Country and personal plots of various sizes need to be divided into functional zones where you can relax, arrange a food preparation area, or set up an orchard and vegetable beds. Greens, berries and vegetable crops are useful for adults and children leading a healthy lifestyle; their cultivation can be optimized by increasing productivity, which is possible when constructing a greenhouse on your own plot.

To build a greenhouse, you can use a variety of available materials, glass frames and high-density polyethylene film, but polycarbonate is especially popular among experienced gardeners.

After studying the provided photos of polycarbonate greenhouses and detailed descriptions of their own construction, you can choose the best option for growing environmentally friendly and natural food for the whole family.

How to choose a design

If you decide to build a polycarbonate greenhouse with your own hands, it is advisable to choose a design that allows you to use the main advantage of this material - its ability to bend. These are two types with curved roofs with arch-shaped supports.

In one design, the arcs extend from the ground itself. If they are curved in the form of a radius, a lot of area is lost at the edges, since it is very inconvenient to work there due to the small height.

Another design solves this problem - with a composite frame welded from several pieces. Straight posts emerge from the ground/from the base, which rise to a height of at least one and a half meters. An arc is welded to them. With this arrangement, the roof is rounded and the walls are straight.

You can even work along walls without problems, standing up straight to your full height.

But the rounded greenhouse roof has several disadvantages. The first is that it is more difficult to make ventilation windows in it than in a straight line. The problem can be solved by making transoms in the walls rather than in the roof. The second disadvantage of a rounded roof in a polycarbonate greenhouse is that snow falls off from it worse than from flat, sloping surfaces.

If you live in a region with snowy winters, you will either have to make reinforced trusses, or make a pitched roof - with one or two slopes.

There is a third solution - to make a rounded part of the roof from two arches, welded at an angle, which forms a kind of ridge. With this structure, the snow melts well and the ridge can be protected with a wide strip of metal. This will improve snow melting and protect the joint from leaks.

Flaws

In addition to the strengths, there are also weaknesses. First of all, this is the flammability of the material. When exposed to an open source of fire or hot objects, it begins to melt, losing its previous shape.

Polycarbonate is also relatively expensive compared to other materials. However, there is a wide range of this material on sale in different price categories, which allows each summer resident to choose the most suitable option for himself.

How to make a polycarbonate greenhouse with your own hands (drawings)

If you decide to assemble a polycarbonate greenhouse yourself, you will need a design plan and certain materials, a list of which you can find below.

Design selection

First, you need to decide on the type and material of the frame for the future greenhouse. There is a huge variety of both standard solutions and individual projects.

- The choice of material is also important. Construction stores sell ready-made kits made from metal profiles that are assembled like a construction set.

- PVC pipes can also be used as a material. They are easy to bend, lightweight and easy to install.

- And of course, one cannot fail to note wood, which also serves as an excellent frame for these buildings, is accessible, cheap and allows the installation of structures of various shapes and sizes.

Drawing up a drawing

A do-it-yourself greenhouse made of polycarbonate, which will not take much time to draw up, will turn out to be large and comfortable, provided that all the necessary rules are followed.

First of all, you need to decide on the size of the structure. They will depend on the area of your personal plot, what and how much you are going to grow, and, of course, on the cost of materials.

Foundation preparation

The strength and reliability of the greenhouse will depend on how high-quality the foundation you prepare for it. There may be several options here. The most common is a wooden base. To build it, you will need a beam, a level, a screwdriver, a shovel, a 7-meter tape measure, and a construction knife. It is necessary to cut 2 pieces of 3 meters each and 2 pieces of 3.85 meters each.

When assembling a box from timber, for convenience we place the timber on the narrow part for further ease of installation of the polycarbonate, so that it overlaps the timber. Three-meter beams should cover the end of the beam 3.85 m.

But the most reliable will be a concrete foundation. If you are going to make a large greenhouse and use a metal profile or wooden blocks for the frame, then a concrete foundation will be necessary due to the significant weight of the entire structure.

To install a cement foundation, we make formwork according to the dimensions of the proposed foundation. We cover it with cement and let the cement harden and strengthen.

