The stability, reliability, efficiency and durability of the heating system depend on how correctly all its parameters are calculated, how harmoniously its devices, components and necessary devices interact with each other, how well the installation and adjustment are performed. And there simply cannot be trifles in such matters.

It would be completely unreasonable to divide individual devices and components into “important” and “not so important”. Yes, the cost of elements can vary very significantly, the functionality of some is constantly visible, while others are completely invisible and even incomprehensible from the point of view of an inexperienced user. But each performs its own “mission” in the overall operation of the system. Therefore, for example, the question looks completely amateurish: is the expansion tank really that important for a heating system, and is it worth attaching importance to the problem of its selection and correct installation? Meanwhile, the importance of this simple device is difficult to overestimate.

Gas boiler baxi eco four 24

A very popular series among all others in the BAXI line. The 4th generation boiler with a capacity of 24 kilowatts is available in various versions: with an open and closed combustion chamber. Boilers with a closed combustion chamber and forced smoke removal are designated by the letter “F” in the name. Baxi turbocharged boilers are the most popular and are often used when organizing apartment heating, so we will consider the use of an expansion tank in the heating system using this boiler model as an example.

Movement of coolant in the heating system

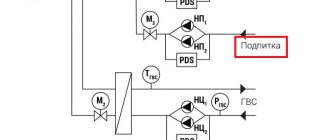

When organizing heating systems, various options can be used, but recently closed systems have become more popular, in which the coolant moves due to the operation of a circulation pump. A gas burner heats water (or antifreeze) in a primary heat exchanger, and a pump pumps it through a radiator system, transferring heat to the premises.

At the same time, for normal circulation of the coolant, the system must be completely filled with water, and since the liquid tends to expand when heated, it is necessary to somehow compensate for the increase in volume. This is why expansion tanks are provided in heating systems.

The diagram shows a system in which the boiler acts exclusively as a heater. In household wall-mounted boilers ECOFOUR, the expansion tank and circulation pump are already built-in, which is why such boilers are convenient to use in small apartments.

Criterias of choice

The choice of equipment depends on several factors, but the basic one is the thermal power of the facility. An accurate calculation can only be performed by a specialized organization. But for an approximate calculation, a simple ratio of power and heating area is used for central regions, for example, in Moscow: for 10 m2 - the required power is 1 kW.

The next criterion is the connection diagram, which depends on the possibility of subscriber input of the electrical network into the house, voltage and number of phases. For a small boiler of 6 kW (object up to 60 m2), you can connect to a single-phase 220V network, while larger power boilers will require three-phase networks (380 V). Many manufacturers produce units with the ability to connect to both three-phase and single-phase networks.

When choosing an electric boiler with a pump, you need to take into account the thermal power

The next factor is that the security system must cope with threats such as low or high pressure of network water, overheating of the heating element or freezing of water. EC control is selected from three options: manual, digital or programmable. It is advisable to choose a unit with power control. In budget models it is stepped, and in devices with programmers it is smooth.

In this case, based on data from pressure and temperature sensors, the software allows you to automatically set the mode. When using a multi-tariff meter, the maximum load on the boiler will operate from 23:00 to 07:00

Of no small importance is the presence of auxiliary devices complete with the pump and expansion tank: temperature and pressure sensors, fittings and pressure gauges

Design and location of the BAXI expansion tank

The baxi eco four 24 expansion tank is a red round tank located on the back wall of the boiler. The built-in expansion tank baxi with a volume of 6 liters is divided into two parts by an elastic membrane, one part is connected to the heating system, the second is pumped with air. Therefore, when the heating system heats up, the increasing volume of liquid overcomes the resistance of the membrane and fills the vacated volume of the tank, and when it cools, the membrane tends to move to its original position and pushes the liquid back into the heating system. Thus, the pressure in the heating system remains practically unchanged during operation.

Pipes

What kind of pipes can be used for installation of filling and connections to the boiler and heating devices?

