In winter, due to a sharp decrease in air temperature and freezing of the soil, ice plugs may form in the external branches of the water supply system. To prevent this from happening, it is necessary to organize heating of the water supply using one or more effective technologies.

The article we presented describes all the methods to prevent the formation of ice in water supply pipes. We will tell you how to properly maintain the functionality of communications in cold weather and prevent equipment breakdown. Do-it-yourselfers will find instructions on how to install thermal insulation and heating systems.

Heated hoses

The heated hose (Pirit Heated Hose) operates from an electrical cord plugged into the outlet, which activates the thermoelement built into the hose.

The heated hose thermocouple, controlled by a thermostat, is activated if the external temperature drops below 350C and turns off if the external temperature is above 400C. That is, if the hose is turned on, then, basically, the thermocouple will be activated. This hose emits external heat, which is extremely useful for gardeners when using the hose in greenhouses and conservatories. The heated hose can be used to prevent frost damage, melt snow and ice, and help seeds germinate. The Pirit Water Line includes an electrical cord and a thermocouple (copper wire) built into the hose. This heated water conduit is designed to be used as a constant source of water when the outside temperature is below 00C. This hose can be left plugged in. The thermocouple is regulated using a thermal relay: it is activated at an external temperature below 20C and turned off at an external temperature above 4.40C. If you leave such a hose on, the water inside will not freeze. This is a very convenient new product if you need to supply water to your house, utility room, RV, trailers on a construction site, pen, boat, mobile homes - anywhere you need a constant source of water during frosty periods.

Characteristics for both models:

Source

Subtleties of underground installation of water supply lines

When it comes to the above-ground part of the water supply system, you need to give preference to products that are strong and reliable enough to successfully withstand changes in temperature and pressure.

In this case, the type of pipe described above is perfect, another advantage of which is ease of installation using fitting fasteners.

And to make it easier to decide which pipes for underground water supply are best suited in each specific case, it is worth paying attention to the existing ready-made water supply projects, proven by practice, and also take into account the requirements of technical standards. With this approach, you will get inexpensive and high-quality plumbing, and installed without much effort.

Heating cables for heating pipes

Found 212 products

Category

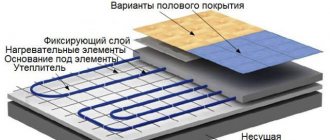

The length of the mat is determined by the length of the underfloor heating cable, complete with a ready-to-install fiberglass mat. This assembly allows you to quickly install a cable already laid and glued into a durable fiberglass base under the floor in rooms of almost any size. When laying the mat, you do not have to independently monitor the exact optimal distance between the wires. When laying, you can cut the mat in the desired location and rotate the laid mat to any angle to go around walls with obstacles and cover the entire floor. Do not cut the cable itself. Stiebel underfloor heating mats have a thickness of 0.5 m, you can choose the most suitable mat (or combination of several) for your room according to its length, the area it covers will be half the length. For example, a 10 m long mat will cover 5 m2. ","sort":101,"additional":false>,>,"id":231293,"type":"specification","label":"Power","description":"

The power of a heated floor is determined by the length of its cable. The manufacturer indicates the maximum area; during operation, it can be adjusted to adjust the optimal heat transfer (for self-regulating cables this happens automatically). For additional heating of an already heated room, in which it is necessary to raise the temperature from 16-18 to 25 degrees, about 120 W of power per 1 m2 will be required. To use a heated floor as the only source of heating, you will need to lay cable at a ratio of 250-300 W per square meter of room. Do not install the underfloor heating system under permanently located furniture and other stationary objects to avoid overheating and damage to the device. Also, when calculating the heated area, take into account only the free space not occupied by the bathtub, toilet, furniture, office equipment and other fixed objects. ","sort":102,"additional":false>,>,"id":231300,"type":"specification","label":"Mate width","description":NULL,"sort": 103,"additional":false>],"booleanFilters":[>,"id":NULL,"type":"is_packaging","label":"Buy in packaging","description":NULL,"sort": 60,"additional":true>,>,"id":NULL,"type":"has_review","label":"Only with reviews","description":NULL,"sort":80,"additional" :true>],”productCount”:104,”queryString”:””>” data-category-id=”2783″ data-category-name=”Electric heated floors” data-bowed-category-name=”in Heating cables for heating pipes" data-rname=»elektricheskie» data-tag-page-id=»3452″ data-make-id=»0″ data-search-string=»» data-reset-link=»/santehnika/ teplye-poly/elektricheskie/dlya-obogreva-trub/#goods» data-is-search-page=»» data-ab-is-expanded-filters=»» data-is-admin=»» >

Source

What are active measures?

