Home / Ceiling design / Design solutions / Using decking boards in the bathroom

Bored by many, tiles and porcelain stoneware are now used most often in bathrooms. However, there are other coatings that can be used here for decoration. One way to create a unique design in the bathroom is with decking. It is rarely used to decorate the interior spaces of a house or apartment, but the unusual solution and properties of the material will allow you to get a very beautiful and completely unique interior.

Deck board platform

Compared to a deck made from a regular floorboard, a larch deck board for a terrace will have the following advantages:

- better insulation - the material retains heat and absorbs noise;

- lasts longer under conditions of changing humidity and temperature levels. For example, a deck board in a bathroom will not lose its appearance for several decades;

- much more resistant to moisture. Regular cleaning, direct contact with water, frequent precipitation - these are exactly the conditions for which deck boards are created;

- less susceptible to rotting and corrosion, which means it will not require additional costs during operation.

Taking into account the above points, ordinary floorboards are used indoors, and deck boards are used in open areas, for example, when arranging a balcony, terrace, porch, or in places where a high level of humidity is expected - for a bathroom, when arranging a private pier, swimming pool, sauna.

Polymer decking

WPC is a wood-polymer composite that can last you up to fifty years. At the same time, it does not have the main disadvantages characteristic of real wood: polymers will not fade, they are also not afraid of water, and it is much more difficult to damage durable parts than wooden ones. At the same time, such parts do not pose any health hazard - there is no release of harmful components.

The main drawback for many is its unprepossessing appearance. Still, this is not natural wood and this fact is very noticeable. If the cost of the material is comparable to inexpensive types of wood, then the appearance cannot be compared at all. The coating looks like boards, painted evenly and nothing more.

Deck board in the apartment

The wooden floor in the apartment provides coziness and comfort, and the interior of such apartments is original. For finishing, parquet, tongue and groove, engineered or deck boards are used, depending on the purpose of the room.

Deck boards in an apartment have a number of advantages compared to other types of finishing. It is easy to install, especially in comparison with parquet boards. No preliminary preparation is required for laying deck boards; the floor can be laid directly on metal, concrete, or wooden bases. The main thing is that they are even. In addition, a deck board in an apartment is a smart investment.

The natural protection of this material from rotting, corrosion, rodents and insects will allow you to enjoy the impeccable appearance of the room for decades without additional costs.

Tree

If you choose natural wood, you won't go wrong. The pattern on the floor surface will be very beautiful and, no less important, absolutely unique. In addition, by choosing a really expensive tree, you will get a coating that can last a very long time - species such as teak, merbau or rosewood can last up to a hundred years. Hardwood floors last less, but still for a very long time - up to twenty-five years.

The disadvantages of natural coating always include its high cost. However, even artificial decking cannot be cheap. Much more important is the fact that wood requires constant care. Wood can dry out, change its color when exposed to ultraviolet radiation, and wear out from mechanical stress. To avoid such consequences. The floors will have to be treated with a special impregnation or oil, and on the reverse side, before installation, all wooden elements are treated with antiseptic mixtures. The outside of the planks is coated with varnish to protect them from water.

Bathroom Deck Board

The most common order our specialists receive is deck boards for the bathroom. This is a great alternative to tiles because decking in the bathroom will not require artificial heating and will create a pleasant woody smell in the room.

As for appearance, wooden flooring has a number of undeniable advantages; it is not without reason that this material is used for finishing saunas, swimming pools and yachts. Of course, natural materials cannot be cheap. Prices for this material cannot be low, but our company can guarantee the best price/quality ratio and delivery without prepayment on the day of order.

Is it possible to use WPC boards for interior decoration?

Modern design often dictates its own rules of the game to manufacturers of building and finishing materials. This is how textured plasters, liquid wallpaper appeared, even WPC decking is sometimes called “liquid” wood and sometimes misleads buyers with this linguistic paradox.

Materials that were previously used only in interior decoration now have cousins specifically designed for outdoor use. And vice versa: many materials that could previously be seen strictly on the street have moved inside the home.

But if brick, natural stone, raw metal, concrete and gypsum garden sculptures in the house no longer raise questions, then with WPC terrace and facade boards everything is a little more complicated.

Is deck board suitable for finishing the floor in a house?

This question can be found on construction and renovation forums. The arguments for using WPC decking boards are its durability, beautiful appearance, and resistance to water. However, we dare to note that these arguments are not given by specialists or manufacturers of decking boards.

What will be the arguments against?