Low operating temperatures and moderate operating pressure allow the use of all types of metal, high-temperature plastic and metal-plastic pipes. The only thing that needs to be mentioned separately is the use of polypropylene:

Pipes must be reinforced with aluminum foil. It will reduce the elongation of the pipeline when heating water in the circuit;

The use of polypropylene pipes without reinforcement for heating needs. The heated spills lengthened and went in waves.

On long straight sections of pipes, expansion joints are needed - U-shaped, ring or bellows. They will not allow the bottling or riser to bend when heating water in the pipes;

Ring and bellows expansion joints for polypropylene pipelines.

- Straight sections are fastened movably with sliding clamps;

- When pipes are laid hidden, gaps remain at the ends of the grooves. They will allow the pipe to lengthen without destroying the groove seal.

What should be the pressure in the expansion tank of a BAXI double-circuit boiler?

If you open the instructions, it indicates the pressure in the expansion tank is 0.5 bar, but this is the minimum value, correctly - the pressure should be about 20% less than the pressure in the heating circuit at room coolant temperature.

Based on the fact that for most systems the recommended filling pressure is in the range of 1.2 to 1.5 bar, we obtain the required pressure in the air cavity of the expansion tank equal to 0.8-1 bar. Experts usually recommend setting the pressure in the BAXI expansion tank to 1 bar.

Do I need an expansion tank for a baxi wall-mounted gas boiler?

The volume of the built-in expansion tank of the baxi boiler is indicated in the characteristics and for the ECOFOUR series it is 6 liters. To answer the question of its necessity in a separate heating system, you need to know the total volume of this system.

Calculating it is not so difficult: the filling volume of the boiler and radiators is in their characteristics, and the filling volume of pipelines can be calculated by knowing their diameter and total length. Water, after heating by 80 degrees Celsius, will increase in volume by approximately 4-5%, therefore, the recommended volume of the expansion tank is 8% of the total volume of the heating system if filled with water and 12% if antifreeze is used as a coolant (thermal coefficient antifreeze expansion is greater). Thus, a standard expansion tank will be sufficient for a heating system with a volume of up to approximately 75 liters when using water and a volume of up to 50 liters when using antifreeze liquid.

These figures are conditional (with a margin) and when selecting the capacity of the expansion tank, you must be guided by the design calculations of a specific heating system, or the manufacturer’s recommendations.

In most cases, the built-in boiler tank is quite sufficient and the decision to use a separate additional tank is made by specialists at the design stage.

Specifics

The question of how these tanks should normally work is related either to operational irregularities or to the need for maintenance. The main purpose of using a tank is to eliminate the effect of increasing heating water. It is getting larger, but the volume of pipes, heating devices and storage tanks is finite. In closed heating circuits, first of all, the filling is 100%, and this means that the excess mass of the coolant must be dumped somewhere. The tank is the right place.

If for no apparent reason there is no way out, the liquid will definitely find a path through which the excess will escape. In most cases, safety valves become such a place, but this is still emergency equipment. Even if they work exactly as they’re supposed to, you’ll have to clean up the spilled water and refill (top up) the system. Installing tanks in advance helps to prevent such formation of events. And even with boiling coolant, keep everything in perfect order.

Malfunctions of expansion tanks

Checking the pressure of the expansion tank is included in the list of annual maintenance procedures and if it is followed there will be no problems, but if neglected it can give the owner unpleasant surprises:

the pressure in the air chamber gradually decreases and with each refill of the boiler the tank fills more and more with water and gradually ceases to perform its function. In this case, the membrane is so pressed against the wall of the air part of the tank that it can be damaged by the valve spool and the tank will have to be replaced.

