Insulation works

Expanded polystyrene is considered a very affordable material for thermal insulation.

In most cases, foam sheets are placed inside the attic, leaving a gap of 5 mm between them. The gaps between the plates are foamed after the installation work has been carried out. This approach to organizing thermal insulation is due to the natural shrinkage of the roof covering. If you put foam sheets close, then under the influence of the weight of the roof they will begin to press one on one and change. Thanks to the installation foam, this process is reduced to zero, and cold bridges do not appear. Among the disadvantages of expanded polystyrene, it is necessary to emphasize its sensitivity to moisture. The material easily becomes damp, and fungus and mold develop on its surface. Due to this, the use of polystyrene foam in wet regions is impractical.

Another popular insulation material is mineral wool. It has low thermal conductivity, provides good sound insulation, and is resistant to moisture and fire. The material is laid in exactly the same way as polystyrene foam boards. But still, additional layers of hydro- and vapor barrier will increase the working life of the material.

Attic insulation with artificial latex is practiced very often nowadays. The structure of this material resembles mounting foam, and its properties after drying are similar to mineral wool. But its application does not require any additional layers, because the material is moisture-resistant and has good vapor barrier.

Artificial latex is applied quite quickly using a special sprayer, having previously protected the face and body with thick clothing and a mask.

Installation of heated floors

The use of a “heated floor” system makes it possible to provide very comfortable conditions for a person, when the difference in air temperature between the lower and upper parts of the room is no more than 2-3?. At the moment, there are a considerable number of different SHADOWS that can be laid both under tiles or decorative stone, and under wood coverings.

a warm “floor powered by electricity” is considered a self-sufficient source of heating and is capable of warming up a room so much that there is no need to recreate radiators in the attic. It can be laid on any type of floor covering. At the same time, cable or film TENS warm up the room equally, reducing the level of heat loss. Basically, equipment of this kind can be used for about fifty years.

Before installation of the “heated floor”, thermal insulation material is placed between the wooden blocks, on top of which a mesh is placed to fix the TENS. Where the wire will pass through the wood blocks, holes are cut into them and insulated with aluminum foil. After laying the heating cable, the final coating is installed.

If the heated floor in the heating system of a house with an attic is provided by a hydraulic circuit, its operation requires the installation of a boiler that will heat the coolant. In this case, polymer pipes can be used - they can withstand the temperature of the coolant, are comfortable to install and have a long service life.

When the concrete has completely dried, a vapor barrier membrane fabric and a final coating are laid on it. 20 days after pouring the concrete, you can perform a test run of hot water.

A warm hydraulic floor can be created in an additional way - by placing a metal plate with gutters for laying polymer pipes. In this case, the substrate and final coating can be laid directly on top of the plate without pouring a concrete screed on top of it. The heat coming from the hot pipes is shared equally throughout the room. In most cases, this option is used as a backup heat source.

The attic and its subtleties as a construction project

A little interesting history to make it easier for you to understand why attics are so problematic in terms of heat.

The concept of an attic was first brought into this world by the French architect Francois Mansart in the 17th century, who proposed using the attic space for household and residential purposes. And already from the beginning of the next century, the poorest people began to live under a usually uninsulated roof. And only much later - bohemia, i.e. rich youth, free artists and poets.

The joy of the Parisians can be understood: at that time, the tax for a house was taken based on the number of floors, but the attic was not considered a floor. Those. It made sense to equip this nice room because of the savings, and therefore the fashion for a residential attic came to Russia much later. It was only in the 1990s that they began to take up the attic in earnest: the market suddenly became flooded with a variety of insulation materials and new building materials.

And today, the attic as a living space is recognized by modern building codes and regulations (SNiP), which state that this term can be used for that attic where the line of intersection of the facade and the roof plane is no lower than 1.5 m from the floor level. But we can tell you with all confidence that the technology for insulating and waterproofing an attic is the most complex and demanding of all existing ones.

Boiler room design and calculation

Dear Customers! The boiler room is a key element of the heating system. Without exaggeration, it is the heart of your home. That's why,

We design boiler rooms only in conjunction with a heating and underfloor heating project . Placing the design of a boiler room in one hand, and heating and underfloor heating in others, means risking the quality of the system. Don't make this mistake. Projects must be carried out by one company. If your specialist does not know how to design boiler rooms, you can contact me for a comprehensive project.

1) Answers to questions First, we ask you to fill out Questionnaires. This will help you collect initial data, take into account your wishes and not forget anything. Based on your answers, We will draw up a Technical Specification and attach it to the Agreement.

2) Advance payment of 50% for the development of a preliminary design. Based on your responses, we approve the volume and cost of design work. We receive from you an advance of 50% for the development of preliminary designs.

3) Draft design We do not release a finished project without agreeing with the customer on the main solutions. Therefore, we first develop preliminary designs “in one line” in order to discuss and approve with you the placement of key equipment. We adjust the draft design as many times as necessary and incorporate your wishes until complete approval. We attach the agreed upon sketches to the Contract as a graphic part of the design assignment.

4) Advance of 50% for the development of the Working Design This payment confirms that you are satisfied with the key decisions and the Sketches have been agreed upon. Previously, we worked on postpaid basis. In this case, the customers were negligent in their preliminary designs and introduced wishes into the finished project, which greatly complicated the work.

5) Working draft Design companies do not develop sketches. They immediately complete a working draft, and then correct it 150 times. This always leads to mistakes, delayed deadlines and customer dissatisfaction. We do not adjust the working draft. We take into account all corrections and wishes at the sketch stage. Strictly according to the preliminary design, we develop a working design once and hand it over to you. Correction of the finished project is permissible, but in an amount not exceeding 15%.

Insulation of attic floors with sawdust

Sawdust is finely ground wood.

- naturalness;

- absence of toxic impurities;

- light weight;

- availability of material.

Technology of attic insulation with sawdust

Before you start insulating them with sawdust, you need to prepare them. Namely, mix cement and water with sawdust in a ratio of 10:1:1.

Pour the prepared mixture onto the attic floor and level it. It is worth noting that sawdust can only be used as insulation without using a frame in a non-residential attic. Otherwise, when walking on the floor, the sawdust will be compressed and the concrete screed will collapse.

build a cellular structure from timber. Pour a solution with sawdust inside each cell. The advantage of this method is that a subfloor can be laid over the timber. And the attic will be usable

Insulation of attic floors with sawdust

Automatic control system for gas contamination and gas leakage protection

Dangerous properties of gas fuel:

- the ability of gas to form fire-explosive mixtures with air;

- suffocating power of gas.

