For many homeowners, creating an autonomous heating circuit is the only way to heat their home if it is impossible to connect the building to a centralized heating main. To ensure efficient heating using the created network, a pump is installed in the heating system of a private house. Tell us about the advantages of having such a device in the thermal circuit of a building. Let's also consider the types of pumps, important parameters for selecting an electrical appliance, and the features of its installation.

Installed pump in a private residential building Source 1-teplodom.ru

General information

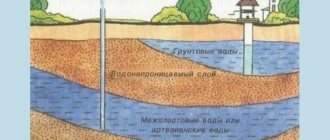

Previously, all houses installed a system through which the working environment moved naturally. The movement of water was ensured by heating it in a boiler or even an ordinary furnace. It cooled in the radiators and other elements of the building’s thermal circuit, after which it was returned to the heating equipment. It was according to this simple scheme that it circulated through the pipes.

Nowadays additional equipment is used everywhere. Before installing a pump in a heating system in a private home, specialists perform calculations and select a device, taking into account the characteristics of the building’s thermal circuit. Professionals also take other nuances into account.

On a note! A thermal circuit with natural circulation is just a relatively simple heating circuit. After all, when installing it, pipes must be laid with a slope, batteries are mounted in strictly specified places, and pipelines of exceptionally large diameter are used. In some buildings, all the rules are difficult or impossible to comply with. Therefore, it is not possible to ensure the required coolant circulation through the system.

Conventional diagram of the thermal circuit of a building with natural movement of coolant Source rtkpipe.ru

Professional installation of additional equipment allows you to solve these problems. Most homeowners turn to specialists for help. After all, they know very well how to properly install a circulation pump in a heating system.

At what speed should the pump in the heating system operate?

The purpose of forced circulation is to effectively heat the house through the reliable delivery of heat to all consumers of the system, right up to the furthest radiator. To do this, the pumping unit must develop the required pressure (otherwise known as pressure), which is ideally calculated by design engineers based on the hydraulic resistance of the pipeline network.

Most household pumps have from 3 to 7 rotor speeds, due to which the performance and pressure generated can be increased or decreased. In order not to torment you with hydraulic calculations, we offer the following method for selecting the optimal speed:

- Find a laser surface thermometer (pyrometer). Put the heating system into operating mode.

- Measure the surface temperature of the pipe at the inlet and outlet of the boiler.

- If the temperature difference is more than 20 °C, increase the rotor speed. After 30 minutes, repeat the measurement.

- When the temperature difference is less than 10 °C, the water flow rate must be reduced. The goal is to achieve a delta between supply and return of about 15 °C.

The minimum number of rotor speeds is 3, but sometimes 7 or more

Advice. Do not switch the pump to a different circulation speed “on the fly”. Disconnect it from the network, move the regulator to a different position, and then put it back into operation.

You can do without a pyrometer when thermometers are installed on the supply and return lines. If the adjustment limits do not allow you to enter the range of 10-20 °C temperature difference, your system is not working efficiently due to an incorrectly selected circulation pump. Too cold return water increases the load on the boiler and increases fuel consumption. Water that is too hot means that it flows too quickly and does not have time to transfer heat to the heating devices.

The leading European brand Grundfos offers the latest generation Alpfa3 circulation pumps, which can independently select performance depending on the load and thus adapt the work to changing conditions. With their help, you can even balance the heating system, which our expert will tell you about in the next video:

The advantage of a system with a pump

Opponents of heating, characterized by forced movement of the medium, note the following disadvantages:

- installing a circulation pump forces you to increase the cost of installing a heating circuit;

- equipment requires an electrical connection, which causes additional costs for electricity;

- the efficient operation of the pumping unit depends on the stability of the power supply, which does not exclude the occurrence of emergency situations if the power supply is interrupted;

- installing an electric pump forces the installation of the entire unit and its regular maintenance, but even in this case it is not protected from breakdowns.

Pumping unit in the heating network of a house Source sovet-ingenera.com

Upon closer examination of each non-delivery, the disadvantages turn out to be not as significant as they seem at first. Moreover, to organize the effective operation of a thermal circuit with gravitational movement of the coolant, one cannot do without certain knowledge, experience, and the implementation of specific rules. Therefore, for its proper installation, you will need the help of specialists who also know perfectly well how to properly install a heating pump in a private home.

To finally find out all the advantages of having a circulation pump unit in the thermal circuit of a building, you need to become more familiar with the system where the coolant moves by gravity.

Schematic diagram of a gravity heating circuit Source oboiman.ru

After determining the installation location of the boiler, be sure to lay a vertical pipeline. It is the accelerating section of the system. For its arrangement, pipes with a large diameter are used. It is recommended to install pipes with a cross-section of at least 1.5 inches.

The acceleration pipeline is laid to the maximum possible height. It should be mounted to a point that is higher than all the radiators in the house. After this, the expansion tank is secured and connected. This device usually has an open design.

The coolant supply pipeline from the expansion tank is laid with a slope of at least 5%. In other words, the slope of the pipe must be at least 50 mm per 1 m. In this case, its cross-sectional size must be at least 1.25 inches.