The heating circuit pressure is at the permissible limit, the expansion tank has not been serviced - there is no pressure in it. When the heating system cools down, the volume of liquid decreases, the pressure drop is not compensated for by anything - the boiler stops due to an emergency. This situation can arise, for example, when the boiler operates for a long time in DHW mode or when there is a power outage.

the owner of the boiler often has to top up the boiler for no apparent reason, for example, while hot water is being used - the pressure on the pressure gauge drops and the boiler stops by mistake - the owner tops up. Since thermal expansion is not compensated by anything, with further heating of the coolant, excess pressure is released through the safety valve. Some users set the reset and simply do not notice this situation. Frequently refilling the boiler with untreated water is detrimental to the heat exchanger!

Control methods

You can control the pressure in the system using a sensor

For monitoring, water pressure sensors are installed in the heating system. These are pressure gauges with a Bredan tube, which is a measuring device with a scale and pointer. It shows excess pressure. It is installed at control nodes defined by regulatory documents. Using a heating system pressure sensor, you can determine not only a quantitative indicator, but also areas with possible leaks and other problems.

The flow of the working medium does not pass directly through the pressure gauge, since the measuring device is installed using three-way valves. They allow you to purge the pressure gauge or reset the readings. This tap also allows you to replace the pressure gauge with simple manipulations.

Pressure gauges are installed before and after elements that can affect pressure losses and pressure increases in the heating system. It can also be used to determine the serviceability of a particular unit.

Baxi boiler pressure drops when hot water is turned on

Sometimes, users encounter a problem when the pressure drops when turning on hot water in the baxi boiler. This problem may just be due to insufficient pressure in the expansion tank. The fact is that when the boiler switches to the hot water preparation mode, the circulation pump pumps the liquid in a small circle, i.e. only inside the boiler itself - through a secondary plate heat exchanger. In this case, the heating circuit actually does not heat up and the coolant begins to cool, the volume decreases and in the absence of compensating pressure in the expansion tank, the pressure of the heating system may drop and the boiler will display error E10.

In such a situation, you can also consider the possibility of a breakdown of the heat exchanger itself (a gap between the plates) and water from the heating circuit entering the hot water system, but this is easy to check. To check, you need to shut off the cold water supply to the boiler and open any drain valve. If water comes out of the tap under such conditions, it is obvious that this is coolant from the heating circuit and the heat exchanger needs to be replaced.

Remember, timely maintenance of a gas boiler will help avoid such situations and increase the service life of the unit.

We also recommend watching a video from one of the users, which clearly shows how to pump up pressure in the expansion tank:

The expansion tank in a heating boiler performs an important function - it compensates for pressure surges when the temperature values of the coolant change, be it ordinary water or antifreeze. The tank itself consists of two parts, between which there is a membrane. One part contains the coolant, the other contains air, through which the required pressure is created. And for normal operation you need to periodically pump up the tank. Next, you will learn how to pump up the boiler expansion tank and how to detect when you need to do so.

A common situation: you turn on the water and run a bath. At this time, the boiler switches from heating mode to hot water supply mode. While the water is being collected, the coolant gradually cools down, and the expansion tank does not function at this time. And when you turn on the tap, the boiler should start heating again, but this does not happen. The reason is a sharp drop in pressure, as a result of which the automation simply blocked everything. This means it's time to pump up the air and increase the pressure in the tank.

Causes and solutions to the problem

The coolant, circulating through the radiators, gives off its heat; accordingly, heating of any room or premises is carried out due to the heat transfer of the radiators. Hot water moves through the pipe system due to a certain pressure pumped by the circulation pump (for now we do not take natural gravity into account).

Calculated parameters of the membrane expansion tank

When the pressure in the heating system drops, the coolant reduces its speed, but also intensively continues to give off heat, which is actually concentrated at only one point. Why is this happening? The cause could be a power failure, a leak, problems with the expansion tank, or even the material from which the radiators are made.

Power outage

The most common reason that the pressure in the heating system drops is a power outage. Simply put, heating equipment simply stops working and, as a result, the pressure in the heating boiler begins to decrease.

