Having decided to install a heated floor in an apartment or house, and having given preference to an electric device rather than a water one, you need to understand that in addition to installation costs, you will have constant costs for paying for electricity. Therefore, you need to calculate in advance how much electricity the warm floor will consume.

The article presents the characteristics of all models of electric floors, their advantages and disadvantages, as well as a comparative analysis of power consumption by each type.

In addition, we have tried to collect here all the advice from professionals that will help reduce the costs of operating these systems and save the family budget.

Classification of heating types

There are several types of electric floor depending on the heating elements from which it is made.

The energy consumption of such floors varies quantitatively. The owner of the premises must understand the exact calculation for each project, because if the heaters are installed or selected incorrectly, a large waste of electricity is possible. Classification of heated floors:

- heating film located under the laminate or linoleum;

- an electrical cable that must be pulled in a tie;

- thermomat is a special heating device.

Each type of electric floor has its own characteristics that affect energy consumption. These include, first of all, power.

Each type of heated floor has its own power ratings

Approximate power figures:

- for infrared film - from 0.2 to 0.4 kW/m²;

- electric heating cable - 0.01−0.06 kW/m². Approximately 5 turns fit in 1 square meter (here it is worth considering the size of the laying distance);

- thermomat - up to 0.2 kW/m².

Temperature is the main indicator that quantitatively shows the level of heating. The maximum temperature of the IR floor is +60°C, for the cable floor - +65°C. Usually the operating temperature is set lower - +30...+35°C. This is quite enough to create a comfortable environment.

You can take a closer look at the energy consumption of heated floors in this video:

The higher the resistance, the greater the energy consumption. Basically, the power of a warm electric floor is 0.1−0.2 kW/m². This information is usually indicated on the product box or instructions included with it. The average electricity consumption is 120 W/m². It is also necessary to take into account when calculating what function the heated floor will perform: additional or primary.

The main one is when the electric floor takes on the main function of heating the room. For example, a country house that has no central heating at all. An additional function is performed when the building has a centralized heating system.

Power level

There are only three types of heated floors:

- cable;

- infrared rods;

- infrared film.

Each type has a number of characteristic features that can affect the energy consumption of a heated floor.

Power

May include:

- consumption level of the heating cable itself. The indicator can range from 120 watts to 2,000 watts. The step of laying the system cable will directly depend on this;

- Warm-up temperature is one of the main indicators. The maximum temperature of a film heated floor is 56°C. For the rod one this figure is 60°C. For cable heated floors 65°C. On average, the operating temperature is set to 35°C;

- the higher the resistance coefficient, the higher the flow rate;

- IR systems consume from 65 to 155 W per square meter of surface;

- IR floor consumes 130-170 W per square meter of area;

- The more powerful the floor heating system, the higher the electrical consumption will be.

How can you reduce costs?

Above you saw how much electricity a heated floor consumes. If you make the calculation for all rooms, you will get a decent amount “for light” at the end of the month. Of course, when you pay the first receipt, you will think about how you can reduce consumption and make the heating system economical.

So, here are some tips that will allow you to significantly reduce the electricity consumption of underfloor heating in your home:

- Take care of high-quality insulation of your home. It was experimentally determined that good thermal insulation reduces energy consumption by 35-40%, which is almost half!

- Be sure to install the thermostat on the wall at the coldest point in the room. Thus, the heating will turn on when the temperature drops below the set point and, vice versa, turn off when the room is sufficiently heated. Temperature controllers, as we have already said, can reduce up to 40% of electricity consumption.

- Install a multi-tariff electricity meter in your home, at which the electricity tariff at night is 1.5-2 times lower (depending on the region). All the same, the electric heated floor will work in your presence, and this is just in the evening when you come home from work. So why pay more? We told you about the most important advantages and disadvantages of two-tariff electricity meters, while also providing customer reviews.

- Place material only in the usable area. You should not install it under furniture and household appliances; this is not advisable from the point of view of reducing consumption and, moreover, is prohibited by the manufacturers of heating materials themselves.

- You can sacrifice a little heating by lowering the room temperature by just 1 degree. A small donation can reduce the energy consumption of an electric heated floor by as much as 5%!

That's all I wanted to tell you about this issue. Now you know how much electricity such a heating system consumes, and how to independently reduce the energy consumption of a heated floor!

We recommend studying:

- The most economical and cheap home heating

- How to check the electricity meter

- Warm floor as main heating

Basic definition of power consumption

The main indicator of thermal comfort in a room is temperature, which depends on standard power consumption. The standard temperature for a room is 19-20°C. The basis is the electricity spent on heating the building and enclosing structures. Such a standard showing the current heat energy consumption is today considered too high.

For modern life, rational use of heat has become one of the main tasks. The use of energy-saving technologies and modern equipment that consumes a minimum amount of energy have become extremely popular. New developments in heating systems from various energy sources can reduce kilowatt consumption by 12 percent. Such heating of the room allows owners not only to make their home warm and cozy, but also to save money during their operation.

Electricity consumption largely depends on the main sources, which are gas, coal, peat, solar energy, and electricity. Proper distribution of electrical household appliances and division of underfloor heating systems into individually controlled zones significantly reduces energy consumption.