Descents to radiators are made of pipes with a minimum diameter of 3/4 inch. The return manifold, which is also placed on a slope, is made of rolled pipe with the same cross-section as that of the upper supply pipeline.

Gravity-flow system with an open tank for expansion of the working medium and an accelerating pipe Source tvoya-stroika.ru

Such a heating device with gravity flow forces the boiler to be installed below the radiators. This is not always convenient or possible. In addition, the length of pipelines is increasing. To avoid all the inconveniences, turn to specialists who know very well how to install a circulation pump in the heating system of a private home. After all, it is this that will allow the supply of heated water to the battery at any point in the building.

It is still possible to implement a gravity circuit in small houses where all heated rooms are nearby. However, even with this arrangement of rooms, it is not always possible to install a system with gravitational circulation.

The need to use pipes with a large cross-section makes it necessary to spend more money on organizing heating. Such pipelines are more difficult to install and very difficult to hide in building structures, and sometimes this cannot be done at all. At the same time, professional installation of a pump in a heating system will cost less than the cost of installing a gravity circuit with large pipes and many associated costs.

Pump in the heating circuit of a house Source onlinetrade.ru

Another disadvantage of the gravity system is the inability to conceal the bottom connection of the batteries. This cannot be done even if the project is developed by experienced designers. In a circuit with coolant gravity flow, it will not be possible to create a pressure greater than 0.6 atm. After all, it is formed in the system due to temperature changes and due to different densities of the liquid.

Important! Pressure 0.6 atm. not enough for modern radiators. In addition, you can forever forget about water-heated floors, which are always installed correctly by specialists. However, for them to work effectively, you will need to install a heating pump. If the device is professionally selected, it will always create the required pressure.

An electric pump to create and maintain the required pressure Source leroymerlin.ru

In order for the gravitational circuit to operate at its designed power, it needs a starting impulse. It can only be obtained by increasing energy resources. If even a short shutdown of the boiler unit occurs, then it will take a long time to bring the heating circuit back to normal operation.

In addition, in a gravity circulation system, fluid moves slowly. Its movement is carried out due to the energy of the boiler, and this reduces the efficiency of the unit and the entire intra-house heating circuit. All these problems can be solved by installing a circulation pump for heating - professionals will help you how to install the unit correctly.

Important! Even inexpensive circulation equipment consumes a maximum of 90 W per hour. More expensive models have lower characteristics. It is significantly less than the total energy consumption that will occur when operating heating with gravitational movement of the coolant.

Characteristics, including power, of common circulation units Source 1-teplodom.ru

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

The low speed of the working medium in the gravitational system is one of the reasons for uneven heating of radiators. In this situation, the heat transfer of the batteries can only be regulated by changing the amount of coolant that passes through them. However, this method will not allow for precise adjustment.

If we take into account that the pressure in the circuit is still low, then there is a high probability of blockage of one of the batteries in the house or even an entire section of the system. In this case, you should completely forget about the possibility of mixing coolant from the return pipeline. Therefore, you shouldn’t even think about high-quality regulation of heat transfer from heating devices.

The conclusion is that the gravitational circuit is not an effective system. Its arrangement leads to irrational consumption of energy resources. Therefore, it is better to spend money once on installing additional equipment than to pay large sums annually for the operation of an inefficient heating circuit. All owners of private residential buildings are recommended to contact professionals who know perfectly well how to install a heating pump in a private house.

Installing a pump in a heating system Source stroikairemont.com

The operation of the circulation pump completely depends on a stable supply of electrical energy. This problem is solved by installing an uninterruptible power supply. It can also simultaneously ensure the operation of the boiler unit. It all depends on its characteristics. Experts will also always help you in choosing a device.

On a note! Even an inexpensive UPS will allow boiler equipment to continue operating when problems arise with the central power supply.

If it is decided to connect a circulation pump, then the homeowner can consider switching the operation of the heating circuit to gravity circulation of the coolant. In most cases, experts offer just such a scheme to owners of modern houses. It involves installing a bypass. A pump and two valves are installed on it. The third shut-off valve is installed in the area that bypasses the bypass.

The advantages of the pump also include its durability if it is manufactured by a reputable company. Homeowners do not have to worry about the vulnerability of such equipment. Typically its service life is tens of years.

Most modern circulation pumps are durable equipment Source elektro56.ru

All pumping units must be serviced regularly to ensure they operate properly for many years. However, the benefits of such a device are undeniable. Therefore, even the purchase of an expensive pump is justified.

Other parameters for pump selection

In addition to the key parameters, when choosing a specific model, you need to pay attention to a number of its important characteristics.

Working temperature

The documentation for the pump indicates at what coolant temperature it can operate. For most manufacturers, especially models in the budget segment, this figure is overestimated. So, if 90% is stated on an inexpensive device, in practice it will be able to operate without failure with a coolant of 70-80 degrees Celsius.

