Since ancient times, the main decoration of wooden architecture was house wood carving - decorating the facade of a house with various patterns and entire designs carved from wood. The central element of the home's exterior decor has always been window frames, handmade by folk craftsmen and craftsmen.

This is what homemade carved platbands look like

Anyone can try to revive the ancient practice of wood carving and make window frames with their own hands, if they are not afraid of carpentry. The joy of the creative process and contemplation of the result of one’s labors will undoubtedly bring satisfaction to the creator.

Carved frames for windows in a wooden house: we understand the advantages and disadvantages

Today, during construction, the emphasis is on originality. Returning to past trends is a fashion trend. Houses made of timber and wood are complemented by carved platbands, but at the same time they look modern and stylish. In addition, decorative items on the windows emphasize the status of the owner and his excellent taste.

Traditional window decor has many advantages:

- Attractive appearance - window trims perform a decorative function, visually expanding and stretching the building. They look quite unusual, adding festiveness and personality to even the most ordinary home.

- They perform the protective function of the space between window openings and wall surfaces, excluding the ingress of moisture and dirt.

- They do an excellent job of reducing heat loss and sound insulation.

- When made by hand, they have a fairly low cost.

- Carved platbands look equally advantageous with both plastic and wooden windows. When decorating PVC windows, you can give preference to plastic platbands, which are made in the same color scheme as the windows.

You also need to remember about the possible disadvantages of window frames:

- If carved window frames are made of wood, this requires further care. Without it, they will simply lose their attractive appearance and will look unaesthetic. The formation of fungus and mold on the window is possible.

- During operation, the owner of the house will need to regularly treat the carved platbands with compounds that prevent swelling.

A little bit of history

The facade of a house is its appearance. By appearance we judge the structure itself. The word “platband” came to us from the Old Russian language and means “on the face.”

Therefore, in order to scare away unwanted guests and protect the home, carved frames were made for windows in a wooden house. Their design could be different. For example, circles, triangles or crosses. This is not a coincidence, the circle has a closing line through which negative energy cannot penetrate, and crosses and triangles have angles, which, according to the Slavs, also had protective properties.

Platbands protect the house from evil spirits

Over time, these simple figures gradually turned into patterns. As the ornaments became more complex, the technology for their production also changed. If initially they tried to protect doors and windows, then later they began to decorate cornices, pediments, and porches with patterns.

Carved platbands for a wooden house - materials for manufacturing

What material to choose for making carved platbands? You can make a choice in favor of:

- Natural wood. It is considered the most preferable, as it maximally emphasizes the style of the ancient era, looks aesthetically pleasing and attractive. The main disadvantage is the need for constant care. Products will have to be treated with special impregnations, since wood can darken and is exposed to moisture.

- PVC or plastic. In this case, carved window frames are more resistant to aggressive environmental factors. They will not lose their appearance and quality characteristics due to temperature changes and heavy precipitation, and are practically not exposed to moisture. Constant maintenance is not required - just wet cleaning with products as they become dirty is enough. In addition, such window trims can be bought in any store - the only question is whether their design will correspond to personal preferences.

- MDF. Window trims are made from environmentally friendly material, which contains wood waste. Externally, the products are very difficult to distinguish from natural wood - modern technologies make it possible to imitate any shape. Special care is also not required. MDF is best used indoors. MDF trim placed on the outside of the building will quickly deteriorate and lose its original appearance.

- Polyurethane - it is highly practical.

General requirements and recommendations

Schematic arrangement of platbands

When making platbands with your own hands, it is necessary to take into account that any decoration, although it is an original element of decoration, at the same time remains part of the structure of the window opening.

- First of all, cashing should not interfere with opening windows and closing shutters. This requirement, simple at first glance, is not so easy to implement in practice, and it is when determining the dimensions of the frame that mistakes are most often made.

The internal dimensions of the frame must be such that the platband completely covers the end of the frame, but does not interfere with the full opening of the windows. That is, when drawing up a drawing, you must first determine the working area of the windows in the open position and only then develop the installation diagram of the platband.

In cases where the casing is joined to external slopes (and this often happens when installing PVC double-glazed windows in a casing made of embedded timber), its internal contour must correspond to the outer perimeter of the slopes.

- The next general requirement for the design of the platband is that the upper block (bar) must be thicker than the lower one. This is necessary to reduce the amount of water falling on the bottom of the cashing.

More strict options for exterior window decoration do not involve a difference in the thickness of the slats, but the installation of ebb and flow, both under the window and above the frame.

