Repairing a gas stove with your own hands is prohibited by Russian law. True, criminal liability is not yet provided for; if an accident occurs, troubles are expected. In the hero city of Volgograd, one smart guy introduced combustion products from a water heater into the ventilation hole. 4 people died. The authorities classified the case based on the article causing death by negligence. Gas service technicians have the right to replace equipment and perform service work. This is relevant, starting with connections and ending with switching to a different type of fuel. Below are a couple of recommendations, not a user manual, just general techniques.

When to contact a specialist

To repair electric ignition, you do not need to have much experience and knowledge; even inexperienced users can handle it.

However, sometimes it is necessary to conduct a thorough check and diagnostics of the device. You certainly won’t be able to do this with a flashlight and a simple screwdriver. For this reason, it will be necessary to call a specialist. Of course, the services of a specialist can be expensive, but sometimes a breakdown of the electric ignition can occur as a result of a serious reason that can pose a threat to humans.

Sometimes repairs should be left to professionals

In any case, before you start repairing the electric ignition device, you should carefully study the device diagram. This will help fix the problem much faster without harming the device.

It is important to check the combustion first; sometimes it may be a problem with the burner or other components

Causes and troubleshooting

Regardless of the age of the gas stove, the electric ignition function can break down at any time, and the cause of the breakdown is not always a consequence of improper operation.

Of course, sometimes a malfunction of the piezo ignition occurs after wet cleaning of the hob, as a result of which moisture, along with the detergent, gets inside the stove. In this case, the breakdown can be easily eliminated without repair.

If during operation of a gas stove one or more of the previously listed symptoms are observed, then the problem lies precisely in the piezo ignition.

Internal structure of the stove

Before you start repairing a Gorenje gas stove, it is important to understand the structure of the equipment in order to understand in which area you need to look for a breakdown. And also study the rules for the safe operation of gas appliances

Despite the huge variety of equipment in different price categories, all gas stoves have the same structure, and differences can only be observed in the original parts of each model.

Almost all new models of Gorenje gas stoves are equipped with a piezo ignition system, which often causes frequent equipment breakdowns

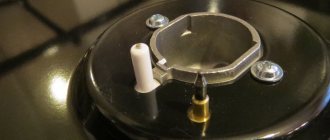

A classic gas stove is equipped with four burners, each of which is secured to the inner panel with bolts. The burner includes a lid, a divider and an injector, and a copper tube with a special “American” type fastening is connected to it. This is how gas is supplied to each burner.

If there is an electric ignition system, two candles are supplied to each burner: one is intended for ignition, and is powered by a piezoelectric element, while the second acts as a thermocouple that controls combustion.

The auto-ignition spark plug has a ceramic caftan, which prevents the spark from breaking below the set level, while the candle with a thermocouple is equipped with a bronze caftan, a powerful heat conductor.

The gas stove manifold, which is responsible for controlling the gas flow, is located under the top panel of the equipment. It is presented in the form of a thick tube, from which solenoid valves diverge to each burner - conductors responsible for controlling the gas flow. This way, even if one burner flame goes out, the other burners can still function safely.

The principle of operation of the piezoelectric element

The electric ignition function is used only on gas stoves, allowing blue fuel to be ignited automatically, thereby eliminating the need for the user to come into contact with an open flame.

This seemingly convenient piezo ignition function is considered one of the most capricious and unreliable devices of a modern gas stove.

The electric ignition system is equipped with special piezoelements, which, when turning the switch on the control panel, produce a spark to ignite the gas flow.

If we consider the principle of operation of piezo ignition of a gas stove in more detail, it looks like this:

- when you turn the switch of a certain burner, voltage is applied to the capacitor area;

- then the capacitor begins charging, after which the level on the thyristor increases;

- as soon as the level reaches the set limit, the capacitor begins to discharge;

- the resulting voltage activates the spark gap, and as a result, a spark ignites the gas.

The process of igniting gas by turning on the electric ignition takes a matter of seconds, while in new models of stoves the spark always hits the area of the switched-on burner. The piezo ignition device operates from an electrical network with a voltage of 220 volts.

Often, a breakdown of the electric ignition system of a gas stove occurs as a result of a sharp jump in voltage, which may require repairing the device and replacing failed parts.

The cost of carrying out work by specialists

Malfunctions occur suddenly and require quick fixes, especially when a gas stove breaks down. However, not all home appliance owners have the necessary skills. When it is impossible to carry out repairs yourself, you have to call a specialist to your home. What expenses await the owner:

- replacement or repair of a gas supply valve - from 300 to 1,200 rubles;

- nozzle cleaning - from 400 rubles;

- replacing the oven lamp - from 400 rubles;

- gas adjustment - from 500 to 900 rubles;

- lubrication and cleaning of rods on the feed lever - 900 rubles;

- replacement of rods - 1200 rubles;

- thermocouple replacement - 900 rubles;

- replacement of the ignition unit - 900 rubles;

- cleaning of supply contacts - from 900 to 1,100 rubles;

- change of sealing gum - from 500 rubles;

- replacement or repair of a spark plug - 800 rubles.

Prices depend on the stove model and the region where household appliances are serviced and repaired.

Safety rules for stove repairs

When inspecting and repairing the stove, you must follow simple safety rules - turn off the fuel supply, turn off the electrical power, and children and animals should not be left in the room. Upon completion of work, you should make sure that the burners are burning evenly and that the connection between the stove and the gas pipeline is tight.