The key requirement here is to match the parameters of the heater and the heating network as a whole . In a heated floor system, the water temperature is quite low. As well as in several other schemes. But when using a heating boiler, you will either need to buy a fairly expensive pump, or regulate the water temperature at the inlet of the pipe network.

High-quality and reliable circulation units have acceptable working fluid parameters of 110-130 degrees. The cost of such solutions is high. However, users have minimal complaints about their reliability.

Operating pressure

In one- and two-story houses, the pressure in the heating network usually does not exceed 2 atm. Very rarely this parameter is from 3 to 4 atm. A pump correctly calculated according to the pressure characteristic will cope with the task assigned to it. However, if you need to choose an inexpensive circulator, you should pay close attention to its operating pressure indicator.

Protection systems

Automatic protection is an extremely useful option for the circulation pump. It significantly extends the service life of the device or blocks the occurrence of emergency situations. Two types of protection are common today.

- From overheating. A thermocouple that monitors the temperature of the electric motor will automatically turn off the pump if it overheats.

- From dry running. Particularly important in models with a wet rotor. It will prevent the engine from overheating.

In addition to caring for the engine, dry running protection plays another role. It stops the pump, thereby preventing the impeller and seals from failing. Jamming and damage are excluded.

Number of speeds

With correct calculation, it does not matter how many speeds the circulator has. But if you want to optimize the operation of the system, achieve lower noise levels and save energy, you should pay attention to three-mode models. This is an affordable home option.

Circulation pump Grundfos ALPHA2 32-40, 3 speeds

More complex pumps can have more speeds or be electronically controlled by an external signal, providing smooth power delivery and fully controlled flow.

Structural design

When talking about structural design, we mean the dimensions of the fittings, dimensions and material of the housing. Regarding the latter, everything is simple. Cast iron housings are strong, durable, and promote better heat removal from the engine. Inexpensive plastic ones are practical and acceptable for pumps installed in places where they are not subject to temperature changes or mechanical damage.

The fittings should ideally correspond to the network parameters. That is, for a 25 mm plastic pipe, a pump with the same characteristics is selected. Larger fitting diameter is allowed. The pump can be connected using various types of adapters. But a smaller diameter is not allowed.

Pump dimensions are standardized

The dimensions of a standard pump are standardized. This is 180 mm between the connection points on the fittings. All bypasses and surges that are offered in stores are designed for this exact size. There are more compact solutions for placement inside equipment or in limited space. The length of this pump is 130 mm.

Main types of pumps for the heating circuit of a private house

Many well-known companies are engaged in the production of circulation pumps. For example, these are Wilo and Grundfos. Regardless of the brand, devices require electricity to operate. In the devices, the hydraulic and electrical parts are isolated from each other. This division is performed in two ways. The design of the pump depends on the specific option.

Dry type pumps

This type of pumping equipment is distinguished by the presence of a so-called dry rotor in its design. In such a device, the hydraulic part is completely separated from the electric drive. In this case, the impeller rotates due to the movement of the shaft around its axis.

Dry-type circulation pumping equipment Source simpalsmedia.com

Pumping equipment with a dry rotor has an elongated housing, since the electric motor is located on the side of the hydraulic unit. Due to this massive shape, a cantilever installation of the circulation pump in the heating system is performed. The installation process is simplified due to the presence of special brackets on the body. The equipment may also have an installation platform.

Pumping electrical appliances with a dry rotor are powerful devices with high performance. They are installed when it is necessary to supply a large amount of coolant. In addition, such pumping devices are capable of creating the necessary pressure to move liquid through extended systems. Therefore, their installation is carried out in large mansions with several floors.

Dry-type pumps have a number of disadvantages:

- Labor-intensive installation due to large dimensions.

- A complex sealing system on a rotating shaft that wears out during operation. Therefore, it is necessary to constantly carry out maintenance, and sometimes even change the sealing elements.

Dry-type pumping equipment with a complex sealing system Source yut-market.ru

- High noise level during operation, as the electric drive is cooled by air. Because of this feature, the installation of a circulation pump in a heating system in a private house is usually carried out in a boiler room, isolated from other rooms of the building.

Wet pumps

Pump circulation devices with a so-called wet rotor differ in design from electrical appliances of the “dry” type. First of all, their pump operating unit is connected to the power element hermetically due to the presence of ring gaskets between them. The two parts are screwed together.

The working unit has the shape of a snail. On both sides there are fastenings that allow connection to heating pipelines. Typically, manufacturers equip equipment with threaded pipes or flanges. The first elements allow coupling connections to be made.

Design of a household circulation pump Source superpumps.ru

The power section contains the stator winding. The pumped liquid never gets into it. To seal this part, the design contains a stainless steel glass. Therefore, the sealing elements are placed on fixed parts. Because of this, they do not wear out when the circulation pump for heating is running - specialists always know how to install it correctly.

An impeller is attached to its rotor shaft. These two parts are rigidly connected to each other. The bearings on which the rotor rests are lubricated with coolant. At the same time, it fills almost the entire space of the device. This allows heat to be effectively removed from the heating parts of the pump. Therefore, it does not overheat and does not need an additional cooling system.

