The Wilo circulation pump in the Ariston double-circuit boiler ensures the supply of heated liquid to the heating radiators, cooling the primary heat exchanger, after dispensing hot water to protect the heat exchanger from the formation of scale on its internal walls.

Ariston boilers in the Genus Premium, Clas System, Genus, Clas models are equipped with a Wilo MTSL 15/5 HE - 2 circulation pump, its malfunction leads to an emergency stop of the heating device.

To repair the boiler circulation pump, you need to know its components. The working device includes the following components:

- housing with inlet and outlet pipes;

- rubber gasket;

- Electrical engine;

- turbine;

- plain bearings;

- fasteners;

- air vent;

- starting capacitor;

- control terminal.

Electricity consumption

You can often hear that a pump consumes a lot, but how much does it really mean?

Circular pumps do not lift water from the depths, but simply ensure its movement in a closed system. For this reason, the devices provide high performance with low power, usually sixty to one hundred watts. This is approximately the same as a regular incandescent lamp.

The power consumption of the pump and its size depend on many parameters. You can find energy-saving models with electronic filling. They are equipped with electronic frequency control and belong to the A-class. The devices are capable of automatically adjusting power in case of network parameters deviation. Despite their higher cost, the device pays for itself very quickly.

Before we find out how many kW we are consuming and calculate the electricity consumption of the pump, it is necessary to obtain information about the thermal power of the device. The following indicators are accepted:

- small private house - one hundred kilowatts (0.1 kilowatts) per square meter;

- apartment in a multi-storey building - seventy watts per square meter;

- industrial premises - from thirty to fifty watts per square meter.

It is necessary to independently calculate the required thermal power, taking into account the purpose and degree of thermal insulation. There are many convenient and understandable tables available on the Internet.

It is difficult to calculate how much electricity a pump consumes. Many aspects are taken into account. In an hour, a conventional pump consumes about four watts; in a day, the device consumes from forty to eighty watts. Indicators may increase or decrease depending on the weather, the degree of insulation of the room, and the intensity of use.

You can choose the right pump taking into account the following parameters: performance, pressure, design, operating efficiency. If you are at a loss as to which device to choose, seek help from a specialist.

Number of pump speeds

Well-known manufacturers of pumping equipment for heating equip their units with shaft rotation speed switches; in some models, the speed of the device is automatically adjusted. During operation, this creates additional convenience: since heating the liquid takes quite a long time, to quickly warm up the premises, you can set the maximum speed of the electric pump or save energy by setting the minimum speed of the electric motor when the room is heated.

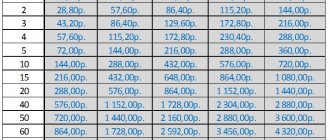

The number of speeds, depending on the manufacturer, can be from 2 to 4 - the more there are, the more effectively you can use the circular in the heating system, and the most economical option is electronic speed control.

Fig. 13 Selection of electric pump according to pressure characteristics

Calculation of system hydraulic resistance

A calculation based on the power of the boiler may not be enough, because the system differs from system to system in length, pipe diameter, the presence of turns, the number of radiators and fittings - and these are all obstacles in the flow path.

Knowing the hydraulic resistance is important in order to determine the required pressure. Pressure is an indicator of the height to which a given pump can theoretically raise a column of water

Reflects the pump's ability to overcome system resistance

Pressure is an indicator of the height to which a given pump can theoretically raise a column of water. Reflects the pump's ability to overcome system resistance.

It is possible to calculate the exact pressure at home only if you have access to technical literature. The exact calculation formula is:

H = (R * L + Z) : p * V

- H is the required value (pressure).

- R – resistance of the straight section (100 – 150 – obtained experimentally).

- L – total length of pipes.

- Z – tabular data. Resistance of each fitting and fixture.

- P – coolant density.

- V – coolant movement speed.

And for approximate calculations you will only need to measure the total length of the pipes and estimate the amount of fittings.

For every 10 m of pipes you will need 0.6 m of pump pressure (supply and return are measured, rounded to the nearest ten and the resulting figure is multiplied by 0.6).

20–70% is added to the result (the minimum figure for simple systems, the maximum for those overloaded with reinforcement).

For reference:

- A three-way mixer takes up 20% of the speed;

- Fitting – 30%;

- Thermal relay – 70%.

Pumping systems audit

Almost 20% of global electricity consumption comes from pumping systems. From 40% to 60% of the electricity consumed by pumping systems can be saved!

The three main cost items (acquisition, maintenance, electricity) over 10 years of operation are distributed as follows:

85% - energy costs

10% - technical and service maintenance

5% — purchase of equipment

It is the most expensive part of expenses (electricity) that can be significantly reduced! How? We suggest conducting an audit of the pump.

Correct calculation of the coolant in the heating system

Based on a set of characteristics, the undisputed leader among coolants is ordinary water. It is best to use distilled water, although boiled or chemically treated water is also suitable - to precipitate the salts and oxygen dissolved in the water.

However, if there is a possibility that the temperature in a room with a heating system will drop below zero for some time, then water will not be suitable as a coolant. If it freezes, then with an increase in volume there is a high probability of irreversible damage to the heating system. In such cases, a coolant based on antifreeze is used.

Breakdowns and troubleshooting methods

Depending on the problem, the cause of the breakdown and its elimination are determined:

- The circulation pump does not turn on and does not make noise. The reason is a burned out winding or a broken fuse. The fuse or winding is changed;

- When the unit is turned on, a hum is heard, but the shaft does not rotate. Why does the unit hum but not work? Most likely, during prolonged inactivity, oxidation of the shaft occurred. If the device is blocked, it is disconnected from the network. The screws connecting the engine and the housing are unscrewed. The motor is removed and the shaft is turned. For low-power units, the shaft is unlocked using a screwdriver;

- The pump turns off after it is turned on without starting to work. The reason is scale between the stator and rotor. After dismantling the engine, salt deposits are removed;

- During operation, the device begins to heat up. Why does the engine get hot? There are several reasons for heating. Incorrect installation, poorly lubricated bearing, low mains voltage, system clogging. To eliminate the voltage problem, an uninterruptible power supply (UPS) is installed for the heating pump. A UPS is used for continuous power supply and protection against power surges. In the absence of electricity in the network, the UPS will ensure the operation of the unit for fifteen minutes (used as a power source). The UPS will protect the pump motor in the event of a surge, sudden drop or fluctuation in the voltage in the network. By connecting a UPS, the heating system will be protected from power surges. Mains power will be safe;

- food problem. The compliance of the actual voltage in the network with that specified in the characteristics is checked;

- the impeller is blocked. To troubleshoot the problem, you need to know how to disassemble the device. To eliminate the breakdown, the wheel is dismantled and the foreign object is removed. To prevent reoccurrence of blocking, a filter is installed at the pump inlet;

- When turned on, the pump may hum. The reason is accumulated air. To fix the problem, you need to bleed the air from the system. Automatic air vents will constantly bleed air. An air vent is needed to bleed air during operation and startup of the system;

- The unit vibrates during operation. The reason is bearing wear. The bearing needs to be replaced. The second reason is a clogged filter. The filter needs to be washed and cleaned;

- after switching on, the electric motor protection is activated. The reason is the engine electrics. It is necessary to contact a specialist;

- The water pressure is lower than specified in the technical specifications. We made a mistake while installing the device. Found in three-phase types of equipment.

