Today, facade panels are used more and more often for finishing houses. This is due to the high performance characteristics of such materials, because they are distinguished by durability and aesthetic appeal with the ability to imitate the colors and textures of brick, stone, and wood. Facade panels are resistant to moisture, sunlight and other external influences, including mechanical damage. They withstand frost and temperature changes well.

Types of facade panels for exterior decoration of a house

Not all types of facade panels are suitable for finishing private houses. The point here is not only the complexity of installation and the high cost of the material, but also its appearance. For example, translucent panels only go well with houses of the high-tech architectural style, while metal panels are best used for cladding office buildings, warehouses, industrial and commercial facilities.

The following materials are optimal for finishing a house with panels:

1. Facade siding. One of the most popular finishing options. Available in the form of long strips mounted on a frame. Produced in any colors from the RAL palette, its pattern can imitate timber or brickwork. Siding has a low cost, but it is very thin - no more than 15 mm, so it is easily damaged in the event of an impact or other mechanical influences. If the material is of poor quality, then over time it “fades” in the sun, losing its original color.

2. Fiber cement boards. An excellent option for finishing the facade of a private house with brick panels. They are made from environmentally friendly raw materials - cement and small synthetic fibers. The material is not afraid of moisture, does not freeze, and has high decorative characteristics. The disadvantages of fiber cement panels include their heavy weight. After completion of the cladding, they place additional load on the supporting structures and foundation of the building.

3. Porcelain tiles. Visually, such panels imitate stone cladding. Due to the large size of the slabs, they will allow you to perform decorative finishing of the facade in a short period of time. The cladding turns out to be beautiful and durable, it does not fade in the sun and can withstand up to 50 freeze-thaw cycles, that is, it is most resistant to climatic factors. The disadvantages of the material include high cost, heavy weight, and difficulty in cutting on site.

4. WPC (wood-polymer composite). These façade materials are made from a mixture of wood ground into fibers and liquid polymer. Dye is added to the mixture during mixing. WPC is produced in the form of boards or slabs (planken, lining). This is an excellent option for finishing the walls of a house made of sip panels. This cladding not only visually, but also tactilely resembles natural wood. At the same time, it does not have the disadvantages of the latter, since it is not exposed to moisture; composite boards do not need to be regularly opened with varnish, fire retardant or fungicidal compounds.

5. Clinker facade slabs. They are used if the house is facing with brick panels. This is a multilayer material consisting of a layer of OSB, insulation (expanded polystyrene) and thin clinker tiles. Visually, it looks like rectangular slabs with jagged edges. Clinker facade panels are relatively expensive, but at the same time they immediately serve as cladding and insulation. That is why they are often called thermal panels.

6. Basement siding. Made from polymers (PVC, polypropylene). Produced by manufacturers in the form of slabs having a square or rectangular shape. They have locking connections along the edges, which greatly simplifies the installation of such cladding. Most often, basement siding imitates the texture of stone and brickwork. This facing material is dyed in bulk, so it does not fade over time. It is not afraid of mechanical damage, resistant to scratches and stress. The thickness of the basement siding is greater than that of the facade siding - up to 30 mm.

7. Metal. They can have a rectangular or square shape. Made from steel or aluminum. The former are cheaper, but if the outer polymer coating is damaged, they are subject to corrosion. The disadvantage of such cladding is its “noisiness” due to gusts of wind or raindrops.

8. Translucent. Made from transparent polycarbonate or double-glazed windows. They often have a coating that repels the sun's rays. This helps to avoid excessive heating of the building walls in summer. This type of cladding is very difficult to install and is expensive.

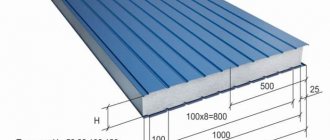

9. Sandwich panels. Available in the form of large blocks. The design of the façade sandwich panel involves the presence of two metal plates, between which the heat-insulating material is located. From the outside, this finish looks like corrugated sheeting. Among the advantages is that there is no need for additional insulation. The disadvantages include the low decorative characteristics of facade panels.