Frame

The durability of the entire structure depends on the frame. Manufacturers offer several types:

- Wood. Low cost, but capable of absorbing moisture, which contributes to rotting and frequent repairs

- Plastic. Durable, rot-resistant, light weight, easy to install, but expensive

- Aluminum. Identical to plastic

- Steel. Strong, durable, withstands heavy loads, low cost, but susceptible to corrosion.

Making a frame from a metal profile

- If you are going to make the frame yourself, then you will need: metal profile: square pipe 25 x 25 mm, pipe bending machine, welding machine, angle grinder.

- And for further assembly of the greenhouse: polycarbonate sheets, metal strips, metal corners, self-tapping screws, including roofing ones.

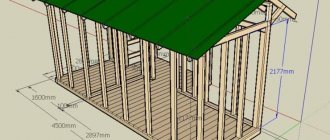

You can easily make a polycarbonate greenhouse with your own hands, the drawings of which are ready. We take a square metal pipe 25x25 mm, preferably galvanized, and roll it through a pipe bending machine, resulting in an arc of the required size.

- We cut the pipe to the size of the structure and weld arcs to it, in increments of 0.65-1.0 m. We make 7 arcs: two for the ends, 5 for the gaps.

- We make the ends - we connect the ends of the arcs with a three-meter square pipe 25x25 mm, weld the door frame and vents. Or such a frame can be purchased at a specialized store.

Industrial greenhouses and their types

Industrial greenhouses are usually distinguished by their shape, size and seasonality of use.

Industrial greenhouses made of polycarbonate are:

- Arched. Perhaps the most popular type of greenhouse. Its advantages include good illumination, resistance to strong side winds, and it can withstand heavy precipitation (good in winter and rainy weather). The arch-shaped design allows the construction of a large-scale greenhouse complex;

- Lancet. All characteristics and shape are very similar to an arched greenhouse, however, the pointed structure has a pointed roof. Such a roof does not allow snow to accumulate, and sunlight easily penetrates into the greenhouse;

- Gable. The least popular industrial polycarbonate greenhouse among farmers. This form must withstand heavy loads; this requires the manufacture of a reinforced frame. In terms of area, the gable greenhouse is inferior to the arched type.

By size, industrial greenhouses made of polycarbonate are divided into small, medium and large. Drawings are usually made according to these parameters. The photo of the greenhouse complex you need can also be found in special magazines.

In addition to the standard dimensions of greenhouses, you can order the desired design that will satisfy the needs of the farmer.

Industrial greenhouses are also divided according to the season of their use:

Seasonal. Seedlings in such greenhouses are grown from spring to autumn

Industrial greenhouses of this type have an important advantage - they do not need to be dismantled for the winter; the manufacture of such greenhouses involves a strong frost-resistant structure that will withstand loads from snow. One of the disadvantages is that the soil in such a structure will freeze very much in cold weather.

This is due to the fact that the ground outside the building is covered with snow, which somehow warms it. But snow simply doesn’t get into the greenhouse. As a result, after 3-4 years the soil will not be as fertile. However, professional farmers have found a way out of this situation: they personally fill the ground with snow into the greenhouse complex.

Year-round industrial greenhouses. You can run a business using such greenhouses all year round without compromising your finances. This structure requires special equipment, including lighting and heating. Most often, the production of this type of greenhouse involves growing flowers, sales from which in winter will recoup all the costs paid for the maintenance of a year-round structure. So-called winter greenhouses have good financial returns.

There are a lot of options for organizing closed ground, but which greenhouse design will be the best in a particular case - here you need to thoroughly understand

Every farmer with imagination can improve the classic version and thus invent his own greenhouse, but if the basic requirements are not taken into account and the calculations of professionals are not taken into account, the early harvest may be in jeopardy

Do-it-yourself arched polycarbonate greenhouse: drawings, photo materials, sketches

- Arched structures are perfect for both small country greenhouses and massive greenhouses intended for commercial purposes.

- Answering the question of how to make a greenhouse from profile pipes with your own hands, we can safely say that the primary thing is to develop drawings and make correct calculations. Arch-shaped greenhouses made from pipes have their own design features. The main determining factors are the height of the structure and the dimensions of standard covering sheets.