In the event of a serious breakdown, it is undesirable to carry out repairs yourself, without the appropriate experience. In this case, it is better to call a specialist from an organization with which an agreement has been concluded for servicing gas equipment.

For unauthorized interference in the gas supply system, liability is provided for, specified in Article 9.23 of the Code of Administrative Offences. The fine will range from 10 to 30 thousand rubles.

If a fire or explosion occurs due to the fault of the owner of the equipment, charges will be brought against him, in accordance with paragraph 6 of part 3 of Article 158 of the Criminal Code of the Russian Federation. The amount of penalties for illegal actions: from 100 to 500 thousand rubles. Punishment for this offense is also provided in the form of imprisonment for a term of up to six years or forced labor for a term of up to 5 years.

Gas oven goes out due to faulty thermostat

Correct operation of the thermostat is very important, since the entire cooking process depends on it.

The thermostat provides gas supply to the main and frying burners of the oven and maintains the set temperature in the oven by increasing and decreasing the gas supply inside the oven. If the oven begins to cool, the thermostat will increase the gas supply, thereby increasing the heat. If the oven temperature reaches the set value, the thermostat reduces the gas supply to maintain a constant temperature. One of the malfunctions is that the flame decreases to an unacceptable level, which leads to the thermocouple cooling down and to an emergency shutdown of the oven.

Did you know that after 10 years the gas in the oven can go out due to poor ventilation. Carbon monoxide accumulates and extinguishes the burner. Move the stove away from the wall 5-10 centimeters, remove the towels from the handle. Wash the back wall of the stove and the ventilation duct from grease.

Briefly about the power of the burners and stove

The total power of the working surface depends on the number of burners and their direct power, indicated in the equipment passport. The average for one burner is 2-2.5 kW. With decent gas quality and normal pressure in the line, this value is quite enough for comfortable and relatively quick heat treatment of products. In this case, the maximum power of the burner is determined when the regulator is turned to the maximum and gas is fully supplied.

Manufacturers often offer household hobs, the burners of which have different power ratings:

- on small ones - 0.7-1.2 kW;

- on average - 1.3-1.8 kW;

- on large ones - up to 4 kW and more.

Such a technological solution is quite logical and convenient: it makes no sense to brew coffee in a Turk on a powerful WOK burner or try to boil a large volume of water on a small one. Choosing different capacities allows you to save gas, and if the room temperature is maintained using an air conditioner, you can also save electricity.

If you have a faulty electric ignition

Almost all devices are now equipped with it, which has a positive effect on ease of use. Let's first define how electric ignition works and works.

Electric ignition consists of four parts:

- transformer (unit) operating from a 220 V electrical network;

- electrical wire leading from the transformer to the ignition mechanism;

- ceramic candle;

- ignition button located on the control panel, next to the rotary switches.

The mechanism of electric ignition is as follows:

- When you press the button, the circuit closes;

- The transformer generates the current for the spark;

- The pulse is supplied through the wires to the gas burner;

- The ceramic candle produces a spark and the burner ignites.

It is noteworthy that the candle fires on all burners without exception, however, only the one that receives gas is ignited.

It is very important to ensure that the network always has one voltage - 220 V. To protect your stove, you can buy a household voltage stabilizer, which will protect you from unexpected current surges

Otherwise, short circuits and unstable operation of the network negatively affect the electric ignition and can cause breakdown. If your hob exhibits the following malfunctions, then the problem is with the ignition:

- you turn on the button, but the ignition does not work;

- one or all spark plugs spark;

- you release the button, and the ignition works.

You turn on the button, but the ignition does not work

The first and most common reason is contamination of the mechanism button and/or burner with dirt and combustion waste. Cooking food entails splashing fat and food all over the stove, so this problem is not uncommon. Clean the ignition button, wipe the burner, clean the nozzle with a needle or any other thin stick, wait until everything is dry.

Care of gas hobs

One or all spark plugs are sparking

If the spark plugs on all burners sparkle orange or yellow and operate intermittently, then the problem may be a faulty electric ignition unit. It needs to be replaced, but doing it yourself is extremely difficult. The block is located in the middle of the panel; it needs to be disassembled and the contacts disconnected, so it is better to trust professionals in this situation. To be sure that the problem is in the transformer, do the following:

- in the dark, with the lights off, turn on the ignition button;

- if a spark appears on all burners of the color described above (yellow, orange), the unit definitely requires replacement;

- if the spark is blue, the unit is working.

If the integrity of the spark plug is damaged or its rod is oxidized, it will spark orange or yellow intermittently. This is solved by replacing the faulty spark plug. However, such problems are quite rare and this is due to the design of the candle itself. It is a steel wire, one millimeter thick, encased in porcelain. For a candle to become unusable, it must be in very unfavorable conditions of high humidity or subject to shock.

Care and operation of electric hobs

You release the button, but the ignition works

This may be due to a faulty transformer or oxidation of the contacts.

When washing the panel or boiling water, liquid can penetrate into the middle of the device, onto the contacts. With constant leaks and heat coming from the burners turned on, the contacts oxidize. They become rough, they can stick together and break. Their technical cleaning and high-quality drying will help.

Design and main components of an electric stove

The electric stove looks very impressive - it is a complex household appliance, but its design is quite simple, and all the main working elements are located in a special heat-resistant case, which is made of stainless steel.