10. Aluminum composite. They are considered a type of sandwich panels. They use aluminum plates instead of metal sheets. Between them there is a composite material - aluminum-composite facade panels are thinner than classic sandwich panels. They are not as noisy as metal cassettes, but they are also more expensive.

How to cover the outside of a house cheaply and beautifully?

If we talk about cost, then the cheapest finishing option would be siding. The next best option in terms of price are fiber cement boards, then WPC. The most expensive types of cladding include porcelain stoneware and clinker facade panels.

Regarding aesthetic characteristics, all facade slabs are available in a variety of colors, so you can easily choose an option for any facade design. Of course, visually porcelain tiles look much more beautiful than siding.

When choosing plastic panels for finishing the facade of a house, one should take into account their performance characteristics, as well as the material of the building walls. For example, sandwich panels are not suitable for vapor-permeable walls, since they are insulated with expanded polystyrene. You can, of course, provide a vapor barrier layer from the inside, but this will lead to additional financial costs. And moisture will not escape through the walls, but it will remain inside the room, and with excess humidity the risk of the formation of fungus and black mold increases significantly. To avoid this, you will have to spend money separately on the installation and subsequent maintenance of a high-quality ventilation system.

Houses made of aerated concrete or wood can be clad with thermal panels only using lathing with a ventilation gap. If installed directly on the walls, they will stop “breathing”. This will lead to condensation and freezing of the walls.

Video description

About log siding in the following video:

Fiber cement

Despite the fact that fiber cement panels with wood texture appeared on the construction market relatively recently, they have already been appreciated - both by users for their good performance characteristics and by installers for the ease of working with this material. Since, in addition to the quality of the material, one of the most important criteria for its selection is service support, in order to reveal the full range of advantages, we will consider fiber cement facade panels of the Cedral brand.

Fiber cement siding has received well-deserved positive reviews from customers, thanks to its following positive qualities:

- Environmental friendliness

When fiber cement was first invented, asbestos was one of its main components. But its use was abandoned in 1976 because researchers were concerned that asbestos dust was harmful to health. Today, in the production of fiber cement siding, cement, sand, water and natural reinforcing fibers from cellulose are used, that is, fiber cement has become completely natural.

Eco-friendly fiber cement panels are even used for terraces and gazebos Source cedral.world

How to install facade panels?

Technologies for decorative finishing of panels:

- Laying cladding directly on the wall.

- Installation on a frame system.

- Arrangement of a ventilated facade.

In the first case, the facing material is fixed to an adhesive or cement base. And for a ventilated façade and frame system, frame assembly is required. It can be wooden, steel or aluminum. Using wood is the most budget option. It requires additional care, treatment with fire retardants and compounds that protect the material from pests. This frame is only suitable for lightweight cladding materials. For example, siding or clinker panels are often attached to the bars.

The frame and ventilated system is convenient because, in parallel with the cladding, you can immediately insulate the outside walls of the building and increase their sound insulation. Thanks to the ventilation gap, the problem with condensation is immediately solved; the steam will simply evaporate freely into the atmosphere. But such cladding will cost more, because in addition to the façade panels, it is necessary to purchase a fastening system for them.

Let's look at each of the technologies for installing facade cladding using specific examples.

Characteristics

Polymer siding for exterior decoration is made on the basis of polyvinyl chloride , with the addition of several components that improve the physical properties of the base material (durability, ductility and elasticity, strength characteristics).

The manufacturing process is nothing more than the extrusion of this solid base into the desired shape and size.

The outer surface of facing vinyl siding can be structured or smooth, glossy or matte, visually imitate any texture, or be multi-colored.

Inside, the panels have a honeycomb structure with a large number of voids of the same size. Thanks to this, siding performs additional thermal insulation and sound insulation functions.

Finishing with stone panels - frameless installation

If thermal panels are used, then there is no need for additional insulation. Otherwise, slabs of dense mineral wool or expanded polystyrene are laid on the wall. The insulation is covered with a plaster mesh on top. It is fixed to it with staples and improves adhesion to the cladding.

Decorating a house with wood or stone panels without using a frame has a number of features:

- Facade thermal panels have factory-installed tongue-and-groove connections. They need to be inserted tightly until it stops so that there are no gaps left.