Do-it-yourself heating pump repair (video)

Prevention of breakdowns

To prevent breakdowns, you need to check the serviceability of the heating pump yourself. Before the heating season begins, the unit is checked for breakdowns.

- Check for lubrication. When the pipes dry out, lubricate them.

- Check that the device is connected to the network correctly. When planning the heating system, it is necessary to place the pump in front of the boiler. This measure will reduce the formation of air jams to zero.

- The equipment is checked using a tester for correct connection to the network.

- Cleaning the filter from dirt.

- Before starting the heating, the equipment is tested. To pressurize the heating system, water or air is supplied to the system. For crimping, a hydraulic or pneumatic pump is used.

Correct and incorrect installation of the circulation pump

The influence of the crimping process on the injection mechanism

The pressure testing process ensures high-quality maintenance of the entire heating system.

In order for the entire system to operate without leaks and turn on without problems, this procedure is carried out. The procedure is carried out after disconnecting the system from the network and removing the coolant. Before the procedure, the pipes must be pressed (cleaned) of scale. Scale, deposited on the internal parts of the pipes, reduces their permeability by fifty percent, increasing the load on the supercharger. It will become difficult for the pump to pump water through the system and it will quickly fail. Circulation will be disrupted throughout the entire system. Heating will not be effective.

If the heating system is not pressurized once every five years, the centrifugal pump will not cope with its task.

The role of the pump in the heating system

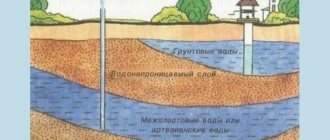

The coolant can be moved through pipes in two ways. The first of them is called natural, that is, without the use of any additional interventions. The liquid moves due to the difference in density of cold and hot water. Ordinary gravity also plays a role - when installing a natural heating system, the pipes are located slightly at an incline.

The problem is that the coolant flow with this approach is quite slow due to the low pressure. The result is clearly uneven heating of the rooms in the house - the further the room is from the heating boiler, the colder it will be. And the larger the house, the more significant this difference will be. After all, while the coolant slowly flows through the pipes, it has time to cool down.

This is why natural circulation is only good for small apartments and houses. The length of the circuit with this approach is limited, as is the number of radiators, for the reasons described above. For a large house, this is not at all an option, since most of its rooms will remain cold, and there is nothing to say about the rooms located on the second floor.

This is where the circulation pump comes to the rescue. It is a motor with a rotor that is lowered into the coolant and rotates there, creating the required level of pressure and forcing water or antifreeze to move at the required speed.

A separate advantage is the ability to control the operation of the heating system. As a rule, the circulation pump has several power modes, with which you can vary the speed and strength of heating the house if necessary. For example, if the home is not permanent, but seasonal, and the owners have returned to it after a long absence, you can first set the pump power to maximum and quickly get a warm, comfortable atmosphere. And then reduce the pressure in the system and, accordingly, the heating intensity.

Installation features

As a rule, circular electric pumps are installed in the main using a bypass - a parallel pipeline with a ball valve through which coolant is supplied when the pump branch is turned off. This design allows you to remove the circular valve for adjustment, repair or replacement without draining the coolant from the system.

Choosing the right circulation pump for heating is a responsible task, the solution of which is best left to specialists. The comfort and efficiency of the heating system (optimal efficiency of the device), as well as energy consumption, the savings of which, with the right solution, can reach 80%, depend on the selected unit.

If you wish, you can independently select a circulation pump for the heating system, make calculations using formulas; the highest accuracy of calculations is obtained when using computer programs. When working with programs, you need to understand how to enter data correctly - in many cases this requires special technical knowledge, which will take some time to obtain

A few additional tips

Longevity is largely influenced by the materials from which the main parts are made. Preference should be given to pumps made of stainless steel, bronze and brass. Pay attention to what pressure in the system the device is designed for.

Although, as a rule, there are no difficulties with this (10 atm is a good indicator). It is better to install the pump where the temperature is minimal - before entering the boiler. It is important to install a filter at the entrance. It is advisable to position the pump so that it “sucks” water from the expander. This means that the order in the direction of water movement will be as follows: expansion tank, pump, boiler.

Conclusion

You should not strive to comprehend complex engineering mathematics.

At home, an approximate calculation will be enough. All resulting fractional numbers are rounded up.

Selection by size

You've probably noticed that the range of companies includes units with the same characteristics, but different dimensions and pipe sizes. How to select external pump parameters:

- For installation on pipelines, bypasses and mixing units of underfloor heating, standard blowers with a length of 180 mm are used. “Shorty” 130 mm are installed inside heat generators or on highways in very limited space.

- The diameter of the connecting pipes is selected to match the cross-section of the main pipeline. Increasing the standard size is permissible, but decreasing it is strictly not recommended. That is, a unit with 32 mm fittings can be installed on a DN 25 pipeline.

- Pumps with Ø32 mm nozzles are used on primary rings and boiler circuits, as well as in modernized gravity systems.

The performance characteristics of the pumps do not depend on their installation length - 130 or 180 mm

Note. The dimensions of ready-made bypasses sold in stores are adjusted to fit a standard pump with an installation length of 18 cm.

The number of supercharger speeds does not play a special role. At home, 3 modes are quite enough, the optimal speed is the second. The air from the units is bleed through the side screw, so you should not buy products with a separate air vent.

Operating principle and purpose of the pump

The main problem for residents of the top floors of apartment buildings and owners of country cottages is cold radiators. In the first case, the coolant simply does not reach their home, and in the second, the furthest sections of the pipeline are not heated. And all this is due to insufficient pressure.