Solving this problem is quite simple - you need to resort to alternative power sources. These can be all kinds of uninterruptible power supplies, batteries, etc. The only thing worth taking care of is that these devices are always in working and charged condition. Therefore, do not forget to check their performance from time to time and recharge them until they are fully charged.

If for some reason the pressure in the boiler drops, and you do not take any measures to stabilize it for a long time, this can lead to the radiators defrosting.

The consequences of inaction can be very different, ranging from expensive repairs of the heating unit to major repairs with the replacement of almost all of its components.

Leaking pipeline, radiator, tap, etc.

In addition, a leak in the heating main can cause a drop in pressure in the heating system of a private home. In this case, it is necessary to carefully check all pipes and radiators for leaks and, if necessary, carry out repair and restoration work.

VIDEO: How to increase the pressure in a gas boiler in a simple way without special equipment.

This method will be useful if there is low pressure in the water supply system or there is no water.

Expansion tank settings

Why else might the pressure in the heating system drop? If the problem is not leaks, then there may be a problem with the settings of the expansion tank (expansion tank). After all, it is precisely due to this structural element that the pressure in the heating system is adjusted.

Schematic design of the expansion tank

During heating, water expands in volume (on average 0.3% per liter of liquid), which leads to an increase in pressure in the heating line. While the expansion tank compensates for the excess coolant. If necessary, excess liquid enters it or, conversely, returns to the circuit.

How to determine that the reason why the pressure in the heating system drops is precisely a malfunction of the compensator (expansion tank)?

Everything is quite simple. During heating of the coolant, the pressure will increase, as a result of which an emergency decrease in the expansion chamber is observed using a special valve. After cooling the water in the main, it is at a level below the required level.

To adjust the operation of the expansion machine, you should use the instructions that came with this equipment. It specifies what the pressure should be. After this, you should reconfigure the tank, following the following step-by-step instructions:

- First of all, it is necessary to close all taps at the inlet and outlet of the heating element.

- Next, using the drain fitting, you need to completely drain the liquid.

- The next step is to drain all the air that is in the expansion chamber. To do this, we take a special nipple, which is included in the kit of this equipment.

- Now we need a car pump. And if you don’t have one, then probably one of your neighbors will definitely have this device. We connect the pump to the expansion tank and pump air until the reading on the device reaches 1.5 bar. During this process, water may leak out of the fitting, but this does not mean that there are any problems. Therefore, there is no need to worry about this.

- The next stage is re-bleeding the air.

- If the tank is connected to the boiler via a hose, it must be disconnected. Thanks to this, you will be able to get rid of excess liquid. As soon as all the coolant has been removed, reconnect the hose.

- Then we take the car pump again and pump air until the indicator on the device reaches the mark indicated in the instructions for the expansion tank.

- After this, close the fitting through which the coolant was drained.

- And the final stage will be opening the taps and filling the line with coolant.

How to pump air into the boiler expansion tank?

Please note that you will not be forcing air into the system itself, but only into the expansion tank. Accordingly, it is not advisable to look at the boiler pressure gauge. Your main reference point is the pressure gauge on the pump itself. You can use a regular pump that is used to inflate car tires. You can, of course, use a compressor. Although not necessary. Your task is to pump up the pressure to just 1 atmosphere. An ordinary pump will handle this quite well.

The upload process consists of four steps:

- First, unplug the system and remove the plug from the outlet. This will primarily keep you safe.

- Next, drain the water from the boiler. If the equipment is new and installed correctly, then there is no need to drain all the water. It is enough to turn off the cold water supply, open the hot water supply tap, and also open the hot water supply valve on the closest mixer. This way the water contained in the boiler will be completely drained. Most modern boilers have special fittings for draining water. You can use them, but it is inconvenient - you will have to drain the water into buckets, basins, large bowls, then pour it out and repeat the procedure. The first method is faster and easier. Draining water from a gas boiler is necessary to make sure that you will pump air into the expansion tank. If there is any water left in it, it will be ineffective.