The components of gas fuel do not have a strong toxicological effect on the human body, but at concentrations that reduce the volume fraction of oxygen in the inhaled air to 16%, they cause suffocation.

When gas burns, reactions occur that produce harmful substances, as well as products of incomplete combustion.

Carbon monoxide (carbon monoxide) is formed as a result of incomplete combustion of fuel. A gas boiler or water heater can become a source of carbon monoxide if the air supply and flue gas removal system is faulty (insufficient draft in the chimney).

Carbon monoxide has a highly targeted mechanism of action on the human body, including death. In addition, the gas is colorless, tasteless and odorless, which increases the risk of poisoning. Signs of poisoning: headache and dizziness; there is tinnitus, shortness of breath, rapid heartbeat, flickering before the eyes, redness of the face, general weakness, nausea, and sometimes vomiting; in severe cases, convulsions, loss of consciousness, coma. Concentrations in the air of more than 0.1% lead to death within one hour. Experiments on young rats showed that a CO concentration of 0.02% in the air slows down their growth and reduces activity compared to the control group.

Gas alarm - gas leak sensor

and carbon monoxide gas alarms in residential buildings and apartments containing gas boilers, hot water heaters, stoves and other gas equipment

The methane gas alarm serves as a leakage sensor for household natural or liquefied gas from gas equipment. The carbon monoxide alarm is triggered in the event of malfunctions in the smoke exhaust system and the entry of flue gases into the room.

Gas sensors must be triggered when the gas concentration in the room reaches 10% of the LPL of natural gas and the CO content in the air is more than 20 mg/m3. Gas alarms must control high-speed shut-off valves installed at the gas inlet into the room and shut off the gas supply based on a signal from the gas sensor.

NCPRP and VKPRP are the lower (upper) concentration limit of flame propagation - the minimum (maximum) concentration of a flammable substance (gas, flammable liquid vapor) in a homogeneous mixture with an oxidizer (air, etc.) at which it is possible for a flame to spread through the mixture to any distance from ignition source (open external flame, spark discharge).

If the concentration of a flammable substance in a mixture is less than the lower limit of flame propagation, such a mixture cannot burn and explode, since the heat released near the ignition source is not enough to heat the mixture to the ignition temperature.

If the concentration of the flammable substance in the mixture is between the lower and upper limits of flame propagation, the ignited mixture ignites and burns both near the ignition source and when it is removed. This mixture is explosive.

If the concentration of a flammable substance in the mixture exceeds the upper limit of flame propagation, then the amount of oxidizer in the mixture is insufficient for complete combustion of the combustible substance.

The range of concentration values between the LCPRP and the VCPRP in the “combustible gas - oxidizer” system, corresponding to the ability of the mixture to ignite, forms the ignition region.

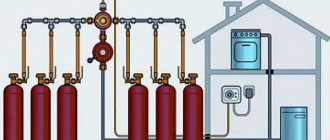

System for automatic control of gas contamination and protection against gas leaks in the boiler room of a private house: 1- carbon monoxide gas contamination alarm; 2 - natural gas alarm; 3 - shut-off valve on the gas pipeline; 4 - gas boiler; 5 - a detector in the house, notifies the residents of the house with light and sound.

Indoor gas control systems with automatic shutdown of gas supply in residential buildings should be provided when installing gas equipment, regardless of the installation location and its power.

The installation of a shut-off valve on the gas pipeline should be provided: - in front of gas meters (if a disconnecting device at the inlet cannot be used to turn off the meter); — in front of household gas appliances, stoves, cooking boilers, heating stoves, gas equipment and instrumentation; — in front of burners and igniters of gas-using equipment; — at the gas pipeline entry into the room, when a gas meter with a disconnecting device is placed in it at a distance of more than 10 m from the entry point.

Gas alarm in the cottage kitchen: 1 - natural gas alarm; 2 - shut-off valve on the gas pipe.

Read: “How to properly install a gas alarm in your home”

Next article:

How to properly make a chimney for a boiler in a private house.

Previous article:

How to make a house warm. Energy saving house.

What is the main source of energy for heating your home?

Vote! Find out what others have chosen.

Look!

— all polls

More articles on this topic

- Bearing capacity of soils at the base of the foundations of a private house

- Septic tanks and wastewater treatment stations Eurolos autonomous sewerage

- How to install a plastic window in a house correctly according to GOST

- How to properly make natural ventilation in a private house

- Proper waterproofing of the basement wall of a private house

- Self-learning room thermostat for gas boiler

- Correct wooden house made of construction timber

- Installation and installation of windows in a private house with your own hands

Features of adding an attic with your own hands to an old house

If you plan to complete the attic in an old private house or country house to create additional living space, then in this case the issue of dismantling the roof is relevant. You can dismantle it yourself; be sure to follow safety precautions so that the beams do not fall on your head.

The construction of an attic involves certain loads on the foundation and walls of the building

It is especially important to correctly distribute the loads on the walls, therefore, before building the attic, the load-bearing wall structures are carefully strengthened

The ceiling of an old house is both the ceiling of the adjacent floor and the floor of the attic, so it is necessary to take into account the movement of warm and humid flows so that condensation does not form in the ceiling, and as a result, rot and fungi. To avoid problems, you need high-quality insulation and waterproofing of the floor.

After completing the preparatory procedures, you can begin to connect and build the attic floor

During completion, it is important to strictly adhere to the design scheme for the construction of the walls and roof of the attic. Violation of the project entails not only deviations from the design of the attic floor

Also, improper distribution of load on load-bearing structures can lead to the destruction of the walls and foundation of the house.

Design

A shed roof is a lightweight roofing structure consisting of only one slope. It consists of a wooden rafter frame, sheathing, pediment and covering material. The construction of a pitched roof attached to a house differs from a free-standing one in that one side of it is attached to the load-bearing wall of the structure. A rafter frame of this design consists of the following elements:

- Mauerlat. This term refers to the timber that serves as a support for the rafters of a pitched roof. It is made from hardwood and treated with an antiseptic composition. The weight of the roofing covering is transferred to the Mauerlat, which it evenly distributes and transfers to the load-bearing walls and foundation. To make a roof for an extension with your own hands, one mauerlat beam is fixed to the wall of the main house, and the other is laid on support pillars.