When should a pump be used?

The only correct solution in a situation with insufficient pressure would be to modernize the heating system with coolant circulating under the influence of gravity. Installing a pump will help here. The basic schemes for organizing heating with pump circulation are discussed here.

This option will also be effective for owners of private houses, allowing them to significantly reduce heating costs. A significant advantage of such circulation equipment is the ability to change the speed of the coolant. The main thing is not to exceed the maximum permissible readings for the diameter of the pipes of your heating system in order to avoid excessive noise during operation of the unit.

Thus, for living rooms with a nominal pipe diameter of 20 mm or more, the speed is 1 m/s. If you set this parameter to the highest value, you can warm up the house in the shortest possible time, which is important when the owners were away and the building had time to cool down. This will allow you to get the maximum amount of heat with minimal time.

The pump is an important element of the home heating system. It helps improve its efficiency and reduce fuel consumption

Operating principle of the device

The circulation unit operates using an electric motor. It takes heated water from one side and pushes it into the pipeline on the other. And from this side a new portion arrives again and everything repeats.

It is due to centrifugal force that the coolant moves through the pipes of the heating system. The process of operating a pump is a bit like the operation of a fan, only it circulates not air around the room, but coolant through a pipeline.

The body of the device is necessarily made of corrosion-resistant materials, and ceramics are usually used to make the shaft, rotor and wheel with blades.

Circular pump device

In the domestic water supply, the leading place is occupied by electric pumps of the centrifugal principle of operation - during intake, the liquid enters the centrifugal wheel through the inlet located in the center of its axis and is pushed out through the side outlet pipe.

In circular machines, the coolant enters the working chamber through the central hole, and then is pushed out by the blades of the centrifugal wheel through the outlet pipe located in the side of its body. Thus, according to the principle of operation, circulation devices can be classified as centrifugal types, having an efficiency coefficient of no more than 80% and sensitive to solid impurities in water.

Structurally, the electric pump consists of a housing, inside which is placed a moisture-protected electric motor with an impeller on the shaft; generally, the wheels of closed-type pumps consist of two disks, between which feed blades are placed.

Rice. 3 Option for installing the pump in a single-pipe circuit with heated floors

Installation recommendations for all types of systems

There are recommendations for installing all types of pumps:

- Installation of the system, which includes a circulation pump, is carried out with the connection of a backup power supply with a operating reserve of 4-6 hours.

- For 1;-2-circuit systems, the installation of a bypass is mandatory, since in the event of a power outage it will ensure the natural movement of energy flow in the system.

For reference! A bypass is a bypass, a small section of pipe with shut-off or adjustable valves, sometimes with a check valve. It is built to bypass the circulation pump and, when it stops, ensures free flow movement.

- The operation of the pump can only be checked when the system is full. The main indicator of correct installation is the uniform distribution of heat between all radiators.

- Pumps with a wet rotor type are installed in a vertical position.

Manufacturers usually illustrate how to install the pump correctly Source as-elit.ru

- Installation of a coarse filter is required, and installation of a fine filter is desirable.

- The pump must be located in a place accessible for maintenance.

- After all the calculations, add 20% of the rated power, so you will ensure gentle operation of the equipment in the optimal mode of 85-90%, excluding operation at the limit of possibility.

Solid fuel boilers

This type requires separate consideration. When the electricity is turned off, the pump stops, but heating of the energy carrier in the boiler continues: it is impossible to quickly extinguish burning wood or coal, after 3-5 minutes the temperature will reach critical levels and the pressure relief valve will operate. If the pump is installed on the outlet pipe, the reset occurs after 4-6 minutes, while its installation on the return pipe increases this time to half an hour.

Power connection

The circulation pumps operate from a 220 V network. The connection is standard; a separate power supply line with a circuit breaker is desirable. The connection requires three wires - phase, neutral and ground.

Circulation pump electrical connection diagram

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power wire. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing several bolts and find three connectors. They are usually labeled (the pictograms are N - neutral wire, L - phase, and “ground” has an international designation), so it’s hard to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - install a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pulls” electricity to a maximum of 250-300 W. But when organizing, you need to calculate everything and select the battery capacity. The disadvantage of such a system is the need to ensure that the batteries do not discharge.

How to connect a circulator to electricity through a stabilizer

Hello. My situation, a 25 x 60 pump is located immediately after a 6 kW electric boiler, then the line from a 40 mm pipe goes to the bathhouse (there are three steel radiators) and returns to the boiler; after the pump, a branch goes up, then 4 m, down, rings a house of 50 sq. m. m. through the kitchen, then through the bedroom, where it doubles, then the hall, where it triples and flows into the boiler return; in the bathhouse there is a branch 40 mm up, it leaves the bathhouse and enters the 2nd floor of a house of 40 sq. m. m. (there are two cast-iron radiators) and returns to the bathhouse in the return line; there was no heat on the second floor; the idea of installing a second pump in the bathhouse for supply after the branch; the total length of the pipeline is 125 m. How correct is the solution?

The idea is correct - the route is too long for one pump.

Price factor

When choosing a circulation pump, the cost of the device itself and its efficiency in operation are important. As a rule, the operation of the pump is justified by savings on fuel consumption, and the cost of the model itself is determined by its performance. In Moscow, the price range for pumps is very large. Conventionally, they can be divided into 3 categories:

For 3.5-7 thousand rubles you can buy basic functions, with a minimum operating life and most often one-time use;

Comparison of characteristics of pumps in the economy segment Source ms.decorexpro.com

- Devices costing 7.5-20 thousand are “workhorses” that accurately provide the declared characteristics, with a service life no less than that specified by the manufacturer and with several degrees of protection and an optimal safety margin;

- VIP systems with full automation, a set of additional functions, a high safety margin and the ability to provide a large volume of heat will cost from 20 to 45 thousand rubles.

Manufacturers and prices

Despite the wide range of pumps in stores, it is not easy to choose a truly high-quality product. The market is flooded with Chinese goods and counterfeits of famous brands. First, let's list the popular manufacturers in the CIS:

- The highest price category is Grundfos (Denmark), Wilo (Germany). Prices for original “Germans” start from 75 euros, “Grundfos” UPS series – 65 euros.

- Middle category – DAB, Aquario (Italy), Sprut (quality China). The cost of units of various models ranges from 40-100 euros.

- Other cheap pumps (Oasis, Neoclima, “Whirlwind”, “Caliber” and so on ad infinitum). Price – from 20 euros per piece.