- Pump up the tank. Each tank has a regular nipple to which the pump can be easily connected. In most cases, you do not have to remove the boiler lid to access the nipple. When you pump up the tank, constantly monitor the pressure gauge on the pump. Your task is to pump up to approximately 1.2 atmospheres. This is the optimal value. If it turns out more, you need to loosen it. Otherwise, the system may simply not work until the pressure returns to normal. If you see water still coming out of the faucet while pumping, this is normal.

- Connect the boiler. When the pressure in the expansion tank reaches normal, you can reconnect the boiler. First, close the water supply tap and open the cold water tap. At the same time, dirty water and air bubbles will begin to flow. When this stops, the tap can be closed. Next, the feed tap must be opened again to fill the boiler to its operating condition. Here you need to look at the pressure gauge located on the body.

After this, you can open the supply and return taps. If you see that the pressure is weakening, you can add water. Next you need to remove air from the pump. Unscrew the plug at its end and bleed the air in the same way as is done on Mayevsky taps.

An important question for owners of wall-mounted and floor-mounted heating boilers: “how often do you need to pump up the expansion tank?” We recommend doing this every two years in new boilers, and every year in boilers that have already been in service for several years. Optimally - before the start of the heating season.

Flaws

Along with many positive characteristics, electric heating boilers with a circulation pump also have certain weaknesses:

- The costs of operating such equipment are directly dependent on electricity prices. This explains the fact that most countries have recognized electric heating systems as not as efficient as gas and solid fuel counterparts. To reduce operating costs, it is recommended to use a heat storage tank. This will significantly reduce heat loss and energy consumption for the preparation of warm water.

- Dependence on proper supply of electrical energy. A double-circuit electric boiler and circulation pump are energy-dependent devices. Therefore, if there are power outages in the region, it is advisable to choose a different type of heating for your home. One option is to install a backup heat source in case of an “emergency” situation. Most often we are talking about a solid fuel stove or fireplace. They are far from full-fledged heaters, but they will certainly be able to provide backup during a short shutdown of the main boiler.

- The need for high-quality electrical wiring. This is a prerequisite for the electric boiler in combination with the circulation pump to operate without any interruptions. It often happens that the wiring in the house does not meet the requirements, and it has to be completely changed. This in any case entails additional costs.

Naturally, people are also concerned about the cost of an electric boiler with a pump. Its size is largely influenced by which model was chosen: the more powerful the device, the more expensive it costs. You should also pay attention to manufacturers, among whom there are several proven domestic companies. In any case, do not delude yourself with cheap samples of dubious quality.

How to identify a malfunction and why does the pressure in the expansion tank drop?

The most common signs of malfunction:

- “Jumping” pressure during boiler operation. For example, when the system operates for heating, it increases, and when switching to hot water supply it decreases. In the latter case, the indicator may even drop to zero.

- You have to constantly recharge the heating system, although leaks cannot be detected, and the heat exchanger works normally. Often the problem arises when there is a heated floor in the house.

In some cases, the reasons for the drop in pressure can be discovered independently. Very often they arise precisely because of coolant leaks. Moreover, more often when using antifreeze as a coolant. Antifreeze, due to its consistency, can penetrate even the smallest cracks, and the pressure drops. To correct the situation, you need to find the leak and fix it, then pump up the tank to the required pressure.

During operation, the pressure in the boiler itself may drop and return to normal after startup. If it does not align, this is a sign of a malfunction. Further, the system will fail even more. In such a situation, it is best to immediately contact a specialist for diagnostics, service and repair.

Advantages

The popularity of electric boilers with a heating pump is explained by the following positive characteristics:

Rich assortment. Models of various capacities are available for sale, which makes it possible to acquire exactly the brand that best suits the operating conditions. In this way, you can choose a heating device for both a country house and an industrial premises: there are always options with suitable parameters in stock.