Comparative analysis of the consumption of heated floors by type

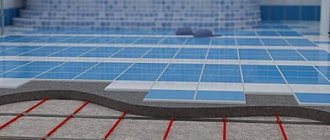

All electric floors use induction heating of the surface, that is, using electric current. Electricity is converted into thermal energy with approximately the same efficiency. The amount of energy consumption of a heated floor is affected by the installation method and the floor covering.

The following factors are of great importance:

Thermal insulation and reflectance of the underlying material; The degree of heat loss in the screed is important for structures installed in the screed. Having analyzed the above, we can summarize that:

Having analyzed the above, we can summarize that:

- The most energy efficient heating devices are those placed directly under the decorative item;

- laying high-quality insulation with a reflective surface and insulating the edges of the screed from the walls will reduce the differences between models in terms of efficiency.

Despite the slight discrepancy in the level of electricity consumption of different types of electric floors, there are still differences. The most significant consumption of the film is 220 W/m2, the degree of maximum heating is +40 degrees.

When installing the cable in a screed - 150 W/m2. Therefore, if the design allows, it is more economical to lay the cable system in a screed. With high-quality thermal insulation, the device will warm up the screed for about 8 hours, and then it will release it to the room.

However, this difference in electric current consumption by different types of systems is not significant when they are installed in small areas. The costs of installing them throughout the apartment differ significantly.

Calculation of energy costs for electric floors depending on the type of room

There are certain standards according to which a device of its own power is recommended for each room:

- in living rooms, kitchen and corridor - up to 120 W per m2;

- in the bathroom - 150 W/m2;

- in the loggia - 200 W/m2.

In addition, the power of the system is influenced by its purpose - whether it will be primary or additional heating.

For example, if a warm floor is the main source of heat in a room with an area of 20 m2, with a usable area of 8 m2, then the heat loss will be equal to 2 kW/hour. Based on these data, the power is calculated:

- heat loss/area = 2/8 = 0.25 kW/m2

If you live in a region with a harsh climate, then it is worth adding 25%.

Electric floor consumption calculation

ETP heating is effective, but too high energy consumption makes it unprofitable. Costs are calculated taking into account the operating mode and type of floor heater, otherwise the data will be unreliable.

To calculate the approximate energy consumption of a heating system, you must start by determining the total power of the heated floor installed in the room (Ptot):

Рtotal = Sob * Рmax;

where: Sob is the heated area of the room, free from furniture; Pmax is the maximum power of the heated floor per 1 m2.

The total power (Ptotal) is initially already indicated by the manufacturer (for example, the power of the Thermo TVK-130 heating mat is 130 W/m2).

Example:

The area of the room is 10 m2, the DEVI heating mat is installed on 6 m2. The maximum power (Pmax) of the installed heated floor is 150 W/m2.

Ptotal = Stotal * Pmax = 6 m2 * 150 W/m2 = 900 W

Type of thermostat used

The power of the heated floor consumed during the day (Pd) depends on the type of thermostat:

- with a mechanical thermostat, heated floors work on average 12 hours a day;

- programmable on average 6 hours a day, thanks to numerous modes for controlling the operation of the heated floor.

Рд = t * Ptot;

where:t is the operating time of the heated floor per day.

Example (for heated floor):

The DEVI heating mat installed indoors has a total power (Ptot) of 900 W.

1) with mechanical thermostat:

Рд = t * Ptot = 12 h * 900 W = 10,800 W = 10.8 kW

2) with programmable thermostat:

Рд = t * Ptot = 6 h * 900 W = 5,400 W = 5.4 kW

To evaluate the result obtained, it is necessary to compare the data of the heated floor with the energy consumption of an average convector. For such heating devices, there are only non-programmable thermostats with an on/off function.

Example (for a convector):

A 1,500 W convector is installed in the room. The device is turned on for an average of 12 hours a day.

Рд = t * Ptot = 12 h * 1,500 W = 18,000 W = 18 kW

The result obtained is 8 kW more than the power consumed by a heated floor with a mechanical thermostat and 12.6 kW more than that with a programmable thermostat.

Let's determine the cost of running a heated floor per month.

The approximate cost of 1 kW in Russia is 3 rubles. The average number of days in a month is 30. Thus:

Cost of underfloor heating per month = Rd * 30 days * 3 rubles

Example (for heated floor):

1) Warm floor with mechanical thermostat: The power consumed by a DEVI heating mat installed in a room reaches 10.8 kW.

Cost of work, etc. per month = Rd * 30 days * 3 rubles = 10.8 kW * 30 days * 3 rubles = 972 rubles

2) Heated floor with programmable thermostat: The power of the heated floor is 4.68 kW.

Cost of work, etc. per month = Рд* 30 days * 3 rubles = 5.4 kW * 30 days * 3 rubles = 486 rubles

Example (for a convector):

The power consumed by the convector per day reaches 18 kW.

Cost of convector operation per month. = Рд* 30 days * 3 rubles = 18 kW * 30 days * 3 rubles = 1,620 rubles

Obviously, to achieve a comfortable temperature in the room, heated floors work more efficiently than convectors. Being a heat storage system, a warm floor retains heat even when turned off (especially in the case of a thick screed).

Factors that reduce energy consumption

As already mentioned, when installing electric heated floors in all rooms of the apartment, the payment costs will be impressive, which will affect your family budget.