The latest development is the Grundfos Alpfa-3 “smart” pump, which transmits information to a smartphone and helps balance the system

Comment. It is likely that we did not include some very worthy products in the highest or middle price category. The most common brands are listed here.

What is the difference between inexpensive and counterfeit pumps and high-quality superchargers:

- service life – 1…3 heating seasons;

- The product number is only on the sticker, the unit body is clean;

- pumping devices from the same batch often come with the same numbers;

- the weight of the fake is noticeably different from the original (it is lighter);

- A low-quality unit begins to make noise and squeak after working for 1 season in a closed heating system, and the housing gets very hot.

Sometimes counterfeit heating pumps are indistinguishable from the original, only the price is half the price. The secret is in the aluminum winding, which reduces the cost of the product. How to check: find a lot of the original model on the company’s official website and compare it with a market copy. Most likely, an informed seller will refuse to weigh a counterfeit device or will immediately recognize the unknown origin of the product.

Video description

And some more thoughts about circulation pumps in the following video:

Possible causes of problems

In some cases, it is not enough to limit yourself to only external work, and you have to get to the internal elements of the structure. It is important to know how to properly disassemble the pump so as not to damage the performance of its parts.

In general, the process is not particularly difficult. The main thing is to stock up on a product called “liquid key”. During long-term use of the device, its elements are tightly glued together by scale, so it is not so easy to separate them. It is undesirable to use ordinary brute force here, since you can damage the part beyond the possibility of subsequent restoration.

The function of the “liquid key” is to soften the scale, as a result of which disassembling connections will become much easier. It is easy to use - apply the product to the desired location, wait for the time indicated on the package, and then proceed to separate the elements. In addition to the “liquid key”, you will need a Phillips screwdriver and a hexagon. Almost every home craftsman has these tools in his kit.

We also recommend keeping a camera or smartphone with a camera nearby during the disassembly process. If you take photographs of each operation, then later it will be much easier for you to assemble the circulation pump to its original state. We especially recommend doing this to those who are encountering this process for the first time.

So, let's get to work.

- Disconnect the device from the network. This is the most important safety requirement when working with electrical equipment. Working with a live device poses a danger to health and life.

- Close all shut-off valves involved in the circulation pump piping. This will help avoid a flood when disconnecting the device. If the system has a bypass to bypass the pump, then turn off the taps on it as well.

- Disconnect the circulation pump from where it is attached. To do this, carefully unscrew the corresponding fittings and remove the equipment.

- Now evaluate the condition of the bolts that secure the cover of the cylindrical body. If they are “grown” to their place, use the “liquid key”. After processing and waiting for the required time, unscrew the bolts and remove the cover. Check the condition of the fastener threads - if they are worn out, then it is better to subsequently replace these elements with new ones.

- After removing the cover, you will see an electric motor with a rotor inside the housing. It is held in place using either bolts or special fasteners. In any case, you need to unscrew the clamps and pull the rotor out. If scale prevents you from doing this, then use the “liquid key” again.

- After you have removed the rotor, inspect its external condition. Also inspect other elements that are located inside the cylindrical body. If any external defects are detected - for example, cracks - replace the corresponding part with a new one.

After complete disassembly, you can carry out a thorough diagnosis, and then reassemble the device, replacing the failed elements with new ones. However, sometimes it happens that it is easier and cheaper to replace the entire pump. If you are generally satisfied with its performance, then you can go to the store with your old device and buy a new one with the same parameters.

If the device does not meet your requirements according to some criteria, then you need to reselect it. You can learn about what characteristics and nuances should be taken into account in the corresponding article on our portal. Good luck!

Advantages of a separate pumping unit

The use of pressure equipment is justified from the point of view of saving fuel and increasing boiler efficiency, which is why many companies integrate pumping units into boilers. But installing the unit separately has its advantages: quick replacement without removing the boiler, the ability to control the process in case of emergency situations (for example, using a bypass). In addition, the pump can be installed in a system not provided for by the project at the initial stage.

Despite the apparent simplicity of the choice, the parameters of the pump must be technically justified, for which mathematical calculations are carried out taking into account the laws of heat engineering, the individual characteristics of the system, therefore the exact choice must be made by a specialist who takes into account all factors based not only on theoretical knowledge, but also on practical experience.

Briefly about the main thing

Installing an electric pump in the heating circuit of the house allows you to provide the necessary pressure in it. This will allow the premises to be heated as efficiently as possible. Electric pumps are installed in homes in “dry” and “wet” versions. The second type of device is more common.

They usually try to install the electric pump on the return line after all radiators, tie-ins and a reservoir for expansion of the coolant. If necessary, it can be mounted on the supply, but at the maximum distance from the boiler.

The pump is installed on a bypass. This is a loop with a filter and shut-off valves. First, all its elements are assembled into a single structure, and then it crashes into the main pipeline with a separate tap to shut it off.

Other pump calculation options

The above calculation method is one of the options for calculating the necessary parameters. A number of manufacturers use a different technique. You can also entrust the calculation of the circulation pump to a qualified specialist. Knowing the details of the design of a particular system and its operating conditions, he will professionally make all the calculations.

Usually the maximum load for the operation of the heating system is determined. In reality, it will be lower, so it would be wise to purchase a device whose parameters are slightly lower than the calculated data. Calculating the power of the heating circulation pump reflects the optimal result. Purchasing a more powerful device is not advisable and the system’s performance will not improve, and costs will increase.

After receiving the calculation results, it is necessary to pay attention to the pressure and flow data on pump models, taking into account its operating speeds. The characteristics can be reflected on a graph with two coordinates - pressure and productivity, and then the point of intersection of these values can be determined

Based on the graphic image, the desired heating pump model is selected for a particular home. Point A in the figure corresponds to the required parameters based on the calculation results, and point B indicates the actual characteristics of a certain device model specified by the manufacturer. The circulation pump is more suitable for the operating conditions in a particular heating system, the smaller the distance between these two points.