Important! The “wet” type pumping device has an end plug that is used to remove air from the housing. This ensures that the entire device is completely filled with liquid.

At the end of the electric pump there is a plug for bleeding air. Source saucyintruder.org

When the rotor rotates in the working environment, energy losses occur. This reduces the efficiency of pumping equipment. However, this is a minor drawback, since the device consumes a minimal amount of electrical energy.

When operating a “wet” type electric pump, there is practically no noise. The device is easy to install and compact in size. However, you still need to know how to properly install the heating pump. After all, there is one important rule - the rotor axis must always be horizontal. In this case, the device body itself can occupy any position depending on its shape. If the rotor is positioned horizontally, then its bearings will always be wet, which prevents them from breaking due to excess heat.

Important! A filter is installed in front of the pump, which prevents solid particles from entering the bearings of the device.

How circulation pumps work

The circulation pump is a centrifugal type of device. The mechanism of the unit is enclosed in a housing, which can be made of any stainless metal or impact-resistant plastic. The body consists of two halves. On one side there is an electric motor, on the other side there is a chamber for pumping coolant. The chamber cavities are equipped with outlets. They can be threaded or flanged.

The main working unit is an impeller mounted on a ceramic rotor. Rotating from the drive - an electric motor, it creates a directed flow of working fluid in the heating network pipeline. All technical characteristics of the device depend on the design, dimensions, external data of the impeller, and its rotation speed.

Through outlets, the pump is connected to the water main. On one side and the other, the unit is attached to the pipes via a quick-release coupling. Typically this connection is a fitting with a union nut. The flange connection is secured with four bolts with nuts, flat washers and spring washers. A sealing gasket made of paronite or heat-resistant rubber is installed between the flanges.

ATTENTION! The connector where the two halves connect has two holes for drainage. Through them, condensate that accumulates in the stator half of the electric motor is removed

It is strictly prohibited to cover drainage holes! When installing heating equipment, it is also necessary to remember that the impeller must be located strictly horizontally as part of the heating system. The pump itself can be installed in any position of the pipeline relative to the horizontal axis. It can be located on a horizontal section of the pipeline, vertical, at any angle to the horizon. But the impeller axis must be oriented strictly in the horizontal plane!

Basic selection parameters

Before connecting a circulation pump to the heating system, professionals select a device taking into account the features of the existing heating circuit of the house. During this process, they must pay attention to the following parameters of the device:

- The operating voltage should be 220 V. This characteristic allows you to connect the electric pump to a household power line. Therefore, there is no need to install separate wiring.

- Power – the optimal value is the minimum value. It is recommended to choose a device with power consumption class A. This device is the most economical. As the class decreases, power consumption increases.

Manufacturers produce modern pumping units with two or even three operating modes. They allow you to change the pressure of the pumped liquid. At the same time, the power of the device will change. These parameters are usually marked on the body of the electric pump.

Power connection

The circulation pumps operate from a 220 V network. The connection is standard; a separate power supply line with a circuit breaker is desirable. The connection requires three wires - phase, neutral and ground.

Circulation pump electrical connection diagram

The connection to the network itself can be organized using a three-pin socket and plug. This connection method is used if the pump comes with a connected power wire. It can also be connected via a terminal block or directly with a cable to the terminals.

The terminals are located under a plastic cover. We remove it by unscrewing several bolts and find three connectors. They are usually labeled (the pictograms are N - neutral wire, L - phase, and “ground” has an international designation), so it’s hard to make a mistake.

Where to connect the power cable

Since the entire system depends on the performance of the circulation pump, it makes sense to make a backup power supply - install a stabilizer with connected batteries. With such a power supply system, everything will work for several days, since the pump itself and the boiler automation “pulls” electricity to a maximum of 250-300 W. But when organizing, you need to calculate everything and select the battery capacity. The disadvantage of such a system is the need to ensure that the batteries do not discharge.

How to connect a circulator to electricity through a stabilizer

Installation of an electric circulation pump

Before starting installation work, each specialist already knows where to install the pump in the heating system - on the supply or return. Typically the installation is carried out on the return pipe. Installation is carried out directly in front of the boiler. In this case, it is better to choose a place after the tank in which the coolant expands.

On a note! It is recommended to install expansion tanks with a membrane in heating systems with quiet movement of the working medium. It is for this reason that the installation of electric pumps is carried out after them. After all, a device for circulating coolant contributes to the creation of flow turbulence.

If an open tank is installed, then the electric pump can be installed anywhere in the common return pipeline, but only after the last connection into it. The same recommendation applies to the membrane expansion tank. The location of the electric pump on the return line after the expansion tank extends the service life of the circulation device. Indeed, in this case it will pump a cooler coolant than when installed on the supply side.

Layout of the pump on the return after the expansion tank Source 1-teplodom.ru

Important! Modern pump models are designed to operate at a maximum temperature of 110°. This allows them to be installed on the supply pipeline. However, when choosing this option, you need to carefully balance all the parameters of the thermal circuit. After all, after the pumping unit, the working environment receives a vacuum. Taking this point into account, circulation devices should not be installed immediately behind the boiler, since when the heating circuit operates at maximum, boiling of the liquid in the batteries may occur. This situation poses a great danger.

