have to make two separate patterns.

The blanks for the armrest and the outer part of the backrest must be folded with the edges outward, and the seams must be drawn. Along the marked lines, the internal and external parts are connected.

Internal patterns are made with a margin of 20 cm on each side.

Blanks are made with a small margin.

Attach the parts for the inside of the back and seat to the furniture with pins to determine the location of the seams.

The parts of the case are fastened with pins.

The finished parts are sewn together with a margin, so that later you can “adjust” the size of the cover using darts and gathers.

Decoration

The best way to decorate a chair is with cute pillows of different sizes. Sewing them is simple and quick. These can be miniature thoughts of different shapes, sewn from the same material as the cover/upholstery or other fabric. For example, bright pillows are perfect for a plain, light-colored chair.

The best decoration for a chair is various pillows.

You can decorate the cover with sewn-on ruffles and frills. Usually they are sewn to the bottom of the cover, as well as along the edge of the furniture itself.

About padding and covers

Any soft chair, on a rigid base or frameless (see below), is filled with soft and fairly elastic material. Horse hair is now available to only a few, whalebone is not available to anyone at all, so amateur chairs are most often stuffed with foam rubber or polystyrene foam (foamed polystyrene) in granules. They have a common property: they are easily electrified and retain static electricity for a long time, which is not at all good for health. Therefore, the upholstery of pillows, mats, and other soft furniture components must be made of 2 layers: external decorative and internal antistatic. This, in addition, simplifies the maintenance of decorative cladding and its replacement if necessary.

The antistatic cover of upholstered furniture is sewn from cotton fabrics according to the same patterns as the decorative one. There are almost no alternatives to cotton as a surge arrester: the leakage resistance of a chair on wooden legs, standing on a laminate floor, with an outer covering made of very well-electrified silk, with an internal cotton cover, lies in the range of 1.8 - 5.6 MOhm , which ensures almost instantaneous charge drain from the electrophore machine. Synthetic winterizer is somewhat worse: it does not rot, but the outer covering should also be antistatic, made from natural furniture fabrics.

The antistatic filler of upholstered furniture, remarkable in its mechanical properties and in itself, is polyurethane foam (PPU). But not a construction self-foaming sealant/thermal insulator; mechanically it is not suitable for furniture, but the so-called. neoprene foamed under special conditions during manufacture. Neoprene is available in granules and sheets; The latter, by the way, are used to make wetsuits. The material is expensive, especially sheet material, but there is no need for invention. Car seat inserts are made of neoprene. So if you come across a junkyard jalopy, try to get your hands on the seats and backrests. They won’t be counted as metal anyway, but by shredding the inserts you’ll get excellent padding for a couple of chairs.

For more information on sewing chair covers, we recommend a separate material at the link.

Decoration

Handmade furniture is decorated in different ways. The simplest is:

- Textile upholstery.

The texture and color scheme of the fabric is selected depending on the area of use, the overall interior and personal wishes. For modern trends: leather, eco-leather, jacquard, flock are used. For classic motifs it is better to use velor, corduroy, linen, cotton . If the furniture will be used outdoors, wear-resistant fabrics that are resistant to negative environmental factors are selected. - Making a cover. For indoor or outdoor furniture, it is recommended to make removable covers. With their help, you will not only decorate the interior or exterior of your yard, but also make caring for the chairs more convenient. After all, the covers can be easily and simply removed for washing, and if necessary, they can be replaced with new ones.

- Skin tightness. Leather upholstery is used only for home furniture. It will bring a certain luxury, respectability and rich appearance to the interior.

- Aging. Decorating antique furniture pieces is appropriate for Provence, loft, baroque, and renaissance styles. To achieve this, the products are given a shabby appearance, using paint with a gilding or patina effect.

Children's room

The room for the child should be spacious enough for games, cabinets, tables and chairs, toys and other accessories. And most importantly - a comfortable and functional place to relax. Installing a bed is not always justified, especially in small rooms. Frame products also do not always meet safety aspects.