First of all, the composite board was developed specifically for street use. This means that the material was tested under appropriate conditions, its characteristics were refined, and sometimes the proportions of the composition were changed. All so that the WPC can withstand aggressive outdoor conditions, temperature changes, rain, and bright sun. And at the same time it remained safe, environmentally friendly, and fully recyclable.

There are no such cataclysms at home, some might say, so there is nothing to worry about.

But besides the material itself, there is also a technical side: fastening the decking board and its operation. For better results, manufacturers recommend making gaps between the boards, and raising the flooring itself from the base by at least 5-7 cm to ensure thermal expansion and air circulation. This is how natural ventilation of the deck board occurs, due to which excess moisture under the terrace evaporates.

There are also differences inside the house, for example in humidity. In summer it is slightly higher, and in winter, when the heating is on, the humidity drops sharply. The deck board may not respond adequately to these changes if you lay it too tightly. Lack of space for expansion causes board distortions.

Another important feature is the pattern of the decking board: the comb or grain of the wood. When used in the garden, both patterns perform best. The coating is non-slip (even when wet), easy to clean with water under pressure, and all particles of dirt and dust flow off the terrace. When used at home, dust can accumulate in the comb, and if you do not have a powerful enough vacuum cleaner, cleaning can become extremely unpleasant.

Is façade board suitable for finishing walls in a house?

Accent walls as a design technique have appeared quite a long time ago. Almost any wall can become an accent wall, but most often it is the wall opposite the door. This is how one of the principles of design and decor is fulfilled - “go for the beautiful,” that is, immediately attract the attention of those entering.

Placing accents using finishing materials is always an interesting solution. But the question arises: how safe is it to use “outdoor” materials for interior wall decoration in a house?

From a safety point of view, we can say the following: façade boards made of WPC can be used as a decorative material to highlight zones in a room. Unlike a decking board, the “facade” is not functional, that is, it simply hangs on the wall for beauty. But in the opinion of manufacturers, such decor may look rude. Even in loft or industrial style, wooden beams or planks are most often used.

Again, let us remind you that WPC façade boards were developed specifically for street use. It protects the wall structure from moisture, retains heat, and prevents mold due to ventilation. It is these qualities that make composite facade boards ideal for constructing ventilated facade systems.

And if you decide to decorate the walls inside the house with it, you must understand that you are paying for functions that you will not use.

Use construction and finishing materials for their intended purpose and do not believe everything that users say on the Internet. It’s better to ask questions to specialists - representatives of manufacturers of terrace and facade boards made of WPC.

Deck fence

Another unexpected modern solution for a country house could be a fence made from deck boards. Different types of wood can be used to make deck boards, the most popular of which are larch and pine. At the request of the client, the board can be made of valuable wood. If independently calculating and ordering the required quantity of deck boards causes difficulties, our managers will always provide the necessary advice and make recommendations. You can contact the company either through the form on the website or by phone.

Installation of plastic decking boards

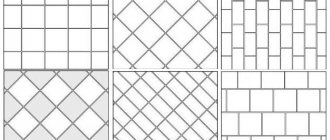

Installation of a plastic decking board (as well as a wooden one) consists of preparing the base, then begin to fix the planks with self-tapping screws into pre-drilled holes with a countersink on one side, and fix the other side of the plank with hidden fasteners in the groove connection. Attach a terrace board to each joist without gaps. Assembly is carried out according to the tongue-and-groove pattern - the protrusion of the long end part of the plank is inserted into a similar groove of the adjacent plank, then the fixation is repeated with a hidden screw. The last plank is attached on both sides, like the first.

According to a simplified scheme, it is even faster to assemble terrace boards (only with self-tapping screws without hidden fasteners), and this option is possible for any premises with a constant environment (humidity, temperature). Self-tapping screws with a countersink head are recessed flush, leaving the fastening area clean and unnoticeable. The base for decking can be made from wooden elements (joists), from a light metal frame using rubber seals, and combined options are also possible.

The planks are laid like regular tongue and groove boards, even easier thanks to the ideal geometry of the tongue-and-groove joints. Preparing the base for the decking board is somewhat more difficult - this base must be level and stable. The most popular way to prepare and level the floor is to install joists on which the deck boards will be laid. When installing lags, gaps from the walls are left of approximately 20-30 mm based on compensatory extensions; the interval between lags is within 350-450 mm. The deck boards are mounted across the joists and usually along their length, and the direction of the joists is selected from this calculation.