The most common malfunctions, their causes and solutions

There are situations when the heating circulation pump does not work. Many of the problems can be fixed on your own. Faults can be recognized by a number of their distinctive characteristics.

p, blockquote 10,0,0,0,0 —>

The circulation pump hums, but the impeller does not rotate

Users often wonder: why is the heating circulation pump humming and what to do in this situation? Often, pump noise and complete immobility of the impeller occur due to oxidation of the drive motor shaft.

p, blockquote 11,0,0,0,0 —>

This situation can happen due to the fact that the hydraulic machine has not functioned for a long time. In order to repair the pump with your own hands, you need to perform the following sequence of actions:

p, blockquote 12,0,0,0,0 —>

- Initially you must turn off the electrical power;

- then it is necessary to drain all the liquid from the pump and the adjacent pipeline;

- after this, you need to unscrew the screws and dismantle the drive motor together with the rotor;

- and the last thing you should do is to move the pump from a dead center, to do this you need to rest your hand or a screwdriver on the working notch of the rotor.

Components of the circulation pump

The pump will make noise, but will not function even if some foreign object gets inside the structure, which will interfere with the rotation of the wheel. Here you need to check the heating circulation pump, find the extra part and resort to repairing the circulation pump:

p, blockquote 13,0,0,0,0 —>

- the power supply is initially turned off;

- then the water is drained from the pump and pipeline,

- after which you need to disassemble the circulation pump as shown in the diagram in the figure;

- next you need to remove the foreign object;

- and at the final stage, a mesh filter is installed on the inlet pipe.

The circulation pump gets hot

It is important that the temperature regime of the device is identical to the temperature regime of the coolant pipes. If it has increased, it means there were some mistakes made during the installation process or you are simply using it incorrectly. The reasons why the device may overheat are as follows:

p, blockquote 14,1,0,0,0 —>

- The installation was carried out incorrectly. It’s easy to identify the problem: if the pump heats up immediately after installation, then this is clearly the reason.

- System clogged. During long-term operation, various deposits accumulate in the pipes and rust forms, which impedes the passage of liquid. Consequently, the pump is overloaded in order to ensure normal coolant circulation. This causes the engine to overheat, but unscheduled maintenance can solve the problem.

- Foreign object. When there is too much slag in the communications from pipes and radiators, pieces of rust or plaque begin to flake off. Their entry into the device jams the electric motor. If you do not disassemble and clean the device in time, there is a high probability of the electric motor coil breaking and you will encounter the problem that the heating circulation pump will not turn on at all.

- Bearings do not have enough lubrication. When there is not enough lubricant, the bearings begin to wear out very quickly, which negatively affects the service life of the device as a whole.

- Low voltage in the network. At voltages below 220 V, the electric motor overheats very quickly, which leads to failure.

p, blockquote 15,0,0,0,0 —>

The pump is turned on and does not hum or work.

If the pump is turned on and does not make any noise, but does not function, then there may be some problem with the electrical power supply. It is important to know how to check the heating circulation pump in this case.

p, blockquote 16,0,0,0,0 —>

To do this, it is not necessary to resort to disassembling the unit. You need to take a tester and check the level and presence of voltage at the terminals of the device. Most often, to solve this problem, it is enough just to correctly connect the pump to the power supply.

p, blockquote 17,0,0,0,0 —>

If there is a fuse in the design of the circulation pump, then it could simply blow out during the process of transmitting voltage to the electrical networks.

p, blockquote 18,0,0,0,0 —>

In order to operate the pump, you need to replace the blown fuse.

p, blockquote 19,0,0,0,0 —>

Circulation pump power supply diagram

How to repair a heating circulation pump if it turns off on its own

If you are faced with a situation where a layer of lime deposits has appeared on the internal walls of the device and the functioning pump periodically turns off, then you need to urgently solve this problem.

p, blockquote 20,0,0,0,0 —>

You need to disassemble the device and clean all its internal parts. The procedure must be completed as soon as possible. Being late may result in permanent failure of the circulation pump.

Features of selecting a circulation pump

The pump is selected according to two criteria:

- The amount of pumped liquid, expressed in cubic meters per hour (m³/h).

- Pressure expressed in meters (m).

With pressure, everything is more or less clear - this is the height to which the liquid must be raised and is measured from the lowest to the highest point or to the next pump, if the project provides more than one.

Expansion tank volume

Everyone knows that liquid tends to increase in volume when heated. To prevent the heating system from looking like a bomb and leaking at all the seams, there is an expansion tank into which the displaced water from the system is collected.

What size tank should I purchase or make?

Everything is simple, knowing the physical characteristics of water.

We multiply the calculated volume of coolant in the system by 0.08. For example, for 100 liters of coolant, the expansion tank will have a volume of 8 liters.

Let's talk about the amount of pumped liquid in more detail.

Water consumption in the heating system is calculated using the formula:

G = Q / (c * (t2 - t1)), where:

- G – water consumption in the heating system, kg/sec;

- Q – amount of heat compensating for heat loss, W;

- c is the specific heat capacity of water, this value is known and equal to 4200 J/kg*ᵒC (note that any other coolants have worse performance compared to water);

- t2 – temperature of the coolant entering the system, ᵒС;

- t1 – coolant temperature at the outlet of the system, ᵒС;

Recommendation! For comfortable living, the temperature delta of the coolant at the inlet should be 7-15 degrees. The floor temperature in the “warm floor” system should not be more than 29 ᵒ

C. Therefore, you will have to figure out for yourself what type of heating will be installed in the house: will there be radiators, “warm floor” or a combination of several types.

The result of this formula will give the coolant consumption per second of time to replenish heat loss, then this indicator is converted into hours.

Advice! Most likely, the temperature during operation will vary depending on the circumstances and season, so it is better to immediately add 30% of the reserve to this indicator.

Let's consider the indicator the calculated amount of heat required to compensate for heat losses.

Perhaps this is the most complex and important criterion, requiring engineering knowledge, which must be approached responsibly.

If this is a private house, then the indicator can vary from 10-15 W/m² (such indicators are typical for “passive houses”) to 200 W/m² or more (if it is a thin wall with no or insufficient insulation).

In practice, construction and trade organizations take the heat loss indicator as a basis - 100 W/m².

Recommendation: calculate this indicator for a specific house in which a heating system will be installed or reconstructed. For this, heat loss calculators are used, with losses for walls, roofs, windows, and floors being calculated separately. These data will make it possible to find out how much heat a house physically releases into the environment in a specific region with its own climate regimes.

We multiply the calculated loss figure by the area of the house and then substitute it into the water consumption formula.

Now you need to deal with the issue of water consumption in the heating system of an apartment building.

What indicators to consider when choosing a pump

The correct choice of pump is based on the hydraulic resistance that the device itself overcomes in the process of creating the required pressure and force of water flow. For an optimally selected pump, the recommended power should be lower than the calculated one, by 10-15% of the calculated power. If the required power level is exceeded, the device may have a shorter service life, which will lead to its rapid wear. The noise level in the heating system may increase. If the power of the unit is less, then under these conditions the required amount of coolant will not be provided.