However, there are ways to reduce energy consumption:

- Carrying out high-quality insulation - good thermal insulation reduces consumption by 35 - 40%.

- Installing a multifunctional meter - the cost of electricity used at night is about 2 times lower. Moreover, heating mainly works when there are people in the house, and this is usually in the evening and night.

- Installation of heated floors should be carried out in a free area. Laying it under furniture is not only unprofitable, but also prohibited by the system manufacturer.

- Use of finishing coatings with a good degree of thermal conductivity.

- Installing a programmable thermostat, especially in residential areas, will allow you to save a third on energy.

- In sparsely inhabited rooms, not maintaining a high degree of heating is an unnecessary waste of energy.

In addition, if you reduce the heating level by just 1 degree, this will not have much effect on the atmosphere in the room, but the savings will be 5%.

Climatic conditions are also of great importance. The greater the difference between the temperature in the room and outside the window, the power consumption of electricity increases.

Thermostat is an indispensable device for reducing costs

Separately, it should be said about the thermostat - its use can reduce energy consumption by up to 40%. It is recommended to install the device in the coldest place in the room. When the temperature drops below the set value, it will turn on the heating, and when the desired value is reached, it will turn off.

For your information! Most regulators are designed for a voltage of 10 amperes; such a device can withstand a load of no more than 2300 W.

In many ways, electricity consumption is influenced by the type of thermostat, they are:

- mechanical - the design is simple and inexpensive, the daily working time is about 12 hours;

- programmable - equipped with several modes that allow you to control operation; such a device operates only 6 hours a day.

Using an example, we will consider which type of thermostat will be more economical. To do this we use the formula:

Рд = t * Ptot;

t—device operating time;

Ptot—power.

When installing a mat with a voltage of 900 W, and using a mechanical type regulator:

Pd = t * Ptot = 12 h * 900 W = 10,800 W = 10.8 kW

If a software controller is installed, then:

Pd= t * Ptot = 6 h * 900 W = 5,400 W = 5.4 kW

From this calculation it is clear that the use of a programmable controller will significantly reduce your costs.

If the warm floor acts as the main heating in all rooms, then the installation of several regulators will be required, which are connected to one centralized system.

When thinking about installing an electric floor in a house or apartment, you should make all the required calculations, taking into account the maximum load in winter. Only after weighing all the pros and cons, you need to make a decision about installing such a structure.

Energy consumption calculation

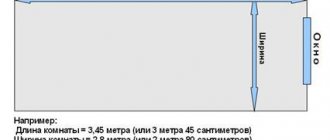

Before you begin calculations and select components, you need to develop a plan of the room in which the heated floor will be installed. It can be drawn on paper or compiled in a computer program.

What you need to know for calculations:

- heated area (recommended 70-80%);

- floor covering characteristics;

- quality of walls and ceilings;

- the ability of the wiring to withstand the load.

It is recommended to do general heating using resistive cables, and for comfort - with heating mats or IR floors.

To determine heating efficiency, use the formula P=S*k, where P is the floor power, S is the area to be heated, K is the specific power.

Power density differs for each room. For living rooms and kitchens on the 1st floor it is 140-150 W/sq.m., on the 2nd floor and above 110-120 W/sq.m.

For balconies and loggias with insulation, the specific power is 140-180 W/sq.m. Bathroom on the 1st floor – 120-150 W/sq.m., on the 2nd floor and above – 110-130 W/sq.m.

Calculation example

The calculation will be made for the bathroom on the top floor, used for the main heating. The total area of the premises is 10 sq.m. The heated area is 10*0.7=7 sq.m. (with an occupied area of 70%). Specific power 180 W/sq.m. Then the resulting value will be 7*180=1260 W. This is the total heat transfer. Calculations are made in a similar way for other premises.

You need to be able to calculate electricity consumption - the amount of monthly payment for electricity directly depends on this value.

The calculation was made for a room with an area of 20 sq.m., a heated capacity of 14 sq.m. and a floor operating time of 6 hours a day. Specific power 150 W/sq.m. Then the electricity consumption is 150*14=2100 W. The monthly rate is 6*2100*30=37800 W/h or 378 kW/h. This value is then multiplied by the regional cost of 1 kW.

Features of calculation of IR structures

When choosing and calculating film floors, you need to take into account a number of features. First of all, they should be laid on a surface free of furniture. Secondly, the minimum distance to the wall or furniture should be 20 cm. Laying only in a “dry” way. It should also be taken into account that installation and calculation depend on all electrical connections located below the surface.

Recommendations for choosing film systems:

- for additional heating, 120-150 W/sq.m. is required;

- for the main one 170-220 W/sq.m.

Calculation algorithm:

- Calculation of heated area.

- Calculation of the share of heated power. You need to multiply the heated area by 100% and divide by the total area of the room. With an indicator of more than 60%, the specific power of the film should be from 160 to 220 W/sq.m. If the share is less than 60%, the specific power is 220 W/sq.m.

- Accounting for large heat losses. If the room is located on the ground floor, above an arch or in an old building without thermal insulation, the power density should be 220 W/sq.m.

- Calculation of installed power. The specific power is multiplied by the heated area.

Based on the calculated data, a suitable IR film is selected. It is better to take in small pieces for proper installation. Each segment must have its own thermostat.

