Lining is a smooth board that has grooves on one side and tenons on the other. The material is used for finishing and insulating premises. If you have previously purchased lining for finishing a room, remember that you need to store it in a dry place where sunlight and moisture do not penetrate. The material must be stored in its original packaging to prevent damage to the material.

The length varies from 2 to 6 meters, here you need to select it depending on the surface you want to finish, be it a ceiling, balcony or other surface.

The length must be accurately taken into account when finishing, otherwise you will have to cut the elements yourself, and this significantly slows down the process of installation and repair in the room, even if you only want to cover the ceiling. Installation is quite simple even for a person who is not involved in repairs.

Methods for covering a room

Length joining is most often done when the ceiling is sheathed. In this case, there are several docking options:

- The joining takes place along one line; when using this method, the joints are covered with decorative overlays or special slats.

- The so-called seam spacing, when the end is sanded, thereby obtaining a neat and unprotruding seam, and each board that is placed is further trimmed. Docking with this method is neat and economical, since almost all the material is used.

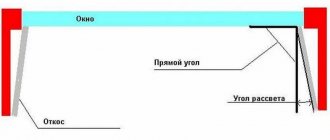

During installation, you need to take into account that the joining of the lining in the corners must be of high quality so that air does not pass through the cracks. Laying the plank in a corner can also be done in two ways:

- Fasten two small pieces of suitable size into the corner (as well as the sheathing strip). Before this, the log needs to be sanded and prepared for installation. The log should be small in size so that subsequent joining occurs at the correct angle. In the corner, which was made from logs, attach a plank, a little thicker than the lining. Join the elements with the plank. Next, the plank is joined to the lining. Then the element is fixed to the inner beam.

Headlining

The ceiling lathing is mounted on hangers or brackets. The horizontal level is set with a laser level, focusing on the lowest point of overlap. A fishing line is stretched along the walls, and frame bars are placed along it in increments of 25-35 cm for eurolining, 40-60 for other types. When finishing an entire room with clapboards, first the walls are sheathed, then the ceiling.

Before fixing the lining, all communications are laid and embedded parts for massive lamps are installed. If the ceiling is insulated, use a stapler to attach a vapor barrier film to the sheathing or wooden wall from the side of the ceiling. Thermal insulation is inserted between the frame bars and covered with a membrane. The rough surface should be directed towards the insulation.

They begin to install the lining on the side opposite to the entrance so that the last cut board does not catch the eye. If the length of the lamellas is insufficient, use a layout with joints along one line or with staggered seams. The border is covered with a decorative strip or the ends are carefully sanded. Then the docking point is neat and unnoticeable.

Unusual ways

If laying on flat surfaces usually does not raise any questions, then joining the lining at an angle of 120 degrees is considered quite difficult even for specialists in this matter; here you need to accurately measure the parameters, since the length of the strip may be longer or shorter than expected.

To install the lining at 120 degrees, you will need a special j-lining, the length of which differs from the standard one. This material is more convenient to work with corners and you can carefully lay the lining at 120 degrees.

Docking at 120 degrees

Docking at 120 degrees occurs in several difficult ways:

- One plank is placed next to another so that there is no gap between them, so with the help of special objects you can measure any angle that you need.

- The fastening is installed through the upper points of the fastening corner using special roofing felt nails.

Docking at an angle requires the presence of a sheathing on which decorative lining is attached. What to do if the joints at the corners are very noticeable and are located with a large gap? Specialized stores sell a plinth-type plank that covers the joints and does not allow wind, moisture and air to pass through. The lining can also be painted with special wax paints, which are well absorbed into the wood and form a moisture-proof layer, again protecting against bad weather conditions if you live in a private house.

Ceilings in bathhouses and saunas are sometimes finished with lining; this material is moisture-resistant and unpretentious, mold does not form on it, which means it is well suited for rooms with high humidity. The material is considered a universal finishing material, which is why it is so often used in construction. You can choose material of different colors and lay it out in a checkerboard pattern so that the room is not only warm and dry, but also comfortable to be in. You can also choose lining from different materials, for example, oak, cherry; these types of trees themselves look beautiful and noble.