- Installation of facade panels is carried out from the corners and from bottom to top. When installing each new row of cladding, you should carefully monitor its horizontal position. A building level is used for checking. It is recommended to first install a starting bar at the bottom.

- When forming corners, the edges of the panel are cut off. The cutting angle is 90°. Next, the tile and the layer of insulation located underneath it are cut at an angle of 45°. When joining thermal panels cut in this way, 90° is obtained.

- All joints are blown with foam and then rubbed down. Grout consumption is about 2 kg/m2.

- If the thermal panel is not fixed with an adhesive base, but with self-tapping screws, then the fasteners cannot be tightened until it stops. This is necessary to compensate for thermal expansion in case of temperature changes.

The frameless installation method can only be used for perfectly flat walls that do not have significant differences. Otherwise, it is better to install lathing or a ventilated facade, which will help hide unevenness by adjusting the thickness of the beams or the length of the brackets.

Specifications

If you want to purchase panels for facade cladding made of plastic, you need to familiarize yourself with their technical characteristics, which are as follows:

- Panel thicknesses are 6, 8, 10 mm;

- product width 1300 and 1850 mm;

- Product lengths are available in 2800, 3050, 3650 mm;

- the material weighs respectively 8.4 11.2 14 kg/m2;

IMPORTANT!

During installation, products can be sawn into fragments, giving them the required size.

- the tensile strength indicator is 100 MPa;

- the size change parameter in the case of high temperature conditions is 0.15%;

- the level of bending strength is 140 MPa;

- the density parameter is 1.4 g/cm3;

- linear expansion coefficient parameter, in the case of temperature fluctuations is 0.9 x 10 -51/k;

- thermal conductivity index is 0.3 w/m*k;

- the material is resistant to temperature changes ranging from -60 to plus 85 degrees Celsius;

- belongs to flammability group g1;

- Available in a rich range of colors, which include both monochrome colors and imitation of various natural materials.

Finishing a house with fiber cement panels using ventilated facade technology

When cladding walls with fiber cement panels, they can be attached directly to the wooden sheathing. But at the same time, you will have to drill through holes in the slabs. Such a facade does not look very aesthetically pleasing, so they often give preference to a hanging frame. It allows the use of clamps for hidden installation. In this case, the surface of the fiber cement panel is not damaged; it is fixed using special “tongues”.

The cladding technology includes the following stages:

- Cleaning walls from old finishes. Defects and irregularities are eliminated, cracks and seams are sealed if mortar has fallen out of them.

- Applying markings according to a pre-prepared scheme. This will allow you to position the brackets correctly. This is important because they are the ones who must evenly distribute the load of the cladding on the wall. The pitch and number of brackets are selected depending on the size of the panels and their weight.

- Installation of plumb lines. They are located from the wall at a distance equal to the thickness of the thermal insulation.

- Installation of brackets. Façade anchors are used. The drilling depth is selected depending on the weight of the facing slabs. To do this, technical tests are first carried out with one fastener, checking its load-bearing capacity. For walls made of foam blocks, it is necessary to use special chemical anchors. A paronite gasket is placed under each of the brackets. It prevents moisture from penetrating into the hole.

- Adjustment of the length of the bracket depending on the size of the insulation. Extensions are used if necessary. The width of the ventilation gap is 40-100 mm.

- Installation of insulation. The wall is primed with a deep penetration compound. Stone wool is used as insulation. A metal base profile is installed underneath. Installation of slabs begins from the bottom row. The rows are laid in such a way that the joints of the top are in the middle of the bottom. To fix the insulation, disc-shaped (mushroom-shaped) dowels are used - 5 pcs. on the stove (in the center and along the edges). Slots are made at the locations of the brackets. If cracks appear, they are filled with construction foam.

- Laying a waterproof membrane. The individual sheets are overlapped with a width of 15 cm. The membrane is fixed with staples.

- Installation of horizontal guides. It is recommended to make the step no more than 60 cm. The guides are attached to the brackets using blind rivets.