- Rafter legs. These elements of the rafter system are made from boards measuring 50x150 mm or 100x150 mm. Cuts are made at both ends of the rafters in order to secure them to the Mauerlat. They carry the weight of the roofing material, distributing the load evenly and transferring it to the support beam.

- Strut. A strut is an additional element of the rafter system, which serves to strengthen the structure in cases where the slope has a length exceeding 4 m. The struts rest one side on the mauerlat, and the other on the middle of the rafter leg.

- Lathing. Sheathing refers to boards with a cross-section of 40x150 mm, which are laid on the rafters to make a stable base for laying roofing material. If soft types of roofing are used to cover the extension, a continuous sheathing is constructed from sheets of moisture-resistant plywood.

Warm floor

4.1. Water

If the boiler power allows, then it is a good solution for heating the attic. Plastic pipes will not create a significant load on the floor. For a small roof space (and height) this is a good option.

The question arises - what to do with the screed? She's needed. If you turn to a professional, he will tell you what technology allows you to do without it.

About the most popular pipes for underfloor heating, their characteristics and product prices - here.

4.2. Electric

There is a large choice of options here - cables, mats and IR films. What is preferable is decided individually, taking into account the characteristics of the attic.

The pros and cons of various schemes are discussed in detail in this article.

Radiator installation

They are included in the general heating system of the house. In principle, there is nothing particularly complicated. But there are a number of nuances that you should be aware of.

- Is the boiler's power sufficient to prevent it from operating at maximum capacity with the additional load of an attic? Otherwise, the heating device will not last long. And replacing with a new unit is also not a pleasant prospect. Firstly, such equipment is expensive. Secondly, the question will arise of what to do with a used boiler.

- Most likely, you will need to install another pump or purchase a more powerful one. The same thing - what to do with the old one, which is in working order? And the problem with the pumping device will have to be solved, since the attic means not only an increase in the length of the route, but also an increase in the coolant to a height.

What is an attic roof? Finishing the attic floor

Unlike the attic, the attic roof has a more complex structure, because it is also the ceiling of the living space. In addition to the standard set, it must contain heat, steam and sound insulation layers, as well as finishing on the inside. Mineral wool can be used as a thermal insulation material. Also, the role of additional insulation can be played by the lathing, which in the rafter system of attic roofs is usually made solid.

The interior decoration of the roof-ceiling depends on how the attic will be used. For dacha premises, lining, sheets of chipboard, fiberboard or plywood are quite suitable. For residential premises, the finishing is chosen to be more substantial and, accordingly, more expensive. Basically, this is a matter of personal preference of each owner.

The external finishing of the roof - roofing material - largely determines the level of comfort of the attic, so its choice should be taken seriously. Among the main requirements for roofing material is a high level of noise and heat insulation. The most common materials are tiles, slate and bitumen-based materials. It is not recommended to use metal sheets, which not only will not retain heat, but will also create noise when it rains. Ruberoid is also not a suitable option for an attic roof - in the warm season it heats up on its own and transfers heat to the room. In addition, in hot weather it emits a specific odor.

We calculate the heat: what will be in the attic?

And now - about the important points. As you know, heat always moves upward. Therefore, if you don’t want the attic to become too hot and stuffy, and the rooms on the floors below to become colder, block off this heat access. How? To begin with, be sure to install doors between the first and second floors, if there are any. Next, think carefully: will you somehow heat the attic? If not, then the heat that will come from the floor below will be enough for her (provided that there is no door above the stairs). If so, then the attic floor will need to be insulated in the same way as the pitched walls, thereby creating a barrier for heat from below. The room below will become warmer, and the attic will now have its own personal microclimate, which can be regulated.

But why, for example, make the attic colder than the living rooms? This is a completely rational solution if you are going to organize a library or a personal mini-gym in it, which do not need either excess heat or excess water vapor from below.

We heat the attic space or how to do heating in a house with an attic correctly

There are two ways to use a country house - live in it periodically, for example, only in the summer, or permanently. Today we will analyze the second option, in particular, we will focus on projects with an attic floor. In this case, you will need efficient heating for the attic space, which can be autonomous or connected to the general heating system of the house. Let's look at it in more detail.

The photo shows methods of heating the attic floor

Preparation

In any case, we will first need to properly insulate the attic, otherwise the cost of heating it will be very high. Since the floor is located in direct contact with the roof, it is necessary to carry out work on its thermal insulation.

- mineral wool,

- polyurethane foam,

- foam class G1,

- foamed polymers.

Advice: pay special attention to the insulation of the attic; the better you do it, the more comfortable the living conditions in it will be, and the less money you will have to spend on additional heating. High-quality heating is impossible without proper roof insulation. High-quality heating is impossible without proper roof insulation

High-quality heating is impossible without proper roof insulation

Selecting a heating system

If the house is just being built, it is necessary to provide heating for the attic floor at the design stage. However, as construction practice shows, most often the attic space is turned into an additional living area after all the work has been completed.

In this case, you cannot do without additional costs associated with wiring the necessary communications and choosing the optimal option for heating the room:

- "warm floor" system,

- fireplace installation,

- autonomous heating system, the price of which may vary,

- connecting the floor to the finished heating system of the house.

Do-it-yourself attic heating using infrared panels

What to pay attention to

Whatever you choose, you must first develop a heating system design, in which you try to take into account all the design features of the building, the need for materials, their cost and quantity.

The heating diagram for a cottage with an attic will allow you to understand:

- where to install the necessary equipment,

- how to lay out pipes so that you can get the maximum effect from the distribution,

- Where is the best place to place ventilation?

General heating scheme for a house with an attic

Don't hesitate to seek professional help to get a safe and effective system. Although, if you have certain abilities and the necessary materials, you can do the heating of the attic floor with your own hands.

- boiler,

- circulation pump,

- pipelines,

- systems for air supply and removal of fuel combustion products.

The heating boiler should be selected depending on the availability and ease of use of certain types of fuel. Its power must correspond to the size of the room. You can calculate them yourself or get them from specialists.

Tip: the standard calculation of heating power is 1 kW per 10 m2. In this case, the ceiling height is assumed to be 2.5-2.7 m.

Stove or fireplace

An excellent option for a heat source in the attic, which can also become an interior decoration. The main question that remains to be resolved before installing the fireplace is whether the ceilings will withstand it, since the structure has significant weight. It may be necessary to carry out work to strengthen them.