Advice! If the pump is installed on a supply pipeline, then it must be installed at the greatest possible distance from the boiler unit.

Before connecting a circulation pump, professionals always first study the existing system. If branches extend from the central supply pipeline in different directions, pumping devices are installed on each of them. Such heating circuits are often found in buildings with extensions or in large houses that have two wings.

One of the options for a branched heating circuit with two circulation pumps for radiators and heated floors Source akak7.ru

In buildings with a branched thermal circuit, the optimal place to install the electric pump is the supply pipeline, but only after it has branched. In this case, the circulation device must be installed before the battery or the first riser.

When choosing a location for a circulation device, they are guided by the heating scheme in a particular house. There is no general rule for the placement of a device that pumps coolant. Specialists take into account the characteristics of a particular heating network and the availability of free space on its pipelines.

In addition, professionals control the location of the device’s rotor axis relative to the ground. It must always be parallel to the horizon. In addition, access to the electrical pump installation box is provided. After all, it is designed for connecting wires and there is a mode switch in it. Therefore, the installation box should not be located at the bottom of the device.

How the unit works

The principle of operation of the circulation unit is very similar to the operation of a drainage pump. If this device is installed in a heating system, it will cause movement of the coolant by capturing liquid on one side and pumping it into the pipeline on the other side

The principle of operation of the circulation unit is very similar to the operation of a drainage pump. If this device is installed in a heating system, it will cause the movement of the coolant by capturing liquid on one side and pumping it into the pipeline on the other side. All this happens due to the centrifugal force, which is formed during the rotation of the wheel with blades. During operation of the device, the pressure in the expansion tank does not change. If it is necessary to increase the coolant level in the heating system, install a booster pump. The circulation unit only helps water overcome the resistance force.

The device installation diagram looks like this:

- A circulation pump is installed on the pipeline with hot water coming from the heater.

- A bypass valve is installed on the section of the line between the pumping equipment and the heater.

- The pipeline between the bypass valve and the circulation pump is connected by a bypass to the return pipeline.

This installation scheme involves the release of coolant from the device only if the unit is filled with water. To keep the liquid in the wheel for a long time, a receiver equipped with a check valve is built at the end of the pipeline.

Circulation pumps used for domestic purposes can develop a coolant speed of up to 2 m/s, and units used in the industrial field accelerate the coolant up to 8 m/s.

It’s worth knowing: any type of circulation pump operates from the mains. This is quite economical equipment, since the motor power for large industrial pumps is 0.3 kW, and for household appliances it is only 85 W.

Features and installation procedure of the electric pump

To find out how to properly install a circulation pump, it is recommended to use the heating project. It is usually developed during the design stage of the house. If the heating circuit of a building is being modernized, then in this situation the best place to install the device is the bypass.

The presence of a jumper with an electric pump, filter and shut-off valves allows the heating network to function if the building loses power or an electrical appliance breaks down. Thanks to the bypass, it will be possible to switch the system to circulate the medium naturally. This will prevent you from being left completely without heat in the event of an emergency.

The bypass jumper can have almost any configuration. Often there is not enough space for installation. Therefore, non-standard solutions are being implemented. However, more often the installation is still carried out according to standard schemes.

One of the options for a bypass jumper for an electric heating pump Source e.allegroimg.com

If there is free space, a ready-made bypass assembly is usually installed. This design is manufactured in production shops. It is equipped with taps or valves are built into it. The finished bypass unit can be mounted by welding or connected via thread. Any such structure has a free area intended for installing an electric pump using flanges or couplings.

Thermal circuits in houses are often created from polypropylene pipes. This option simplifies the process of installing a circulation device for pumping coolant. The master usually spends about 1 hour on the work. More time is required if installation is carried out on metal pipes. It is necessary to use not only welding, but also packing of threaded connections.

During installation of the circulation pump, the technician carries out the following actions:

- prepares components - filter, shut-off valves, threaded pipes, drains;

- connects all threaded elements of the assembly using a special sealing tow and paste;

- assembles the loop together with the pump without carefully tightening the union nuts;

An assembled loop with a pump and a unit that is mounted underneath it Source 1-teplodom.ru

- outlines and cuts out an area on the return line for installing the tap;

- carries out welding work - first tacks the metal elements of the assembly, then removes the pump to prevent it from being damaged by welding splashes and completes the operations started;

- assembles the unit under the pump and carries out its installation;

- the circulation device is installed in place;

- carries out the final tightening of the American electrical appliance.

Important! On the electric pump, the direction of the arrow must coincide with the actual movement of the working medium in the heating pipeline.

At the end of the work, the master connects the wires. They are connected to the terminals located in the mounting box of the circulation device.