The first thing to do is to provide a special easy-to-detach pipe connection during installation. Such connections should be at the exit from the well and at the area where the water supply is introduced into the house. This will allow you to quickly remove ice plugs by simply disassembling part of the pipeline.

Today, heating is most often carried out using a special cable. It is stretched along the pipe, and in winter its power should be enough to restore water supply. To do this, when choosing such a cable, it is necessary to take into account the climatic conditions of the region in which it will be installed.

To heat a pipe, there is no need to purchase an expensive two-wire analogue. If temperature differences in winter are small, then a conventional single-core analogue is sufficient. You can buy a cable designed for underfloor heating. It's quite inexpensive.

There is one drawback: such heating should be turned on for no more than 10 minutes, otherwise the element will burn out. If this time is not enough, then the procedure should be repeated a little later (in half an hour). You shouldn't heat the pipe all the time. It does not freeze quickly, and with the cable always on, a lot of electricity is wasted. It is fastened using special clamps. In some cases, homeowners use tape.

If the system uses special pumps, it is recommended to make a small hole in the pipe. Its diameter is no more than 3 mm. It should be located 5 cm from the pump. Then the water constantly flows, so it does not freeze. Of course, if a pumping station is used, this approach is unacceptable.

Laying pipes below freezing depth

This method is advisable to use if in winter the soil freezes no deeper than 170 cm. A trench is dug from a well or borehole, the bottom of which is 10-20 cm below this value. Sand (10-15 cm) is added to the bottom; the pipes are laid in a protective casing (corrugated sleeve), then covered with earth.

To avoid having to insulate the outdoor water supply in cold weather, it is better to do this in advance

This is the easiest way to make winter water supply at the dacha, but it is not the best, although it is the cheapest. Its main drawback is that if repairs are necessary, you will have to dig again, and to the full depth. And since it is difficult to determine the location of a leak with this method of laying a water pipeline, there will be a lot of work.

To ensure that there are as few repairs as possible, there should be as few pipe connections as possible. Ideally, there should be none at all. If the distance from the water source to the dacha is greater, make connections carefully, achieving perfect tightness. It is the joints that leak most often.

Choosing a material for pipes in this case is not the easiest task. On one side, a solid mass presses from above, so a strong material is needed, and this is steel. But steel laid in the ground will actively corrode, especially if the groundwater is high. The problem can be solved by properly priming and painting the entire surface of the pipes. Moreover, it is advisable to use thick-walled ones - they will last longer.

The second option is polymer or metal-polymer pipes. They are not subject to corrosion, but they need to be protected from pressure - placed in a protective corrugated sleeve.

One more thing. The depth of soil freezing in the region is determined over the past 10 years - its average indicators are calculated. But firstly, very cold winters with little snow occur periodically, and the ground freezes deeper. Secondly, this value is the average for the region and does not take into account the conditions of the site. Perhaps it is on your piece that freezing may be greater. All this means that when laying pipes, it is still better to insulate them, lay sheets of polystyrene foam or expanded polystyrene on top, as in the photo on the right, or lay them in thermal insulation, as on the left.

You might be interested in reading “How to make automatic watering“.

The most common mistakes made when laying underground pipes

The underground installation of communications, of course, largely depends on the type of soil in a particular location. And, often, many difficulties arise with it during work, since the composition of the soil may simply not make it possible to deepen the pipes to the distance specified in SNiP. In particular, the soil may be very compact, rocky or boggy, so that you simply cannot get to the desired depth. In this case, many difficulties can arise in winter.

However, even in this case, there is a way out - insulating the pipeline in various ways. In this case, a reasonable option would be to dig a trench as deep as possible and insulate the pipes well.

Pipeline insulation

When supplying water to a private house from a well and a borehole, the pipeline can be laid at a very shallow depth - 40-50 cm - this is quite enough. Just laying pipes in such a shallow trench needs to be insulated. If you want to do everything thoroughly, then line the bottom and sides of the trench with some kind of building material - bricks or building blocks. Everything is covered with slabs on top.

An example of laying pipes above the freezing depth in a prepared ditch. The insulation of the water supply is carried out with a special insulation, with a suitable internal diameter

If desired, you can fill in the soil and plant annuals - if necessary, the soil can be easily removed and free access to the pipeline is provided.