Sequence of finishing work

The first step is choosing a wall decoration option. Fastening the lining can be done in two ways:

- Along the walls;

- Along the sheathing.

The first option is preferable in a wooden house, since wood tends to expand or shrink in size and “breathe”. If the base material is the same as the coating, their joint oscillatory motion will not cause multidirectional stresses leading to deformations and the appearance of defects on the surface.

In brick and concrete houses, before attaching the lining, a sheathing is installed, which can also serve as a frame for laying thermal insulation. It is convenient to place corrugated hoses for electrical wiring and heating pipes in the space between the covering and the wall.

The second is the correct measurement of the room and calculation of materials. This will help you avoid unnecessary expenses or waste time on additional trips to purchase missing components. The amount of lining is determined based on the area of the walls, excluding openings. The length of the ceiling and floor plinth is equal to the perimeter of the room. To decorate the corners you will need shaped strips. Materials are purchased with a margin of 10-15% for defects or other defects.

Wood is a living structure, sensitive to fluctuations in humidity and temperature.

Before starting work, it is unpacked, allowed to “get used” to the new conditions, and treated with antiseptics and fire retardants, if there is no factory preparation.

Before installing the sheathing or directly attaching the lining to the wall, prepare the surface - clean, level, seal the cracks, and coat with antiseptic compounds. This will protect the structure from the appearance of mold and fungi.

The third step is installing the sheathing. Most often it is made from wooden blocks with a cross-section of 20x30, 40x50 or larger. The thickness of the element depends on whether insulation will be laid under the lining. A ventilation gap is left between the thermal insulation layer and the coating, which prevents condensation from accumulating.

The frame pitch is 40-60 cm, the direction is perpendicular to the finishing boards. The space between the bars should be filled tightly with insulating roll or slab material. For residential premises this is usually mineral wool; outside, expanded polystyrene foam or other polymers are more often used. They are not afraid of moisture. Before attaching the lining, perform a vapor barrier and waterproofing. A film or membrane is used that allows the liquid to evaporate, but does not allow it to pass in the opposite direction.

The geometry is controlled using a bubble or laser level. Dowels or construction nails are used as fasteners for the sheathing.

How to do something yourself, with your own hands - home craftsman website

AN EXCELLENT TOOL FOR CRAFTERS AND HANDCRAFTS AND EVERYTHING FOR THE GARDEN, HOME AND Cottage LITERALLY FOR FREE + THERE ARE REVIEWS.

Covering walls and ceilings with wooden clapboard is one of the simplest and cheapest methods of interior decoration. Lining is not a scarce commodity, and its use does not require professional skills or complex tools. However, as in any business, there are subtleties and peculiarities here. Dmitry Tokarev shares some of them.

Wood is a capricious material. Even if you buy the lining in a package during the dry season and make sure of its ideal geometry, do not rush to rejoice. In a room with new temperature and humidity characteristics, this material quickly takes on the shape it needs, not you. The longitudinal planes are bent, and the worst trick is to tighten the paneling with a screw.

Trick 1 – Conditioning the lining

My first trick. Having printed the lining, I put it in piles, lay it with spacer boards and tape it together along the edges and in the middle. Sawn strips of fiberboard are convenient as spacers. In this form, the lining remains for 6-7 days in the room where it is planned to be used. In the future, the geometry of the aged material will not float away.

What do you use to cover it with?

This kind of cladding is now made from 3 materials:

- Plastic.

- MDF.

- Tree.

Plastic and MDF cladding are often of the same type, but with wood it is a little more complicated; in addition to wood species, the lining is also divided into classes and types.

Plastic lining

The plastic cladding consists of hollow honeycomb strips separated by internal stiffeners.

The width of the strips varies from 100 to 380 mm, and the length from 2000 to 6000 mm. The thickness varies around 10 mm.

