Electric boilers are the easiest to install and connect; they do not require a chimney, supply and exhaust ventilation, or a separate room for the boiler room. Since standard heating element models already contain all the necessary elements and components (circulation pump, expansion tank, safety group, etc.), when organizing a simple heating system, communications around the electric boiler are minimal.

All these factors allow you, having basic skills and knowledge, to install and connect an electric boiler yourself, without the involvement of specialists. But please note that the condition for providing a warranty from most manufacturers is that installation is carried out by a specialized service organization. However, the ease of installation also has a positive effect on the cost of the work of the craftsmen.

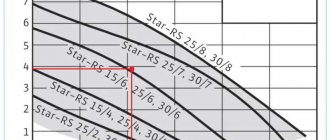

What types of pumps exist

The emergence of different types of heating systems led to the development of different pump models. Each type differs from the other in price, components, principle of operation and number of functions and properties. Let's take a closer look at the main types of this device.

A pump designed with dry rotors:

- It differs in that the hydraulic parts of the device have absolutely no contact with the electric drives. The work occurs with the help of a rotor, which is a shaft moving clockwise.

- It is worth noting that these models have a rather impressive mass and shape, because the design consists of two parts that are not connected in any way. At the same time, the installation process looks quite simple, because such pumps are provided with special fasteners.

- The complexity of the design is due to the fact that the device has a fairly large operating power and has the ability to create pressure to move the water mass if the system is long.

- Disadvantages include massive shapes and rapid wear of rotors, which require periodic replacement.

A pump designed with wet rotors:

- The fundamental difference is the design of such pumps, because here the hydraulic parts are connected to the power elements using an annular gasket. However, they have a simpler shape that resembles a snail.

- Their designs also provide for the presence of fasteners that will allow installation of the device in heating boilers. Such models also work using a rotor, but its design allows it to not wear out so quickly and not create a lot of vibration and noise.

- Also, such structures do not function as efficiently, but they also consume less energy. Their installation is advisable in systems that do not have a long length.

It is worth noting that the connection diagrams for pumps in private houses differ greatly from the diagrams of apartment systems, because their length is much shorter. Therefore, when choosing a pump, you should take into account the length of the heating.

Do it yourself

diagram of a heating element electric boiler

To work you will have to use some materials and tools:

- Angle grinder or grinder.

- Welding machine of any kind. It is best to use an inverter device for this purpose. It is suitable if you have experience in welding. If it is completely absent, then it is best to ask someone to help in this regard. All welding work must be carried out with the highest quality so that there are no leaks anywhere.

- Sander.

- Multimeter.

- Sheet steel , the thickness of which will be at least 2 mm.

- Adapters that are needed to connect the structure to the heating system.

- Tens (it is best to purchase 2 pieces).

- Steel pipe - it is best to buy a pipe with a diameter of 159 mm, its length should be about 50-60 cm.

You can make the following types of boilers yourself:

- single-circuit;

- double-circuit;

- induction;

- wall;

- floor;

- electrode;

- heating elements;

Manufacturing instructions:

- At the first stage , pipes are made to connect the heating boiler to the heating system. In this regard, you first need to cut a certain number of pipes from pipes that were specially prepared for this. You will need 3 pieces in total - one with a diameter of 3 inches and 2 of 1.25 inches.

- When all this is done , they are engaged in the manufacture of a container for the tank, that is, the largest pipe where the coolant will be heated. First, markings are made on the pipe, a hole is cut in it, and the edges are carefully processed so that there are no sloppy cuts or metal shavings on them. Prepared pipes are welded to the holes. Now you need to cut two circles from a steel sheet, which will be slightly larger in diameter than the pipe that serves as a heating tank. This will allow them to be welded more accurately. All areas where joints are located are carefully sanded.

- A 1.25-inch diameter pipe needs to be welded to the top Subsequently, another heating element will be welded to it. When all this is done, they begin to prepare the area where the first heating element will be attached. To do this, make 2 holes in the bottom of the structure, then grind the holes and install the heating element.

- When all this is done , the boiler is connected directly to the heating system itself. This is done using pipes made at the very beginning of the work.

A separate issue is connecting the structure to the electrical network. If you do not have the skills for such work, then it is better to contact an electrician. Then they install a less powerful heating element, which should have a thermostat. It is attached to the upper pipe.

All work can be considered completed. The main thing is now to check how efficient the design is. Use a multimeter to check the temperature of the coolant, which should be about 70 degrees.

What parameters should you pay attention to?

When purchasing pumping equipment, you need to consider several parameters that each device must have.

This list includes:

- Operating voltage indicators. They should be two hundred and twenty volts, because this voltage allows the pump to be connected to household electrical lines. This parameter indicates that the device has sufficient household voltage and there is no need to install additional wiring.

- Power indicators. The main indicator that indicates how much energy the device consumes and what power it operates with. Often even the most minimal capacities are enough. Such devices are not only economical, but also effective in a small system.

It should also be mentioned that there are models that have not one operating mode, but several. This makes it possible to regulate pressure indicators and accordingly increase the power indicators of the device.

Power calculation

First, you will need to perform a power calculation so that the thermal energy source provides the total load for heating and domestic hot water.

Calculation of the heating power of an electric boiler for heating with your own hands is carried out either according to an aggregated indicator, or a more accurate method, using the calculation of heat loss through external wall structures and window openings of the house. In the first case, the calculation is made in the ratio of 1 kW per 10 m2.

That is, for a house of 50 m2 you will need a boiler of 5 kW, and for 100 m2 - 10 kW.

For DHW load an additional 30% is added. For more accurate calculations, you will need to know the minimum temperature during a cold five-day period for a specific area of residence, which is given in SNIP, and take into account heat loss through the external surfaces of the house.

