An expansion tank is used to balance the autonomous heating system.

Its task is to equalize the volume of coolant heated to high temperatures and maintain a given pressure.

The reliability of performing the functions assigned to this element depends on how correctly its volume is selected.

This parameter is not a constant and depends on specific conditions. Below we will look at how to calculate an expansion tank for a closed heating system.

Operating principle of the expansion tank

The principle of operation of the compensating device is simple; it does not contain any complex technical solutions. However, the slightest error in the calculation can lead to failure of the heating system as a whole.

The internal space of the tank is divided into two parts by an elastic membrane. The upper cavity is called the air cavity - air is pumped into it. The purpose of this operation is to create an initial pressure in the container. Water from the system is supplied to the lower cavity. As soon as the membrane takes a stable position - it lies on the surface of the liquid, the system can be considered ready for operation.

Operating principle of a closed expansion tank

The heated coolant expands, and its excess enters the tank, displacing the membrane towards the air chamber. As soon as the water begins to cool, the membrane returns to its original position under air pressure, thereby maintaining the set pressure in the heating system.

An expansion tank that is too large is not able to create the required pressure in the system. The insufficient capacity of the compensating device will not allow it to accept all the excess expanded water.

Therefore, it is so important to correctly calculate the optimal volume of this important element of an autonomous heating system.

In the heating system, an expansion tank for heating must be installed without fail. Why this is needed, read on the website.

The heating diagram for a two-story house is presented here. What is the fundamental difference from the heating system of a two-story house?

Methods for bleeding air from a heating system are described in this review.

Equipment and principle of operation

The expansion tank, in addition to the housing, includes a membrane (cylinder or diaphragm), the upper part of which is filled with inert gas or air. The lower compartment of the sealed container is intended for coolant.

Along with an increase in temperature, the water expands, and the excess mass of the coolant enters the membrane. The volume of the chamber with air decreases, and the pressure in this part of the closed system increases, compensating for the pressure in the line. When the coolant temperature decreases, the reverse process is observed.

The membrane in the tank is pressed tightly against the inner wall, since its entire volume is filled with gas.

When water gets inside, the pressure increases. At the moment the heating starts, there is a risk of damage to the diaphragm from a pressure surge, and then the pressure gauge gradually changes the readings and the integrity of the part is out of danger.

To avoid damage to the membrane, it is necessary to install a pressure gauge safety valve that reacts to increased pressure (for private houses the norm is from 3.5 to 4 bar).

Advantages of the flange model

The advantages of flanged devices include the following characteristics:

- withstands greater pressure inside the system than a device with a constant diaphragm;

- it is possible to replace the membrane if it is damaged;

- horizontal and vertical installation of the device.

Guide values for water content in heating systems

To determine the volume of the expansion tank, you need to know how much coolant fits in the heating system. This parameter is equal to the sum of the volumes of the boiler, pipelines and heating devices.

Approximately per 1 kW of system power there is:

- 7 liters – when used in a convector system;

- 10.5 liters - if radiators are installed as heating devices.

The presence of heated floors requires a coolant volume of 17 l/kW.

Calculating the capacity of a heating system is quite complex; only specialists can do it. A consumer who does not have engineering knowledge can use the approximate relationship - 1 kW of boiler power = 15 liters of coolant volume.

For example, with a boiler power of 25 kW, the volume of water in the system will be:

25 x 15 = 375 (liters).

Installation

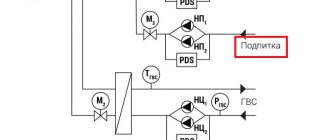

Installation diagram of a tank in a private house system

If you are confident in the calculations and your own abilities, the tank and all materials have been purchased, then you can install the container yourself.

Tools you will need:

- Step and adjustable wrenches;

- Soldering device for plastic pipes;

- Wrench for installing plastic pipes;

- In some cases, a welding machine and an angle grinder are needed.

Before installation, you need to turn off the power to the boiler, turn off the valves and drain the coolant if it is already in the pipes.

The installation is carried out taking into account certain rules.

- The tank must be mounted and installed so that it can be easily approached for adjustment and maintenance.

- The room temperature should not be below 0.

- A pre-shut-off valve must be installed on the supply pipe, which will allow the expander to be removed for maintenance and repair.

After installing the tank, you need to start the entire heating system. If boiling is detected in it, then the reason lies in the incorrectly selected pipe diameter. It's not about the tank. The installation of the expansion tank is described in the following video:

Expansion tank volume

The choice of expansion tank size depends on three main parameters:

- the volume of coolant in the system - the larger it is, the larger the dimensions of the tank should be;

- coolant temperature - the higher the heating, the greater the capacity of the expansion tank should be;

- pressure in the system - the higher its permissible value, the smaller the volume of the tank should be.

In other words, the volume of the expansion tank is directly dependent on the amount of coolant and its temperature, and inversely dependent on the pressure in the heating system.