Pump marking

All the data the user needs is contained in the markings on the front panel. The numbers on the circulation pump mean:

- type of device (most often it is UP - circulation);

- speed control type (not specified - single-speed, S - step switching, E - smooth frequency control);

- diameter of the pipes (indicated in millimeters, means the internal dimension of the pipe);

- pressure in decimeters or meters (may differ among different manufacturers);

- installation dimensions.

The pump marking also contains information about the types of connections of the inlet and outlet pipes. The complete coding scheme and word order looks like this:

Responsible manufacturers always follow standard labeling rules. However, individual companies may not indicate some of the data, for example, installation dimensions. You need to find it out directly from the documentation for the device.

It is worth choosing a pump only from trusted brands. Reliable devices are also available in the mid-price category. And if you need the highest quality and have the opportunity to pay one and a half to two times more, you should pay attention to products from the GRUNDOFS and WILO brands.

Briefly about the main thing

Installing an electric pump in the heating circuit of the house allows you to provide the necessary pressure in it. This will allow the premises to be heated as efficiently as possible. Electric pumps are installed in homes in “dry” and “wet” versions. The second type of device is more common.

They usually try to install the electric pump on the return line after all radiators, tie-ins and a reservoir for expansion of the coolant. If necessary, it can be mounted on the supply, but at the maximum distance from the boiler.

The pump is installed on a bypass. This is a loop with a filter and shut-off valves. First, all its elements are assembled into a single structure, and then it crashes into the main pipeline with a separate tap to shut it off.

Installation rules

The design of a household circulation pump from any manufacturer provides for its fastening to pipelines or shut-off valves using union nuts (American). This allows it to be quickly dismantled if necessary, for example, for replacement or repair. When installing the pump unit, follow these recommendations:

- Place the device on any sections of pipelines - horizontal, vertical or inclined, but with one condition: the rotor axis must be in a horizontal position. That is, installation “head down” or up is unacceptable.

- Please note that the plastic box with electrical contacts is located on top of the case, otherwise it will be flooded with water in the event of an accident. Yes, and servicing the product will not be easy. This is easy to achieve: unscrew the screws securing the casing and turn it to the desired angle.

- Remember to follow the flow direction indicated by the arrow on the housing.

- So that the product can be removed without emptying the system, install shut-off valves before and after it, as shown in the diagrams in the previous section.

A visual aid showing what position the pump unit should be in

Advice. It so happened that the load from the weight of the circulation unit will fall on 1 or 2 ball valves (depending on the orientation of the area in space). Hence the recommendation: do not save money and buy high-quality shut-off valves, whose body will not crack over time from mechanical stress.

System check

For normal water circulation, the heating system needs to warm up. It takes 2-3 hours. Wait the specified time and check each battery by touch, they should all be at the same temperature.

If you find a hotter or colder one, try deflating. For overheated batteries, you need to bleed them in a subsequent radiator, for cold ones - in the previous one. Most likely, the problem will be resolved.

Another possible reason is a leak. Carefully inspect the connection points between the batteries and the pipe. Even if there are no obvious puddles, water may appear at the joints. Recheck the connection and the problem will go away.

The last uncharacteristic point is extraneous noise in the pump. In new models, this problem only occurs if foreign objects, rust or other debris gets into the pump. To avoid this, it is recommended to install a filter on the supply pipe. Eliminated by disassembling and cleaning the pump.

Types of open heating schemes

In an open heating system, the coolant moves in two different ways. The first option is natural or gravitational circulation, the second is forced or artificial stimulation from a pump. The choice of scheme depends on the number of floors and area of the building, as well as on the expected thermal conditions.

Natural circulation in heating

The gravitational system does not have any mechanism to ensure the movement of the coolant. The process is carried out solely by the expansion of hot water. For the operation of the circuit, an accelerating riser is provided, the height of which is at least 3.5 m.

If you neglect to install a vertical transit riser, then there is a high probability that the coolant coming from the boiler will not develop a sufficient speed

The natural circulation heating system is optimal for buildings with an area of up to 60 square meters. m. The maximum length of the circuit capable of providing heat is considered to be a 30 m mainline. An important factor is the height of the building and the number of storeys of the house, which allows the installation of an accelerating riser. The natural circulation scheme is not suitable for low-temperature applications. Insufficient expansion of the coolant will not create the proper pressure in the system.

Possibilities of the gravity circuit:

- Connection to heated floors. A circulation pump is mounted on the water circuit leading to the floor. The rest of the system operates as usual. If the power goes out, the house will continue to be heated.

- Working with a boiler. The heating device is mounted at the top of the system - slightly below the expansion tank.

To ensure uninterrupted operation, a pump can be installed on the boiler. Then the heat supply and hot water production scheme automatically becomes a forced option. Additionally, a check valve is installed to prevent recirculation of the coolant.

Forced system with pump

In order to increase the speed of the coolant and reduce the time for heating the room, a pump is built in. The movement of water flow increases to 0.3-0.7 m/s. The intensity of heat transfer increases, and the branches of the main heat up evenly.

Pumping circuits are constructed of both open and closed types. In open circuits, the expansion tank is installed at the highest point of the system. The presence of the pump allows you to increase the pipeline between the heating boiler and the batteries, both in height and in length (+)

- The circuit with a built-in pump is volatile. To ensure that the heating of the room does not stop during a power outage, the pumping equipment is placed on the bypass.