Rod infrared floors can be installed over the entire surface of the room. You need to select additional components and a thermostat. It is better to install wooden and thin coverings using thermostats with two temperature sensors (floor surface and air).

Five ways to cut costs

Whatever the total electric floor power and power consumption, resource costs can always be reduced.

Install the thermostat correctly

It is best to place any type of device in the coldest area. In this case, the heating will turn off only when the entire room is well warmed up, and turn on, accordingly, when there is sufficient cooling. This arrangement of the equipment helps to configure it as accurately as possible.

Heat only the usable area

The heating floor does not need to be laid under bulky furniture and large equipment. Only the usable area should be heated. This is more economical and safer for the system itself, which can fail as a result of overheating.

Install a multi-tariff meter

Its main difference is the different cost of energy during the day and night. If residents gather in the house in the evening and go about their business in the morning, you can save significantly on heating. In this case, in the absence of people, the temperature is maintained at a low level; before their appearance, it rises. At night, a comfortable microclimate is established, while electricity at this time costs much less.

Insulate the building as much as possible

High-quality thermal insulation significantly reduces energy consumption for heating. On average, this figure is reduced by 30-40%, provided that the insulation of windows, doors, walls and ceilings is done correctly.

Try lowering the temperature

The feeling of warmth is very individual, and a slight decrease in its amount is almost unnoticed. Research shows that a drop in room temperature of just one degree is almost negligible. Even if there is slight discomfort, it passes quickly. But at the same time the savings will be 5%.

Source

How to reduce electricity costs when using film

Power selection

For comfortable floor heating in city apartments, a film with a power of 150 W/m2 is sufficient. Film heated floors are installed in places where heating is required.

For basic heating and comfortable floor heating, film heated floors with a power of 220 W/m2 are used, for example, Marpe Normal GSM thermal film. In this case, you should follow the manufacturers' recommendations for installing heating systems on the ground floors, in country houses and balconies using solid carbon films (for example, Marpe Black Heat), which have additional layers of moisture protection. The coverage area is about 70% of the total area of the room.

Insulation of the room

When using infrared heated floors as the main heating in a country house, the ventilation of the room will be of great importance. If all the heat generated is lost through the cracks, the film will work longer to maintain the required temperature and, accordingly, the amount of electricity consumed will be much higher.

To save energy, it is necessary to use insulation materials that reduce heat loss. Double and triple glazed windows, as well as tightly fitted doors, avoid large amounts of heat loss.

Using a thermal insulation layer

When installing infrared heated floors both in country houses and in apartment buildings, it is recommended to use a thermal insulation substrate. It is made of chemically cross-linked solid polyethylene foam with a closed porous structure several millimeters thick and a non-metalized reflective layer. Such a substrate not only protects the film from condensation and short circuits, but also allows you to direct all the heat into the room, excluding heating of the interfloor ceiling, while saving up to 40% of electricity compared to cable heating systems.

To fully heat the room, it is enough to cover about 70% of the floor area of the room. Installing heating elements under furniture and household appliances is not only impractical in terms of energy consumption, but also undesirable due to the possibility of damage to the floor covering or overheating of the film.

Using programmable thermostats

A significant reduction in energy consumption will be ensured by the use of programmable thermostats for each room. This will allow you to regulate the temperature in each room separately depending on the day of the week and time of day.

If non-programmable thermostats are aimed at maintaining a given temperature, turning off heating when the desired value is reached and turning it on when the temperature drops, then programmable ones are able to regulate it depending on time or turn off heating altogether. By reducing the heating temperature by 1 °C, approximately 4% of energy is saved. The use of a programmable thermostat compared to a conventional one provides savings of up to 30% in energy.

By following these recommendations, you can significantly save on energy costs and keep your home warm when using film heated floors.

Still have questions?

Check out our other articles on film heated floors. In them you will find useful tips, reviews and answers to popular questions.

You can also get a free consultation on underfloor heating, help with calculations and selection of necessary components by phone or email.

Here you will learn:

Infrared heated floors have become an excellent alternative to traditional water floors that use coolant energy for heating. They are chosen by many consumers, seeking to obtain an additional source of heat. The energy consumption of film heated floors is a little bit higher, but in comparison with traditional electric heating it is somewhat lower. Specific numbers will be discussed in our review.

How much electricity does a heated floor consume per 1 m2 per hour or month, how to reduce consumption

Having decided to install a heated floor in an apartment or house, and having given preference to an electric device rather than a water one, you need to understand that in addition to installation costs, you will have constant costs for paying for electricity. Therefore, you need to calculate in advance how much electricity the warm floor will consume.

The article presents the characteristics of all models of electric floors, their advantages and disadvantages, as well as a comparative analysis of power consumption by each type.

In addition, we have tried to collect here all the advice from professionals that will help reduce the costs of operating these systems and save the family budget.

Installation

To install an IR film floor, you need to perform a series of sequential steps:

- First of all, it is necessary to develop a project and make all the necessary calculations.

- Get all the necessary materials and tools.

- Install the IR floor.

- Start the system and check operation.

- Carry out a clean finish.

Area calculation

The main distinguishing property of infrared film flooring is that it is not installed under furniture. Therefore, when calculating the amount of material that will be required and choosing the location for placing the film, you need to subtract the area where the film will not be laid.