- We would like to emphasize that the casing is exposed for a long time to direct exposure to solar ultraviolet radiation, as well as strong changes in temperature and moisture. No matter how high-quality the wood processing is, it will in any case change the original dimensions and begin to allow moisture to pass through to the fasteners.

Therefore, the classic method of assembling it does not involve the use of metal nails and screws (they rust and fall out). The best option for manufacturing a wide frame and panels for platbands is to use glued compositions from boards and wooden dowels.

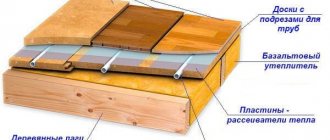

Below is an example of making a prefabricated shield for a decorative cornice without the use of metal parts.

Assembling a panel for a wooden platband

The illustration shows that the shield is assembled from boards glued end to end. Laying of boards is carried out in accordance with the internal pattern of the wood. Adhesive composition - PVA or waterproof wood glue (curing time - 2-3 times for glue polymerization).

The tightening is done using ropes and pegs that enhance the compression.

We make carved window frames with our own hands: how to choose the right wood?

Despite the wide choice of materials, most home owners prefer wood. It is necessary to select the type of material taking into account the performance characteristics:

- Hardwoods - for example, beech, ash. Such boards have the greatest strength and rigidity. If you plan to create light and delicate patterns, this will be quite problematic.

- Soft hardwoods - alder, aspen, etc. These types of wood are quite easy to process even for a beginner, so they are suitable for creating platbands with a large number of patterns. There is also a drawback - window frames made from such boards will have to be constantly treated with special means, otherwise they will simply lose their original appearance over time.

- Apple, cherry - wood species are ideal for creating small products that can later be easily attached to the main product.

- Birch, pine - wood has excellent quality characteristics and is easy to process even by hand. Using such materials you can create even the most complex elements. In addition, carved platbands made from such types of wood are quite simple in further use.

Please note: it is not necessary to make carved platbands for a wooden house from one material. For example, hard hardwood can be used to make the base, as they have sufficient strength, and additional openwork details can be created from soft wood. In this case, be sure to use professional protective impregnations.

What it is?

Let's try to figure out what platbands are and why they are needed. Since ancient times, it was customary in Rus' to install carved platbands on houses. In addition to decorating the house, they also performed a certain mystical function: it was believed that the platbands served as a talisman for the house and saved residents from negative energy. Craftsmen often carved patterns on the frames that depicted various mythological creatures that protected people from all sorts of misfortunes.

Usually, when constructing wooden houses, gaps remain between the wall and the window or door, into which wind, dust and moisture enter; because of these gaps, cold and drafts enter the house. And as time passes after the construction of the home, the wood dries out and becomes deformed, which is why these gaps can increase. With the help of platbands it is possible to minimize these distances, and thus reduce thermal energy losses.

Platbands are used both outside and inside the premises, that is, they are divided into external (the street part of the house) and internal. The latter also help to hide wires when installing electrical wiring, for example. So, the platband is a strip made of various materials, which is installed around the perimeter of windows, doors, as well as other structurally expressed parts of the house for the purpose of decorative design, protecting the gaps between fragments of the building elements of the structure, as well as to perform other functions.

How to choose patterns for carved frames for windows in a wooden house - templates

The process of selecting a pattern for window frames at home should be approached wisely. You shouldn’t consider the first option you come across. If there is such an opportunity, you can select several of the most preferred options and simulate conditional models on the computer - ordinary photo editors will do. When choosing a pattern for carved platbands, it is worth considering several key aspects:

- The color scheme of the trim and walls of a wooden house must be combined.

- It is very important to consider the size - for example, too massive platbands are not suitable for small windows. Such a frame will look bulky. Likewise, for large windows you should not choose trim that is too narrow.

- All elements of the template must be combined with each other, so it is best not to place floral, ethnic and animal ornaments on the same frame.

As for the choice of pattern, it all depends on the individual preferences of the home owner. Among the most popular solutions:

- Traditional ornaments. The choice is truly huge: grape leaves, plant patterns, weaves, tiaras, horns and ears.

- Animal ornaments – along with plants and other decorative elements, animal figures are used. It is not recommended to use human and animal figures on the same frame at the same time. Most often, when making window frames, figurines of bears, snakes, birds, fish and dragons are used - they symbolize abundance, prosperity, goodwill and hospitality of the home owners.

- Modern - preference is given to conciseness and simplicity. Usually regular elements are used, as well as columns, porticoes, and chapels.