The operating principle is similar to all electrical household appliances: current passing through heating elements (heating elements) heats them to a given temperature. The stove has several burners on the hob, and their number varies: a minimum of two, and the standard is 4 pieces. For example, the budget electric stove Mechta 15M has only two burners and a small oven, while the product of Belarusian engineers Hephaestus has a standard set of burners and a large oven.

The structure of the burners is quite diverse. The classics are burners on an enamel hob with heating elements inside, modern ones are solid ceramic surfaces with various types of heaters built into them. Let's look at the main types of burners.

- Old domestic versions are equipped with cast iron products; they heat up slowly and also cool down, creating a steam effect in the kitchen, but they are resistant to moisture and high temperatures.

- Tubular spirals - they are made of a hollow tube; when heated, such devices not only give off heat, but also promote the circulation of warm air inside their body, which significantly increases their efficiency. These products are very difficult to repair yourself.

- Ceramic burners are very simple in design, they are easy to repair at home - a nichrome spiral is placed in special cells in a circle and secured. Modern models increasingly use glass-ceramic solid plates - they are more durable and easy to clean.

- Halogen devices are special burners with a similar emitter that are installed in different places on the hob. A stove with such burners provides fast heating, in a second, and low energy consumption, so they are the most economical, but only professional craftsmen can carry out repairs.

All models of modern stoves use a special cross-section power wire to transmit current to the burners; in addition, they are connected to regulators and thermostats, ensuring their protection from overheating.

Thermocouple failure

The device provides gas supply to the burner and, together with the solenoid valve, forms a gas control system. It is this system that ensures the ignition and operation of the gas oven. If you cannot light the oven, then the following thermocouple malfunctions are possible:

- The tip of the device is offset relative to the flame. Weak heating of the thermocouple does not allow the solenoid valve to open and blocks the gas supply;

- The tip is dirty and prevents the device from heating;

- Prolonged operation of the thermocouple has led to overheating and wear of the structure; it does not ensure the opening of the gas supply valve.

Rules for using the oven

Usually, all problems with a gas oven begin at the moment when the owners stop properly caring for it. This does not apply to manufacturing defects, which can be detected before the warranty expires.

To avoid breakdowns, follow the rules:

Remember, working with gas is a high-risk activity; do not expose yourself and your loved ones to it. Take this issue seriously and use the help of professionals.

What to do if a problem is detected?

It happens that the problem of weak gas supply and flame extinction is caused by accumulated grease on the electric ignition or regulator. By cleaning them from contaminants, you can eliminate this problem. Also check the spark plug; if the holes are clogged, the flame crown will be small or smoky.

It may be worth monitoring whether oxygen is entering the oven. To do this, check that the oven door is closed tightly.

Many, noticing that something is wrong, wonder: what is wrong and how to fix the stove themselves? However, if you encounter any problem that requires appropriate qualifications, it is better not to try to fix the stove yourself. Such intervention without the appropriate skills and knowledge is fraught with big problems.

If you yourself do not have the necessary tools and knowledge to fix problems, then calling a specialist will be the best solution.

If your gas stove has not passed the warranty period, then call the service center of the company where you purchased the equipment. If the warranty period has expired, then call a qualified specialist from other companies in your city. The technician will be able to professionally fix all problems and tell you how to care for the stove.

Prevention

Prevention when working with the oven

In order for the oven to work properly and its parts to break less often, you need to use the device according to the instructions. And also don’t forget to take care of it. Do not leave the oven until it is covered with grease and smoke. Wash the inside of the cabinet with warm water and dishwashing liquid. And at the end of cleaning, wipe it dry.

Obedient equipment and delicious food in your home!

Main reasons for extinction

Among modern manufacturers of slabs, such as Veko, Hephaestus, Indesit, Darina, it is difficult to single out a leader, since the equipment from each of them is quite in demand among consumers. But sometimes while the gas oven is operating, the flame may go out, which causes indignation among the owner of the unit.

This is why the oven in a gas stove goes out during operation:

- premature release of the control knob;

- The thermocouple is burnt or worn out;

- the solenoid valve has failed;

- The oven thermostat has calibrated;

- The oven door is too tight;

- The thermocouple is installed above the flame;

- the connection in the gas control system has become loose;

- the flame smokes (gas burns incorrectly);

- The oven thermostat has become faulty;

- the gas valve is stuck.

Thus, a fire can go out due to many reasons. However, of all the users of modern technology from Veko, Hephaestus, Indesit, Darina, the owners of Hephaestus slabs most often complain about this problem.

Oven bottom

Why does the oven go out in a gas stove Hephaestus

Often the problem of the fire disappearing after releasing the gas control knob. However, this does not cause such an inconvenience as the disappearance of the fire right in the process of cooking. This trouble especially often haunts the owners of the Hephaestus gas stove. Why does the Hephaestus gas oven go out during operation? Most often, the problem lies in the built-in gas control.

Oven repair

Additional Information

It is not prohibited to use classic household methods, such as soda, vinegar, citric acid or alcohol.

To clean a gas oven, you can use store-bought and folk cleaning products.

Use a regular foam sponge, or a soft washcloth or cloth. Apply products only with a creamy consistency, distributing them evenly over the enamel. To completely remove adhered grease and stains, leave for 1-2 hours so that the product removes all dirt and germs from the surface of the gas stove. Next, remove the burners and soak them together with the cleaning agent in water for 1-2 hours.

Afterwards, rinse everything off with a damp sponge, wipe with a cloth and replace the dry burners.