Calculation of the total area of the room S=a*b Calculation of the heating area Sob=S - (X, Y, Z) where, S - total area of the room, m²; a, b - length and width of the room, m; Sob—heating area, m²; X, Y, Z - fixed or low-cost interior items (furniture, household appliances, etc.). When calculating the heated area, keep in mind that the IR film is laid at a distance of 100 mm or more to any vertical surface.

Once the size of the required area has been identified, the next step is to calculate the power.

| Film power | 150 W/m² | 220 W/m² |

| Main source of heating | At least 95% of the area | At least 70% of the area |

| Additional heating source | At least 60% of the area | At least 40% of the area |

| Flooring type | laminate, linoleum, carpet | parquet, carpet |

Energy consumption calculation

Energy consumption of IR film floor E=S*k*T where, E - energy consumption, W/hour; S—total area of the room, m²; k is the conversion factor (depending on the set temperature; if the system is turned on at 50%, the factor will be equal to 0.56); T is the thermal power of the floor, W. The amount of money spent on infrared floor heating is calculated based on the electricity tariff in your area.

Installing a thermostat can reduce the cost of infrared heated floors by approximately 35%.

Criteria for choosing thermostats for heated floors.

Power calculation

If the area of the room that is planned to be heated with a film floor is very large, several sets of IR film will be needed to install such a system. In such a situation, you need to sum up their power.

Using several sets of IR film Ptot = P1+P2+…+Pi Using part of the set Ptot = 1.10*L

where, Ptotal is the total power of the film floor, W; P1…Pi is the power of a separate set of film, W; L is the length of the infrared film used during installation, m; 1.10 is the conversion factor for the power of the film floor.

Calculation of the number of thermostats

The main purpose of a thermostat for infrared heated floors is to regulate the degree of heating.

If you connect several sets of film flooring at once, then several thermostats are needed at once, since the power consumed by the heated floor is summed up.

It is recommended to install the thermostat at a height of 15-20 cm, above the level of the final coating.

It is better to place the thermostat on a wall that is perpendicular to the direction of the stripes.

There are two connection methods:

- Zoning and connecting each zone to a separate thermostat.

- Connect a solid state relay or magnetic starter. You cannot make such a connection yourself; this requires the knowledge and skills of an electrician.

You can read about cable underfloor heating here.

Computing technology

It should be noted right away that today there are services, such as online calculators and programs for calculating heated floors for individual conditions. Such programs are really very convenient and allow you to immediately determine the exact power of the film coating or heating cable. If for some reason you do not trust computer calculations, we recommend doing everything the old fashioned way - using simple formulas.

So, the formula for calculating electric heated floors is as follows:

P=Pm*Sroom,

Where:

- Pm – the power of the heating material, which you must choose yourself (more on this below), m2;

- Sroom – usable area of the room.

As you can see, the calculation formula is far from complicated, but it contains two unknowns that you must determine yourself. As for the usable area of the room, everything is simple. The heating mat, cable or film should be laid only in places where household appliances and furniture will not be placed. Firstly, this is already prohibited by manufacturers, because... foreign objects on the floor will interfere with heat transfer, causing the material to overheat. Secondly, what is the point of heating the surface where no one will walk? This is a waste of electricity. In the diagram you can see what the usable area of the room looks like for calculating an electric heated floor:

Useful heating area

Calculation of the usable area for laying an electric heated floor is carried out as follows: the width of the surface must be multiplied by the length.

As for the power of the heating material, you must choose it yourself, depending on the type of room. For each room, the power of infrared film or mat will be different, which is obvious - the balcony and corridor need heating more than the bedroom and children's room, which are additionally heated by water radiators.

We provide to your attention the most optimal values for calculating the power of an electric heated floor:

- kitchen: 110-130 W/m2;

- bathroom (WC): 120-150 W/m2;

- balcony: 180 W/m2;

- hallway: 110-120 W/m2;

- corridor: 110-120 W/m2;

- living room 110-130 W/m2;

- bedroom 110-130 W/m2.

Please note that the above values are suitable if the electric underfloor heating will be used as an additional heating system. If you decide to use this option as the main heating system, for each room you need to choose a heating material with a power of 140-180 W/m2

The usable area is known to you, the power parameters have also been selected. All that remains is to substitute the values into the formula and make a general calculation of the electric heated floor by power. To help you understand how to calculate this parameter, we will provide an example for one of the rooms below.

Installation of infrared film heated floor

The thickness of the infrared film allows it to be used with any type of floor covering. It can be mounted on walls and ceilings, creating heating for the entire volume of the room. First of all, you need to draw up a diagram of the location of the heating elements, taking into account the furniture available in the given room.

After this, you need to carefully prepare and level the surface. The differences in the concrete screed should not exceed 1 mm per 2 m.p. To avoid heat loss through the floor slabs, a thermal insulating substrate in the form of foamed polypropylene, 3-4 mm thick with a one-sided foil coating, is laid on the floor. Thermal insulating strips are joined together and fixed using special thermal insulating tape. At the end of laying, the strips are carefully trimmed along the edges along the entire perimeter of the room.