The platbands on the windows of a house with an additional upper part (face) look especially noble and expensive. Making such a part requires careful and painstaking work, as well as good artistic skills. Particularly popular:

- tiaras, which are a symbol of the sun;

- medallions and crowns of their plants.

If you do not have special skills, give preference to concise and simple templates. Firstly, such templates are easy to transfer, and secondly, the likelihood of material damage due to cutting errors is minimized.

Even the simplest window frames can be decorated with additional, more complex products and secured to the base using liquid glue. If it is difficult to do them yourself, you can order cutting from a professional craftsman.

Adviсe

- If you want to decorate your house with wooden trim, you can purchase selected material that has been kiln-dried. In such a chamber, moisture is rapidly removed from the wood, bringing its level to a maximum of 12 percent. Boards that are cracked and warped during drying are rejected, and only a high-quality product reaches the consumer. Therefore, when buying it, you don’t have to worry about the fate of future products.

- It is better to look for boards that have undergone special treatment in hardware stores or sawmills. In no case should specimens have large knots, resin residues or other traces of a negative property that could make themselves felt when creating a pattern. It is best to order boards whose width is 10-15 centimeters and thickness 3-4.

- Before starting the actual creation of platbands, it makes sense to hone the carver’s skills and the skill of creating a specific design on cheap boards.

When creating platbands, the owner of the house was given the opportunity to express himself, conveying certain information to others. For example, the sun in the center of the upper part of the casing means energy and life. The snake as a decorative element represents fertility and wisdom. The cross, inscribed in the carved decor of the window frame, symbolizes the harmony of spiritual and material aspirations.

Floral ornaments personify unity with nature, and such a common element as earrings signals the hospitality of the owners of the house. The frog is a sign of continuity of life and resurrection.

Popular templates and sketches of patterns for making window trim for a wooden house

The pictures below show both simple and complex sketches of platbands.

Pattern selection

You can buy ready-made platbands (the simplest ones or unusual ones, which are prepared to order). There is no industrial production of these parts; they are made to order by craftsmen in carpentry workshops. Or you can show all your imagination and create unique and inimitable platbands with your own hands. The most important thing is desire and great patience!

Patterns that will decorate the finished product can also be found by referring to thematic sources on paper or located on the Internet. In addition, there are many companies and designers who are ready to handle the implementation of all the customer’s thoughts into a finished pattern.

You can also create a drawing yourself. It is better to choose patterns that are not oversaturated with the smallest details. It is desirable that the general appearance of the image be easily understood at a sufficient distance. The drawings of the upper and lower parts should be made in the same stylistic direction.

If you do not have sufficient experience in carpentry, it is better to give preference to patterns that do not require complex execution. Their topics can be very diverse - flora and fauna, elements of nature, sun signs, etc.

Examples for cutting elements from wood

How to correctly print a template and transfer it to material

Unless you have polished artistic skills, it's best to print out a template or sketch on a printer. Preference should be given to a 1:1 scale - this will avoid cutting errors and size discrepancies. Professional copy centers provide large-format printing services - the service will cost up to 300-400 rubles, depending on the complexity and size.

You can transfer simple drawings yourself - use regular tracing paper or thin paper. The finished template is connected to a wooden panel, the drawing is transferred with a pencil. Experts recommend preparing several templates and cutting each element separately:

- bottom bar;

- top bar;

- vertical slats or frames.

Please note: be sure to highlight the slot locations in color in the drawing - this will avoid mistakes in future work.

Preparation and installation process

Before starting the installation, markings are made on the wall and the main mounting points of the platband are marked. This will help you navigate and correctly install each of its elements.

You definitely won't be able to do the job alone. You will need at least one assistant who will visually monitor the correct placement of the platband. If we are talking about a heavy, three-dimensional structure, you cannot do without a whole team, and for safe installation you will need scaffolding or a simple block lifting device.

The method of fastening the finished casing depends on many factors and is selected individually. The simplest of them seems to be the use of self-tapping screws, anchor bolts or nails with decorative heads. The hidden fastener looks impressive. To do this, dowels are used - wooden cylinders that are glued into the wall in advance. To install them, holes are drilled in the platband frame.

We make platbands for windows on a wooden house ourselves - a step-by-step process

Before you start creating a platband, you should select and print a sketch. We have already talked about this in detail in the section “Templates for carved platbands for a wooden house.”

How to create patterns correctly? Two main methods have found widespread use:

- Carved carving - involves the creation of a through ornament, which in appearance resembles lace.

- Overlay carving - the key difference is that all the elements that make up the window casing are made separately and placed on a pre-prepared base.