PVC lining is most often used; it has a wide range of models and a reasonable price, but there is one serious drawback: polyvinyl chloride fades in the sun. Acrylic panels are more expensive, but they do not fade, plus the colors are brighter and the material itself is stronger.

Plastic lining is divided into external and internal; external models are usually called siding

MDF planks

MDF planks are used only for interior decoration, but unlike plastic, they cannot be installed in wet rooms.

Modern MDF lining differs from laminate flooring in its density, but otherwise these materials are similar.

Instructions for installing MDF lining are not much different from arranging a plastic covering

Wooden lining

This cladding is regulated by two standards:

- Domestic GOST 8242-88.

- European DIN 68-126/86.

As for wood species, linden, spruce and pine are considered popular. Elite finishes include oak, larch and Karelian birch.

The name eurolining does not guarantee that the material was made abroad. It’s just that the planks are made according to the DIN standard, and they could have been made at the nearest sawmill, which has the appropriate equipment.

- Dimensions according to domestic GOST . In stores, the length of wooden lining ranges from 1500 - 3000 mm, the minimum width is 76 mm, the maximum is 200 mm. The thickness depends on the configuration, so thin strips such as Standard, Shtil, etc. have a thickness of 12 - 16 mm, and semicircular lining (Blockhouse) reaches 40 mm.

- Dimensions according to DIN standard. The most common length of eurolining is 2.7 m, width 80 - 120 mm, and thickness 12.5 - 19 mm.

In theory, both of the above standards allow for the production of planks up to 6 m long, but due to difficulties with transportation, such material is usually made to order.

Visually, the European standard can be distinguished from ordinary lining by the longitudinal compensation grooves on the back side.

The configuration of the planks is also very different, both in price and in appearance:

- Standard, Shtil and Softline are considered the most popular and affordable.

- Eurolining is the same Standard, only with different sizes.

- Semicircular lining or Blockhouse is more expensive, now this model is very popular.

- Landhouse and American models are considered specific in the domestic market. Their price is average, but their popularity is lower than that of traditional lining or Blockhouse.

Contours of different types of lining in section and appearance in the photo

Types and features of material

The origin of the name of the material has its own history. Previously, freight cars were finished with such groove boards . For other purposes, the material was practically not used, not to mention the cladding of living quarters.

However, over time, they learned to use it for finishing baths and saunas, which provided comfortable operating conditions for the room, since the surfaces did not heat up to such high temperatures as the air (how to line a bathhouse with clapboard?).

Lastly, the panels migrated to the interior of residential apartments, in particular for finishing the kitchen, hallway and corridor, but the name “lining” is used to this day.

Depending on the type of wood, the panels are:

- conifers, usually pine;

- fake;

- alder;

- from larch.

Different types of wood have different properties, so they may not be suitable for exterior decoration or use in rooms with high humidity, such as larch or cedar.

By standard size they are distinguished:

- narrow canvases with a thickness of 13 cm;

- wide stripes up to 24 cm;

- thin from 1.5-1.9 cm;

- increased thickness up to 2-2.5 cm with a shortened tongue.

Categories:

- block house with a rounded surface contour;

- American - with several grooves on the inside of the profile;

- regular with different widths;

- Eurolining with standardized dimensions.

Type of veneer covering:

Lining made of wood or MDF belongs to the category of wooden or natural panels, and PVC belongs to plastic or artificial coverings.

The following classes of panels are distinguished :

The differences between the material of each category lie in the presence of knots, their number and type.

- Category A lining has a small percentage of these formations that do not fall out over time.

- Group B includes materials of the lowest quality, most often for rough or facade finishing.

- The highest quality panels in the Extra category , where not only are there no knots, but the surface of the material is perfectly smooth. Such products are intended for cladding inside saunas and baths.

Based on surface type, materials are divided into:

We invite you to watch a video about the types of lining:

Choice: wood or metal?

Professional craftsmen consider timber to be the most popular building material for sheathing under lining. Ease of use during installation work, small “weight category” - and creating a frame with your own hands will be easier and faster. This material also has sufficient functional durability. So we choose a wooden beam.