- Installation of a vertical profile. Installed on top of horizontal. A compensation gap is left between individual sections of the profile. It prevents deformation of the façade cladding in the event of temperature changes. EPDM tape is attached to the frame elements. It ensures a tight fit of the plate to the guides.

- Installation of cladding. The plates are fixed using covered fastenings and clamps. They are invisible from the outside; the cladding looks like a single whole. Such fastenings allow, if necessary, to quickly repair the hotel part of the facade without disassembling it entirely.

When choosing load-bearing frame elements, you need to focus on GOST R 58154-2018 “Materials for substructures of suspended ventilated facade systems.”

Installation of metal siding

Everything starts identically: materials are prepared, the future structure is drawn schematically, and installation is carried out. The profiles are installed in accordance with the drawn diagram at right angles to the base of the house in increments of 50 cm. The supporting profiles must be secured with dowels.

Metal siding: installation on an aluminum frame

Remove disturbing elements from the building facade

After installing the vertical profiles, it is necessary to install transverse bulkheads. Here you will need to make tabs on each side of the panel for attaching to the profile. There are ready-made frames, but such structures have a clear drawback - they must be attached directly to the walls of the house. If the wall is made of foam concrete, then such a frame may collapse. It is also not recommended to install the frame on sand-lime brick. Red brick walls are also not suitable for a finished frame. In addition, such structures are more expensive than those installed by yourself.

Installation of vertical posts in a horizontal profile

Aligning the metal frame vertically and horizontally

We install additional vertical posts under the siding (based on the recommended dimensions of 40-60 cm)

The most common fastening of metal profiles to each other

Frame for siding

After the bulkheads have been installed, various types of insulation can be inserted into the resulting rectangles.

Laying insulation boards

Mineral wool can be attached with direct hangers

The insulation layer is covered with a wind-vapor barrier fabric

Once the insulation is installed, the panels can be secured to the frame. Each panel has holes for screws. This allows you to hide the seams and not interfere with the aesthetic appearance of the facade.

Additional elements

Metal siding kit

Schematically the installation looks like this.

Stage 1 . Drawing up a diagram of the house and the future frame for the panels.

Installation diagram

Stage 2. Cleaning the building of unnecessary decorative elements.

Stage 3 . Production of an external frame on the walls of a building or installation of a ready-made one.

Stage 4 . Installation of flashing, starting strip and the very first row of panels. A level is used to determine the correct angle.

Low tide installation

We fasten the ebb with self-tapping screws in increments of no more than 40 cm

We install the planks with an overlap

Setting external corners

Fastening the inner corner

Installation of the starting profile

We screw in the screws in the center of the holes, check the tightness of the fastening by slightly moving the bar left and right

Installation of platbands on windows

Fastening the window profile

Stage 5. The following rows are installed, followed by fastening to the frame.

We snap the first panel into the starting strip and fasten it to the sheathing with self-tapping screws

We insert the next panel into the locking part of the previous one and repeat the installation

Installation of metal siding

Stage 6 . Installation of the finishing strip, soffits and decorative elements.

Installation of the finishing profile

We make holes in the last panel with a punch, snap the panel into the finishing profile

Installation of spotlights

In the future, similar installation elements are saved for each type of panel. This is also a plus of the panels - their installation is similar, which means you can easily learn how to install the facade.

Metal siding is a good option for a summer house and a one-story house. Such panels perfectly replicate the effect of wood. In addition, the products are perfectly processed without unnecessary tools. Easy care - just wash the contaminated part of the house with water.

Metal siding

File for download. Production of metal siding installation works

Instructions

Prices for popular models of multifunctional cutters

Multifunctional cutter

Installation of basement siding on the frame

Finishing the facade of a house with PVC panels has its own differences. The sheathing used to install basement siding must be “checked”, since the facing material itself has a square or rectangular shape. Bars or profiles are placed at the joints of PVC plates.

Be sure to use the starting and j-profile. They will help cover the sections of the facing material and provide additional support for it. There are special corner panels for decorating corners. Moreover, it looks beautiful when they have a different color from the wall decoration.