Using a fireplace as a heat source

Tip: the load can be reduced by using metal pipes and lightweight refractory bricks.

You can also purchase ready-made structures made of cast iron or steel. Such fireplace stoves are capable of creating a comfortable temperature in a room up to 200 m2.

- objects of high fire hazard,

- arrangement requires the use of non-combustible materials in the interior, properly installed chimneys and high-quality ventilation.

Tip: to reduce the risk of fire, install structures at some distance from the walls or place them in the middle of the room.

Using an electric fireplace does not require much maintenance and is safer, although electricity will increase your heating costs. To reduce them, you can install convectors that will automatically turn off after reaching a certain temperature in the room.

Installation of a steel water heating convector

A house with an attic floor has an excellent appearance and can be used year-round or from time to time. A properly executed heating system allows you to create a comfortable temperature in the room under the roof.

Insulation of heating pipes in the basement Pipes and plumbing

House heating costs are increasing every year. Each owner is looking for ways to save: the boiler turns on periodically, or constantly works only at a minimum, and so on. The use of such methods leads to a significant decrease in the temperature in the house. But few people think about how efficiently the living area is heated, because most of the heat is lost on the way to it.

If heat loss can be minimized, then the rooms will warm up better and faster; therefore, continuous operation of the boiler will not be required, and it will be possible to resort to savings without compromising the temperature. Since boilers are often located in basements and other utility rooms, we will consider how to insulate heating pipes in the basement and other possible places where the system passes.

Main load-bearing elements

The design includes the following components:

Rafter legs that transfer the load from the weight of the roofing and the wall to the walls of the house. The section is selected depending on the angle of inclination, span, pitch and design load. A professional can perform detailed calculations correctly. For private construction, you can use approximate values, but it is best to provide a small margin. Spreaders are rafter legs that rest on mowers on one or both sides. The cross section is calculated in the same way as for rafters. Sloping legs are a design that is used in a hip roof. This element serves as a support for the narodniks. The cross-section is taken depending on the load and span; in any case, it should be larger than that of the rafter legs. Mauerlat is an element that serves as a support for the footrails and transfers the load from the roof to the walls, distributing it evenly. It would be correct to choose a section with dimensions of 100 by 100 or 150 by 150, depending on the complexity of the object. Installation of the Mauerlat is not carried out during the construction of frame and wooden houses, since in this case its role is played by the upper crown of the walls or trim. The crossbar is a beam that also serves as a support for the rafters, but in the upper part. The crossbar is installed at the ridge of the roof or at a break in the slope, in the case of a broken structure. The cross-section should be taken depending on the conditions; the recommended value is 200 by 200 mm. Struts, racks, grips are additional elements for securing elements. They are used to reduce the cross-section of load-bearing structures. Their cross section is most often chosen constructively

It is important to consider the convenience of making connections.

A do-it-yourself attic roof must be erected starting with the selection of sections of all elements of the roof frame. The material for manufacturing is selected taking into account the following conditions:

- the wood must be coniferous (pine, spruce, larch);

- material grade – first or second;

- humidity no more than 15%.

Window calculation

According to SNiP, the area of all windows must be at least 10% of the total floor area. When dividing the attic into several rooms, each of them must have a window.

Sloping windows

The easiest way is to do inclined installation with your own hands. But such windows will serve as part of the roof, so care must be taken to seal the abutment joints. Like roofing, windows will be subject to significant precipitation in the form of snow. To prevent them from failing, it is necessary to install reinforced double-glazed windows and reinforced frames.

Installing inclined windows has some advantages:

- there are no sharp transitions between shadow boundaries, which increases the amount of light penetration into the room;

- the relief of the roofing remains unchanged;

- ease of installation allows you to do everything yourself.

When calculating inclined windows, you need to know that their area increases with the angle of inclination. You can adjust the area by the height of the window, reducing it on steeper slopes.

When deciding on the size of the windows, you need to take into account that they will have to be fastened with your own hands between the rafters. In order for the frame to fit well, its width must be at least 40 mm less than the pitch of the rafter legs. Otherwise, you will need to install a reinforced beam. Such a violation of the frame structure requires additional calculations. If you want to install a large window, then it is better to mount 2 smaller ones side by side. The effect will be the same, but less work.

Dormer windows

A vertical window, recessed into the roof or installed at the end, is called a dormer. Building a roof with recessed windows with your own hands is difficult. The assembly of the rafter system and the laying of the roofing becomes more complicated, as an additional valley appears on the sides and top. In snowy regions, snow guards must be installed above recessed windows, otherwise they may be demolished when a large mass of snow melts.

Recessed windows have one advantage, which is expressed by standing near them at full height. This design is most often installed when creating an exit to a balcony with your own hands.

If we consider the minuses, then there are much more of them:

- less light transmission than from inclined structures;

- deep shadows tire your eyesight;

- The roof topography becomes more complex, which increases the difficulty of do-it-yourself installation.

Calculation of a water heating system

This calculation includes determining the required boiler power and the number of battery sections.

Boiler

Let's determine the thermal power of the boiler required to heat a house with an area of 150 m². Calculation formula:

where S is the area of the house, QU is the specific power per 10 m2. The specific power depends on the terrain (in the central zone of the Russian Federation it is 1.5). According to the standard, for every 100 m² you need 10 kW of power. Substitute into the formula: QT = (150 · 1.5) / 10 = 22.5 kW.

Number of battery sections

To correctly distribute the thermal power between rooms, it is necessary to calculate the number of battery sections. The initial value is the heat transfer of the section. It is indicated in the technical documentation of the battery.

Let us assume that the heat transfer of the section is 150 W. If you divide this number by 100 W/m² (10 kW/100 m² according to the above standard), you get the area that this section can heat. In this case, we get 150 W / 100 W/m² = 1.5 m².

Since the area of the house is 150 m², the number of sections N = 150 m² / 1.5 m² = 100 sections. Sections will be distributed in rooms depending on the area of each of them (1 section per 1.5 m²).

Heated floor power

The calculation for electric and electric water floors is simple and is based on the following standards:

- room or kitchen - 0.12–0.14 kW/m²;

- balcony with glazing - 0.13–0.17 kW/m²;

- bathroom - 0.15 kW/m².

If the premises are on the ground floor, the power is increased by 20%.

For water heated floors, the length of the pipes to be laid is calculated using the formula:

where L is the length of the pipe, S is the area of the room, a is the distance between the pipes (pitch), LT is the length of the supply pipes, LPT is the length of the through pipes.