- Polycarbonate sheets are traditionally sold with parameters of 6 x 2.1 m. A sheet length of 6 m will limit the height of the arched structure.

To obtain an arched shape, the sheet is placed in a transverse (relative to the frame) position.

In this case, the radius of the semicircle will be 1.90 m, and the width of the structure will be 3.80 m. Taking into account the geometric formulas, the height of the greenhouse will be equal to the radius, i.e. 1.90 m. This height of the greenhouse is not suitable for everyone.

- In order for the arched greenhouse to have a height that meets your needs, you can resort to arranging a base. Moreover, by stopping at a base height of one meter, you can get the width of the greenhouse up to 2.4 m, and increase the total height of the entire structure to 2.2 m.

Having correctly set the main dimensions of the greenhouse, you can develop drawings and sketches for making greenhouses from a profile pipe with your own hands.

Another feature of arched frame shapes is that the profile needs to be bent into the desired shape. If you don’t have a special machine for bending pipes, you can purchase ready-made arc-shaped profiles or create an arched shape from short sections connected to each other by metal plates.

To design a small (4-5 m) arched greenhouse, two arc-shaped frames will be sufficient: the initial and final ones. In the case where the length of the greenhouse is 6 m or more, the required number of support frames is calculated, which must be a multiple of the thickness of the polycarbonate sheet. A separate diagram indicates the dimensions of the window and door opening.

Helpful advice! When choosing the width of the greenhouse, it is necessary to take into account the number of beds planned in it and the arrangement of the path between them. Convenient width for processing - up to 0.7 m.

Next, a drawing is developed that specifies the features of installing a polycarbonate greenhouse cover with your own hands (the videos will help you understand the process in detail) indicating the fastening spacing.

He must take into account that polycarbonate panels in arched greenhouses should be positioned with edges along the arc.

It is also necessary to take into account that the bending radius of polycarbonate sheets should not be less than that provided by the manufacturer for this material. Polycarbonate sheets should be covered with punched tape at the ends. For clarity, you can use a selection of photos of polycarbonate greenhouses.

Winter greenhouses - beauty and benefits all year round

Winter wall greenhouse

Many summer residents prefer cost-effective winter greenhouses. Such structures not only provide the family with fresh vegetables and herbs, but also decorate the yard. Some structures serve as additional insulation for a home, as they protect the walls of a residential building from the external environment - the photo of greenhouses of this type clearly shows the principle of construction.

Beautiful winter greenhouse on a high brick plinth

When building winter greenhouses, first of all, they think through the heating and lighting systems and select the materials that will be used. Most often it is glass, polycarbonate, brick, wood. And since such structures are designed for more than one year of use, many owners try to ensure that the warm, functional room has an attractive design.

An elegant double-glazed pavilion is equipped for growing vegetables all year round

Winter greenhouses are often equipped in such a way that they have enough space not only for growing crops, but also for arranging a recreation area. High warm beds, soft lighting, an abundance of plants - in such a green corner it is pleasant to relax after a hard day.

Beautiful winter greenhouses have taken their rightful place in the construction of ecological and “smart” houses. In such buildings they themselves became part of the heating system. Similar structures are designed and erected simultaneously with the main building. Glass walls provide enough light for plants, and solar thermal collectors heat not only the greenhouse, but also the house.

Geodesic greenhouses - economical and efficient

Recessed geodome - functional economical greenhouse

Today, geodesic dome greenhouses are becoming increasingly common. The original shape, high strength, good lighting and free air circulation, moreover, with equal material consumption for the construction of such a dome and a conventional greenhouse, in the first case, more usable area for plants is obtained. The buildings are heated by accumulating solar heat in water containers.

Beds under the geodome

The beds under the dome are located around the perimeter and in the center of the structure, and are also suspended from the frame.

Depending on the diameter, such a greenhouse can be equipped with a completely cost-effective all-season greenhouse, the maintenance of which will not require large expenses. It is precisely because of its cost-effectiveness that the geodome is attractive to adherents of an environmentally friendly way of life.

Pyramid - a mathematically verified ideal shape

According to the classification, unusual pyramid greenhouses are classified as a separate type. But in essence they can be classified as geodesic, only the simplest ones - only four faces.