Timber for lining

We will use standard size bars - 50 by 25, 60 by 27 millimeters. This building material is almost ideal both externally and internally. But when purchasing, make sure that there are no defects or chips on it. It is also important to know the moisture level of the wood. Recommended – 16 percent, no more.

Tools and Fasteners

During the installation of wooden panels, various fastening methods are used:

- clamps , which are inserted into grooves and attached to the wall surface with studs;

- self-tapping screws , screwed directly into the canvas, fixing it to the sheathing made of wooden blocks (what is it for and how to make the sheathing?);

- nails designed specifically for fastening lining, with very small heads, 2.5-3 cm long and approximately 1 mm thick.

For cutting canvases the following is used:

- electric drill;

- jigsaw;

- regular hacksaw for wood.

The result is not always a perfectly even cut, so it needs to be carefully sanded using sandpaper.

Required: processing solutions

Do not neglect antiseptics and insecticides. This step extends the durability of the sheathing. The minimum level of treatment is a solution against fungus, rot, and mold. And insect control products should be used in houses standing on the ground - dachas, utility rooms. By the way, the cost of the compositions is not too high, and the right thing to do would be to play it safe and treat both the wooden frame and the wall with the ceiling in any room where the sheathing under the lining is being installed. The rules for using solutions are usually written on the packaging - read before you start spraying.

This is what a timber frame looks like

How to install panels if they are short?

When using short sheets to create a continuous coating, you will have to join them together. To do this, a method is used in a checkerboard pattern, with seams staggered or along one line of the ends of the strips. Each of these methods has its own differences, which require either additional equipment or good skills in working with wood.

- In the first case, the seams are located chaotically , which slightly distracts from the integrity of the canvas and creates the impression of an idea. Here the main difficulty lies in finishing the end of the lining of each contacting material. The smoother the cut, the less noticeable are the gaps and cracks at the joint.

- In the second case, a special additional device will be required to connect different lengths of canvas . If the strips are connected without an H-shaped profile, then they can even be positioned offset, but covered with thin wooden slats or planks. However, installation of continuous decoration of seams is a simpler and less labor-intensive process.

Technology of how to join lining during finishing and repair

The video will show you how to join lining lengthwise on the ceiling, in the corners of a bathhouse, and we will tell you about the main points and subtleties that are important to consider when doing the work yourself. Firstly, it should be noted that technology such as joining linings when finishing and repairing along the lengths is an excellent way to increase the size of the panel, if necessary. Secondly, if you do everything correctly, the sheathed ceiling will be of high quality.

Bath decoration

Technology for installing lining on a frame

You probably already know that before joining the lining in the corners, you need to equip the ceiling with guides, that is, a frame to which the PVC panels are sewn. As a rule, the walls and ceilings in a bathhouse are logs, and logs do not have a perfectly flat surface. Only one question may arise here - how to join corner profiles for lining? This will require corner profiles, or moldings, which greatly simplify the task.

After all the preparatory work has been done and the logs are covered with guides, you can begin installation. If you carry it out in a new, not yet settled, wooden house or in a bathhouse, then you should leave a gap of one and a half to two centimeters between the panels and the ceiling. It is needed so that the shrinkage of the structure, which will certainly occur within two to three years, is compensated.

There are two options for how to properly join the lining along the length:

- in one line;

- with seams staggered, or in a checkerboard pattern.

In the first case, you will get one vertical seam. It will need to be covered with a lath or plank (or any other profile) upon completion of installation. This design will look more advantageous and serve for many years.

In the second case, it is necessary to grind the ends of the part so that the seam is as little noticeable as possible. Each new row should begin with the cut board in the previous row. In this way, waste-free installation of the material will be achieved, which is obviously more economical.

You can learn how to properly join the lining on the ceiling by carefully studying the photo and video materials on the website. If the length of the panels is chosen correctly, then the finishing of walls made of PVC panels will be completed with minimal waste.