Diagram of the circulation pump.

The calculation of the pump power indicator is based on the diameter and length of the pipeline, the level of water temperature and coolant pressure. Ten meters of the heating system should be provided with half a meter of pressure using a pump. During the calculations, the coolant flow rate is compared with the level of water flow used in the boiler, the power of which is known. You should have data for calculations about how much water is needed for the normal operation of each of the rings of the heating system. Calculation of heat losses of a building can be made on the basis of tables of thermal conductivity of materials. The length of the heat pipeline and the number of heating radiators are also taken into account. The power of the battery is determined by the required amount of water per minute to ensure optimal heating of the room.

The circulation pump can be equipped with either an electronic or manual speed controller. If the pump shaft speed is set to the highest level, then the maximum operating coefficient of the device should be obtained.

Common breakdowns

The most common problem that causes equipment that provides forced pumping of coolant to fail is its prolonged downtime.

Most often, the heating system is actively used in winter, and is turned off during the warm season. But since the water in it is not clean, sediment forms in the pipes over time. Due to the accumulation of hardness salts between the impeller and the pump, the unit stops working and may fail.

The above problem can be solved quite easily. To do this, you need to try to start the equipment yourself by unscrewing the nut and manually turning the pump shaft. Often this action is more than enough.

If the device still does not start, then the only solution is to dismantle the rotor and then thoroughly clean the pump of accumulated salt deposits.

Where to put

It is recommended to install a circulation pump after the boiler, before the first branch, but on the supply or return pipeline it doesn’t matter. Modern units are made from materials that can withstand temperatures up to 100-115°C. There are few heating systems that work with a hotter coolant, so considerations of a more “comfortable” temperature are untenable, but if you feel safer, put it in the return line.

Can be installed in the return or direct pipeline after/before the boiler up to the first branch

There is no difference in hydraulics - the boiler, and the rest of the system; it makes absolutely no difference whether there is a pump in the supply or return branch. What matters is the correct installation, in terms of strapping, and the correct orientation of the rotor in space

Nothing else matters

There is one important point regarding the installation location. If the heating system has two separate branches - on the right and left wings of the house or on the first and second floor - it makes sense to install a separate unit on each, and not one common one - directly after the boiler. Moreover, the same rule remains on these branches: immediately after the boiler, before the first branch in this heating circuit. This will make it possible to set the required thermal conditions in each part of the house independently of the other, and also in two-story houses to save on heating. How? Due to the fact that the second floor is usually much warmer than the first floor and much less heat is required there. If there are two pumps in the branch that goes up, the speed of movement of the coolant is set much lower, and this allows you to burn less fuel, without compromising the comfort of living.

There are two types of heating systems - forced and natural circulation. Systems with forced circulation cannot work without a pump; systems with natural circulation work, but in this mode they have lower heat transfer. However, less heat is still much better than no heat at all, so in areas where electricity is often cut off, the system is designed as hydraulic (with natural circulation), and then a pump is installed into it. This gives high heating efficiency and reliability. It is clear that the installation of a circulation pump in these systems is different.

All heating systems with heated floors are forced - without a pump, the coolant will not pass through such large circuits

Forced circulation

Since a forced circulation heating system without a pump is inoperative, it is installed directly into the gap in the supply or return pipe (of your choice).

Most problems with the circulation pump arise due to the presence of mechanical impurities (sand, other abrasive particles) in the coolant. They can jam the impeller and stop the motor. Therefore, a mesh dirt filter must be placed in front of the unit.

Installing a circulation pump in a forced circulation system

It is also advisable to install ball valves on both sides. They will make it possible to replace or repair the device without draining the coolant from the system. Turn off the taps and remove the unit. Only that part of the water that was directly in this piece of the system is drained.

Natural circulation

The piping of the circulation pump in gravity systems has one significant difference - a bypass is required. This is a jumper that makes the system operational when the pump is not working. One ball shut-off valve is installed on the bypass, which is closed the entire time the pumping is running. In this mode, the system operates as forced.

Installation diagram of a circulation pump in a system with natural circulation

When the electricity goes out or the unit fails, the valve on the jumper is opened, the valve leading to the pump is closed, and the system operates as a gravity system.

Installation features

There is one important point, without which the installation of the circulation pump will require rework: it is necessary to rotate the rotor so that it is directed horizontally. The second point is the direction of flow. There is an arrow on the body indicating which direction the coolant should flow. This is how you turn the unit so that the direction of movement of the coolant is “in the direction of the arrow”.

The pump itself can be installed both horizontally and vertically, just when selecting a model, make sure that it can work in both positions. And one more thing: with a vertical arrangement, the power (pressure created) drops by about 30%. This must be taken into account when choosing a model.

How to choose and buy a circulation pump

Circulation pumps face somewhat specific tasks, different from water pumps, well pumps, drainage pumps, etc. If the latter are designed to move liquid with a specific outlet point, then circulation and recirculation pumps simply “drive” the liquid in a circle.

I would like to approach the selection in a somewhat non-trivial way and offer several options. So to speak, from simple to complex - start with the manufacturers’ recommendations and lastly describe how to calculate a circulation pump for heating using formulas.

Select a circulation pump

This simple way to select a circulation pump for heating was recommended by one of the WILO pump sales managers.

It is assumed that the heat loss of the room per 1 sq. m. will be 100 W. Formula for calculating consumption:

Total heat loss of the house (kW) x 0.044 = circulation pump flow rate (m3/hour)

For example, if the area of a private house is 800 sq. m. the required flow rate will be:

(800 x 100) / 1000 = 80 kW - heat loss at home

80 x 0.044 = 3.52 cubic meters per hour - the required flow rate of the circulation pump at a room temperature of 20 degrees. WITH.

From the WILO range, the TOP-RL 25/7.5, STAR-RS 25/7, STAR-RS 25/8 pumps are suitable for such requirements.

Regarding the pressure. If the system is designed in accordance with modern requirements (plastic pipes, closed heating system) and there are no non-standard solutions, such as high floors or long heating pipelines, then the pressure of the above pumps should be sufficient.

Again, this selection of a circulation pump is approximate, although in most cases it will satisfy the required parameters.

Select a circulation pump using the formulas.