Types and characteristics

The material is obtained from molten blast furnace slag, stone (rocks) or glass. The structure of these fibers is thin, randomly arranged villi, ranging from 2 to 60 mm in length. This insulation is produced in the form of mats or slabs. In order for the fibers to better adhere to each other, the slabs are additionally impregnated with special oil (to repel moisture) and phenol alcohol.

Depending on the origin, they differ:

- Glass wool. It is made from a molten mixture of broken glass, sand, limestone, and soda. The fibers are 15-50 mm long and their thickness is 5-15 microns. The material is chemically resistant, difficult to ignite (withstands up to +500 o C).

Stone wool. To make it, gabbro-basalt rocks are melted. The thickness of the fibers is 4-12 microns, and their length is up to 16 mm. It heats up to 300 o C without igniting.

Installation of natural ventilation

A natural ventilation system is created during roof installation. To implement air exchange, you will need to install special elements responsible for air exchange under the roof. For air flow, soffits are used, which are installed around the perimeter of the building. The perforated surface allows air to enter the attic. To remove exhaust air, point or continuous aerators are used, which are installed on the slope of the roof.

Aerators can be installed on the roofSpecial aerators are mounted on the ridge. It is thanks to ridge aerators that the efficiency of all natural ventilation increases, because the area of the outlet surfaces of the elements is much larger than that of conventional ones. The number of aerators is calculated individually and depends on the total roof area. For 100 m2 of area to be ventilated, 2 aerators are installed.

Ventilation outlet through the roof

This is exactly the solution that heating engineers recommend. And not at all because they want to get more money from you. The fact is that each horizontal section of pipe reduces natural draft, and therefore the efficiency of ventilation.

It is better to entrust the design of the ventilation shaft of a private house and its access to the roof to builders: not only the cross-sectional area and height above the roof are important here. The area and type of premises, the material and shape of the duct, the type of ventilation, pipe insulation, temperature in the attic, weather conditions and other factors are important.

To fully ventilate the attic, it is necessary to provide air exchange within the room and remove moisture from the roofing pie

A vertical pipe leading to the roof will save the house owner from problems with condensation in the attic and on the facade, and a deflector or roof fan installed on the top of the pipe will provide the necessary level of draft.

Arranging a passage through an already assembled roof is a difficult, costly and thankless task, so it is better to provide a ventilation outlet on the roof at the stage of its construction.

Features of the event

Usually in a cold attic only the ceiling is insulated. Then the roof truss system is left open so that it can be freely inspected and problems that arise can be corrected. If you insulate the roof with mineral wool, it becomes an attic, which can be used for a different purpose than the attic.

It is very important that the insulation is done correctly, otherwise condensation will form. Accumulating on the ceiling, moisture will seep through the ceilings. Mold and mildew may appear

And the rafters will rot from the inside

Mold and mildew may appear. And the rafters will rot from the inside.

When using mineral wool as insulation, consider its weight. The ceiling and floors must withstand the expected load with a margin, the structure must be reliable.

Instructions for insulating the attic floor with mineral wool on the video:

When planning your work, make calculations: how much material do you need to purchase? Its quantity depends on the area on which the material will be laid and the number of layers. The thickness of the thermal insulation layer depends on the climate of the region.

Step by step instructions

First, prepare the “territory”, clear the ceiling of possible debris and thyrsus. Metal roofing elements should be painted with oil paint to prevent condensation from accumulating on them.

Then a lining material is laid on the ceiling as a vapor barrier layer. If it is not there, the mineral wool will absorb all the moisture from the warm, humid air that rises from the living rooms.

Over time, it will lose its thermal insulation qualities. A budget option is to use glassine; a vapor barrier film will cost more. It needs to be laid with a slight overlap, the joints should be fixed (glued with tape or secured with wooden slats).

Place mineral wool between the joists tightly, without gaps or cracks. The joints of the material also need to be taped.

Place clean, dry, even boards on top of the joists. They will be the floor in the attic. And the mineral wool will be ventilated, “breathe” under them, and will dry out in case of moisture.

This installation is sufficient if waterproofing material is laid under the roof and there are no gaps in the attic.

If there is no waterproofing material under the roof, then it is worth covering the thermal insulating mineral insulation with a vapor barrier. The easiest way is to attach the plastic film with thin cross bars.

Mineral wool is ideal for insulating wooden floors. You can use any type: in rolls or in slabs. Choose a material of the desired density, follow the installation instructions, then the room will be warm and comfortable for a long time.

Insulation of a cold attic with mineral wool

A vapor barrier is placed under the mineral wool.

To insulate the ceiling of a cold attic with mineral wool, you can take material of any density, from low to high. At the same time, it is still preferable to choose lighter materials so as not to create additional loads on the beams. Some experts are inclined to believe that glass wool is better suited for insulating an attic with mineral wool than stone wool. The latter is too brittle, and it weighs a lot. Also read: “Which insulation to choose for walls and ceilings.”

As you already understand, insulation of a cold attic of a private house with mineral wool is carried out by laying thermal insulation between the load-bearing beams directly on the rough ceiling of the first floor. Due to the high hygroscopicity of mineral wool, it is necessary to use a vapor barrier film. In principle, even simple polyethylene can be used. There will be no special loads on the film and if installed carefully it will not tear. To be completely confident in the reliability of the protective layer, you need to use a polypropylene vapor barrier reinforced with fiberglass mesh.

Insulating the attic with mineral wool, technology:

- the supporting beams are sewn up from below - this is the rough ceiling of the first floor;

- on the attic side, a vapor barrier is laid on the rough covering;

- Mineral wool is placed on top of the film.

Vapor barrier tapes should be laid overlapping, the joints should be taped with double-sided tape. The mineral wool is placed outward so that there are no cold bridges at the junction of the insulation with the beams.

Insulating a cold attic with mineral wool is always preceded by calculating the thickness of the thermal insulation. In any case, the layer will be at least 10 cm. Mineral wool is available in a thickness of 5 cm. It is better to lay thermal insulation in two layers with offset joints. This will eliminate the possibility of heat loss through the joints of the mineral wool sheets.

After insulating the attic floor with mineral wool, you can immediately lay the floor on top of the beams. It is advisable to first cover the insulation with waterproofing - a material that does not allow water to pass through, but allows steam to pass through, but only in one direction

It is important not to confuse which side to lay the waterproofing on, otherwise moisture will accumulate in the mineral wool, as a result of which the thermal conductivity of the material will increase significantly

It is quite possible to use a fireplace to heat a country house. To do this, a heat exchanger is built above the firebox.