Some gardeners tend to endow such structures with almost magical properties - and tomatoes and cucumbers grow better in them, strawberries are more fragrant, and parsley is greener. But there is no mysticism, it’s just that with this form, all the plants inside are illuminated by sunlight in the most optimal way.

Futuristic greenhouse of the future - a variant of a geodesic design

Anne Romeu's greenhouse is equipped with innovative technologies

This is not footage from space science fiction. This is a photo of the greenhouse of the future built by Ann Romme in Denmark.

The structure was designed taking into account “green construction” - environmentally friendly modern materials are combined with energy-saving technologies. You can create any microclimate inside - all parameters of lighting, temperature and humidity are controlled by special sensors. The frame of the greenhouse is assembled from modules according to the principle of a geodesic dome.

Drawings of a greenhouse frame with a gable roof

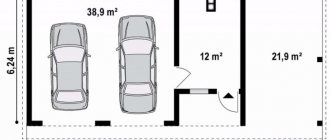

Projects for greenhouses with a gable roof involve making the greenhouse frame with your own hands from a 40*20 mm profile pipe. Such a profile will be able to withstand significant loads in the form of a snow cap or gusty wind.

- The drawings show a diagram of the supporting frame, including the dimensions of the walls, the angle of inclination of the roof, in which ventilation vents are traditionally installed. If you are planning a small greenhouse, you can consider an option with a pitched roof, one edge of which will be located higher than the other, ensuring water drainage and snow removal.

- The angle of inclination of the rafters in the roof of a gable structure is 25-30 degrees. This slope will facilitate the drainage of precipitation from the surface. The roof is considered to be quite flat and does not require the installation of auxiliary slopes on the rafter system.

- In structures of this type, it is assumed that a more durable profile (20x40) will be used for the main posts and base, rafters and ridge beam. For horizontal jumpers, you can use a 20x20 profile pipe. The drawings provide for the arrangement of vertical posts in increments of one meter. It should also be taken into account that if the greenhouse is covered with polycarbonate sheets, the joining lines must be on the profile.

The rafters are also placed at a distance of no more than one meter from each other.

- The design of a greenhouse with a gable roof has some unique features. Here you will need to carefully approach the cutting of polycarbonate sheets for gables. If all dimensions are maintained according to the drawings, this will lead to economical consumption of polycarbonate.

Coating

Greenhouses come with glass, polyethylene and polycarbonate cover:

- Glass is distinguished by its fragility, heavy weight and labor-intensive installation process.

- Polyethylene wears out quickly and collects water on the surface of the film.

- Polycarbonate is strong, easy to work with and durable.

Today, the best greenhouses are polycarbonate-covered greenhouses.

Seasonal greenhouse projects

There are no specific requirements for reliability and strength for the construction of seasonal greenhouses. The drawings of these structures are easy to develop and do not involve complex calculations. The frames of such greenhouses can be built from lightweight profile pipes, and the covering material can be polyethylene film or thin polycarbonate sheets.

As a rule, light greenhouses and greenhouses are not equipped with a foundation.

The type of frame of a seasonal greenhouse does not matter much - the main criteria are ease of assembly and budgetary cost of the structure. Several recommendations will help you avoid mistakes when building small greenhouses:

- When developing drawings and sketches, the presence of ventilation hatches at various levels should be taken into account. This will facilitate high-quality ventilation of the greenhouse;

- Fastening of polycarbonate sheets should be done using fastening profiles that do not damage the surface of the plastic. In addition, they can be easily dismantled at the end of the season, eliminating the possibility of deformation of the light frame of the greenhouse;

- the project should provide for the option of simply disassembling the frame for transfer to another location or storage for the winter.

Arrangement of the greenhouse inside: partitions and storage rooms

Different types of plants are usually grown in greenhouses, for which it is necessary to create different greenhouse conditions. Landscaping for them can be created by installing a partition inside that will ideally match your greenhouse interior. Typically, such a device is made of polycarbonate or polyethylene.

The arrangement of the greenhouse inside can be supplemented by creating a reliable partition that will create different conditions for unfriendly crops.

You also need to provide a place for gardening tools so as not to constantly carry them into the house. To do this, you need to build a small vestibule where buckets, shovels, rakes, watering cans and other tools will be stored. You can arrange such a compartment in any place convenient for you.