For a house 50 square meters

For a small one-story country house, which has plan dimensions of 7x7 m, with a ceiling height of 2.4 m, and 4 double-chamber double-glazed windows of 1x1.2 m, the amount of heat loss that the electric boiler must compensate for is determined.

Calculation of the power of an electric boiler with your own hands for a house of 50 m2:

- The required indoor air temperature is 18 C.

- The average temperature of the cold five days a year is -15 C.

- DHW requirement, 4 people.

- The area of a brick wall is 2 bricks (51 cm), 67.2 m2.

- Window area, 4.8 m2.

- Wall area without windows, 62.4 m2.

- Ceiling and floor area is 49 m2 each.

- Heat loss from windows, 0.476 kW.

- Heat loss from walls, 5.15 kW.

- Ceiling heat loss, 0.43 kW.

- Floor heat loss, 0.43 kW.

Thus, the total heat loss for a house of 50 m2 is 6.486 kW, the power of the electric boiler must be at least 7 kW, this is enough to heat the premises.

For 100 square meters

Calculation of the power of an electric boiler unit for a country house with an area of 100 m2:

- Internal air temperature, 18 C.

- The average negative temperature is -15 C.

- DHW requirement, 4 people.

- The area of the outer wall is 2 bricks (51 cm), 100 m2.

- The area of window openings is 6 m2.

- The area of wall structures without windows is 94 m2.

- Ceiling and floor area is 100 m2.

- Heat loss from window structures, 0.714 kW.

- Heat loss from walls, 7.33 kW.

- Ceiling heat loss, 0.875 kW.

- Floor heat loss, kW: 0.875 kW.

Thus, the total heat loss for a house of 100 m2 is 9.794 kW, the power of the boiler with electric heating is chosen to be 10 kW.

How to properly install a circulation pump

Studying the diagrams for connecting the pump to the heating, we can say that this is not an entirely simple process, because you need to carry out several preparatory measures and carry out the necessary calculations.

In general, this process occurs in several stages, which include:

- Work to drain coolants from the system.

- Cleaning work for every pipe in the heating system.

- Bypass installation work. In this case, the diameter size should not be the same as the diameters of the main pipes, but slightly smaller.

- Installation work of the filter device.

- Installation of pump shafts.

- Installation work on shut-off valves and ball valves.

- Work to fill the system with water resources and bleed off air masses.

- Checking the system's functionality.

You should strictly follow the step-by-step instructions, because one minor mistake can lead to breakdown of the entire system.

Reasons for the popularity of electric boilers

Electric boilers do not have mechanical elements, making them much easier to use. In addition, the likelihood of a breakdown is reduced several times.

Electric boilers are equipped with an automatic temperature control system. This helps to turn it off at the slightest change in ambient temperature. If the need arises, the boiler will either increase the temperature or reduce it.

The device operates safely, without producing carbon monoxide and other harmful substances, so it can be installed to heat any premises, including children's and bedrooms. In addition, installation of equipment does not require obtaining appropriate permits from regulatory authorities.

In this video you will learn how to make an electric boiler:

Such boilers can be used as additional equipment for heating a room or made the main source of heat in the house. The device is powered by a 220 V network and, as a rule, weighs about 20 kg. Even with such small dimensions, it is capable of heating up to 400 cubic meters of air.

Many electric boilers are characterized by good efficiency. For example, to heat 30 cubic meters of air you need to spend 4 kW of electricity per day. The use of such devices allows you to heat a much larger room than could be done with other types of heating equipment.

Tools for connecting the circulation pump

In addition to the device itself, you will need a certain amount of special material and tools.

This list includes:

- Pump equipment.

- Connection fitting.

- Check valves or bypass valve.

- Shut-off valves.

- Coarse type filter.

- Connecting type couplings.

- A means of winding and paste for plumbing purposes.

- Keys.

- Welders.

This list is a list of the basic tools that you will need when carrying out installation work.

Necessary materials

The list of materials will depend on the chosen design, the number of heating elements and the principle of operation. If the body is made of sheet metal, a metal sheet of at least 3 mm will be required, otherwise a pipe Ф219х3.

One heating element requires approximately 10 cm in diameter, i.e. for pipe F 219 it is possible to install only 2 heating elements. The length of the housing should be 500 mm longer than the electrodes.

Auxiliary materials will require welding electrodes, sealing material, thermal paint, valves, safety valve, thermometer, pressure gauge.

Electrical equipment is calculated strictly according to the boiler power, with a power of more than 5 kW, a special permit from Energonadzor and independent power supply to the electric boiler through an individual protection system will be required, and each heating element must be equipped with its own automatic circuit breaker.

With three-phase power supply at home, each heating element is installed on a separate phase. A general set of materials for connecting the boiler: cable, circuit breakers, starter and contact blocks.

The best pump manufacturers

Before purchasing this device, you need to study the list of proven manufacturing brands.

These include:

- Russian manufacturer Unipamp.

- Danish manufacturer Grundfos.

- German manufacturer Vilo Nova.

- Italian manufacturer of DAB.

Where can I buy

You can purchase a water heater as quickly as possible at your nearest specialty store. A good option in terms of price-quality ratio is purchasing from the AliExpress online store. Mandatory long waits for parcels from China are a thing of the past, because now many goods are in intermediate warehouses in destination countries: for example, when ordering, you can select the “Delivery from the Russian Federation” option:

| HYUNDAI Instant Electric Water Heater | Electric water heater TINTON LIFE with temperature display | Stainless steel liquefied water heater |

| 2500W floating electric water heater, for bath, swimming pool | RX-21.3500W instantaneous electric water heater | Kitchen electric water heater HYUNDAI |