Mount selection

To fasten the lining along the length, you can use both nails and self-tapping screws or clamps. Each of them has its own advantages and disadvantages.

A kleimer is a device designed specifically for these purposes, so if you want to make it easier to join the lining during finishing and repairs, choose it. It slides into the groove of the lamella and is tapped until it completely adheres to the board.

For fastening with nails, it is most convenient to use a hammer to avoid deforming the edge of the board with hammer blows. The nail should be inserted into the groove at an angle of approximately 45 degrees and driven into the middle with a hammer. After that, you can hammer it completely with a hammer. The disadvantage of this traditional method is that even using a punch, it is rarely possible to avoid deformation of the groove edge. The second drawback is the lubricant with which all nails that go on sale are treated: both hands and gloves will be dirty, and if you then touch an untreated board, you can easily ruin its appearance.

In order for the joints to look neat in the end, you should take a responsible approach to the choice of cornices and skirting boards, which can hide all the imperfections and become the highlight of the interior.

See also:

vagonkagid.ru

Useful tips

Despite the simplicity of processing and ease of installation, there are several useful tips for lining to ensure that the coating turns out beautiful, durable and with the necessary properties of the finishing material. Some useful tips:

- To ensure that the size and shape of the canvas do not change as the material is used, it should be kept with a layer between strips of thin fiberboard in the room in which it is planned to cover the surfaces.

- If a batch comes across a “crooked” fabric, then due to the fragility of the connecting side grooves and protrusions, it is very difficult to insert it into a flat product. It is better not to use such canvases, but to use them for sealing places where trimmings are required.

- When using clamps, the protective oil coating containing metal particles must be removed from their surface. This will protect the wooden panels from accidental contamination (how to clean dirt on the lining?).

- To prevent burrs or chips from appearing on the canvas when self-tapping screws are used for fastening, you need to drill a hole with a thin drill at the site of the upcoming fixation.

- To disguise chips, joints and other damage between the canvases, you can use various paints and varnishes, wood putties or decorative elements, for example, thick twine or cord.

Wood is considered a very capricious material , which during operation is capable of changing its dimensions and shape. This must be taken into account when installing canvases on wall surfaces, especially in rooms with high humidity.

For the best result and invisibility of seams between strips of lining along the length, it is necessary to use an H-shaped profile or special thin wooden strips. However, installation with staggered seams will significantly save material, reducing its consumption due to the use of all scraps.

Lathing for lining: step-by-step instructions

Preparation of the bar

The material for work should be prepared in advance. The timber should be kept for several days in the room where the finishing will be done. This will allow the building materials to acclimatize, and their temperature and humidity will become similar to that in the room.

Next, the sheathing elements are treated with an antiseptic compound (if possible and, if necessary, with an insecticide). This can be done either using ordinary brushes, processing everything in order and carefully. If the volume of work is large enough, then you can build a small trough from boards and cover it with polyethylene. We pour an antiseptic composition there and dip each of the bars. This option will provide high-quality protection against mold and mildew.

Antiseptic trough

Preparing the walls

While the timber is drying, we prepare the surface of the walls. To do this, mark the width of the racks using a pencil and using a level so that all the lines are as even as possible. Such a “drawing” will allow you to clearly see how the entire structure will subsequently look, simplifying the work and controlling the correct location of the sheathing elements.

You should also determine the starting point for installing the sheathing. It can be the lowest corner available in the room (we find it using a water or laser level). After the necessary measurements, we draw out the wall and draw a horizontal line.

Marking Lathing with timber

How to hide wall defects

If the unevenness is significant, then it is necessary to secure the beam using special hangers, which should be positioned in a line (every half a meter) and secured perpendicularly. The prices for this type of fasteners are low, so the costs will not increase significantly. When fastening, the ends of the hangers are bent in the direction of the bar, after which it is leveled and fixed. This option is convenient due to its simplicity and accuracy: you can level surfaces quite quickly and easily.