Benefits of a storage room:

- Convenient, all tools are at hand;

- Aesthetic;

- You can store not only tools, but also fertilizers.

Sometimes small shelves, different shelves, and cells are made in this pantry. Then all the tools will have their place and will be convenient to find. Also, the appearance of the greenhouse will not be spoiled by tools standing in plain sight.

Features of the design of the greenhouse-bread bin

The main advantages of the greenhouse-bread bin are:

- unusual ergonomic design;

- minimum number of connecting lines;

- regulation of greenhouse ventilation by opening the lid to the required angle of up to 90 degrees;

- ease of assembly and full use of greenhouse space.

The drawing of such a greenhouse provides for the construction of the upper part of the frame from two half-arches, which are fixed to the base on hinges. The frame of the greenhouse is made of a profile pipe of small cross-section. The radii of the lids are selected taking into account the fact that they can easily open without interfering with each other.

The difference in diameter is equal to the width of the polycarbonate sheet - this ensures that there are no gaps when closed.

Helpful advice! Considering the fact that small greenhouses are usually used for growing seedlings that require a special microclimate, it is recommended to use polycarbonate with UV protection for the coating. The percentage of heat retention of this material is much higher than that of polyethylene film.

The dimensions of the greenhouse are selected individually. The length can be from 3 to 4 meters, the height is no more than one meter. The width is taken taking into account how the greenhouse will open - from one or both sides.

For one-way opening of the greenhouse, it is advisable to choose a width of 0.7-1.2 m, so that it is comfortable to care for the seedlings.

Underground or buried structure

It is known that in winter the ground freezes slowly. At an air temperature of ±1°C, the soil temperature at a depth of 1 meter is about 10°C. When setting up a greenhouse, one cannot help but take advantage of this natural bonus. For construction, you must first dig a hole, 1 to 1.5 m deep, and install a transparent coating on top.

One of the options for a recessed greenhouse is an improved design - a thermos greenhouse, which provides even greater indoor temperature and illumination even in cloudy weather. For a thermos greenhouse, you need to build a reinforced concrete foundation. The coating is often double-layered. Inside, the walls are covered with reflective paint or other material that acts as a solar energy collector.

The disadvantage of this variety is that it is difficult to organize proper drainage in the underground part.

A large in-ground greenhouse takes quite a long time to build due to the need to dig a pit. In addition, you will have to take care of steps at the entrance, waterproofing and protection from pests, which implies additional costs.

Types of polycarbonate

There are three types of this material:

- Monolithic. It looks like glass, but transmits light better, is two to four times lighter, and several times (100-200) stronger. Thickness - from 0.75 mm to 40 mm. The disadvantage is the high price. This material is used if there is a risk of damage - it often hails, the greenhouse is positioned in such a way that icicles and snow can fall on it. There is multilayer monolithic polycarbonate. There can be up to 3-5 sheets, they can have different properties. For example, for greenhouses a double layer is usually used - the first layer is characterized by increased strength, the second does not transmit ultraviolet radiation.

- Corrugated (profiled). Appeared relatively recently. It is formed from a monolithic sheet on which a relief is formed. There are types similar to corrugated sheeting and slate. The thickness of this type of polycarbonate is 0.8-1.2 mm. With such a small thickness, it can withstand hail impacts up to 20 mm in diameter, bends well, and tolerates frosts down to -50°C.

- Cellular (cellular, structured). Consists of two (or more) polycarbonate sheets connected by jumpers. The shape, size, thickness of the jumpers - all this affects the quality and performance characteristics. The thickness of cellular polycarbonate is 4, 6, 8, 10, 16, 20, 24 and 32 mm. For greenhouses, it is better to take no thinner than 10 mm, multilayer.

What type of polycarbonate is best to use for building greenhouses? Depends on the operating mode of the greenhouse. If it is heated, you will need a cell phone. If this is an option exclusively for the warm season, a corrugated (or monolithic) one is more suitable. Monolithic is also not bad, but corrugated has more rigidity.

For greenhouses that are planned to be used from early spring or throughout the winter, cellular polycarbonate is installed.