Please note: Follow safety precautions when using the stove and do not panic if you smell gas. Just turn off the gas pipe valve and try not to stay in the apartment until specialists arrive

Adviсe:

Do not turn the gas knobs to full power, as if the gas supply is too powerful, the flame may come off the burner, thereby releasing carbon monoxide into the air. Do not leave a switched on gas stove unattended. Monitor the quality of the equipment; if you see a yellow flame, the oven in the gas stove does not burn, or any other problems arise, call specialists in a timely manner. Do not allow liquid to splash onto the surface of the stove, as this may extinguish the fire and cause a gas leak. Check your gas water heater. Pay attention to whether the hood is working. It is very simple to determine this; you need to bring a burning match to the chimney, hold it for a while, if the flame is drawn in, it means the hood is working properly

If the flame burns as usual or deviates to the side, then the water heater cannot be used.

It is necessary to periodically monitor the operation of the oven.

Problems with burner control knobs

Gas supply handles for the burner are one of the most necessary parts; without them it is impossible to use the stove. Behind the outer skirted flag, which you turn, there is a gas tap, which can have a gas control sensor built into it.

Electric ignition built into the handle is rare on Hephaestus stoves - it is usually located with a separate button.

Over time, the knobs may stop turning, become stuck, or become loose. We'll tell you what to do about it later.

The handle is difficult to press and turn

This problem is not uncommon; if you start it, the handle may stop turning completely. The cause is usually grease that has accumulated between the flag, skirt and front panel of the cooker.

Hot, it splashes during cooking and easily flows into all the cracks, and then cools, thickens and turns into a kind of glue.

Carefully pry up the skirt and handle with a knife, screwdriver or other flat object. Do not use too much force - you may damage the enamel or plastic.

To get rid of the problem, the flag with the skirt must be removed from the stem and washed thoroughly. The handle needs to be pulled towards you - it is simply pressed tightly onto the rod, without latches or other fasteners. For convenience, you can grab it with pliers, preferably through a non-slip cloth, one of those sold for cleaning.

The skirt usually comes off on its own after the handle is removed, but if it does not turn with the flag, it can be secured with a latch. In any case, you can pick it out with a knife. Remember its position so that when assembling, the latches close to the panel or flag.

Many models have a reinforcing metal plate in the handle; do not lose it. After washing all the parts, as well as the front panel under the handle, put everything back in place. Don't forget to install the spring if you had one.

The checkbox scrolls or jumps off

This problem is rare with Hephaestus slabs, but it does happen. The reason is usually that a metal plate has fallen out of the flag and is lost, which clings to the recess on the rod.

You can cut such a plate from a metal preservation lid and insert it into a special groove, or buy a new flag. If the handle on your model is completely plastic and its inside is licked off, only buying a new one will help.

The handle turns hard

It happens that even after the flag and skirt are perfectly washed, the handle still turns tightly. The reason is that the lubricant on the gas taps has run out.

It is better to invite a specialist to carry out preventive maintenance, because mistakes during such repairs can lead to leakage or clogging of gas supply pipes

If you decide to lubricate the gas taps yourself, buy a special graphite lubricant for this. Turn off the gas supply to the stove. Then remove the handles and the front panel - we described how to do this above.

In Hephaestus slabs, the stem is fixed in the tap with a flange connection; to remove it, simply unscrew 2 bolts on the sides. Immediately wash the stem from grease and dust.

Then the spring and the tap plug are removed - the last one needs lubrication. This is a cylindrical part with a through hole and a cut on the side, through which gas is supplied to the burner. You need to lubricate the cork very little; the layer should be invisible, but noticeable to the touch. It is more convenient to put a little lubricant on your finger and rub the plug.

After assembling the faucet, do not rush to replace the front panel. First, put the flag on the stem without it, open the gas and apply a soap solution to the tap. If no bubbles appear anywhere, wipe everything dry and reassemble the stove.

Ways to increase the power of a burner

Based on the design features of the burner, several methods of increasing the power of the stove are popular. But is it appropriate to test them on your own experience?

It is worth recalling that even independent repair of gas appliances is prohibited, and even modifying equipment at home is an undertaking bordering on dangerous and even deadly sabotage.

Unfortunately, explosions and carbon monoxide poisoning are tragedies that shock the public with the frequency and number of victims. Therefore, it is definitely not worth altering the design of the burner for the sake of your own convenience. And the methods described below are more useful for understanding theory than for practical application.

Method #1 - boring or replacing the jet

The nozzle through hole is one of the main regulators of the gas volume, which gradually enters the burner. To increase the power of the burner, you need to carefully bore the nozzle or replace it with a part with a wider feed hole.

For boring, you can use a sharp knitting needle with a diameter of up to 3 mm. But you shouldn’t get too carried away - uncontrolled enlargement of the hole or replacement of the nozzle is fraught with extremely unpleasant consequences.

It is impossible to increase the gas flow without miscalculations, since the burner itself must be able to process it. Excess gas will cause the flame to pull away from the burner. The fire will change color to red, soot will appear, which is almost impossible to remove from the dishes. The problem can be solved by installing a larger diameter burner.

However, replacing the burner is not always possible due to the design of the stove body itself. Even if you actually replace the burner, the new volume of gas transmitted through the nozzle may not be enough. This threatens even bigger problems: the flame can jump down and burn out near the nozzle itself.