After this, a roll of thermal film is rolled out. Parts of the required length are measured, cut according to the marked marks and laid on the floor according to the drawn up diagram. The incision sites are located approximately 18 cm apart and are marked with dotted lines, next to which scissors are drawn. It is forbidden to cut the film diagonally, as in this case it will become unusable. There must be a gap of at least 10 cm between the heating film and the wall. The strips themselves are laid on a thermal insulating substrate with a gap of 5-10 mm between each other.

In the places of cuts, the conductive busbars remain open; strips of bitumen insulation, which is included in the heated floor kit, are glued to them. The contact is inserted exactly in the center at the end of the conductive busbar and tightly fixed with pliers. A current-carrying wire is clamped into the contact terminal, the end of which is stripped to 5-10 mm. After this, the joint is completely covered with bitumen insulation.

Sections of infrared heated floors, cut in the form of strips, are connected in parallel using stranded copper wires with a cross-section of at least 1.5 mm2. Automatic operation of the thermostat at the right time is ensured by a temperature sensor.

The temperature sensor is installed near the wall where the thermostat is planned to be installed, at a distance of approximately 20-25 cm from the edge. A groove is made in the floor using a hammer drill, where the sensor is placed. After that, it is covered with infrared film on top. To display the true floor temperature, the sensor must be placed on top of an insulating substrate.

Next, a thermostat is installed and connected to the prepared location. After this, the functionality of the installed heated floors is checked. After switching on, all connected thermal films should heat up. After making sure that the system is in working condition, you can begin laying the final floor covering. Correct assembly of the entire structure guarantees a significant reduction in heat losses and significant savings in electrical energy.

Infrared heated floor

Infrared film for heated floors

Installation of infrared heated floor

How much electricity does a heated floor consume?

Infrared heated floor under laminate

Warm floor on the balcony

How can you reduce your energy consumption?

So how much energy does underfloor heating consume? And is it possible to legally reduce the existing indicator? There are only two such methods. You can install high-quality thermal insulation in the selected room or use denser (warmer) floor coverings. You can install a similar system under laminate, but it does not belong to the category of warm coatings. Such actions can reduce the electrical energy consumption of a heated floor by a third. Tile material can be used on any type of coating. It undeniably has a high thermal conductivity coefficient, which will lead to significant savings.

The heated floor switches off from time to time

The surface of the tile and floor is treated with glue, after which it is placed on the surface, observing the selected geometry of the pattern. Grouting is carried out only after the material has completely dried. If there is poor quality glue, an additional layer of primer is required. But the main way today is to use a high-quality thermostat. How much your system consumes will depend entirely on you.

Selecting a thermostat

How much electricity the system consumes can only be determined experimentally by carrying out the necessary calculations. To minimize the cost of paying electricity bills, it is recommended to install a thermostat. It is a device that allows you to turn on the heating at a time convenient for you at the moment when it decreases in the room. You can set the temperature yourself, based on personal preferences. Provided that the system turns on only after the surface has cooled, you can save about 40%. In this case, the sensor should be installed in the coldest place in the room.

Thermostat location

Thermostats can be:

- Sensory. They are new and allow you to control the system using a touch screen.

- Electronic. Equipped with a display that shows all available settings. It receives information using external or internal sensors.

- Programmable. Belongs to the category of electronic thermostats. Allows you to customize the system more finely, thanks to many additional functions and settings.

- Mechanical is the simplest and cheapest. Its work is completely autonomous.

Features of different types of infrared floors

The production of infrared floors is constantly being improved. Manufacturers are trying to take into account consumer preferences. According to the type of construction, IR floors are:

- film;

- rod-shaped.

Film, in turn, are divided into solid and striped, according to the type of carbon fiber applied, which is the source of infrared radiation. The film with continuous carbon fiber coating is easy to install and easy to cut. It transfers heat from the entire area, the heating dynamics are higher than when applying carbon in strips.

The carbon strips are arranged in groups, between which cuts can be made. Since the connection to the power source is parallel, if any unit fails, the remaining area of the “stripe IR film” will remain operational.

In this case, a film with a continuous coating is more advanced, since only the places where there is a tear or a cut fail. The service life and price of solid carbon film are higher than that of striped film.

The IR rod floor looks like a rope ladder. Many rods, which are filled with carbon, copper and silver, are connected to each other by wires. The rod mat has the ability to self-regulate. Its installation differs from the film type in that installation requires a “wet” cement screed. However, the service life is even higher than that of solid film, and it is not afraid of heavy mechanical loads.

Features of laying film heated floors under various coatings

Before installing the film, you need to perform calculations and make a layout design. First, a floor plan is drawn up and locations for furniture installation are marked. When starting installation work, you need to know in advance the specifics of laying the material, taking into account the floor covering.

Installation features vary depending on the type of finishing material

Film heated floor under laminate

Laminate is a popular coating that in itself is quite warm and pleasant. But installing heated floors will help create more comfortable indoor conditions without excess humidity.

The advantage of using this technology is that when installing a heated film floor under a laminate, no screed is required. You can see how the process happens in the video below:

Watch this video on YouTube

An important requirement for installing an infrared floor is a level base. It is important that there are no cracks or deformations on the wooden base

Installation under laminate

Parquet

Parquet board is a rather fragile material. When using it, heating to more than 27 degrees is prohibited. If a varnish coating is used, the optimal temperature is 21 degrees.

When combining the coating with a “warm floor” system, it is necessary to heat all the planks evenly, and the boards must be made of materials resistant to high temperatures.