Insulation for water pipes

Two types of insulation can be used:

Thermal insulation for pipes in the form of a shell is made from the following materials:

Insulation of water supply pipes in a private house is done using thermal insulation

Mineral wool - glass wool and stone wool - have one significant drawback: they are hygroscopic. By absorbing water they lose most of their thermal insulation properties. After drying, they are only partially restored. And another very unpleasant moment is that if wet mineral wool freezes, after freezing it turns into dust. To prevent this from happening, these materials require careful waterproofing. If you cannot guarantee the absence of moisture, it is better to use another material.

Initial stage of work

Any installation of water pipes begins with drawing up a project.

The scheme must be well designed, otherwise the pipeline system will not be able to function properly. This does not mean that the project should become a miracle of engineering - the main thing is that you can easily navigate the finished circuit, so that if errors arise during the work, you can easily figure it out and quickly solve them.

The project must contain the following information:

- Soil properties - its type, whether it is loose, rocky or sandy.

- The area of land over which the pipe will be laid. It is necessary to calculate so that you can always consider the number of forks and entrances.

Remember that the laying of water supply pipes must pass along a pre-leveled area. Ignoring this nuance may lead to unexpected bad consequences in the near future.

Heating

When planning the installation of winter water supply, you need to keep in mind that insulation only helps reduce heat loss, but cannot provide heat. And if at some point the frost turns out to be stronger, the pipe will freeze. Particularly problematic in this sense is the area where the pipe leads from the underground sewer into the house, even a heated one. Still, the soil near the foundation is often cold, and it is in this area that problems most often arise.

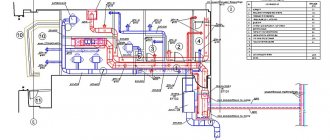

If you don't want to freeze your water supply, heat the pipe. For this, a heating cable or heating plates are used, depending on the diameter of the pipes and the required heating power. Cables can be laid lengthwise or wound in a spiral.

Method of attaching the heating cable to the water pipe (the cable should not lie on the ground)

A heating cable is good for everyone, but it’s not so rare that our electricity goes out for several days. What will happen to the pipeline then? The water will freeze and may burst the pipes. And repair work in the middle of winter is not the most pleasant experience. That’s why they combine several methods - they lay a heating cable and insulation on it. This method is also optimal from the point of view of minimizing costs: under thermal insulation, the heating cable will consume a minimum of electricity.

Another way to attach a heating cable. To reduce your electricity bills, you also need to install a heat-insulating shell on top or secure roll insulation

Laying a winter water supply system in a dacha can be done using the type of thermal insulation shown in the video (or you can take the idea and do something similar with your own hands).

Video description

How to ground a water supply is shown in the video:

- Most often, for self-installation, a linear cable laying method is chosen.

- The level of heat transfer directly depends on what pipes are installed in the room. For plastic pipes, this figure will not be high, which means that when installing a heating cable for a water supply system, you will need to wrap the pipes with aluminum foil.

- Before attaching a cable to the outside of a metal pipe, it is important to ensure that there is no rust. If there is one, it requires cleaning and treatment with a special antiseptic. If this is neglected, there is a risk of damage to the insulation in the future.

- If fastening is carried out from the outside, then the distance between the insulating bundles should not be more than 30 cm. If you take a wider step, then after a while the fastening elements will separate.

- In practice, some craftsmen pull two wires at once to increase the heating rate. It is important that there is a small distance between the cables.

- For fastening to plastic, it is better to use special clamps.

Fastening with clamps and thermal insulation in section Source yandex.net

- If you decide to twist the wire in a spiral, then initially the pipe is wrapped with metallized tape.

- To fix the insulation, it is better to use special ties. They can be purchased at any hardware store.

- It is necessary to completely isolate the temperature sensor from the electrical cable to eliminate the risk of short circuit and fire. To do this, it is necessary not only to maintain a distance between these devices, but also to make the insulating gasket with a special material.

- Heating the pipelines with a heating cable using a thermostat will ensure constant temperature maintenance. It is better to install this device next to the electrical panel or directly in it. It would not be superfluous to install an RCD.

Wire with thermostat Source www.elektrikaup.ee

Winter water supply at the dacha: new technologies in insulation

There is an interesting option, a polymer flexible pipe, insulated at the factory. There is a layer of waterproofing on top of the insulation, and along the pipe there is a channel for laying a heating cable. Such pipes are called anti-freeze pipes or insulated pipes. For example, even in the northern regions, it is possible to make winter water supply at the dacha over the surface using ISOPROFLEX-ARCTIC pipes.

Insulated pipes for winter water supply at the dacha

There is also a new way to insulate the winter water supply at the dacha - liquid thermal insulation or thermal insulation paint. It can be applied to an already installed water supply system, which can be a good solution.