But a sluggish flame and soot in this case are the lesser of evils. A falling flame indicates incomplete combustion of the gas, which releases combustion products dangerous to life and health - soot and carbon dioxide.

Method #2 - reducing the jet-mixer length

Fortunately, this method is less popular among tips on how to try to increase the power of a gas stove. This method is more dangerous than the previous one, as it involves even more interference in the design of the burner, is less effective and can also lead to negative consequences.

The size of the area that is emphasized in the description of the burner design also affects the power of the flame produced. If you reduce this zone, gas will flow into the burner faster and the burner power will increase slightly.

However, the portion of air required for normal combustion simply will not have time to be added to the incoming gas. As a result, the modernizer will receive the same red flame with soot, which is likely to come off the burner.

Method #3 - removing the divider

You can try to increase the burner power without affecting the operation of the nozzle. The divider covering the burner evenly divides the flow of the gas-air mixture, distributing the flame into separate bundles. Removing the divider increases the area of contact between the flame and the cookware. The column of fire becomes higher and larger, and the heat treatment itself proceeds faster.

However, this is only a temporary measure and is not suitable for every pan. For this kind of cooking, you need to use tall cauldrons or special WOK pans. Additionally, a fire uncontrolled by a cutter becomes quite dangerous.

Method #4 - increasing gas pressure

The pressurization method is only suitable for stoves connected to gas cylinders. The standard pressure in a cylinder for domestic use is about 1.6 MPa. But this value is not constant: the force of gas pressure on the walls of the vessel can be influenced by both the degree of filling of the cylinder itself and the temperature in the room, the composition of the gas, etc.

Installation of a gas stove with electric ignition

Darina, Hansa, Ardo – so different and at the same time the same. The repair of gas stoves by Hephaestus is exactly like the repair of Ariston; gas stoves are made up of standard units. It is enough to look at a single device to understand the circuit. Have a reference book to help you properly maintain gas pressure. When set correctly, the flame is even and blue. Orange flashes indicate an imbalance in the fuel mixture. If the settings are incorrect, the flame will fail (especially typical for carob ovens).

For those who have read the reviews of the VashTekhnik portal regarding gas instantaneous water heaters, independent repair of gas stoves will seem like child’s play! You cannot do it yourself, but you can clean the device. The technician will have to clean candles, combustion sensors, burners, and sometimes nozzles. There are a lot of interesting things inside the gas stove. Anyone learning how to properly clean equipment should understand what we will see inside. Under the gas stove table:

- Burners. They are often bolted to the gas stove table. Each burner consists of a lid, a divider, and an injector (nozzle). They are not rigidly fastened under the table; each is fitted with a steel or copper tube; the fastening is carried out like an American one. You will need a key of approximately 13 to remove the products. It is more convenient to clean if something is clogged inside. Beware of tearing off the head or thread - you will have to replace it. After assembly, check the tightness by washing. The procedure involves applying foam to the disputed nodes.

- There are two candles around the perimeter of the burner. One serves as ignition (due to a piezoelectric element or an electronic circuit), the second is a thermocouple, included in the combustion control circuit. It's quite easy to distinguish. The high-voltage spark plug is covered with a ceramic caftan so that the spark does not strike below a predetermined level. When the arc flows, you can see: the tongue of the discharge licks the body of the burner. Gas stoves with electric ignition will be properly grounded by a technician. Beware of using plumbing connections or connectors pierced with metal threads. During installation, the hoses are separated from the riser by special gaskets. Failure to follow the rule will easily provoke an explosion in favorable situations. We wrote in more detail, we remind you again. The candle with a thermocouple is covered with a bronze caftan that conducts heat. The faster the semiconductors cool down, the flame goes out, and the protection that cuts off the gas supply will work more reliably.

- Most often there is a collector under the table. A thick tube from which a line goes to any burner. The gas flow is controlled by solenoid valves. The number is usually equal to the number of burners. When the burner flame goes out, the rest will burn. The expediency of the decision can be challenged, but this is how it is done. Each solenoid valve contains an inductor. The thermocouple heats up, an EMF (tens of millivolts) appears, keeping the devices open. Complete activation procedure: turn the gas supply regulator, press down. We press the piezo ignition button, or the electronic circuit performs a set of procedures independently. We hold the handle for a fixed time. The thermocouple warms up, an EMF begins to be generated, the electromagnetic valve is held open due to the phenomenon discovered by Seebeck. As soon as the gas goes out, the sensor plug cools down and the gas supply stops. The process is inertial, we believe that the day is not far off, flame ionization sensors will begin to be used in gas stoves, allowing the protection to operate instantly.

- Similar to the gas manifold, there is a distribution valve panel inside. Single high-voltage wires run to each ignition electrode. Another way to distinguish a thermocouple: two wires with a thinner cross-section stretch to the sensor. The spark breakdown goes to the housing, the second ignition wire is superfluous. If the gas stove is deprived of grounding, we have a chance of getting an electric shock. Fatalities are possible - an additional reason to entrust the installation to a professional. The collector is connected via connectors. There is protection against incorrect orientation of the plug; you can easily mix up some places. When you open the burner, a spark will jump on another divider. It’s not very pleasant, a flash of flame is possible.

If the charge is generated by an electronic circuit, you will find a simple thyristor, diode, capacitor, and fuses inside. The circuit operates, powered by a capacitor charge with a subsequent burst of energy from the spark gap of the spark plug. Repair of electric ignition of a gas stove concerns the listed elements. The fault is easy to notice. Burnt elements are black or similar in color.