Subtleties of doing business

You can reduce the cost of production and increase profits by purchasing materials from the manufacturer. This can be done by concluding agreements for the supply of products. And in order to conclude an agreement, you need to register an individual entrepreneur.

Only an individual approach to each client will help you win the competition and, over time, purchase professional equipment that will allow you to establish a serious technological process.

Video on the topic: Greenhouses - Video review

Selection of questions

- Mikhail, Lipetsk — What discs should I use for cutting metal?

- Ivan, Moscow - What is the GOST for rolled sheet steel?

- Maxim, Tver - Which racks for storing rolled metal products are better?

- Vladimir, Novosibirsk — What does ultrasonic processing of metals without the use of abrasives mean?

- Valery, Moscow - How to forge a knife from a bearing with your own hands?

- Stanislav, Voronezh — What equipment is used for the production of galvanized steel air ducts?

Choosing cellular polycarbonate

It is not difficult to choose corrugated or monolithic - we are guided by the stated characteristics. It is only important that there is protection from ultraviolet radiation. There are no other pitfalls. But with a cell phone there are many nuances. You need to pay attention to the following:

- The thickness of the outer layers and their number. The sheets should be of the same thickness without sagging or thinner places.

- The location of the jumpers and their thickness.

These types of cellular polycarbonate can be

- The presence of a layer that protects against ultraviolet radiation.

The easiest way to check the quality of cellular polycarbonate is to try to squeeze it between your fingers. If it doesn’t press through, even if you make a significant effort, you can take it. If it squeezes easily, look for another one.

Characteristics of the structure

The main difference between industrial greenhouses and country greenhouses is the scale of the structure. In terms of these parameters, industrial buildings are significantly superior to their homestead counterparts. The area of such buildings can be measured in hundreds and sometimes thousands of square meters.

Such large structures require a heavily reinforced frame that can withstand the load of greenhouse cladding. It is also necessary to take into account the periodically added snow load. Frame failure can completely paralyze work.

To maximize profits from the harvest, large-scale greenhouses use the following technical capabilities:

- heating;

- ventilation;

- artificial lighting;

- use especially ;

- isolation from weeds and harmful insects;

- saturation of the internal space of the greenhouse with carbon dioxide.

Installation features

According to the technology, polycarbonate is mounted using starting and connecting profiles. First, profiles are installed on the frame, a sheet of cellular polycarbonate is inserted into them, which is fixed to self-tapping screws with special press washers, which at the same time protect the attachment point from leaks.

Profiles, in addition to holding the sheets in place, also protect the cuts from dust and dirt getting into the bottom. The system looks neat and works well, but all the components cost a lot of money.

Aesthetics for a greenhouse is not the most necessary property, therefore, if you need to save money, they prefer to mount it in a simple way, without profiles and press washers. Here's how to do it:

- The edges of each sheet are covered with silicone. They must be closed, otherwise condensation will accumulate inside, in which mold and fungi will develop over time, and the polycarbonate will lose its transparency. So the edges must be sealed carefully, leaving no room for air and moisture to penetrate.

- The sheets are laid with an overlap of several centimeters, and pressed on top with a strip of tin. The fasteners are installed in an “overlapping” manner through a tin strip.

You can place regular wide washers under the screw heads.

The UV protection layer must face outward during installation. It is important. Otherwise it doesn't work.

This is what directly concerns the fastening of cellular polycarbonate. There is one more point that became clear during the operation of polycarbonate greenhouses. Polycarbonate should not be placed close to the ground. It is desirable that it starts at least half a meter from the surface.

Why? Because firstly, it still gets dirty and almost no light passes through it, so it does not affect the overall illumination. Secondly, it begins to deteriorate—blacken and flake.

It is not clear what causes this reaction, but it is common. So, when developing a model of a polycarbonate greenhouse with your own hands, provide half-meter walls made of another material - brick, building blocks. Doesn't matter.

Greenhouse construction technology

It is worth noting that the production of industrial greenhouses is a complex technological process that requires a serious professional approach. The construction of industrial greenhouses begins with the development of a detailed design, which must take into account all the technical requirements for the facility. At this stage, the customer must finally decide on the list of crops that he plans to grow, production volumes and optimal technologies.