With bottom or top position

There are three options for connecting a storage tank and using the water supply:

- Top location of the container. In this case, water is drawn under the influence of gravity. The higher the accumulator is located in relation to the consumer, the stronger the water pressure. Every 10 meters of height adds 0.1 atmosphere, or approximately 1 bar.

- Bottom location of a simple storage tank. Gravity will no longer help, and a pump is used to supply it to the water supply system, raising the pressure to the optimal level.

- Membrane-type storage tanks themselves create the required pressure for water supply. A lower location at the consumer level is optimal for them, since there will be no advantage from installing in an attic or tower.

How to determine the best option?

If a house has several floors and it is possible to place a storage tank in the attic, then this will eliminate the need for additional installation of a pump, and there is no need to spend money on an expensive membrane tank. In fact, this is an analogue of a water tower. However, raise the container so high as to ensure a comfortable pressure of 2-2.5 atm. it's still difficult. Moreover, the question arises of insulating the tank so that the water in it does not freeze in winter.

In the event of an emergency shutdown of water, the existing pressure is 0.2-0.3 atm. It will be quite enough to use the faucet in the sink, toilet or even shower, but it will not be possible to use some household appliances, such as a washing machine or dishwasher, which require more pressure to operate the solenoid valves.

Installing the tank at the same level as the consumer is suitable in cases where it is not possible to raise the tank to the attic or at least to a higher floor. The same applies to installing a storage tank in an apartment. You will need a small pump to supply water under pressure to the water supply. To ensure adequate operation, the pump will require a diaphragm expansion tank.

A storage tank with a membrane is perfect for storing water reserves both when using a centralized water supply system and in an autonomous system. However, it does not require additional equipment or overhead location. However, its cost is significantly higher than any conventional storage tank, even in combination with a simple pump.

Coefficient of increase in volume of water/water-glycol mixture depending on temperature

As is known from the laws of physics, all liquids expand when heated (as, indeed, do any bodies). This fact must be taken into account when calculating the volume of the expansion tank.

Water increases in volume when heated to 950C by 4%. This statement is quite accurate, so it can be used in calculations without fear.

If a water-glycol mixture is used as a coolant, the picture changes somewhat, depending on the ethylene glycol content.

Expansion tank in the heating system

In this case, the expansion coefficient of the working fluid is determined as follows:

- 4% x 1.1 = 4.4% - with an ethylene glycol content of 10% of the total coolant volume;

- 4% x 1.2 = 4.8% - if the volume of ethylene glycol in the mixture is 20%, etc.

The above values will vary depending on the temperature to which the coolant is heated. For example, at 80 degrees the coefficient of expansion of water will be 0.0290. If 10 percent of its volume is replaced with ethylene glycol, the coefficient will be equal to 0.0320. A mixture of glycol half and half with water (50%) is characterized by an expansion coefficient of 0.0436.

Useful tips when choosing

When purchasing and installing an expander, there are several nuances to consider.

- When choosing a location for installing the tank, it is necessary to take into account that it cannot be installed immediately behind the circulation pump.

- Commercially available tanks come in two colors: red and blue. In the first, the membrane is stronger, but made of technical rubber. Blue tanks are used for water supply; they contain food-grade rubber, but it is less strong and durable.

- When installing, you need to use a special sealant.

- If you decide to go with an open system, then the tank must be placed at the highest point, and when installing the pipeline, the recommended slope must be observed.

- The size of the tank should not be less than the calculated value; a slightly larger volume is allowed. When using forced circulation, the capacity cannot be less than 15 liters.

- Antifreeze can act as a coolant. For a glycol mixture, it is better to choose an expansion tank whose volume is twice as large as the calculated one.

The main advice is to contact professionals, because installing a tank only seems simple. In addition, you cannot do without a special tool.

Calculation of the volume of the expansion tank for heating

The basic formula by which you can calculate the required volume of the expansion tank looks like this:

V = (VL x E) / D , where

VL is the total capacity of the heating system, which includes the volume of the boiler, all heat accumulators (convectors, radiators, etc.) and the pipeline;

- E – coefficient of expansion of the working fluid (coolant);

- D – efficiency of the expansion tank (membrane).

The last parameter depends on two quantities - pressure:

- PV — maximum worker in the system;

- PS - charging the membrane tank.

For cottages, PV = 2.5 bar is considered sufficient.

PS must be equal to the static pressure of the heating system and is taken as 0.5 bar = 5 m.

Heating with natural circulation is used less and less due to the obvious disadvantages of this system. A closed heating system with forced circulation has a number of advantages.

You can see the installation diagram of the circulation pump in the heating system below.

Calculation example

As an example, consider the heating system of a cottage with an area of 300 square meters. m. to provide autonomous heating, a 30 kW boiler was installed. In addition, a heat accumulator with a volume of 1000 liters is used. The height of the system is 5 meters.