How does electric ignition work?

Electric ignition makes it possible to light the stove safely. It reduces the possibility of getting burned to a minimum, because with piezo ignition there is no need to use lighters or matches. There is also no contact with flame. With electric ignition, gas ignition occurs from the activation of a piezoelectric element on the gas device. The piezoelectric element gives a spark, after which automatic electric ignition takes place without the use of other devices. Repair of gas stoves with electric ignition can be done either with the help of a specialist or with your own hands: it all depends on the type of breakdown and knowledge about the operation of the structure.

For what reasons does a gas oven turn off?

All kitchen equipment of this type is divided into dependent (together with the stove) and autonomous, electric and gas.

Advantages of gas-powered equipment:

- simplicity and low cost of operation;

- independence from power outages;

- Possibility to connect to both a gas pipeline and a cylinder.

There are three disadvantages: a limited set of functions, a small range and high cost.

Stove with gas oven

If the electric oven of a gas stove goes out during operation or immediately after the handle is released, then:

- smokes gas;

- the gas supply valve is jammed;

- the door fits too tightly;

- the magnetic valve or thermocouple is worn out;

- The thermostat has been calibrated;

- the connection in the gas control system has become loose;

- The thermostat has failed.

It is impossible to carry out diagnostics and repairs on your own due to the lack of diagnostic equipment, components and spare parts. You need to call the service center and ask the operator about the cost of the service and the technician’s working hours.

Autonomous gas oven

An autonomous gas appliance most often turns off if the electric ignition does not produce a spark or, conversely, constantly sparks. There are many reasons for the problem; they can be determined after disconnecting the ignition from the network and removing the electronic unit.

Most often, the ignition system fails if:

- burnt tracks (soldered joints);

- the resistor burned out (turned black);

- one or both windings of the transformer have burned out;

- the capacitor has failed (swollen) or the tourist;

- candles broke;

- contacts have oxidized (due to moisture ingress);

- the handle is dirty (overgrown with grease);

- the injectors are clogged.

The handle can be cleaned independently; other causes can only be eliminated by a specialist.

This is especially important if the device is under warranty. A service center specialist will diagnose and replace spare parts free of charge.

How to fix the Hephaestus stove timer?

You can only remove and repair a mechanical timer yourself; with an electronic one, it is better to contact a specialist. The alarm clock mechanism looks like a large metal tablet.

To get it, remove the handle, lift the stove table and unscrew the fasteners. Then open the timer case, blow it out and brush off the dust, lubricate the pendulum and gears.

To avoid pouring too much, use machine oil in a special oil can with a thin spout or an ordinary syringe

Try turning the knob to start the timer. Started ticking? This means you can assemble and install in place. No? Try taking it to a watch repair shop, or buy a new one.

Symptoms of a problem

The principle of operation of a gas oven is to heat the air by burning gas supplied from a city pipeline or cylinder. The supply of natural fuel is regulated using a tap on the gas pipeline. The fuel then passes through the nozzle, mixes with air and ignites, providing the heat required for cooking. Most often, equipment malfunction is caused by failures of the gas control system, which causes a sudden extinguishing of the fire. Signs that the oven on a gas stove is not working are as follows:

- gas flows, however, when pressing the button, the flame does not ignite;

- the device heats food poorly or unevenly;

- the doors do not fit well or the oven does not close;

- the fire goes out some time after ignition;

- The heat in the oven is not adjustable;

- does not go out while you hold the handle;

- the fire is yellow-red, the oven is smoking;

- the burner flames have different heights;

- jamming occurs when opening the door;

- The oven gets very hot during operation.

Adjusting the flame on the stove burners

It is necessary to debug the normal operation of the burner in cases where the flame loses its efficiency and quality. Setting up a gas stove should also be done by a specialist. But understanding the algorithm of this process will be useful for any user.

First, it’s worth understanding what a properly burning stove flame looks like. The fire should be blue. An intense bright blue glow is a sure sign that the stove is working correctly and does not need debugging. A yellow, orange or red flame indicates an incorrect composition of the combustible mixture. In this case, there is clearly not enough air; its flow must be increased.

To change the gas-air mixture entering the burner, it is necessary to adjust the operation of the air dampers, which are usually located near each burner.

Direct setup goes like this:

- after disconnecting the stove from the gas system, it is necessary to gain access to the adjustment mechanisms under a special partition or in the gas control knob;

- the stove is reconnected to the main line, gas is supplied alternately to each burner;

- the volume of air entering the mixer is adjusted by turning a special screw;

- As soon as the flame in each burner acquires the correct color, you can turn off the stove again, reassemble it and connect it to the main line.

When setting up the stove, you may need to work with the gas control valve and its thermocouple. If the flame regularly goes out at a minimum fuel supply level, perhaps the problem lies in the gas control. The operating principle of this option is based on a special sensor that responds to the energy released during the combustion process. If the flame goes out unexpectedly, the thermocouple sensor cools down, signaling the gas supply to stop.

However, oxidation processes and a decrease in the sensitivity of the sensor due to the ingress of liquids or the formation of deposits from food deposits can provoke incorrect gas shutoff outside of an emergency situation. Therefore, both the stove and this block should be kept clean, and if necessary, call a professional to clean it.

If you are faced with unusually noisy operation of the burner, we recommend that you find out the cause of the noise of the burner and how to eliminate it.