Read about how to choose the sizes of brackets for radiators here.

Choosing a boiler for heating the attic of a bathhouse

First of all, you need to decide on the type of device. The market offers many models operating on different types of fuel:

- Gas

. They are connected to natural gas mains. They can also run on liquefied bottled fuel. - Liquid fuel

. Such devices mainly run on diesel fuel. - Solid fuel

. They use coal, coke, and firewood to operate. - Electrical

. Such devices are the easiest to operate, environmentally friendly and do not require additional chimney equipment. - Universal

. The most functional are boilers that operate on all major types of fuel. They have two chambers: one is for solid fuel, the second is for liquid fuel and gas. In this case, the device is equipped with a special heating element.

The power of an attic heating device is not calculated according to the traditional formula of 1 kV per 10 m2, since the ceiling in such a room is sloping. Calculations are made according to the principle of 500-700 V per 10 m2. The cost of a boiler is determined not only by its power and burner type, but also by the body material (steel, cast iron). It is worth noting that foreign models are more functional due to modern automatic equipment. German and Swedish equipment is considered the highest quality and most durable, but it will not be cheap. Boilers of the Bosch, Vaillant, Viessmann brands cost from 28 thousand rubles.

In the middle price range, the most functional are Italian, South Korean, Czech, Spanish, Slovak and Japanese boilers. Companies such as Baxi, Beretta, Ferroli, Ariston, Protherm, Dakon have proven themselves well. Their price starts from 20 thousand rubles. The cheapest models are domestic ones, for example, “Signal”. The price for them starts from 8 thousand rubles.

Fireplace

When giving preference to a fireplace, you should remember some features when installing it. If this heating method was not taken into account when developing the project, the floor will have to be strengthened. For the simple reason that the fireplace itself already has sufficient weight, and when fired, its mass increases several times more. The ideal option to make the attic heated would be a lightweight fireplace with a lightweight pipe structure, or an electric fireplace. It is the latter heating method that is safe and easiest to use.

Heating a private house with an attic

Adding another level to the house or converting the attic space are the most common options for solving the housing problem in a limited area. Creating a favorable microclimate in the attic in the technical aspect is a rather difficult task. The main reason is that the additional “squares” are under the roof. It is through it that increased heat exchange occurs, since hot air, according to a well-known law, tends upward. And this part of the building is ventilated more intensively. This determines the specifics of attic heating. What heating technologies exist?

Heated attic for year-round use

Modern design does not ignore attic and attic spaces and considers them valuable living space. Very often, an empty room under the roof is converted into bedrooms, a study, a children's room, or used as a billiard room. It is the low ceiling, under the slope of the roof, that allows you to create a cozy atmosphere for relaxation.

Roof insulation scheme.

However, in order for this additional area to become a residential part at any time of the year, you need to take care of its heating. It is no secret that heating an attic is a rather complex technical task, which first of all begins with the process of thermal insulation of the roof. It is this kind of work that will allow you to retain heat and use the room for year-round use.

Dimensions of wooden parts of the attic frame

Beams, item 7 in the figure, are an element of the load-bearing frame of the attic roof. In addition, in the design shown in the figure, these parts simultaneously serve as floor beams for the lower floor of the house.

The cross-section of the beams depends on the magnitude of the loads acting on the floor, the length of the span to be covered and the distance between adjacent beams (beam spacing). The floor loads in this structure are the sum of the normal floor loads plus the roof loads.

For beams less than 6 m long, in most cases it is enough to choose a beam with a section of 100 x 200 mm. The clear distance between adjacent beams is 0.6 m.

When installing a ceiling, it is necessary to properly perform sound insulation. During construction, owners usually do not pay due attention to this issue, and then regret it.

The beams, item 4 in the figure, serve as beams for the attic floor. The same part acts as a tightening for hanging ridge rafters (item 1). Details of the device and calculation of the beam cross-section can be found in the article “Attic flooring using wooden beams.” The cross-section of the beams is chosen as for a non-operational attic floor.

The cross-section of other frame parts also ultimately depends on the size of the house, the distance between adjacent elements, as well as loads - the weight of the structure, wind, snow, and operational loads.

When choosing the dimensions of the attic frame parts, the standards of manufactured lumber are also taken into account. For beams, timber or edged boards of large sections are usually used. In some cases, it is advantageous to make beams from boards held together in two or three layers.

Large spans, more than 6 m, are covered with beams or factory-made trusses.

Lumber for roof frame parts must correspond to the first quality category for load-bearing structures. If there are knots on the edges of the timber beams, then the timber is laid with the knots facing up.

Edged boards are usually used for rafters and other frame parts. Read details about the dimensions and structure of the roof truss system: “Roof of a private house“.

When constructing the attic frame, it is beneficial to be guided by the project. Working without a project leads either to excessive consumption of lumber or to insufficient strength of the structure.

Watch a video on the topic of designing an attic frame.

Watch a video about assembling the frame of a sloping attic roof.

Pediments of a sloping roof

After installing the attic frame, the gables are sheathed. It is more profitable to do this before installing the roof sheathing. It will be more convenient to cut the gable trim in place, along the border of the rafters, to fit it to the roof overhang. If you do the sheathing and roofing first, then the sheathing of the gables will then have to be carefully measured, marked and adjusted to the roof overhang.

In addition, a roof with open, unsealed gables has a large windage area. In strong winds the roof can be blown off.

In some house designs, the gables are not sewn up, but are laid out from the same material as the walls. That is, the gables are a continuation of the walls of the house.

Products for Auto ⇆

Dormer windows

When planning an attic, you should take into account the recommendations of SNiP. They recommend making the window area no less than 10% of the floor area. So if the attic is divided into several rooms, each should have a window.

Installation of skylights in the roof

Of all the methods shown in the photo for installing skylights with an attic, inclined installation is the easiest to implement. In this case, it is necessary to ensure the proper degree of waterproofing of the junction, and also to use special models with reinforced frames and reinforced glass - the load on the surface can be significant.

Advantages of a sloping roof window:

- more light, less sharp boundaries of light and shadow;

- the roof surface remains flat, its relief is not complicated;

- relatively easy installation.

The steeper the slope relative to the floor, the smaller the window height should be.