Thanks to a creative approach, you can make safe upholstered furniture that a child can independently move, disassemble and assemble.

Making armchairs and chairs from foam rubber, polyurethane foam and mattresses is an excellent and profitable way to recycle old things. Old beds, wardrobes and sofas are used as starting materials. Their components are used as blanks for frames, sides, armrests and niches for things.

To make folding upholstered furniture, you will need:

- roulette;

- hacksaw;

- square;

- electric drill;

- screwdrivers;

- spanners;

- sandpaper;

- PVA glue;

- sewing machine;

- ruler;

- marker.

If a sofa is being disassembled, then the work uses a folding mechanism, corners, bolts and nuts.

Based on the availability of material for the work and the experience of the craftsman, a product design is drawn up. It can be folding or on casters with an insert.

Assembly is carried out in the following sequence:

- Dismantling old furniture into components.

- Cutting wood into blanks, making patterns for covers.

- Making frames and bases for pillows.

- Sewing covers, equipping them with removable zippers at the joints. Covering the soft part with fabric.

- Installation of folding mechanisms.

Finally, the chair is decorated.

Wooden chair for country kitchen

What distinguishes this self-made specimen from an ordinary chair is that:

- The back of the chair is tilted by 10 degrees, and the supporting strips are cut not from one board, but glued together from two, which reduces wood consumption

- Made from one piece of wood. The master set himself the task of making a chair from a single piece of 2x4 wood. You will find a diagram of cutting a piece in the photo below.

- In the back of the chair, the horizontal slats have decorative cutouts that you can draw to suit your taste. And also the ends of the back have attractive bevels.

Step-by-step photo master class. Blueprints

Here we see a swinging chair (or rocking chair) in the Adirondack style, which is quite an unusual combination. Pay attention to the height of the backrest, which is made long enough so that you can lean your head on it to rest.

READ MORE: Grout for beige tiles 19 photos how to choose the right color to grout the seams

It is very important to make a correctly shaped rocker arm that provides swinging. When making such a chair, carefully study its shape.

Wood as the main material

Before starting work you need to prepare:

- plywood sheet;

- soldering iron;

- hacksaw;

- hammer;

- meter;

- compass;

- strong scissors;

- drill;

- self-tapping screws;

- screwdriver or hexagon;

- fabric and foam rubber;

- glue;

- paint;

- metal rims;

- stapler

For the workflow, you need to take care of it in advance;

- planks 50-60 cm made of timber with a section of 2.8;

- plywood 3 cm;

- self-tapping screws;

- screwdriver;

- sandpaper;

- saw;

- pattern;

- chalk or felt-tip pen.

Making a chair (chair) from pallets

You can make such a design with your own hands, spending only a few hours. During the work you will need the following:

- wooden pallets (you can buy new ones or disassemble old ones that are no longer used);

- hammer;

- nails;

- sandpaper;

- fastenings;

- primer.

Impregnation for wood

Pallet chair

Step one: in this case we will need to take two pallets of the same size, which will then be divided into parts. Moreover, if the design involves the presence of additional decorative elements, then more pallets will be needed.

Divide the pallet into parts

Step two: the surface of the wood should be thoroughly sanded.

Sanding the surface of the pallets

Step three: first you need to connect the parts of the seat and backrest together. At this stage, you can make a small cut to get the slope of the back.

Connecting the back and seat

Step four: it is better to fix all the parts with screws, because the connection made from nails is not very reliable.

(schemes, drawings and photos)

This version of a homemade wooden chair is perfect for a summer house. They are easy to make from boards from pallets or pallets. To increase their service life, the author of the photo usually leans these chairs against the trees on his property and brings them into the garage for the winter; the legs of the chair are treated with a special compound that you can buy in any store. According to the author, 8 of these chairs have served him faithfully for 8 years.