Installation of PVC panels on a frame base is carried out in several stages:

- Surface preparation. The old finish is removed. Cracks, chips, and wall defects are repaired with cement mortar. If a seam has fallen out between the bricks in the masonry, it must be repaired. The surface is leveled.

- Installation of sheathing. A wooden sheathing made of timber or profiles is attached to the wall. Self-tapping screws or dowels are used for fixation. First, horizontal strips are installed. The pitch should be equal to the height of the panel. It is important that the joint of the facing panels falls in the middle of the profile. The pitch of the vertical slats is calculated in the same way. They are installed in the space between the horizontal ones or on top if a ventilation gap is installed.

- Installation of insulation. Mineral wool is used as insulation in frame structures. It fits tightly inside the lathing frame. The wall is first primed, and in the case of wooden houses, it is also treated with fire retardants and antiseptic compounds that prevent the development of fungus or mold on the surface. Be sure to apply a fungicidal solution. It will protect the tree from insects and rodents. The top of the insulation is covered with a vapor-permeable membrane.

- Installation of cladding.

A starting profile is installed on the lower horizontal bar. It is nailed or fixed with self-tapping screws. The first row of PVC panels is inserted into the profile. They are leveled and attached to the sheathing using nails. The second panel is connected to the previous one via a lock. If the panel has to be cut, for example, when facing the corner of a building, then a j-profile is placed in these places.

For greater rigidity of the cladding, two vertical jumpers can be installed on one piece of basement siding at once. This is especially true when the PVC panel has a length of more than 1000 mm.

Price list

| Title of works | Price |

| Natural stone or artificial stone on an adhesive mixture: | |

| Steel mesh fastener | 190 rub/m2 |

| Leveling the surface using beacons | 330 rub/m2 |

| Padding | 75 RUR/m2 |

| Stone cladding | 1300 rub/m2 |

| Grouting of seams, rub./m.m. | 300 rub/m2 |

| Based on the hinged ventilation façade technology: | |

| Installation of a metal frame | 500 rub/m2 |

| Facing fasteners: | |

| — Fiber cement panels | 600 rub/m2 |

| — Porcelain tiles | 720 RUR/m2 |

| — Metal cassettes | 720 RUR/m2 |

| — Profiled sheet | 600 rub/m2 |

| — Metal siding | 900 rub/m2 |

| — Composite aluminum cassettes | 720 RUR/m2 |

| — Clinker tiles | 4200 rub/m2 |

| — Planken | 900 rub/m2 |

| — Aluminum cassettes | 720 RUR/m2 |

| — Natural stone | 900 rub/m2 |

| — Terracotta panels | 900 rub/m2 |

| — HPL panels | 720 RUR/m2 |

| — Lamels | 900 rub/m2 |

| - finishing the house with facade panels | 700 rub/m2 |

| Installation of parapet ebb on the subsystem | 900 rub/m2 |

| Installation of slopes and ebbs | 400 r/m. |

Ventilated facades "Turnkey"

| Name | Without insulation | 50mm | 100mm |

| - professional sheet | 2215 | 2500 | 2610 |

| - metal siding | 2715 | 3000 | 3110 |

| - porcelain stoneware | 3045 | 3330 | 3440 |

| - fake diamond | 3045 | 3330 | 3440 |

| - marmorok | 3045 | 3330 | 3440 |

| — fiber cement boards | 3175 | 3460 | 3570 |

| - metal cassettes | 3415 | 3700 | 3810 |

| - composite panels | 3520 | 3805 | 3915 |

| - planken | 4815 | 5100 | 5210 |

| - clinker tiles | 5245 | 5530 | 5640 |

| - aluminum cassettes | 5440 | 5725 | 6835 |

| — HPL panels | 6860 | 7145 | 7255 |

| – terracotta panels | 7815 | 8100 | 8210 |

| - lamellas | 9215 | 9500 | 9610 |

Thermal panels

Clinker thermal panels are based on polyurethane foam and clinker tiles. This combination determines the main advantages of the finish.

Advantages of thermal panels:

- good heat and sound insulation;

- resistance to temperature changes;

- fire safety;

- moisture resistance.

The main disadvantage of clinker thermal panels is the toxicity of some of the components included in their composition.