Source

Design and methods of application

The technical characteristics of heating cables, their types, differ significantly from each other, and are used for heating:

- Water supply.

- Sewers.

- Drains, tanks.

- Pipelines for various purposes.

With all the variety of tasks assigned to these heating elements, their main purpose was and remains to prevent liquids from freezing by increasing the temperature.

Sergey Yurievich

Construction of houses, extensions, terraces and verandas.

Ask a Question

These heating systems are applicable for communications located outdoors - both in the ground and in the open air.

An important advantage in the operation of these systems is the function that is commonly called zonal application. In other words, you can always assemble a mini-system from a set of elements in order to heat a small area without connecting it to the general network. Benefit:

- Saving materials.

- Energy is saved.

There are elements with a length of 150-20 mm, and windings of 200 m.

Components of such systems:

- Inner vein. There may be one or several. It is made of alloys with high electrical resistance, and the higher it is, the greater the specific heat release.

- Insulation. It is made of polymers. As a rule, a screen made of aluminum or copper is used together with it.

- Outer shell. Very durable, made of PVC - it covers the internal elements.

This is roughly what the heating cable looks like, as they say, in cross-section. This can be seen more clearly in the instructions for this element or on the World Wide Web.

Some nuances are possible - different alloys or insulation methods. It all depends on one manufacturer or another.

In addition, the cables are flat in shape. This is why they are called tape.

To improve the characteristics, the copper braid (screen) is covered with a layer of nickel, and as for the outer layer, it is increased.

Requirements for PVC material: moisture resistance and ultraviolet resistance.

There are also so-called food cables - they are used for internal installation and comply with sanitary standards. Drinking water must be safe for health.

Low voltage analogue

In hazardous (explosive, fire hazardous) industries, there is a need for a low-voltage element - this is required by both the technological process and safety precautions.

Thus, 12-14 volt cables are widely used.

How to properly install a foam shell

How to insulate a water pipe with polystyrene foam? To install the shell correctly, you do not need to have any specific skills. Thermal insulation of water supply in this way can be done with your own hands in a short period of time.

The cylinder halves are put on the pipe and secured with special tape. The parts must be installed with an overlap (at least 10 cm). Also, all joints are carefully sealed with tape and a protective layer is applied to the tape.

Shaped shells are used for corner segments, nodes and turns.

Dismantling the insulation is carried out in the reverse order, removing the protective layer, adhesive tape, and then the shell itself.

Basic requirements for insulation

So, we’ve sorted out the insulation, but here it’s just necessary to add the following - for all thermal insulation, without exception, some mandatory requirements are put forward, let’s consider them:

- If the material is used indoors, it must have fire-fighting properties and the ability to self-extinguish.

- Long service life.

- Convenience and ease of installation; the ability to reuse the material is desirable.

- Tightness and water-repellent effect.

Installation of insulation

The design of insulation depends on its type. So, all shell-type cylinders are put on the pipeline in parts. That is, two halves are joined. It is important to place them with offset seams. This will reduce the number of cold bridges. For greater reliability, you can cover the insulating cylinders with oilcloth on top and secure it.

If we are talking about glass wool, then the water pipes are first wrapped with such insulation, and then covered with roofing felt on top. This is necessary, since cotton wool strongly draws water from the soil and wrinkles under the influence of static loads. If it is not protected from water, then the insulation will very soon lose its thermal insulation properties. As an alternative solution, you can use plastic pipes of larger diameter to lay an insulated water pipeline in them. For example, these could be orange sewer pipes for outdoor use.

Which hose to take for the well? How to insulate it? Personal experience

As soon as you have drilled a well, you immediately face the pressing question - which hose to choose, because in stores there is a huge variety of all kinds of hoses - corrugated, reinforced, three-layer, rubber or PVC. During the first year of year-round use of wells, I tried 3 types and chose the optimal one for myself. I’m ready to share my observations of what a hose should be like.

Support

- Privacy Terms

- Contacts

- Complain

Personal Area

- Go out

- Entrance

Login via

- 5 robots and 6 guests

- Yandex [4]

- Googlebot [4]

- Bing [4]

- YandexMetrika [1]

- YandexMarket [2]

- Guests [6]

Copyright © Russian Plumbing 2014 All rights reserved. Official website of the Russian Plumbing chain of stores Design, promotion, development and support of the PRO Department website

Types of materials

There is a fail-safe way to insulate and improve a well in a country house without the use of additional heating equipment - this is to cover all its components and protective structures with thermal insulation material. For professional installation, the following 4 types are used:

- Expanded polystyrene and penoplex.