Base waterproofing

At the preparatory stage, you need to prepare the surface. The room is cleared of construction debris, all cracks and cracks are sealed with special mastic, and the wood is impregnated with an antiseptic.

To ensure effective adhesion of waterproofing materials to a wooden coating, a primer is performed, followed by drying. Vulnerable areas at joints and corners are sealed with insulating tape for additional protection.

Using roll materials

To insulate floors from moisture, the following are used:

- Tol. A special type of cardboard impregnated with tar or a liquid composition based on coal. Indoors, options without sprinkling are used. Placed on the floor using tar mastic.

- Ruberoid. Roofing material with bitumen impregnation. A surface layer of sand, asbestos or talc protects against sticking.

- Isoplast. Made from fiberglass or polyester. Impregnated with bitumen. Waterproofing characteristics are enhanced by polymer additives.

- Mostoplast. The canvas is made from modified bitumen material. Protection against moisture is provided by the presence of polymers in the composition.

Procedure for laying self-adhesive polymer roll waterproofing:

- A layer of bitumen-emulsion primer is applied to the cement-sand screed.

- After the impregnation has dried, a waterproofing membrane is laid out on the surface. Marking in progress. The material cut to size should rest for some time.

- The roll is rolled up on both sides and the protective film is cut. Gradually exposing the self-adhesive base, installation is carried out. A roller is used to remove waves and air bubbles.

- The side overlap should be at least 10 cm, at the ends - from 15 cm or more. These areas are impregnated with bitumen mastic or primer. After similar treatment, the material is applied to the walls by 20 cm.

Coating technology

Liquid waterproofing compounds are thoroughly mixed before use and applied to the prepared surface. Vulnerable areas at corners, abutments and joints are sealed with insulating tape, and a second layer of coating is applied on top.

For floors in wooden buildings, the following types of mastics are used as a waterproofing material:

- Bitumen-polymer. It is made on the basis of plasticizers, organic solvents and latex filler. Does not require heating before use. Characterized by increased plasticity.

- Bituminous. When cold, it is suitable for all substrates, with the exception of concrete surfaces. When heated, it gains versatility.

- Acrylic. Has no smell. The material is highly durable, plastic and environmentally friendly.

Teak flooring in the bathroom, ready-made solutions

Several manufacturers can install teak in the bathroom. The finished parquet already has an insert of black sealant and is coated with oil - all that remains is to lay it.

Teak in the bathroom Komodoor (Indonesia)

Teak parquet for wet rooms from Komodoor has a water joint filled with a special sealant for deck installation Sika. Select variety, thickness 12, 15 mm. The parquet is oiled and is completely ready for installation and use.

PROMOTION

| Dimensions: Finish: Connection: | 15x90 x500/700/900 mm oil tongue and groove | 12x90 x500/700/900 mm oil tongue and groove |

| Price: | from 13,000 rub. | from 11000 rub. |

This parquet has a standard thickness of 12 and 15 mm and a fixed length of planks from 500 mm to 900 mm, which can be chosen, which distinguishes it from its competitors. All other things being equal, teak with sealant from Komodor is a worthy offer for bathrooms.

Deck teak MarQuise (Belgium)

PARQUET BELGIUM teak deck for bathrooms: Teak Java ShipDeck Sika MarQuise. The parquet is oiled and is completely ready for installation and use. The hydraulic joint is filled with Sika sealant.

| Dimensions: Finish: Connection: | 12x70 x300-1200 mm oil tongue and groove |

| Price: | 11000 rub |

Deck teak with MarQuise sealant is perfect for wet areas - bathrooms, washrooms, swimming pools, as well as for any other residential premises.

Teak for bathrooms Navylam (France)

The difference between this parquet is its thickness - 9 mm, which, accordingly, has a pleasant effect on the price (for parquet from France). Navylam parquet (Navilam) has a rubberized insert that fits onto a tenon. This, in turn, increases the waterproofness of the laid floors. Navylam teak is oiled and ready to install.

| Dimensions: Finish: Connection: | 9x68/88x300-1200 mm oil tongue and groove | |

| Price: | from 14400/14600 rub |

Teak for bathrooms Ital Parchetti (Italy)

Ital Parchetti SRL is a unique system for easy and quick installation of parquet floors in bathrooms. The 12 mm thick parquet planks are oiled and have a double integrated joint; they do not require sanding or additional coating. Installation method: gluing to the base. Thus, you get a finished, oil-coated, moisture-resistant floor.

| Dimensions: Finish: Connection: | 12x90x300-1200 mm oil tongue and groove |

| Price: | from 12,000 rub. |

Tenon and groove with an integrated special polyurethane sealing strip with an anti-slip effect, resistant to weathering, ultraviolet radiation, and salt water.