The width of the window frame should be 4-6 cm less than the pitch between the rafters. Then it can be easily installed without disturbing the structure of the frame. If the window is wider, it is necessary to make a reinforced beam above it and calculate the load.

If you need to have a larger window, it is easier to place two narrow ones side by side. They look no worse than one big one, and there will be fewer problems.

Two windows side by side look no worse than one wide one

When installing a dormer window, the roof geometry becomes more complicated: a valley appears on top and on the sides. Because of this, the rafter system becomes more complex both during planning and during assembly. The complexity of laying the roof covering also increases. All valleys are the places where leaks are most likely to occur. Therefore, everything needs to be done very carefully. In regions with a lot of snow, it is advisable to install snow guards over such windows so that they are not blown away in the event of a sudden meltdown.

Installation of a vertical dormer window in an attic roof

The advantage of such a window is that you can stand next to it at full height. But they let in less light, the terrain becomes more complex and the roof becomes more problematic.

A recessed window is usually used if there is access to a balcony through it. In other cases, this method of arrangement is not the best option: little light gets in, the shadows turn out to be very deep, which is tiring for the eye, the geometry also becomes more complex, although not to the same extent as in the previous version.

The easiest way is to make a window at the end of the attic. In this case, a reinforced frame or reinforced glass is not needed. Just high-quality glass is quite enough. It is this option that can most often be seen in country attics: this is the most inexpensive option that can easily be implemented with your own hands.

Attic heating

Wire cross-section (mm 2 )

Current consumption (I) for copper Current consumption (I) for aluminum

- Let's try to calculate the heating for a floor measuring 70m2, on which 20m2 is covered with furniture. This means that we find the total power (with an average power of the IPO of 230 W): P = 50 m 2 * 230 W = 11500 W or 11.5 kW.

- Now you can find out the current consumption: I=P/U=11500/220=52.27A. This result suggests that the heating will have to be divided into two wings and for each, use copper wire with a cross-section of 4.0 mm 2 or into three wings, using a thinner wire of 2.5 mm 2.

Installation of IPO on the floor

Let's say we have already drawn up a heating scheme for a house with an attic, and we have calculated the location and amount of infrared film for the floor. Now you need to take care of the base plane so that it is level. If this were on the first floor of the house, then you would, of course, be offered a cement-sand screed for leveling, but since this is done on the floor, you can use OSB for leveling, simply covering the floor with it.

Considering that the floor temperature will be regulated by a thermostat, you need to determine a place for it on the wall and supply power there. Pack all the wires in a corrugated flexible cable channel, and calculate it so that there is enough corrugation for the sensor that you will install under the film.

- When installing infrared film for heating, you should take into account the possibilities for cutting it, and this, as a rule, can be pieces of 250 mm or multiples of this number. On the surface of the film you will see current-carrying copper buses - you need to lay the IPO to the base with them, and the connection of the cut pieces is made by parallel connection.

- To connect, you need to put terminal shanks on the wires - to do this, the wire is exposed by 8-10 mm and the shank is attached to it using a crimper. To connect the pieces, you will sometimes need to connect two wires to one terminal - the process of fixing it remains the same. Calculate the length of the wires so that they can be hidden under the baseboard.

All connection points need to be insulated and to do this, simply cut pieces of insulation and close the connections from above, and so that the infrared film does not move apart, it should be secured with tape. Where the sensor will be installed, a recess should be made in the main floor so that the device does not protrude above the plane, as required by the instructions. In the end, underfloor heating will make you and your family happy.

Combined insulation technology

In addition to the usual combined attic insulation, where two types of insulation are used to combine their qualities, we also want to tell you how to insulate an attic in a more cunning way - with additional heating.

One of the most atypical ways to heat an attic is to install an infrared heater directly on the pitched walls. The thin film is easily installed under the skin and releases valuable thermal energy. This, in turn, heats the objects in the room, and they also give off additional heat.

Infrared floor heating is based on the well-known principle of heating through current. The current flows through the resistive foil and generates heat up to 45C, which is emitted by infrared invisible rays 9.5 microns long. This warmth is comfortable, and the temperature difference between the floor and ceiling is only 1-3C.

A modern film infrared ceiling heater works for only 15 minutes every hour. A fairly economical option in which the air itself does not heat up, and therefore the heat does not escape through the ridge.

Installing infrared film is also simple and safe, as you can see from the step-by-step photos:

Just keep in mind that each manufacturer has its own subtleties of installing such films, for which you must read the attached instructions. But the principle is the same: spread it out, secure it and connect it.

How to make an attic on an old house

Removing the roof is the first stage. Before starting to build an attic, the first step is to dismantle the old roof.

Some people think that you can do without this process, but dismantling the old roof provides double benefits:

- the attic space will be reliable and will not leak;

- Saves money on repairing an old roof.

Dismantling work begins with the removal of roofing material, such as slate, tiles or other covering

It is important to carry out dismantling carefully and slowly

When the roof is removed, they begin to remove the roofing felt, if any, it is usually placed as waterproofing. Then the sheathing is dismantled. If the planks are in good condition, they are suitable for creating a new roof sheathing.

After complete removal of the roofing materials, they begin to dismantle the old rafter system, if its height does not allow for an attic, or if the bars are unsuitable for further use.

It takes two or three people to dismantle heavy wooden beams; this work is difficult to handle alone.

System design for a two-story house

There is nothing complicated in arranging utility networks, but to develop a project it is better to turn to professional heating engineers. This will save you from miscalculations and help you save money.

If you want to do everything yourself, you will have to study the subject more deeply. Everything is important - from climate and layout to sound insulation and design. This will help you figure out which heating scheme will be optimal in your case: with forced or natural circulation, one- or two-pipe, open or closed type, with water or antifreeze as a coolant.

Attic design options

So, there is a long-abandoned attic; the desire to repair it too. Therefore, reconstruction can begin. When starting to improve the territory, first of all you need to consider:

- Size (square)

- Ceiling height.

- Geometry of the building (number of bevels).

- Technological nuances (air humidity/dryness).

Taking into account all the shortcomings of the initial construction, it is necessary, first of all, to take care of insulation, waterproofing, ventilation and other technical issues. In some situations, it may be necessary to resort to reconstruction of the rafter system and relocation of window openings. When all the engineering nuances are met, you can begin designing your home.