Economical. Due to the high energy efficiency of modern electric heating boilers (their efficiency is close to 99%), their use allows you to save significant finances. An additional economic effect is facilitated by the use of a circulation pump, which is part of the structure itself. Having low energy consumption, it nevertheless significantly increases the rate of coolant passage through all pipes. As a result, rooms warm up many times faster.

Environmental friendliness. Such a heating system does not emit combustion products during operation. Therefore, there is no need to spend money on organizing a chimney and providing additional air flow. For this reason, electric boilers are widely used in city apartments and office premises.

It is important to remember that the absence of smoke does not mean that the ventilation in the house may be poor.

Ease of management. This is facilitated by maximum optimization of monitoring and control devices

As a result, even an amateur can monitor the operation of heating equipment. Most of the models on the market are equipped with automatic control units: this allows you to resort to adjusting the operation of the system in very rare cases.

If you need boiler repair or maintenance, call Profteplo

We work in Kaluga and the region, diagnosing, servicing and repairing systems of any complexity. We carry out both simple tasks of pumping air into an expansion tank, and complex complex repairs of modern systems. We provide a guarantee for all types of work.

If you need advice or want to use the service, just call the number or leave a request directly on the website. The master will arrive on the day of your call and will perform all the necessary types of work.

The expansion tank in a heating boiler performs an important function - it compensates for pressure surges when the temperature values of the coolant change, be it ordinary water or antifreeze. The tank itself consists of two parts, between which there is a membrane. One part contains the coolant, the other contains air, through which the required pressure is created. And for normal operation you need to periodically pump up the tank. Next, you will learn how to pump up the boiler expansion tank and how to detect when you need to do so.

A common situation: you turn on the water and run a bath. At this time, the boiler switches from heating mode to hot water supply mode. While the water is being collected, the coolant gradually cools down, and the expansion tank does not function at this time. And when you turn on the tap, the boiler should start heating again, but this does not happen. The reason is a sharp drop in pressure, as a result of which the automation simply blocked everything. This means it's time to pump up the air and increase the pressure in the tank.

Wall mount

Instantaneous water heaters are lighter, so they are easier to mount on the wall in an apartment. But heavy boilers, which are designed for a water volume of 50 to 200 liters, must be very well attached to the wall.

This is where the installation of the boiler with your own hands begins. Installation can only be carried out using anchor hooks or bolts. Such fastening will be reliable on concrete panel walls or solid brick walls.

But if the wall does not inspire confidence in you: wooden or old brick, then you need to drill through the wall and screw it onto steel strips from behind. Or make a metal frame on the wall and attach it to it using hooks welded to the frame. Well, in general, such a boiler cannot be hung on a plasterboard wall in an apartment.

When installing any water heaters, you must hang them strictly vertically, determining the accuracy of the mounting level. If the boiler hangs unevenly, with a slope, then there will be problems with its operation.

Another nuance that must be taken into account when installing it yourself is that the distance from the shelf to the boiler lid must be left about 15 centimeters.

The video shows in detail how to install a boiler with your own hands:

How to pump air into the boiler expansion tank?

Please note that you will not be forcing air into the system itself, but only into the expansion tank. Accordingly, it is not advisable to look at the boiler pressure gauge. Your main reference point is the pressure gauge on the pump itself. You can use a regular pump that is used to inflate car tires. You can, of course, use a compressor. Although not necessary. Your task is to pump up the pressure to just 1 atmosphere. An ordinary pump will handle this quite well.

The upload process consists of four steps:

- First, unplug the system and remove the plug from the outlet. This will primarily keep you safe.

- Next, drain the water from the boiler. If the equipment is new and installed correctly, then there is no need to drain all the water. It is enough to turn off the cold water supply, open the hot water supply tap, and also open the hot water supply valve on the closest mixer. This way the water contained in the boiler will be completely drained. Most modern boilers have special fittings for draining water. You can use them, but it is inconvenient - you will have to drain the water into buckets, basins, large bowls, then pour it out and repeat the procedure. The first method is faster and easier. Draining water from a gas boiler is necessary to make sure that you will pump air into the expansion tank. If there is any water left in it, it will be ineffective.