- It is characterized by low thermal conductivity, strength and moisture resistance. Suitable for lining both inside and outside caissons, as well as external and underground pipes.

- Foamed polyethylene.

- It is characterized by good thermal insulation and low load resistance. Therefore, it is used for lining internal walls of rooms and external pipelines.

External insulation of a well with foamed heat insulator Source pechiexpert.ru

GNSh “100” series

Main characteristics: — maximum operating temperature 100°C; — hose made of PFTE tube with stainless steel braid; — built-in thermocouple; — thermal insulation: polyurethane foam; — external protection: nylon insulation; — power cable 1500 mm long; — operating voltage 230 V; — minimum bending radius 200 mm.

| Marking | Specific power, W/m | Power, W | Length, mm | Internal diameter, mm | Working pressure, bar |

| GNSH 6-1/100 | 110 | 110 | 1 | 6 | 240 |

| GNSH 6-2/100 | 110 | 220 | 2 | 6 | 240 |

| GNSH 6-3/100 | 110 | 330 | 3 | 6 | 240 |

| GNSH 6-4/100 | 110 | 440 | 4 | 6 | 240 |

| GNSH 6-5/100 | 110 | 550 | 5 | 6 | 240 |

| GNSH 8-1/100 | 130 | 130 | 1 | 8 | 200 |

| GNSH 8-2/100 | 130 | 260 | 2 | 8 | 200 |

| GNSH 8-3/100 | 130 | 390 | 3 | 8 | 200 |

| GNSH 8-4/100 | 130 | 520 | 4 | 8 | 200 |

| GNSH 8-5/100 | 130 | 650 | 5 | 8 | 200 |

| GNSH 10-1/100 | 150 | 150 | 1 | 10 | 175 |

| GNSH 10-2/100 | 150 | 300 | 2 | 10 | 175 |

| GNSH 10-3/100 | 150 | 450 | 3 | 10 | 175 |

| GNSH 10-4/100 | 150 | 600 | 4 | 10 | 175 |

| GNSH 10-5/100 | 150 | 750 | 5 | 10 | 175 |

Series "GNSH 380"

Main characteristics: — maximum operating temperature 380°C; — hose made of PFTE tube with corrugated stainless steel braid; — built-in thermocouple; — mineral thermal insulation; — external protection: steel winding; — power cable 1500 mm long; — operating voltage 230 V; — minimum bending radius 500 mm.

| Marking | Specific power, W/m | Power, W | Length, mm | Internal diameter, mm | Working pressure, bar |

| GNSH 6-1/380 | 160 | 160 | 1 | 6 | 125 |

| GNSH 6-2/380 | 160 | 320 | 2 | 6 | 125 |

| GNSH 6-3/380 | 160 | 480 | 3 | 6 | 125 |

| GNSH 6-4/380 | 160 | 640 | 4 | 6 | 125 |

| GNSH 6-5/380 | 160 | 800 | 5 | 6 | 125 |

Series "GNSH 200"

Main characteristics: — maximum operating temperature 200°C; — hose made of PFTE tube with stainless steel braid; — built-in thermocouple; — thermal insulation: silicone foam; — external protection: nylon insulation; — power cable 1500 mm long; — operating voltage 230 V; — minimum bending radius 200 mm.

| Marking | Specific power, W/m | Power, W | Length, mm | Internal diameter, mm | Working pressure, bar |

| GNSH 4-1/200 | 90 | 90 | 1 | 4 | 275 |

| GNSH 4-2/200 | 90 | 180 | 2 | 4 | 275 |

| GNSH 4-3/200 | 90 | 270 | 3 | 4 | 275 |

| GNSH 4-4/200 | 90 | 360 | 4 | 4 | 275 |

| GNSH 4-5/200 | 90 | 450 | 5 | 4 | 275 |

| GNSH 6-1/200 | 110 | 110 | 1 | 6 | 240 |

| GNSH 6-2/200 | 110 | 220 | 2 | 6 | 240 |

| GNSH 6-3/200 | 110 | 330 | 3 | 6 | 240 |

| GNSH 6-4/200 | 110 | 440 | 4 | 6 | 240 |

| GNSH 6-5/200 | 110 | 550 | 5 | 6 | 240 |

| GNSH 8-1/200 | 130 | 130 | 1 | 8 | 200 |

| GNSH 8-2/200 | 130 | 260 | 2 | 8 | 200 |

| GNSH 8-3/200 | 130 | 390 | 3 | 8 | 200 |

| GNSH 8-4/200 | 130 | 520 | 4 | 8 | 200 |

| GNSH 8-5/200 | 130 | 650 | 5 | 8 | 200 |