Laying under parquet boards

Warm film floor under linoleum

Linoleum is a great option, as it is inexpensive and very practical. This material fits easily into the interior and is easy to care for. When using film flooring, you should choose multi-layer linoleum. The material must be resistant to mechanical stress, deformation and fading. But a coating with a thick thermal insulation layer will not work, as it will make the floors colder. A good choice would be linoleum that is not very thick, but resistant to heat.

The table shows step-by-step installation of film heated floors under linoleum:

| Photo | Process |

| In addition to the heated floor, you will need a thermostat, heat-reflecting material, protective plastic film, tape, a knife, pliers, scissors and a screwdriver | |

| You should select a location for the thermostat on the wall in advance. | |

| For thermal insulation, you need to lay sheets of heat-reflecting material and then pin them with a stapler. | |

| We fix the strips together with tape. | |

| Thermal film should be laid out with the copper strip down. The material is cut into the required pieces along a special dedicated line. | |

| Copper busbars need to be insulated with bitumen insulation. The insulation should cover the silver contacts along the entire cut. | |

| Clamps are attached to the future location of the wires. The contact clamp must be tightened tightly. | |

| The thermal film strips must be secured with tape. | |

| We put the wires into the contact clamp and fix them firmly. The joints are insulated with bitumen insulation. | |

| The thermostat sensor is installed under the film on the black stripe. It must be secured with bitumen insulation. | |

| A cutout is made under the sensor so that the floor covering remains uniform. | |

| Cutouts are also made for wires and contact clamps. | |

| The thermostat is mounted on the wall. | |

| The connecting wires are inserted into the thermostat in accordance with the instructions. | |

| Then the system is tested. | |

| A protective film is placed on top. | |

| The finishing coating is laid on top. |

Warm film floor under tiles

Cable mats are more suitable for tiles. Before installing a warm covering, you need to level and insulate the floor.

Laying film under tiles differs from the method of laying under linoleum or laminate. The film material can be laid on the existing base using a dry method or on a new screed. In this case, the subfloor where installation is carried out must be level.

In some cases, the tiles are laid on glass-magnesite or gypsum fiber plates. Polyethylene is spread over the infrared sheet, and then sheets on which the ceramics are mounted.

Installation of heated floors under tiles

Types of heating elements

Heating by the underfloor heating system is carried out:

- heating cable;

- thermomats;

- infrared device (film or rod).

The cable is mounted in a screed or in an adhesive layer of ceramic tiles. Film coating is used for placement under laminate or linoleum. Each type has its own characteristics.

Types of heated floors

First of all, it is worth noting the characteristic property of a heated floor, which is that heating is produced from below. When heating a room with radiators, the lower part of the room remains colder and to create comfort, a 15% increase in energy costs is required. Naturally, when an electric heated floor is installed, such energy consumption is not required, and as a result, heat savings will be achieved.

Heating cable

The costs for heated floors will be minimal due to the low cost of the cable, which is laid in a screed. You should not skimp on it, and it is recommended to purchase a dry mixture intended for heated floors. It has better thermal conductivity, which reduces the energy consumption of underfloor heating. All this goes into the general expense of electricity, because every little detail must be taken into account.

Everything needs to be carefully calculated, since the thickness of the screed will be about 5 cm, which is a significant cost that will have to be spent on making a heated floor. You can make a high-quality solution with your own hands if you use fine grain and good cement.

Cables are resistive and self-regulating. The first one costs less and should be taken with two wires, so as not to strain with inserting the end back onto the thermostat. In addition, it creates less electrical interference.

Might be interesting

A significant disadvantage of a resistive cable is its overheating if the heat is poorly dissipated for some reason (furniture is placed on top or a carpet is laid on top). When pouring a screed with such a cable, the absence of voids that impair heat dissipation is of great importance.

Despite the high cost, many people prefer to use a self-regulating cable, which increases resistance in areas with high temperatures. The current flows in it in the transverse direction - from one conductor to another (Fig. below). If it decreases in a certain area with an increased temperature, this will not affect the operation of the adjacent segment.

What does a self-regulating cable look like?

Electrical cable mats

An electric heated floor is made from a single-core or two-core heating cable attached to a flexible mesh. It is bought in rolls. The thickness of the mat does not exceed 3.5 mm, which allows it to be placed in a thin screed or in a layer of tile adhesive. The consumption of self-leveling screed is small. The finish can be any: porcelain stoneware, tiles, granite, marble. The choice of heater power on the construction market is large.

The operating principle of a cable mat is no different from a heating cable. A conductor also generates heat when current passes through it. From it, the coated screed is heated by convection, and then the air is heated.

Cable mat

Warm floors are constantly being improved. (Denmark) produces mats containing a heat-insulating layer and a coating that increases the strength of the cable. They are laid out on a flat base and connected to a thermostat. Laminate or parquet boards are laid on top without screed.

Infrared heating

For heated floors, a film with a thickness of no more than 3 mm is used. Heating is provided by carbon-based film heating elements. Unlike cable, heating is carried out by infrared radiation, which increases efficiency to 95%. Any of the known coatings is suitable for such a warm floor.