It is important to take into account the basic requirements for the areas where the construction of a greenhouse facility is planned:

- calm terrain, the maximum permissible slope level is 0.04%;

- protection from northern and northeastern winds, snow drifts;

- availability of water, communications;

- absence of sources that pollute the environment;

- fertile soil suitable for use in soil mixtures.

Important! There is also a certain order of orientation of greenhouses relative to the cardinal directions. It is believed that in areas located north of 60° north latitude, latitudinal orientation is most effective, and to the south - meridional

Deciding on the sizes

To better imagine how to make a greenhouse from a profile with your own hands, you must first decide on the dimensions. And in order not to encounter excessive consumption of material and a large amount of waste, it is advisable to correlate these dimensions with the standard dimensions of corrugated pipes and polycarbonate sheets.

In construction markets and metal depots, profile pipes are sold in 6-meter lengths. In stores you can find a different length - 2 or 3 meters. It is more convenient for independent transportation, but it is more difficult to assemble an arched structure from short sections: there is a need to make additional joints.

If you have no problems with how to bend a profile pipe at home for a greenhouse, it is better to purchase standard whips. Each will make an arch about 2 meters high and with a distance between the legs of 3 meters. This is enough to accommodate two beds and a central passage inside.

If the width needs to be increased to 3.6-3.8 m to arrange three beds, then the height will have to be reduced to 1.8-1.9 m, which can create inconvenience if the gardener is tall.

It would seem that the length of the arch can be increased without problems by welding the required section of pipe. But the length of cellular polycarbonate sheets is also 6 or 12 meters, and such an increase will lead to overuse of this expensive coating, the need for its joining and a decrease in reliability.

Therefore, in such cases, the height is increased due to the foundation or a different form of greenhouse is chosen.

For example, the height of the side walls of a pitched structure should be 1.5-2 meters for ease of work. These dimensions correlate perfectly with the dimensions of corrugated pipes and sheet material, which are cut without waste.

Greenhouse arrangement: additional equipment

You can make work easier and create certain climatic conditions for growing different crops if you purchase special technical equipment. However, it is very expensive, so if possible you should make some equipment yourself.

The arrangement of a greenhouse must be done so that some crops can be grown throughout the year. To do this, you need special devices that will create ideal conditions for plant development.

In order to ventilate the greenhouse, automatic devices are installed that will open and close at the time you specify. Water supply in greenhouses is carried out using a drip irrigation system. Subsurface watering is carried out using a hose and a small number of tees.

Main equipment in the greenhouse:

- Irrigation system;

- Additional lighting;

- Forced ventilation.

In a winter greenhouse, it is imperative to install heating and additional lighting so that the plants feel great in the cold season. Heating is carried out using infrared heating. This system is good because it is economical and the plants will never get burned.

Briefly about the main thing

Such a task as welding a greenhouse from steel profile pipes cannot be called simple. At a minimum, you need a welding machine and the ability to operate it. But you can do without it if you use galvanized profiles that are connected with bolts and special plates.

Conventional pipes will require additional anti-corrosion treatment. Another necessary tool for creating arched structures is a pipe bender.

But you won’t need it either if you choose a greenhouse with a pitched roof or use the DIY bending methods described in the article. Before starting work, you need to decide on the size of the structure, focusing on the standard parameters of corrugated pipes and polycarbonate.

Strengths

Compared to other materials from which greenhouses are made, polycarbonate stands out significantly, having a large number of strengths.

First of all, it is necessary to note the high transmittance of sunlight and the possibility of regulating it by using material of different colors.

Compared to other materials, polycarbonate is highly resistant to mechanical damage, which makes it literally a leader in this matter. It is also not affected by weather conditions. This design can stand in one place for more than 20 years without significant breakdowns or shortcomings.

Due to the flexibility of the material, the greenhouse can be given absolutely any shape, which increases the degree of harmony of this building with other buildings on the site. They also have an aesthetic appearance.

Making a greenhouse in the shape of a triangle

To make the shape of the correct arch, it is best to insert pipes when pouring the foundation. Then you need to make cuts on them (with a grinder or a hacksaw) about 1-2 m in length. After bending and inserting the arcs, they are secured in the pipes with screws, drilled through or filled with cement.