To make your own carved frames from boards for windows you will need:

- jigsaw - necessary for painstaking work that requires special care;

- hacksaw;

- knife, chisel;

- milling machine - used to give products small edges.

Making carved window frames yourself is quite simple:

- Take preliminary measurements of the windows. Make sure your measurements are accurate; it is best to take them several times. This will avoid time costs and damage to materials.

- Select the wood - its width should be in harmony with the dimensions of the window openings. If we are talking about making slotted carvings, it is necessary to use wood with a thickness of at least 30 mm. If preference is given to applied threads, the original blade must have a width of at least 10 mm. Under no circumstances should you use damp or slightly damp wood when making platbands. The canvas must be completely dry.

- Start cutting out the blank for the future platband from the boards using a special stencil. It is best to attach stencils to the surface of the board using glue. The resulting workpiece must be treated with a protective compound.

- Cut out parts and small overhead elements - it is best to use a jigsaw for this work. First you need to cut out the external and then the internal parts on the board.

- For sharpening, you can also use a special electric sharpener with a stone: you can easily give the desired shape to almost any element. The procedure requires special care, so there is no need to rush. Use different types of files for elements of different sizes - this will allow you to get neat parts.

- Sand the resulting small products - it is advisable to use regular sandpaper. Be sure to treat the carved parts with a strong impregnation. In order to remove the characteristic whiteness of wood after sanding, professional solutions based on chromium, iron and copper are used.

- If necessary, you can coat the components of the casing with varnish - this way the products will be protected from exposure to the sun and temperature changes.

Proceed to direct installation connecting all elements. Here you can use both nails without heads and spikes - protruding fastener elements. It is best to make them from hardwood. The normal spike size is from 6 to 25 mm.

Installation of the platband on the window can be carried out in two ways:

- For deaf type:

- On the surface of the window frame and trim, use a pencil to mark the locations of the tenons - elements for installation.

- Using tools, in accordance with the markings, recesses for tenons are created on the window frame - grooves. The diameter of the grooves should exceed the size of the tenons by approximately 2-5 mm.

- The adhesive is applied evenly to the spikes. The tenons with glue applied are carefully inserted into the groove - a pre-prepared recess for the tenons in the frame, after which the platbands are placed on them.

This fastening method is notable for the fact that it allows you to protect the manufactured platbands from the adverse effects of moisture, dirt and dust. It is quite complex and requires care, but allows you to get the most reliable connection.

- Using a through tenon - during installation, the joints should be covered with transparent or colored varnish, and then proceed to installation with glue.

To facilitate the installation process, it is best to frame the window opening with a special strip. It will eliminate possible unevenness of the wall and create a reliable foundation. The thickness of the slats should not exceed 10-15 millimeters.

Please note: under no circumstances should you install the platband using self-tapping screws. Such auxiliary elements can cause wood to crack. Window trims on a wooden house, made of plastic or PVC, should be installed using liquid adhesives.

Important: during installation work, the direction of opening the windows should be taken into account. If the windows in the house open outward, the platbands should be installed at a distance of at least 3 cm from the sashes.

Tools for making slotted threads

For the slotting cutting technique, the main tools are a drill and a saw. In this case, the type of sawing tool can be any: from a hand hacksaw to a jigsaw.

How to make carved platbands in a quick, automated way? To do this, you can use power tools:

- Electric drill. Required for drilling preliminary holes in the workpiece for setting the jigsaw blade.

- Jigsaw. It has high productivity and significantly speeds up and simplifies the production of carved products. For a beautiful, neat cut, it is better to use files with fine teeth.

- Manual frezer. The productivity of a hand router is lower than that of a jigsaw and some skill will be required when handling the tool. However, the cuts produced by the router are very neat, and no pre-drilling of holes is required.

The process of making a platband using a manual milling machine

Caring for carved window frames after installation

Caring for platbands is a mandatory procedure after their installation, especially when it comes to natural wood products. You should use impregnations that promote:

- longer service life;

- preventing cracking:

- protection from exposure to adverse environmental factors and insects.

In addition, the use of special means reduces the likelihood of fires. The procedure should not be abused - the trim on windows in a wooden house should be covered at least once every 1-2 years. Complete care consists of three stages:

- initial application of primer to the surface of the casing;

- coating with varnish or paint – helps to renew the color and reduces the likelihood of corrosion.

If we are talking about plastic or metal carved platbands, then complex care is not required. Clean the elements as they become dirty - a soap solution or other detergent is ideal. Particular attention should be paid to corrosion protection - you can purchase products in specialized stores.