- Pump up the tank. Each tank has a regular nipple to which the pump can be easily connected. In most cases, you do not have to remove the boiler lid to access the nipple. When you pump up the tank, constantly monitor the pressure gauge on the pump. Your task is to pump up to approximately 1.2 atmospheres. This is the optimal value. If it turns out more, you need to loosen it. Otherwise, the system may simply not work until the pressure returns to normal. If you see water still coming out of the faucet while pumping, this is normal.

- Connect the boiler. When the pressure in the expansion tank reaches normal, you can reconnect the boiler. First, close the water supply tap and open the cold water tap. At the same time, dirty water and air bubbles will begin to flow. When this stops, the tap can be closed. Next, the feed tap must be opened again to fill the boiler to its operating condition. Here you need to look at the pressure gauge located on the body.

After this, you can open the supply and return taps. If you see that the pressure is weakening, you can add water. Next you need to remove air from the pump. Unscrew the plug at its end and bleed the air in the same way as is done on Mayevsky taps.

An important question for owners of wall-mounted and floor-mounted heating boilers: “how often do you need to pump up the expansion tank?” We recommend doing this every two years in new boilers, and every year in boilers that have already been in service for several years. Optimally - before the start of the heating season.

Setting principles

When the hydraulic tank is properly pumped, the pressure gauge needle shows smooth development. If jumps appear, additional adjustment is needed. Without this, the network will not work productively.

The gas pressure in the expansion tank is calculated using any of these methods:

- The pressure gauge is located on the outside of the unit. The device displays the required data. You can verify their objectivity by first blocking the valves (this will disconnect the tank from the water supply network). After 10 minutes, air is released into it and immediately released. At this moment, watch the pressure gauge needle. It should move smoothly - this is a sign of correct settings.

- There is no pressure gauge on the tank. A portable version with a similar connector to the container outlet valve in the upper sector is used, put on and tightly secured here. The valve opens and the pressure gauge synchronizes with the hydraulic tank and displays the current pressure in it.

In the case of extremely high pressure levels in the tank, its compensating characteristics do not work, and the integrity of the system components is on the verge of failure. Excess air appears, and pipes and radiators are under enormous stress.

If its parameters are low, the water level displaces the membrane, and the entire tank is filled with HP and gradually expands here. The safety valve reacts to this and the DHW mechanism is turned off.

To avoid these difficulties, optimal parameters are determined and excess air is removed. All actions are performed with a cold network, and 0.2 atm is added to the initial figure.

The statistical head is determined by dividing by 10 from the height of the building. For example, it is 9 m in a house, then the arithmetic turns out like this: 9: 10 + 0.2 atm. To correct these data, air is systematically introduced into the hydraulic tank (to raise the parameter) or removed from it (to lower the number) through a special spool.

How to identify a malfunction and why does the pressure in the expansion tank drop?

The most common signs of malfunction:

- “Jumping” pressure during boiler operation. For example, when the system operates for heating, it increases, and when switching to hot water supply it decreases. In the latter case, the indicator may even drop to zero.

- You have to constantly recharge the heating system, although leaks cannot be detected, and the heat exchanger works normally. Often the problem arises when there is a heated floor in the house.

In some cases, the reasons for the drop in pressure can be discovered independently. Very often they arise precisely because of coolant leaks. Moreover, more often when using antifreeze as a coolant. Antifreeze, due to its consistency, can penetrate even the smallest cracks, and the pressure drops. To correct the situation, you need to find the leak and fix it, then pump up the tank to the required pressure.

During operation, the pressure in the boiler itself may drop and return to normal after startup. If it does not align, this is a sign of a malfunction. Further, the system will fail even more. In such a situation, it is best to immediately contact a specialist for diagnostics, service and repair.