- The pump is installed in front of the boiler inlet on the return pipe. The distance to the boiler is 1.5 m.

- When installing the pump, the direction of water movement is taken into account.

Two shut-off valves and a bypass elbow with a circulation pump are mounted on the return line. If there is current in the network, the taps close - the coolant moves through the pump. If there is no voltage, then the valves must be opened - the system will switch to natural circulation.

A check valve must be installed on the supply pipeline. The element is placed immediately after the boiler and prevents recirculation of the coolant during pump operation

What to do if the device hums but does not turn?

This problem is faced by those pump owners who do not often use the devices and ignore the need to maintain the heating system. To fix the problem you will need:

- Turn off the power to the unit;

- Drain the coolant from the pump and adjacent pipes;

- Remove the screws that secure the motor housing;

- Remove the engine along with the rotor;

- Turn the rotor with a screwdriver, resting against the notch.

If the cause of the breakdown lies in foreign objects getting into the device, then you need to act in the following order:

- Turn off the power to the pump;

- Drain the water;

- Unscrew the screws holding the motor housing;

- Find and remove foreign objects;

- Install a strainer on the inlet pipe.

Once the repair is complete, the device will start working again. The filtration element will protect the device from solid particles, which will significantly extend the service life of the entire system.

Principle of operation

The principle of operation of the circulation pump lies in its ability to create centrifugal force inside the housing, as a result of which the pressure in the internal reservoir of the pump increases. Due to this, the coolant is pushed out into the outlet of the pump. Repeating the cycle ensures a stable pressure throughout the system.

All circulation pumps are divided into two types:

- pumps with a “wet” rotor;

- pumps with a “dry” rotor.

Calculation of operating pressure in the circuit

Video

When choosing a circulation pump for a heating system, calculations must also be made based on such an indicator as the pressure inside the pipeline. To do this, you can use the relationship:

P = (R x L + Z) / pxq, where:

P – pressure value;

R – flow resistance for straight sections of the pipeline;

L – total length

Z is the value of flow resistance determined by the fittings, taps and other fittings used in the system;

р – value of coolant density at operating temperature;

q – value of free fall acceleration.

If there is insufficient data for calculation using the given formula, you can use the simplified relationship:

P = R x L x ZF, where

R is the value of flow resistance in a straight pipe section, approximately 100 - 150 pascals per 1 meter, expressed in a form convenient for calculation, it will be 0.01 - 0.015 meters per meter pipe section;

L is the total length of the pipeline; in a two-pipe heating scheme, both forward and return circuits are taken into account;

ZF – magnification factor, depending on the following indicators:

- for a system with ball valves, for which it is unusual to reduce the clearance of the pipeline, and with correctly selected fittings it is taken equal to 1.3;

- when using throttle or temperature control devices, its value will be 1.7.

Video

When choosing a circular pump for a heating system, calculating its characteristics appears to be a necessary procedure.

The practice of using circulation pumps makes it possible to select them without calculating the necessary parameters. Recommended parameters are shown in the table.

Table for empirical pump selection

Table 1.

| Heated area (m2) | Productivity (m3/hour) | Stamps |

| 80 – 240 | From 0.5 to 2.5 | 25 – 40 |

| 100 – 265 | Is the same | 32 – 40 |

| 140 – 270 | From 0.5 to 2.7 | 25 – 60 |

| 165 – 310 | Is the same | 32 – 60 |

Note: in the third column, the first number is the diameter of the pipes, the second is the lift height.

Video

Using the given data, you can select the right device for stable and long-term operation without much hassle.

Main manufacturers

Circular pumps for heating systems are produced by many European manufacturers with fairly high quality and a wide range.

Wilo company. The pumps of this concern, produced in Germany, occupy a fairly large place in the specialized market. They are distinguished by high quality and stable operation. Almost all models of this manufacturer are equipped with automatic and manual controls. Not only the rotor speed is adjusted, but also the release functions, including the amount of pressure in the system.

DAB company. This Italian manufacturer successfully competes with other suppliers to the Russian market, presenting centrifugal pumps for more than 40 years. A special feature of DAB products is the displays used on the control panel, which are very convenient for interacting with the installation and monitoring the work process.

Manufacturer Grundfos. The Danish company under this name has existed for more than 70 years, supplying the market with pumping equipment for various purposes. It should be noted that this manufacturer is clearly and has long been recognized in the specialized market. The fruitfulness and creativity of the company, which launches up to hundreds of new models of its products on the market every year, is impressive.

This manufacturer’s equipment for heating systems is marketed under the UPS label and the product line is intended for both domestic and industrial use. The main feature of circular pumps for heating is their suitability for operation in a very wide temperature range: from -25° to +110°C.

The UPS product line can operate using 3 performance modes.

Gilex company. A domestic manufacturer of circular pumps, successfully competing in the market with European companies.