Teak for bathrooms Panaget (France)

| Dimensions: Finish: Connection: | 12x90x300-1300 mm oil tongue and groove |

| Price: | from 18900 rub. |

How to make a floor yourself

Every homeowner can, without outside help, make a high-quality and durable floor in the bathroom of a wooden structure. To do this, you need to carefully study the instructions and follow the recommendations.

Laying tiles

By observing the technological requirements when installing the finishing cladding, you can extend the service life of wooden structures and maintain the performance characteristics of the floor covering. Features of laying tiles:

- Due to the light weight of the finishing material, there is no large pressure on the ceiling. The reason is the low density of ceramics.

- It is necessary to make a reliable base under the tiles. It is recommended to reduce the distance between the beams, select their dimensions, the thickness of the flooring and the method of leveling the surface.

- It is allowed to lay a subfloor made of cheap wood. You must first check the material for defects.

- A prerequisite is effective ventilation of the wooden covering. This will eliminate the causes of mold and fungal growths in a damp bathroom.

- To increase the stability and reliability of the base, you need to carefully secure all the components of the subfloor. A similar requirement applies to the leveling material.

At the preparatory stage, it is necessary to form a stationary and durable surface for the tile. To do this, a screed is performed.

Deformation when pouring concrete mortar can be prevented by making a gap around the perimeter of the bathroom. A damper tape is attached to the lower sections of the walls. After this, the cement-sand mixture is poured.

The tiles are laid on a wet layer of concrete. An alternative option is to wait for the screed to dry completely and lay the tiles with a special tile adhesive.

Working with linoleum

Procedure for laying linoleum:

- The wooden frame is impregnated with antiseptics. This will preserve the structure in the absence of ventilation.

- The base is leveled with chipboard or OSB boards fastened with self-tapping screws. Control of the horizontal surface is carried out with a laser level or spirit level.

- Linoleum is brought into the room and cut to size. The canvas should be left unrolled for 24 hours to acclimatize.

- Special glue is used to fix it to the base.

Thanks to the variety of colors, you can create bathroom floors with any design.

Using laminate

When laying, builders advise adhering to the following rules:

- Installing lamellas offset in half a sheet reduces the load on the base floor.

- Laminated boards are fastened with hardware. Additional fixation with adhesive increases the stability of the coating.

- Centimeter gaps between individual elements are left to expand when heated. This allows the material to “breathe”.

Under the laminate floor panels, a backing made of cork, polyethylene foam or polystyrene is laid. It levels the subfloor, absorbs noise, evenly distributes the load between the slats, protects against moisture and deformation, and insulates the coating.

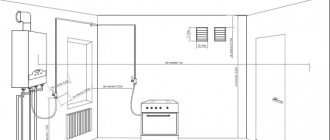

Application of "warm floor" technology

For a wash room in a wooden building, it is recommended to install a heated floor system. You can hide communication pipes and wires under it. The design, based on infrared film, does not require a concrete screed.

In addition to creating a comfortable temperature regime, electric heating of the floor covering in the bathroom serves to remove dripping moisture and dry the room.

Any facing material can be laid on the top layer, which represents the finishing. The only condition is that it must have good thermal conductivity. Otherwise, more energy will be spent on heating.

Some tips

To make a high-quality floor in a wooden house, you should consider a few tips:

- For new construction and the use of ceramic tiles, it is rational to design in wet rooms floors on metal beams with subsequent pouring of monolithic reinforced concrete. This design will allow you to lay screed and tiles without fear.

- If there is no desire to use metal or during major renovations in the house, it is recommended to reduce the pitch of the floor beams. In the room where the ceramics will be laid, load-bearing beams are laid more often, which reduces the load on each of them.

Lining for covering

Most of the lining in saunas and other types of steam rooms is made of larch.

But, since raw boards need to be carefully treated with special chemicals, the cost of such a natural pleasure is also significant, although not as high as that of teak.

Also interesting: Step-by-step instructions: how to make a shower stall from tiles

Preparatory work

Once you have decided on the wood, you should start preparing the floors. As a rule, they start with high-quality preparation of the foundation. The requirements for it are as follows: it must be sufficiently strong, stable and level.

When using cement, make sure that there are no cracks or irregularities in the base. The filling should be distributed as proportionally as possible to each other so that the weight of the future load does not bend the floors in some places.