Wooden wedges can also be used: they are the most important element for leveling significant unevenness in the surface of the walls. Prepare a certain number of wedges of different sizes in advance and treat them with antiseptics. As practice says, they tend to come in handy in most cases.

Hangers will help align the frames evenly

The installation of the sheathing under the lining is constantly monitored by level. We check the position of the bars and only then fasten them. To strengthen the angle, you can install a jumper in these places. This ensures maximum rigidity of the frame and simplifies fastening in corners.

Conclusion

Each of the above-described options for joining the lining along the length is available to the amateur. To make everything work out beautifully, the video in this article provides general instructions on how to traditionally cover a room with wooden clapboard. There the process is shown more clearly.

- Author: Maria Sukhorukikh

Rate this article:

- 5

- 4

- 3

- 2

- 1

(0 votes, average: 0 out of 5)

Share with your friends!

Options for joining planks

Option #1

Connection of plastic and MDF panels:

- H-shaped PVC profile. Most often, joining along the length of plastic and MDF linings is done using H-shaped PVC profiles, as in the photo below. In this version, the planks are simply inserted into the profile on both sides. The downside is that such a profile is visible, and in the case of MDF it also differs in texture.

The H-shaped profile is considered universal, but it is visible

- Thin straight and corner strips. Manufacturers of MDF panels produce thin strips that are glued to the connection line; these strips can be straight or angular.

- T-shaped moldings . They are inserted into the gap between the panels.

T-shaped moldings for hiding the joints between MDF panels are very easy to use

Option No. 2

A decorative overlay at the joint is considered the simplest way to connect wooden cladding along the length. You simply fit 2 rows of planks and nail a piece of wood on top. The configuration and dimensions of the slats can be any, and most importantly, there is no need to adjust the slats too precisely; the slats will cover the entire defect.

Craftsmen use wooden T-shaped slats, they are also called mushrooms. There the rail is inserted into the gap, which must be precisely adjusted to the size of the fungus. Plus, this joint must be on the supporting lath of the sheathing.

The gap between the slats should correspond to the thickness of the fungus stem

Option #3

Installation in a running manner. This option is the most difficult to install with your own hands.

It is being built in several stages:

- No one is going to hide the joints; on the contrary, they are highlighted , so they must be perfectly even. To do this, the ends are cleaned and ground at 90º before installation.

- To ensure that there is no gap at all when joining, lay the planks on top of each other and use a miter saw to cut off the edges of both at once.

- A grinder or electric planer is used to chamfer the outer part of the cut ; the bevel should be the same as the side bevels on the plank itself.

- The planks are connected end-to-end and the cut no longer spoils the view, but is part of the interior.

When installed staggered, symmetrical seams look better

You can do it simpler - when you reach the end of the row, you cut off the excess plank and start the next row with this trimming. But here it will not be possible to build a perfectly symmetrical picture of the joining seams.

Calculation of the required number of parts

They should be taken with reserve. Perhaps some part will be damaged during transportation and installation. There is a certain percentage of defects in ready-made kits. Each prefabricated element must be checked upon purchase.

The calculations use the area of the visible part that is not hidden by the grooves and protrusions covering the joints. To find out the required number of prefabricated elements, the floor area is divided into it, taking into account the finishing of the walls.

If the last row turns out to be cropped, you need to calculate how it relates to the whole. If its width is half the size of the whole, it will require half the material to create it. The boards can be cut and each half used as a separate prefabricated element.

- Doors and partitions

How to cover a door with clapboard yourself

Self-tapping installation

Through fastening with self-tapping screws through the entire board, and not through a groove, is the simplest, fairly reliable, but not the best solution for wooden lining. With this method, the integrity of the material is compromised, so the holes must be regularly treated with special protective mastics to prevent destruction and rotting of the wood. Despite all efforts, over time, the installation sites of fasteners may become noticeable, which significantly impairs the aesthetics of the decorative finish. Usually the first and last panels are mounted this way for reliability, and for the rest they use fastening with finishing nails or clamps.