If you want to understand the required parameters and select it using formulas before buying a circulation pump, then the following information will be useful.

determine the required pump pressure

H=(R x L xk) / 100, where

H—required pump head, m

L is the length of the pipeline between the most distant points “there” and “back”. In other words, this is the length of the largest “ring” from the circulation pump in the heating system. (m)

An example of calculating a circulation pump using formulas

There is a three-story house measuring 12m x 15m. Floor height is 3 m. The house is heated by radiators (∆ T=20°C) with thermostatic heads. Let's make the calculation:

required thermal power

N (from pl.) = 0.1 (kW/sq.m.) x 12 (m) x 15 (m) x 3 floors = 54 kW

calculate the flow rate of the circulation pump

Q = (0.86 x 54) / 20 = 2.33 m3/hour

calculate the pump pressure

The manufacturer of plastic pipes, TECE, recommends using pipes with a diameter at which the fluid flow speed will be 0.55-0.75 m/s, the resistivity of the pipe wall will be 100-250 Pa/m. In our case, a pipe with a diameter of 40mm (11/4″) can be used for the heating system. At a flow rate of 2.319 m3/hour, the coolant flow rate will be 0.75 m/s, the resistivity of one meter of pipe wall will be 181 Pa/m (0.02 mWG).

WILO YONOS PICO 25/1-8

GRUNDFOS UPS 25-70

Almost all manufacturers, including such “giants” as WILO and GRUNDFOS, post special programs for selecting a circulation pump on their websites. For the above-mentioned companies these are WILO SELECT and GRUNDFOS WebCam.

The programs are very convenient, they are quite easy to use

Particular attention should be paid to the correct entry of values, which often causes difficulties for untrained users

Buy a circulation pump

When purchasing a circulation pump, special attention should be paid to the selling company. There are currently a lot of counterfeit products on the Ukrainian market.

How can we explain that the retail price of a circulation pump on the market can be 3-4 times less than that of a representative of the manufacturer?

According to analysts, the circulation pump in the household sector is the leader in energy consumption. In recent years, companies have been offering very interesting new products - energy-saving circulation pumps with automatic power control. From the household series, WILO has YONOS PICO, GRUNDFOS has ALFA2. Such pumps consume several orders of magnitude less electricity and significantly save owners’ financial expenses.

The most popular models of pumping units

Manufacturers offer a wide selection of equipment of different capacities, designed for pumping liquid media with various parameters. But we are only interested in flow-through models that operate in home heating and hot water supply networks.

How to distinguish circulation units from centrifugal and other types of pumps:

- in shape - the electric motor and impeller are installed in one housing, the pipes come out on the sides of the lower part (not in the middle);

- by the presence of a “wet” rotor, which significantly reduces the noise of impeller rotation;

- 2 standard sizes, installation length 130 and 180 mm;

- nominal diameter of the pipes is 15, 20, 25 and 32 mm, connection is coupling (threaded);

- nameplate pressure – 0.4, 0.6 and 0.8 Bar.

The specified parameters can be easily determined by the product labeling. Example: the numbers in the name Wilo Star-RS 15/4 indicate an internal diameter of the connecting pipes of 15 mm (DN 15) and a pressure of 4 m of water column (0.4 Bar). Example two: the Grundfos ALPHA2 25-60 device is connected to DN 25 pipes and develops a pressure of 0.6 Bar (6 meters).

Reference. Manufacturers usually release extended product lines. The German brand Wilo offers circulation blowers with a pressure of 2, 4, 6, 7 and 8 m of water. Art. But the “running” models still remain “fours” and “sixes”, less often – “eights”.

The design of a pump with a “wet” rotor

Of course, there are more powerful pumps, whose pressure reaches 1...10 Bar, but they are not used in private homes. Small units 130 mm long with ½ and ¾ inch pipes are usually installed inside boilers, large ones (18 cm, 1 and 1 ¼") are cut into the heating lines.

Performance Calculations

In order for the pump to work efficiently, you need to select its characteristics correctly. If you are unsure of the data, it is better to consult a specialist before purchasing. The easiest way to find out performance is using the following formula:

- G – volume of required coolant, l/h

- Q – total heating load, W. To make calculations easier, it is better to take a ratio of 1000 W per 10 m².

- Δt is the difference between the temperature of the water leaving the boiler and when returning to it. In calculations it is usually assumed to be 20° C.

For example, you need to choose a pump for a country house of 100 m². It will require 10,000 W to heat it. In this case, the calculation will look like this: G=0.86x10000/20=430 l/h =0.43 m³/h

In total, you will need a pump with a capacity of 430 liters or 0.43 m³/h.

Accelerate further or slow down: at what speed should the heating pump operate?

All modern heating systems are equipped with a circulation pump. With the help of which, a continuous circulation of hot water occurs in the pipes , as a result of which the room is heated.

They are available in different configurations and can have 3 speeds : minimum, medium and high.

What speed should I set on the heating pump at low boiler power?

Adjusting the power of the circulation pump is usually carried out in order to increase or, conversely, reduce its performance . The higher its speed, the faster the hot water passes through the pipes and the more heat it gives off. In turn, the lower it is, the slower the liquid passes through the system, the faster it cools and, accordingly, the heat transfer will be less.

The minimum power of heating equipment is set mainly in the spring . At this time, it is already quite warm outside, but the house itself does not warm up enough and there is a need for a little heating of the room.

Pump speed modes may vary depending on the model and configuration. On average, the minimum is 30-35 l/min , the maximum is 80-90 l/min .

Why do you need to check the settings?

To ensure maximum performance of the device, before using it . This is done, as a rule, according to two parameters.

Noise insulation. There are several reasons why a heater may make a lot of noise:

- incorrect installation;

- air in pipes;

- voltage fluctuations;

- device malfunction.

To avoid these problems, it is better to entrust the installation to a specialist who will carry out comprehensive diagnostics and ensure the correct installation and functionality of the device.

Uniform heating. The main reason for uneven heating of radiators is insufficient power. Low speed contributes to the rapid cooling of the water, as a result of which the heat simply does not reach the end of the system.

Airiness or an incorrectly selected thermostat mode also leads to a similar problem . May affect the performance of the device and improper installation . This is especially true for aluminum and bimetallic batteries, which must be installed as level as possible.

How electronically controlled circulation pumps should work

Models with electronic heating type have two types of speed control: manual and automatic. Manual regulation involves setting the power of the device at the desired level. In this case, pressure drops are not corrected.

Photo 1. Control circuit for the DAB EVOSTA circulation pump with electronic control. Selecting the operating mode is done with one button.