First, let's calculate the total volume of coolant:

VL = 30 x 15 + 1000 = 1450 (liters) , where

- 30 – boiler power, kW;

- 15 – specific volume of coolant per 1 kW of boiler power, liters;

- 1000 is the volume of the storage tank.

Next, we move on to calculating the efficiency of the membrane tank:

D = (PV – PS) / (PV + 1)

In our example:

- PV = 2.5 bar;

- PS = 0.5 bar.

Therefore, D = (2.5 – 0.5) / (2.5 + 1) = 0.57

Now you can determine the volume of the tank:

V = 1450 x 0.04 / 0.57 = 101.75 (liters), where

0.04 – coefficient of expansion of the coolant (in our case it is water without adding glycol).

Manufacturers produce expansion tanks of a certain size range, so it is not always possible to buy a container whose volume is equal to the calculated one. In such cases, the calculation result must be rounded up. In our case, the nearest standard value will be 110 liters. This is the kind of tank you should buy.

Useful tips

It should be remembered that installing an expansion tank in a heating system involves selecting, purchasing and installing a model with a red body. Models painted blue are designed for cold water supply. Structurally, the expanders do not differ from each other, but the red ones are designed for prolonged high-temperature exposure. Despite the generally accepted practice of using a circulation pump only for closed systems, the presence of a pumping unit does not change the state of the system. That is, if you install a circulation pump on a heating system with an open tank, it will not become closed. It’s just that in open systems there is most often no need for such units. The boiling of the coolant in the heating system has nothing to do with the operation of the expander

Most likely, you should reconsider the slope of horizontal pipelines and the diameters of the pipes used. It is not recommended to install the expander in close proximity to the pump due to possible pressure drop. During installation, only special heat-resistant sealants should be used. When installing the expander, take into account the need for its maintenance and possible repairs and ensure free access to the unit. Some boiler models are already equipped with expansion tanks and then there is no need to purchase one additionally.

Recommendations from experts

A closed expansion tank does not have to be installed at the highest point of the system.

The main advantage of membrane expansion joints lies precisely in the possibility of placing it in the place most convenient for installation and operation.

Small tanks with a volume of 20-25 liters are usually installed in systems with a circulation pump whose power is 1.2 kW. Increasing the capacity to 20-60 liters will lead to an increase in pump power to 2.0 kW.

There are compensating devices with a volume of 100-200 liters on sale. In addition to their direct purpose, they can play the role of a storage tank for warm water. True, they can be used in this way only if the main source of hot water is turned off for a short period of time.

The standard sizes of expansion tanks cover a fairly wide range. Among them there are models with dimensions so large that standard doorways do not allow them to be brought inside the room. In such a situation, it is better to replace one huge container with several small ones. The main thing is that their total volume is equal to the calculated one.

Open type containers

These tanks are used for an open heating system (otherwise known as gravity, gravity) and are a metal tank with an open top of any shape. A pipe for connecting a hose or overflow pipe is welded to the upper part of the side wall; the coolant is supplied to the tank from below. The element is installed above the entire system on the supply pipeline, usually in the attic of the house.

Any expansion tank for open type heating performs 2 functions:

- serves to compensate for the expansion of the coolant;

- removes air from the system, since its top communicates with the atmosphere.

This is its advantage, but it is not the only one. An open container can also successfully and durablely serve in systems with forced circulation, since the design of the tank is very simple, there is nothing to break. However, it also has many disadvantages:

- a tank installed in the attic requires good insulation;

- During the season, it is necessary to constantly monitor the water level in the tank and replenish it in a timely manner;

- the coolant is constantly saturated with oxygen from the atmosphere, which is why the metal parts of the boiler corrode faster;

- additional consumption of materials and difficulties during installation.

How to calculate the volume of a cylinder

- First you need to choose through which initial quantities the calculations will be made. In order to find the volume of a cylinder, you need to know its height, as well as its radius, diameter or base area. Each method uses its own formula.

- Next, you need to enter the initial values and units of measurement of the initial values.

- The result will be rounded to the specified decimal place.

- The volume of a cylinder can be expressed in mm3, cm3, dm3, m3 and liters.

- The “calculate” button performs calculations according to the specified condition.

General connection rules

A water tank is installed on a prepared site: a concrete base tied to the foundation, or a reinforced metal frame made of profiled pipe. The design must withstand one and a half weight of the tank and the water in it when completely filled.

The inlet pipe can be of any suitable diameter, water is supplied under pressure. The outlet pipe and pipe to the water supply system are chosen with a diameter one and a half to two times larger than the cross-section of the main line. The optimal size is 32 mm.

Even the best quality insulation only slows down the decrease in temperature in the tank. To prevent water from freezing when installing the tank in an unheated attic or on the roof, you should use any suitable heating system for the pipes and the tank itself.