Basic Rules. What not to do

Below is a list of rules that will help you avoid the most common problems.

It is recommended to use a board 3-4 cm thick as the starting material. Do not immediately grab onto complex patterns

First, it is better to practice on ordinary round parts that are easy to make with a drill. The width of the workpiece should be such that it is enough to cover the ends of the walls and protect it from moisture. Carved elements should be placed along the grain of the wood - this will prevent cracking. When choosing a stencil, it is better to pay attention to patterns with large elements, because

small ones will look crumpled, as a result of which the finish will not have the desired decorative effect.

Moreover, it is advisable to first familiarize yourself with photographs of different products. This way you can find a suitable option or get inspiration for creating something yourself.

Platbands

Application area

Widespread use of framing around various openings has found itself in doors and windows. The location of the planks can be either on the outside of the street or inside the room.

Basically, the same type of platbands are installed, but the threads may differ. And at the same time maintaining the general theme. For example, in a children's room, the bar will have a bunny. Flowers are carved around it. Then the teddy bear in the kitchen should also be framed with the same flowers.

Now the brand is considered to be plastic double-glazed windows. Some people manage to put a wooden plank on them. In this case, you need to paint it white or choose a double-glazed window made of wood.

The strips around the window opening perform several functions:

- They unite all the buildings in the yard into a single style.

- Reduce heat loss.

- Protect from dust and litter, moisture, draft.

- Increases sound insulation.

- I emphasize the uniqueness of the residential building.

- An opportunity to express the traditions of a region, family, country.

- The ability to visually stretch and expand the house.

- They add completeness to the construction.

- Cover the assembly seams.

Related article: Fastening plates for plastic windowsIf we consider the platbands by material, they can be from:

- wood;

- metal;

- plastic;

- foam and polyurethane;

By form:

Before starting work, it is worth stocking up on templates or stencils for carved platbands; without their help it is impossible to achieve an excellent result. And only a master who has been working on wood carving for many years can perform his work without them.

Today you can get stencils freely - in stores, magazines, and the Internet.

You can apply any design on them that the customer or craftsman desires. Plant outlines, animal figures, and patterns of geometric lines and shapes are very popular.

The style of the product can be different, and here the most unusual fantasies of the performer are realized.

Kinds

Judging by the large number of platbands that can be seen on buildings (all of them are different in design, material, configuration), they are presented in significant variety. Let's figure out what modern types of platbands exist and how they differ from each other.

First of all, platbands are divided into categories depending on the material used in their creation.

First of all, you need to name the tree. This is a traditional material, it is good at painting and other processing, and holds the temperature perfectly in our climate. There are a large number of various impregnations, varnishes, enamels and paints for wood, so there will be no problems with the final design of the platbands.

- Composite materials include MDF (medium density fiberboard, in fact, it is compressed wood chips) and the familiar plywood (in fact, also a wood material, only characterized by multi-layering - made by gluing specially treated veneer). This category also includes veneered and laminated trims.

- The building materials market also offers plastic platbands made of extruded polyvinyl chloride (PVC) or other materials (foamed polystyrene, polyurethane). Its biggest advantage is its affordability. Also among the advantages is a huge selection of textures and colors.

- Metal trims are made of steel or aluminum.

There are also platbands made of other materials - stone, ceramic tiles, gypsum cement. It is not recommended to install them yourself. Now let's look at the different types of platbands depending on their shape. Platbands are, in industrial terms, molded products (that is, measured in linear meters). Manufacturers offer three main shapes (meaning the cross-section): flat casing, rounded and curly.

Based on the installation method, platbands are divided into overhead and telescopic.

- The invoice (as the name suggests) is mounted by placing the platband on the desired surface and securing it to it.

- As for the telescopic one, it (unlike the overhead one) has a so-called beak (also sometimes called “wings”) - this is a small protrusion that is located perpendicular to the plane of the casing, which fits into the groove on the box. The distance by which the platband extends from the corresponding box can be adjusted, thereby ensuring complete closure of the gap at the junction of the box and the platband. This is very important if the walls have different thicknesses.

Instructions for finishing window slopes with metal

Korovin Sergey Dmitrievich

Master of Architecture, graduated from Samara State University of Architecture and Civil Engineering. 11 years of experience in design and construction.

Metal-plastic windows are a multifunctional modern product for glazing window openings. The final stage of installing plastic windows is finishing the external slopes. For this, various finishing materials can be used: plaster, paint, PVC panels, plasterboard, but most often metal window trim is produced. Installing a metal slope on windows can be done with your own hands.