This pallet board chair requires minimal tools and time to make. As you can see from the photo, the back boards are not nailed together, but are tied together with a strong thread, which makes it look like a little chaise lounge.

The author himself writes that when re-creating this chair, he would like to change two things about it. The first thing is to make it wider so that it is more stable and it is not so crowded. Second, make it larger between the crossed boards so that the back is not so vertical and you can lie down on it. And now you’ll get a real sun lounger

If you need to do it quickly...

A huge advantage of such a chair is that you can put it together in just a few minutes if you have two pallets, a saw, screws or nails. Here you no longer need (as is usually the case) to disassemble the pallet into boards and pull out all the nails. At your discretion, the wood can be sanded and coated with varnish or paint.

READ MORE: Buzulnik 57 photos, planting and care in open ground, description and choice of ligularia for a pond in landscape design in a flowerbed, propagation and replanting in the garden in the fall

Such a chair can decorate not only a garage or a country garden, but also, with designer painting and wood processing, can add some subtlety to the interior of your apartment.

Step by step steps:

- Sand all parts, mark fastening points with chalk or a washable marker.

- Cut out the sides of the furniture from plywood according to the pattern.

- Connect the sides at the top and at the level of the seat support with drawers.

- Attach the strips to the resulting frame at a distance of 2.5 cm.

- Round the edges.

- Coat the product with varnish.

Storage of drawings and books on upholstered furniture

Disclaimer: all files presented in this section were found in open sources and are provided as is. I do not give consultations or advice on the drawings in this section, and I am not responsible for the consequences of their use. Download and use at your own discretion. Copyright holders contact here.

- Drawings for assembling a children's roll-out sofa. 7 pages.

download

- Step-by-step assembly of the sofa frame. 8 pages.

download

- Eurobook sofa on a spring block. 327 photographs of the manufacturing process, without dimensions. 200MB

download

- Drawings of the base of the Soviet chair. 3 sheets

download

- Corner sofa (full set of documentation) Photo, specification of parts, chipboard cutting map, project file in pro100

download

- 3D project of the Eurobook sofa in the pro100 program format

download

- Installation diagram for Mixotoil and Sedaflex folding beds. 2 sheets

download

- Drawing of a round chair. 6 sheets

download

- Drawings Chair-bed. 14 sheets

download

- Drawing of a sofa with slats. 9 sheets

download

- Drawings of a sofa with Tik-Tak fur (a complete set of documentation, frame and cut). About 100 sheets.

download

- Drawing of a sofa TICK TOCK. 6 sheets

download

- Drawing Eurobook roll-out. 18 sheets

download

- Frameless sofa (full set of documentation). 9 sheets

download

- 3D project of a corner sofa in pro100 program format

download

- Book Upholstery

download

- Book Artistic design of furniture (A.A. Belov)

download

- Book Production of upholstered furniture

download

- Book Upholstery of upholstered furniture. Master class (V. Gibert)

download

- Book Upholstery and reupholstery of upholstered furniture (A. Balavuan)

download

- Book Production of upholstered furniture (Rumyantsev)

download

- A Manual for Drapers, Upholsterers and Decorators 1891

download

- Dolphin mechanism installation drawings

go

novamebel74.ru

Forms

All chairs are divided into:

round;- semicircular;

- asymmetrical;

- in the form of a pear, apple, drop.

Round models according to the type of placement are divided into:

- Floor-standing. They are equipped with legs and installed on the floor. Some models can be equipped with simple transformation mechanisms. They are diverse not only in appearance, but also in functionality.

- Hanging. They are attached to the ceiling, rack or poles. Some models can swing, others can rotate around their axis. Their frame is made of different materials. Most models are intended to be placed outdoors .

Help : oval chairs are often found in offices. They are distinguished by their original appearance, different types of structures, and a wide selection of materials. Such products fit harmoniously into different stylistic trends and become the main decoration of the room.