Symptoms of a problem

Are you trying to light a burner but the ignition is not working? This is a fairly common problem for owners of gas appliances. If you notice problems with the electric ignition, you should call a technician to your home. You can carry out preliminary diagnostics and try to determine the problem, but it is not always worth repairing the electric ignition of a gas stove yourself - this can only aggravate the problem.

Signs by which you can determine that the electric ignition has stopped working are:

- continuous clicking of the electric ignition;

- When you press the button, the electric ignition does not work;

- ignition continues after the button is released;

- constant appearance of sparks when the button is turned off;

- the burner in the gas stove does not work or works with varying degrees of success;

- knocking out the machine gun in the dashboard.

Why does the burner burn poorly?

If, according to the passport, the burner has more power, but in fact does not produce the required volume of flame, it is worth looking for possible reasons for the decrease in the efficiency of the equipment.

The most common reasons for poor combustion are the following:

- line pressure is too low;

- the air-gas mixture enters the burner in insufficient volume;

- the holes in the crown or jet are clogged with combustion products;

- the design of the burner is damaged or the gas hose itself is damaged;

- the burner does not match the installed burner.

The last option is rather an exception to the rule, since all hobs are thoroughly tested at the manufacturing plants. Equipment diagnostics and repairs must be carried out exclusively by a certified gas service technician.

Another reason for the burners not working properly could be an unsuitable jet. Many gas stoves come with two types of these nozzles, each of which is suitable for a specific type of gas: bottled or mains.

The gas pressure in the cylinder is significantly higher than in the pipeline, so nozzles with a narrower opening are used to connect the stove.

It is possible that when installing and connecting the stove to the centralized gas supply pipe, nozzles of the required type were not replaced, so the burner does not work correctly.

What you absolutely can’t do yourself

Unlike situations when a gas oven goes out due to faults that do not require serious repairs that have arisen as a result of improper operation of the device, in some cases you should not try to find and fix the breakdown yourself.

Therefore, it is strictly forbidden to repair the oven on your own in cases where:

- if the thermostat is faulty, the flame is intermittent and goes out;

- contact damage occurred in the gas control system:

- The timer does not work;

- The electrical module is faulty.

You should also not repair damaged electrical contacts yourself. It must be remembered that repairing gas equipment or other manufacturers requires serious knowledge. The operating rules for the stoves prohibit their independent installation and repair.

In the absence of the right to warranty repairs, special workshops are available to consumers. The technician will competently diagnose, fix the problem and give the necessary advice on the safe operation of the stove with a gas oven.

What to do if the stovetop oven stops working

Domestic gas equipment must be serviced by an authorized technician. If you find these and other malfunctions, call us. Self-repair will aggravate the breakdown and increase the cost of subsequent repairs. Don't take risks. Submit a request to call a technician to your home. We will repair any problem. We will replace the broken part and provide a 1 year warranty.

|

|

Why does the oven go out after releasing the handle?

Reason #1. The thermocouple is faulty.

Today, most gas ovens and ovens use an automatic control system that makes them safe to use. One element is a thermocouple, which is attached to the frying burner bracket at a distance of 147 mm from the vertical axis of the burner.

The gas oven is turned on by pressing and turning the tap handle. Electronic ignition ignites the burner where the thermocouple is located. The thermocouple is directly connected to the solenoid valve with a threaded connection. When heated, the thermocouple produces a weak voltage to magnetize the valve. The magnetic field keeps the valve open and gas flows to the burner.

If the tip of the thermocouple burns, the valve will instantly shut off the gas supply, so if the gas oven does not work after releasing the handle, the fault is due to a faulty thermocouple of the gas control system.

Reason #2. Thermal solenoid valve is faulty.

The second element of the security system. Its purpose is to stop the gas supply to the burner if the operating rules are violated. The valve consists of: electromagnet, winding, bottom valve.

When you press the handle, the lower valve rests against the upper valve plate, as a result of which the gas is directed to the burner in the oven, where the thermocouple is ignited and heated. The resulting EMF from heating the thermocouple returns to the valve, where the electromagnet is able to be held open. If the valve receives mechanical damage (winding insulation failure), the valve will move away from the seat and shut off the gas supply.

OR, TRY TO CLEAN THE CONTACT

To a greater extent, the gas in the oven goes out due to poor contact between the thermocouple and the valve.

For this:

- We open the cooking table of the stove;

- Disconnect the thermocouple from the valve.

- We clean the contact with sandpaper and degrease it.

- We tighten the nut back.

How to get to the internal equipment?

For independent repairs and access to all parts, you will have to learn how to disassemble the Hephaestus gas stove, but in most cases it will be enough to remove or lift the table.

It’s not difficult to figure out how to remove the top cover from the Hephaestus gas stove:

- Remove the burners. Place them in the same way as they were placed on the stove, so as not to confuse the two medium-sized ones and avoid guessing when assembling.

- Unscrew the screws that secure the table. Most often there are two of them - under the front burners, but on some models they are placed on the front side. There may also be 2 screws under each burner.

- Carefully lift the table top so as not to chip the enamel. If it still does not give in, check for self-tapping screws on the side surfaces.

- Place a support under the raised table . If the table has been completely removed, place it horizontally next to it so that the fall does not damage the enamel or glass.

It often happens that one of the bolts has become stuck and does not budge. In this case, bend the washer and cut off the head of the screw with a hacksaw.