Heating film for heated floors

A thermomat with carbon heaters mounted on a fiberglass mesh has similar properties. Voltage is supplied from two parallel conductors to semiconductor-type emitter rods. It works on the same radiation principle and is installed under the floor covering. When placed in a screed, it is protected with plastic film from an alkaline environment. Such a warm floor also reduces energy consumption, since its operating principle is the same as that of film.

High quality film heaters are produced by Korean. You can choose a warm floor with a thickness of only 0.42 mm, but this requires special care when handling.

Calculation of electricity consumption of IR film per 1m2

It is worth understanding that each home will have its own electricity consumption. If we talk about the average electricity consumption, it varies from 10 to 60 watts per square meter of area.

For a country house, where infrared heated floors are the main source of heat, the energy consumption will be from 30 to 40 watts per square meter. In an apartment where a heated floor serves as an additional heating element, energy costs will range from 10 to 30 W per square meter.

Heating costs in a home are influenced by various factors:

- total area of premises;

- area of the floor surface covered;

- type of flooring;

- general characteristics of the room (height, wall thickness and volume of the heated zone);

- the presence of windows and doors in the room and their number;

- how much space does the furniture take up?

- additional heating methods.

If you have this data, you can make the most accurate calculation of heat generation and, accordingly, electricity consumption.

To understand how much electricity a warm floor consumes, you need to perform the calculation as correctly as possible, using film consumption of 40 Watt*m2 as a basis. It is worth understanding that after reaching a steady temperature, the infrared coating is turned on 3-4 times in one hour, since the material is heated for 3-5 minutes, after which the heating element cools down by several degrees.

ATTENTION! Calculations are carried out according to the electricity tariff for the Moscow region. which currently amounts to 5.29 rubles/kWh

Thus, if we take the film consumption of 40 W/m2, the calculations show that in one month the electricity consumption for heating a house with heated floors will be about 1648 kWh. The cost of such heating will be 8733 rubles. at the above rate.

If you use infrared film as an additional heat source at a rate of 10 W/m2, the monthly electricity consumption will be 413 kWh. The price per month will be 2203 rubles.

If the walls in the house have good thermal insulation, then less power will be needed for heating, since there will be less heat loss. For a house with well-insulated walls, electricity consumption will be no more than 30 watts per square meter.

How to reduce the energy consumption of an infrared floor

Using the example given, you can see how much electricity a heated floor consumes, and how much you will have to pay for light. When you receive a receipt, a controversial question may arise as to whether it was reasonable to install a heated floor, but there are options that will allow you to significantly save on electricity costs and save your own money.

#1. First of all, you should take care of high-quality insulation of the floors in the house. As statistics verified by experts show, energy consumption with well-insulated floors is reduced by about 40%, and we can say that by half.

#2

It is important to install the thermostat in the coldest point of the room, where when the air temperature drops, the device will turn on the heating and turn it off to achieve the required conditions. Using a thermostat, consumption can be reduced by 40%

#3. A multi-tariff meter in your home will also help you save on costs. Such meters count consumption at different prices, which allows you to save money while you use electricity.

#4. To minimize electricity costs, do not use film under furniture. Such heating will not make the room warmer, but you will have to pay in full. Only open space allows the room to warm up well.

#5. You can reduce energy consumption by lowering the floor heating temperature by one degree. For you and the residents of the house, the temperature drop will be unnoticeable, but the savings will be about 5%.

Saving on electricity when using infrared floors is not difficult, the main thing is to fully adhere to the basic rules of saving.

If you use the hint offered in this material, you can save your electricity costs. Comfort in the house directly depends on the air temperature, so correctly calculated power and electricity consumption will help save on bills.

Opportunity to reduce costs

In some cases, it may seem that the calculation is not very pleasant. Laying the floor itself is not only expensive, but further operation is not entirely unprofitable. However, there are certain rules and actions that will help reduce your energy costs.

1. It is important not only to have a good heating device inside the house, but it is also important to provide high-quality insulation of the house outside. If we talk about specific numbers, heating may require 30-40% less electricity if the house is really well insulated

In this case, we can talk about savings of about a third.

2. When installing a heated floor system, it is necessary to ensure that a thermostat is installed. In this case, we can talk about not constantly turning on the system, but only when the temperature needs to be increased. If we again talk about specific numbers, the thermostat helps reduce costs by about 30%.

3. In some regions there is such a thing as a night and day tariff. When installing a heated floor in such a region, the meter should definitely be replaced. By heating a room at night using the floor, it is possible to significantly reduce costs.

4. The underfloor heating system should be installed exactly where it is needed. Thus, in those places where there is furniture or a room where the heating system is not required anyway. The absence of a heated floor will help you save on electricity.

5. If you lower the air temperature in the room by just 1 degree, it is possible to reduce energy consumption by as much as 5%. Most likely 1 degree and will not be very noticeable to others.

Installation and useful tips

The surface of the base is leveled with specialized compounds. Unevenness or sudden changes can damage certain areas.

Leveling the surface of the base screed

If the base is made of boards, it is recommended to level the horizon using fiberboard or plywood. In case of strong differences, the surface is planed entirely with electric jointers, or the places of the highest differences are planed with hand tools.

- Thermal film;

- Connecting wire;

- Connection terminals;

- Insulating material.

Complete set of required materials

One of the options for the external design of the thermostat

Depending on the floor covering, other components are selected.