Polycarbonate can be fixed in different ways:

- drill through holes in the plastic and profile and secure with screws (this method is not very reliable) - the material may crack;

- make two holes in the sheets for the width of the profile and secure them with wire, clamps or staples.

The side walls are cut out, doors and windows are inserted.

You can make arcs from PVC pipes, because they bend well. But attaching polycarbonate to them is much more difficult. It will be necessary to secure it with clamps or screw the longitudinal elements of the frame every 50-80 cm.

Industrial greenhouses ventilation, heating and lighting

The main system for any industrial greenhouse is irrigation. It can be done in two ways - sprinkling and drip irrigation. In the first case, water sprayers are installed in the greenhouse, which falls from above onto the plants and soil in the form of small particles. As a result, crops receive a sufficient amount of moisture with minimal liquid consumption.

Industrial greenhouses

Sprinkler irrigation is carried out using three types of installations:

- installations fixed between the beds;

- permanent installations under the ceiling;

- mobile sprinkler installed under the ceiling.

Mobile sprinkler system

Drip irrigation is carried out according to a different scheme - a drip tape or hose is stretched between the beds. From the many holes in them, individual drops of water are released, which fall into the soil at the root zone of the plants. As a result, the latter receive a sufficient amount of moisture with minimal liquid consumption and a complete absence of problems with weeds or waterlogging of the soil.

Drip irrigation

Important! Regardless of the irrigation system, an industrial greenhouse will need a powerful filter or even a set of them. This will not only rid the liquid of impurities harmful to plants, but will also extend the life of sprinklers or drip hoses.

No less important for an industrial greenhouse, especially a year-round one, is heating, which is carried out in various ways:

- convection heater;

- air heaters;

- infrared lamps;

- "warm floor" system.

In the first case, fairly powerful heaters are installed inside the greenhouse, in which initially cold air passes through the heating element and is then released into the environment. A more advanced type of heating of an agricultural building is air heaters, which can be built into the ventilation system of the greenhouse.

Alternative heating for industrial greenhouses

Greenhouse ventilation systems

A very effective, but also the most expensive type of heating are infrared lamps suspended from the ceiling. As the name implies, they emit electromagnetic waves in the infrared range, which heat not the air itself, but directly the soil and the plants on it.

Infrared heating of a greenhouse

The latter heating option is a compromise between quality and efficiency. This is a “warm floor” system, which is a network of long plastic pipes installed under fertile soil in an industrial greenhouse during its construction. Water is supplied through the pipes, preheated in an electric or gas boiler. It releases energy into the ground around itself, acting as a radiator of a huge area.

Warm floor system in a greenhouse

Greenhouse plan with water heating

Ventilation for an industrial greenhouse is of particular importance in the summer, when it is quite hot “outside”, and even more so in the greenhouse. Considering the absence of wind inside the building, the most effective way to ensure an optimal microclimate is to install fans on two opposite walls - one takes in air masses from outside, the other takes them out of the greenhouse

Such a system can be supplemented by the installation of many transom windows, which must be installed on thermal cylinders.

Ventilation supply and exhaust units

Automatic greenhouse ventilator Vent-L

In late autumn, winter and early spring, the number of sunny days is very small, and even then the light often falls at a small angle to the horizon, passing through the air. As a result, the intensity of photosynthesis in plants decreases - there is not enough sunlight for this. The use of sodium or LED lamps suspended from the ceiling of the greenhouse will help compensate for their deficiency. In this case, wavelengths are selected at which, according to the experimental results, the efficiency of photosynthesis increases - 440-470 and 660 nm.

LED greenhouse lighting

Dependence of the activity of processes occurring in plants on the light wavelength

All systems for creating a microclimate in an industrial greenhouse are automated as much as possible and financially justified. The use of control of temperature, ventilation, humidity and light levels using sensors and computing means allows, with a high initial investment, to increase the yield of the greenhouse and reduce the cost of operating personnel.

Important! The growth rate of plants and their yield are also affected by the carbon dioxide content in the atmosphere. Inside industrial greenhouses, the value of this parameter can be increased in two ways - either by using gas generators with burners, or by using CO2 spraying from cylinders