The final design and style of the room depend on its subsequent use. In the attic you can equip:

- Playroom for children. Little fidgets will definitely enjoy running around under the roof and spending the night listening to the birds singing and the sound of rain. In this case, it is better to limit yourself to a minimum set of furniture, leaving most of the area free. All the little ones will need is a children's bed for relaxation, several small frameless chairs for relaxation and a shelf with toys.

- Bedroom. A bedroom in the attic is not only very romantic, but also quite practical. By setting up a bedroom on the attic floor, you can rest peacefully in a cozy nest, inaccessible to prying eyes, at any time of the day. To decorate such a room, it is better to use pastel colors, natural materials and a minimum of modern elements - ethnic and vintage styles are perfect for an attic bedroom.

- Rest room. In such a relaxation room you can receive guests without worrying about their leisure time and the comfort of other residents of the house. In the middle of the attic you can place a billiard table, and along the perimeter there is a small bar counter with high chairs.

Project

It is customary to start building an attic with your own hands by drawing up a project. The most obvious solution was to raise the pitched roof a couple of meters relative to its original position, but that was not the case:

- From the point of view of housing legislation, an insulated room with solid side walls automatically turned from a cold attic into a full-fledged residential floor and required registration - lengthy and expensive;

- The second floor would completely block the skylights in the wall of one of the adjacent houses.

That is why it was decided to build an attic with a gable roof. The roof ridge was oriented along the long side of the house.

A few details of the project.

The roof was supposed to be sloping

The sloping attic roof has an important advantage: with a minimum ridge height, it allows you to obtain the maximum attic area with an acceptable ceiling height; Mansard roof

Thanks to the bend of the slopes, the owner receives maximum usable area with a minimum ridge height

Mansard roof. Thanks to the bend of the slopes, the owner receives maximum usable area with a minimum ridge height.

- Gutters were needed to drain rainwater. The roof slopes had to move away from the adjacent walls of neighboring houses. The free space was occupied by gutters made of galvanized steel sheet sealed with bitumen mastic;

- A corrugated sheet was chosen as the roofing covering. Yes, it is noticeably noisy in the rain, but it is not afraid of impacts from slate torn from neighboring roofs (strong winds are typical for Sevastopol in winter), it is lightweight and easy to install;

- I decided to turn the gables of the attic into panoramic windows. This decision was favored by a beautiful view of the sea;

This is how Sevastopol Bay looks from my balcony.

- The attic received its own entrance from the attached balcony. In a slab floor, you cannot simply cut an opening for an internal staircase: support columns must be placed under the slab with a cutout, which would significantly increase costs. How things stand with the family budget after the move - I think it’s clear without my explanation.

The balcony attached to the house quickly turned into a relaxation area for guests and owners.

Design of fireplaces in an attic apartment: selection in the photo

We enjoy admiring the open fire. The flame fascinates, relieves fatigue and awakens pleasant memories. But, in addition, fireplaces in an attic apartment are heat sources that do not depend on the work of utilities and weather conditions.

The location of the attic apartment under the roof of the building allows you to install a full-fledged fireplace in the room. Its creation can be done at the design planning stage or after renovation. This depends on the choice of design and the specifics of the fireplace.

Wood-burning fireplaces require a chimney that removes combustion products and protects the room from unpleasant odors. The pipe must provide good traction.

A fireplace built into the wall will free up space in the attic and will also become a stylish element of the interior.

To increase heat transfer, the fireplace is lined with natural stone, which will fit beautifully into a non-standard setting. The finish can be left exposed or plastered over.

If the area of the room allows, design the fireplace in a free space, for example, in the center of the living room. Relatives and friends will highly appreciate the beauty, comfort and warm atmosphere of your home.

Fireplaces can serve as partitions dividing the area into zones.

A cheaper option is ready-made metal stoves. They can be mounted in niches or placed independently.

In recent years, eco-friendly fireplaces powered by biofuel have become widespread. They do not smoke, so they do not require smoke removal.

System advantages

Stove heating can be installed in any home. The material of the walls does not matter. Stove heating has many advantages over other heating systems. If the house is built of brick, then the stove will heat the house more efficiently.

For stove heating, you can use different types of solid fuel: cardboard, coal, peat, firewood, branches, etc.

This heating does not depend on electricity, which means it works stably. The oven operates in autonomous mode. Stove heating is often used as an additional heat source. Some people use a stove to create coziness in their home. Wood stoves are not as popular as other heating devices, but they are used quite often.

Autonomous heating

An autonomous attic heating system makes it possible to maintain the required temperature throughout the year.

Such a system includes the following mandatory elements:

- boiler;

- chimney;

- air ducts;

- pipes;

- batteries;

- circulation pump.

The boiler is the heart of autonomous attic heating. At the request of the owner, it can be electric, gas, liquid or solid fuel, or combined. The location of the boiler, the type of fuel, as well as the method of removing combustion products are the main issues that need to be decided before heating the attic.

As for the type of coolant circulation inside the heating circuit, it can be natural or forced. As a rule, systems with modern boilers are supplemented with circulation pumps, which makes them energy-dependent. However, gravity systems also have a number of significant limitations - slopes must be observed, pipes of large cross-section are required, and it is impossible to regulate the temperature of the coolant.

When equipping the heating of a house with an attic with your own hands, it is important to correctly determine the power of the boiler based on the area of the room. The standard power value is 1 kW for every 10 m2, provided that the room is insulated and the ceiling height does not exceed 3 m. Therefore, in order to save on fuel, it is worth choosing a low-power boiler according to the attic area.

Wood burning stove made of bricks

The most efficient oven is one that is made of bricks.

With the help of such a stove, the house is heated efficiently. Let's consider the main advantages of a brick kiln:

- The wood stove works without interruption. After all, electrical problems do not affect the operation of the furnace in any way. Therefore, it compares favorably with other heating devices. The wood stove will operate efficiently and without interruption at all times.

- Brick accumulates and gradually releases heat. A hob is often installed in a brick oven. Therefore, in cold weather you can use the oven for cooking. This way you can save money. After all, many homes have electric stoves that consume large amounts of electricity.

- In houses where other heating equipment is installed, a wood stove is installed as a backup heat source. After all, problems with electricity or other types of fuel often occur.

- A brick stove can operate on different types of dry fuel. You can use cardboard, coal, peat, branches, wood waste, etc. You can use modern fuel, which is manufactured for stoves operating on solid fuel.

Thanks to a large number of advantages, a wood-burning stove remains in demand today.