The units are unpretentious in operation and can ensure active circulation of coolants of various densities in heating networks, which determines a wide selection of liquids, including transformer oil. They operate in 3 power modes, stepless adjustment. It compares favorably with its competitors in price level.

Conclusion

The choice of a circular pump for a heating system and its calculation will allow the consumer to make the optimal purchase for the actual conditions of a particular room.

The options for preliminary assessment of the necessary equipment proposed here allow you to confidently make such a choice. I wish you success!

Pros and cons of using a heating pump

Just a couple of decades ago, in the private sector, houses were equipped with gravity-type heating. A wood stove or gas boiler was used as a heat source. There was only one area of application left for large circulation devices - centralized heating networks.

Today, manufacturers of heating equipment offer smaller units that have the following advantages:

- The speed of movement of the coolant has increased . The heat generated by the boiler quickly enters the radiators. Due to this, the process of warming up the premises was significantly accelerated.

- The higher the movement speed, the higher the pipe capacity . This means that an identical volume of heat can be delivered to rooms using a pipe with a smaller diameter.

- Water heating schemes have undergone significant changes . The highway can be laid with the slightest slope. Also, the complexity and length of the line can be anything. The basic rule is the rational choice of a heating pump based on the required power.

- With the help of a household circulation device, it became possible to organize heated floors in the house, as well as an effective closed-type heating system.

- It became possible to hide the entire heating communication line passing through the rooms, which does not always go well with the design of the room. Options for laying pipes behind suspended ceilings, in walls or under floor coverings are quite common.

The disadvantages of pumping systems include the dependence of operation on the supply of electricity and its consumption by the pumping apparatus during the heating season.

The leading company Grundfos, engaged in the development of heating equipment, has released innovative models of Alpfa2 circulation pumps, capable of changing performance based on the needs of the heating system, which allows saving on electricity consumption

Therefore, if the area is often deprived of power supply, it would be advisable to install a device to provide uninterrupted power. The second drawback is not critical and can be eliminated by correctly selecting the power and model of the circulation pump.

Installation of additional equipment

Regardless of the type of heating circuit used, where one boiler serves as the heat producer, it will be sufficient to install a single pumping device.

If the design of the system is more complex, it is possible to use additional devices that provide forced circulation of liquid.

An example of a joint wiring diagram for a solid fuel boiler paired with an electric one. This heating system has two pumping devices

This becomes necessary in the following cases:

- when heating a house, more than one boiler unit is involved;

- if there is a buffer capacity in the piping scheme;

- the heating system diverges into several branches, for example, servicing an indirect boiler, several floors, etc.;

- when using a hydraulic separator;

- when the pipeline length is more than 80 meters;

- when organizing water movement in floor heating circuits.

To perform the correct piping of several boilers operating on different fuels, there is a need to install backup pumps.

For a circuit with a heat accumulator, the installation of an additional circulation pump is also required. In this case, the main line consists of two circuits - heating and boiler.

The buffer tank divides the system into two circuits, although in practice there may be more of them

A more complex heating scheme is implemented in large houses with 2-3 floors. Due to the branching of the system into several lines, 2 or more pumps are used to pump the coolant.

They are responsible for supplying coolant to each floor to various heating devices.

Regardless of the number of pumping devices, they are installed on the bypass. In the off-season, the heating system can operate without a pump, which is shut off using ball valves

If you plan to install heated floors in the house, then it is advisable to install two circulation pumps.

In the complex, the pumping and mixing unit is responsible for preparing the coolant, i.e. maintaining the temperature at 30-40 °C.

In order for the power of the main pumping device to be sufficient to overcome the local hydraulic resistance of the floor contours, the length of the line should not be more than 50 m. Otherwise, the heating of the floors will become uneven and, accordingly, the rooms

In some cases, the installation of pumping units is not required at all. Many models of wall-mounted electric and gas generators already have built-in circulation devices.

Recommendations for proper pump installation

To ensure convenient access for servicing the pump, the unit must be connected correctly. In practice, when installing a pump, the following basic installation rules should be taken into account:

After installing the circulation pump, it should always be accessible so that in the event of a breakdown, it can be easily repaired or replaced.

- Both sides of the pumping unit must be equipped with special ball valves, which are necessary when carrying out maintenance of the entire heating system or during the dismantling of the unit.

- It is necessary to equip the entire system with a filter in order to protect the device from exposure to small particles that lead to damage to the installation and its components.

- Since the water passing through the heating system is far from ideal, additional protection will be required for the pumps to function properly. Therefore, the heating bypass on top must be equipped with a valve, which must be installed. You can choose any valve: automatic or manual. Its purpose is to release air pockets formed in the pipes; its terminals should be directed clearly upward.

- Belonging to the type of wet models, the pump must be installed in a horizontal position so that it is completely immersed in water, and not just a separate part. Incorrect installation can cause damage to the working surface of the unit, and the installation will be pointless.

- To increase the operating potential of the structure, it is necessary to specially treat all fasteners and connections in the system with a sealing agent.

- It is necessary to ensure that the sequence is observed when connecting the pump and fasteners.