In the case of automatic control, the reduction or increase in speed is carried out by the system itself and directly depends on the temperature in the pipeline. The autopilot itself determines the optimal level of performance and, if necessary, reduces energy consumption without reducing productivity.

Important! Automatic reduction of pump speed is only possible after hydraulic balancing of the system.

Useful video

Check out the video that talks about different types of circulation pumps and their characteristics.

A change in temperature outside is a reason to turn on a different speed

The presence of several modes in the heating pump will allow you to adjust the heating level in a particular room . This function is important when there is a sharp change in temperature outside. In this case, the device can be manually switched to the required power or the autopilot can be turned on, and the system itself will adjust to the desired temperature.

Centrifugal pump malfunctions

Before starting the pump, it must be completely filled with water and the air must be released through the air bleeder. If air remains in the housing, there may be no pressure at all in the supply pipeline, or there will be weak pressure accompanied by noise during operation.

A decrease in the pump's rated head can be caused by a clogged suction line, strainer or impeller blades. To prevent clogging of the blades, coarse filters must be installed on the suction pipeline.

Pump head (m) is the energy received by a fluid weighing 1 Newton as it passes through the pump. Typically, pressure is considered from a geometric point of view, as the height to which liquid can be raised due to the energy generated by the pump.

A properly primed pump may not achieve rated flow if the total head does not match the pump parameters. To check the pressure, pressure gauges are installed on the suction and pressure pipelines. If the pressure is not enough to overcome the required height, you need to increase either the shaft speed or install a larger impeller. If, on the contrary, the supply is greater than the pressure height, then the power on the pump shaft increases, which leads to overload of the engine. To avoid this, it is necessary to adjust the operating mode of the valve on the pressure pipeline.

Flow (m 3 /s) is the performance of the pump, i.e. volume of liquid pumped per unit time

The direction of movement of the pump shaft must correspond to the specified one. Otherwise, the pump may fail due to jamming of the impeller shaft, which in turn will damage the housing. To prevent the shaft from spinning in the opposite direction, a check valve is installed on the pressure pipeline.

Increasing the maximum permissible suction lift is a common cause of pump failure. This leads to the possibility of flow rupture, causes the phenomenon of cavitation, and also significantly reduces power. The maximum suction lift depends on the temperature of the liquid, its speed in the suction pipeline, as well as on the resistance at the outlets and friction losses. As the temperature of the pumped liquid increases, the maximum suction lift decreases as the vaporization pressure increases. Friction losses can be reduced by making the suction pipeline as large in diameter and short in length as possible with the minimum required number of shut-off valves. It is also necessary to regularly clean the filter mesh, since dirt accumulated in it significantly increases power loss.

The permissible suction height (m) is the maximum vertical distance from the liquid level in the supply tank to the suction pipe of the pump, at which cavitation does not occur.

Installing a pump with too high a pressure leads to its unreliable operation, since the permissible suction height will be greatly exceeded due to the high flow.

If high pressure of vaporization occurs in the suction pipeline, back-up should be provided, which will also cover friction losses. The minimum head height is usually determined by the manufacturer and is indicated in the pump specifications. To ensure uninterrupted operation of the pump, it is necessary to maintain the required head pressure, which depends on the temperature of the pumped liquid and the pump flow. If liquid is pumped from a closed reservoir, then the head height can be ensured by increasing the pressure in it.

If the suction pipeline is long, it must be laid with a slope towards the pump to prevent air from entering it. When drawing liquid from the tank, the suction pipe must be immersed in it by at least 0.8 m.

After the pump, a shut-off valve must be installed on the pressure pipeline, since the circulation pump is turned on and off with the pressure pipeline closed. If the pressure exceeds 10 - 15 m, then a check valve is installed between the valve and the pump. It prevents fluid from flowing back through the pump during an emergency stop (eg power outage). Also, the absence of a check valve can lead to reverse rotation of the pump shaft during a short-term power outage.

Failure to timely service the seals can cause damage to the centrifugal pump. The causes of damage to the stuffing box are uneven rotation and runout of the working shaft. The oil seal box is tightened with such force that a little water drips out from under it. This creates dry friction for the stuffing box and ensures its cooling. Strong tightening of the oil seal leads to dry friction, as a result of which the durability of the bushing decreases, and if strong local heating occurs, it can be destroyed.

Do I need to reduce power?

In modern models of gas boilers equipped with highly sensitive automation, there is no need to independently reduce power indicators. In equipment of earlier production and the simplest units, similar measures are carried out:

- in case of alteration of the heating system with a significant decrease in the level of overall performance;

- in case of refusal of certain additional functionality, including dismantling the hot water supply system and “warm floors”.

If there are significant differences in the received and minimum power indicators, the equipment “clocks”, accompanied by constant turning on and off of the boiler. In this case, accelerated wear of working components such as the burner, three-way valve and pumping device is observed. In order to prevent boiler failure, it is necessary to reduce the power indicators in one of the available ways:

- replacement of the burner device with a modulating analogue;

- reducing fuel supply by changing valve settings;

- reducing power through service menu settings;

- regulating the functioning of the circulation pump.

In order to reduce fuel consumption, a thermostat is installed to ensure more accurate operation of the equipment, and weather-dependent automation devices are installed. A necessary condition for maintaining the high quality of operation of a gas boiler is proper maintenance of the unit, as well as increasing thermal efficiency by insulating the premises.

How to increase and how to reduce the power of a gas boiler?

Each buyer, when choosing a gas boiler, must clearly know what power unit is suitable for his house or apartment. But it happens that the owner made a mistake in calculating the performance or the conditions changed during the operation of the unit: a boiler was connected, the heating area was increased due to an extension, the heating system was changed, etc.

- 1 How to increase the power of a gas boiler?

- 2 How to reduce power?

How to increase the power of a gas boiler?

It happens that the power of the existing gas boiler is not enough to meet all the needs placed on it. Often an increase in unit performance is required in the following cases:

- when re-equipping the heating system in order to increase its power, for example, adding the number of sections;

- when connecting an indirect heating boiler, heating of which will require about 20% of the unit’s performance;

- increasing the heated area due to extensions or adding previously unheated rooms.

There are different ways to increase the power of a gas boiler. The most reliable and optimal option is to call a service center specialist who can make settings and adjust the power of the unit so that it meets new needs.

It is worth noting that methods for increasing productivity may differ for different boiler models. If the unit has a modulating burner and the required indicator is within its power range, then you can simply adjust the burner device to the required performance.