Under the table you will have access to burner nozzles, gas control and electric ignition systems - almost everything that can be repaired

To repair handles and control buttons, or access to gas valves, it may be necessary to remove the front panel. It is usually secured with two bolts from the bottom or sides, but on some models it is secured with latches. Please note that the front panel is removed with the top cover raised and the gas switches removed.

The oven burner is covered with a tray. If you pull it out, you will have access to the burner itself, the gas control sensor and the piezo ignition spark plug.

Electric ignition does not work on two burners

In some cases, a gas stove on two burners does not light. Sometimes lighting it with a match helps - everything works normally, without interruption. The cause of this malfunction is damage to the spark plug responsible for ignition. We repair electric ignition as follows: clean the spark plug and look at its condition; perhaps it’s enough just to clean the spark plug’s power wire.

If there is a crack on the element, we buy a new part and put it in place of the old one. The electric ignition may also break down due to a faulty ignition button. Moisture or small debris could have gotten into it, or it could have been damaged mechanically. To fix this, you need to clean the oxidized buttons or replace them if they are mechanically damaged.

How to fix it?

Most often, when gas ovens malfunction, owners are in no hurry to contact specialists, hoping to carry out repairs themselves. What kind of breakdowns can be repaired without danger with your own hands? This is discussed below in our article.

- Cleaning the regulator knob. Before starting repairs, turn off the gas supply. Troubleshooting begins with cleaning the taps. After removing carbon deposits, dirt and grease from them, clean the spring. Wipe the cork carefully so as not to damage it. Disturbing the surface will cause gas leakage. Use only a soft sponge. Next, the plug is treated with graphite lubricant without touching the holes. Remove greasy deposits from the stem with a knife. Afterwards, the handle is assembled in the reverse order of disassembly.

- How to fix oven doors. Over time, the oven door becomes loose, causing it to not fit tightly or not to close. To fix the problem, unscrew the mounting screws connecting to the stove. Having loosened them well, move the door in different directions until you find a position in which it is firmly seated on the hinges. To control, place a sheet of paper between the seal and the edge of the oven. If it does not clamp well, do the procedure again. After installation on the hinges, the bolts are tightened into place.

If it is noticed that the loss of heat is associated with damage to the seal located around the perimeter of the door, replacing it will not be difficult.

- Remove the old seal. In some oven models it may be attached with screws; to get to them, pull off the protruding edge of the rubber, in others it is glued.

- Wash the channel and door with liquid detergent. Clean off any old caulk or adhesive residue. Degrease.

- Install a new seal by starting from the top, then down and to the sides. Complete the process by bringing the edges together at the bottom center. If the elastic needs to be glued, choose a food-grade adhesive that is heat-resistant up to 300º.

Among other failure options.

Checking and cleaning the thermocouple. The oven burns as long as you hold the handle - then you need to check the thermocouple mount. In the lowest position it should touch the tongue. If the placement is incorrect, most models allow you to adjust with screws. It is possible that the thermocouple contacts are dirty and this is preventing the flame from being maintained. Try cleaning the part with sandpaper.

Hansa BHGI63112028

Looking for positive and negative reviews of Hansa BHGI63112028?

From 11 sources, we collected 27 negative, negative and positive reviews.

We will show all the advantages and disadvantages of Hansa BHGI63112028 identified when used by users. We do not hide anything and post all positive and negative honest customer reviews about Hansa BHGI63112028, and also offer alternative products. Whether it’s worth buying is up to you to decide!

The best offers for Hansa BHGI63112028

Reviews of Hansa BHGI63112028

Pros: Convenient because the handles are on the side, the cast iron grate does not lose its shape, the burners are rationally located.

Cons: Not reliable, the plastic of the handles is not of high quality, there is a lot of emptiness at the grate above the smallest burner, you cannot place a pot.

I bought this panel 2.5 years ago. For a long time I chose to have the handles on the side, but this is the only thing I liked about using it. After 13 months (!, warranty 12), the far left burner stopped working, no gas was flowing to it (it didn’t flood, didn’t break, didn’t climb inside at all). One of the handles began to “jump out” and became loose. The color of the plastic handles has changed, and not evenly. As a result, the master said that we needed to remove it and take it to them to change something inside. You yourself know how to live without a stove and how much they will repair, we live in Russia :). I spat and decided that when I was completely tired of toiling around on three burners, I would buy a new one. I DO NOT RECOMMEND!

Advantages: Price, performs its functions of heating food. Disadvantages: Plastic gas power regulators. The problem with regulating gas power: the gas seems to have 2 positions: low power and high power. In fact, there is average power, but to get it you need to move the throttle very carefully. I’ll show you with pictures, where there is a larger photo, there is the average throttle position. On the other two, maximum and minimum. I also want to say that I was struck by the lack of difference between the gas power, it is always approximately the same (see photo) There is sooo much idling on the gas regulators, there is a moment where it switches and in it you can find the middle position. Maybe someone will be comfortable - I don’t know. I compare the hob with the Gorenje panel, which has been in our house for more than 6-7 years, it looks like new. In one of the photos there is a pan of oatmeal on the bottom right burner, at minimum power the pan is boiling, on the other burners the porridge falls out onto the stove. Yes, there is a burner where you can cook porridge, but see for yourself. I also want to draw your attention to the fact that the lower left burner is for a large pot or frying pan, you cannot place an ordinary pan like in the photo - the handle will fall off. I bought the stove thinking that I would use the bottom left one, but in the end I didn’t use it.