- Repair of drain pump and filter

Equipment from the German brand Bosch is characterized by high quality parts, reliability and long service life. However, equipment is susceptible to malfunctions and breakdowns due to incorrect choice of programs, physical wear of parts, and poor quality water. If an error code is displayed on the display, you can figure out what kind of breakdown has occurred and eliminate it in a timely manner without contacting service.

It is better to entrust the repair of washing machines to professionals!!!

We present to you our unique catalog of private craftsmen and service centers —

Select your city and artist in the filter: by rating, reviews, price!

Typical malfunctions of Bosch washing machines

The most common problems are:

- no water heating;

- water is not drained;

- the drum does not rotate;

- noise and vibration;

- water does not fill in after starting the program;

- The electric motor does not work.

Let's consider each malfunction, indicating the possible causes that could lead to them.

Water doesn't heat up

The most vulnerable part of the equipment is the heating element (heating element); it is susceptible to breakdowns during intensive use of the device and poor water quality, as a result of which a thick layer of scale from salt deposits forms on it. The solution to the problem in most cases is to independently clean the heating element from scale or replace it. When using a washing machine with hard water, replacement is usually required after 3-5 years of operation.

There may also be no water heating due to the selection of an inappropriate washing program; in this case, re-read the instructions and select the appropriate program and mode.

Water does not fill

Potential reasons:

- low water pressure in the pipeline or shutdown of water supply;

- the filling valve is closed;

- breakdown of the water level controller or inlet valve.

We recommend that you read: How to check the water level sensor yourself?

Water does not drain

If water does not drain through the drain hose, you need to check the program selection. Some models have non-draining programs. If necessary, select the water drain mode.

All the reasons why the washing machine stopped draining water are described in this article.

A clogged drain hose that needs to be cleaned and rinsed can prevent water from draining. You also need to check the filter and pipe for the presence of small objects, hair and threads, wool. Other prerequisites may be pump malfunctions or malfunctions of the electronic board.

It is better to entrust the repair of washing machines to professionals!!!

We present to you our unique catalog of private craftsmen and service centers —

Select your city and artist in the filter: by rating, reviews, price!

The drum does not spin

Most modern models have built-in overload protection, that is, the drum will not rotate and washing will not start until excess items are removed from the drum. If after this, after twisting it with your hand, it rotates, you can start washing.

You may find this article useful: What to do if the washing machine drum stops spinning?

Other causes of malfunction:

- rupture or displacement of the drive belt;

- the heating element is burnt out;

- breakdown of the tachogenerator or pump;

- The electric motor does not work.

Excessive noise and vibration

If you notice a lot of noise and vibration during the first wash, turn off the unit and check that the shipping bolts are removed, as they may cause the unit to vibrate and hum.

Other causes may include insufficient loading, uneven installation, or small objects getting caught.

A common cause is also wear of bearings and seals, clogged filters and pipes, and problems with the drain pump. All these malfunctions can be solved by independently replacing failed elements, or by cleaning the filter and pipe.

Washing machine won't turn on

First of all, check if there is electricity in the outlet, if the outlet is working, if there is water in the pipeline. If there is water and electricity, then the breakdown may be caused by a malfunction of the electronic module; the corresponding error code should be displayed on the display.

The video describes the diagnosis and step-by-step elimination of the spin error. Such problems are associated with breakdowns of the pressure switch, electric motor or control module.

If it is impossible to identify the malfunction and the error code is not shown, then you need to contact a technician for special diagnostics.

Repair it yourself or call a professional?

Do-it-yourself and service repairs have their advantages and disadvantages. Before making a choice in favor of one of the options, you need to familiarize yourself with them.

If the machine is under warranty

If a Bosch SMA is under warranty but fails, the service center must repair it absolutely free of charge.

This service is provided as part of warranty service. The period during which it can be used is 1 year.

The service center technicians will undertake repairs to the device only if it fails due to no fault of the owner. In this case, you cannot open the case yourself and try to fix the problem. To prove eligibility for warranty repairs, you must provide a receipt confirming the date of purchase.

Pros and cons of home renovation

benefits :

- financial savings;

- quick departure of a specialist;

- the ability to independently repair simple breakdowns;

- there is no need to transport the machine;

- the ability to choose a master who inspires confidence.

Disadvantages of home renovation:

- many craftsmen do not provide receipts and do not guarantee work performed;

- there is a possibility of meeting with scammers;

- lack of necessary knowledge, experience and tools.

If possible, it is better to contact a technician who has previously repaired equipment for relatives or friends.

At the service center

Advantages of contacting a service center:

- Large organizations employ professionals;

- warranty for replaced parts;

- the ability to perform complex repairs;

- original spare parts.

The main disadvantage of contacting a service center is the high cost of the services provided. In addition, the equipment will have to be left in the workshop for several days.

Error codes for Bosch washing machines

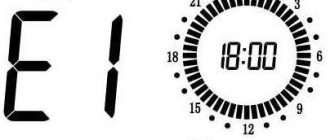

The codes are displayed on the display or using an indication. The user only needs to look at the instructions, recognize the error and take timely measures to eliminate it. On common models Maxx 4, Classixx 5, Maxx 6, Classixx, as well as others, the following error codes are provided:

- F 16 – the door is not closed when starting the program;

- F 17 – exceeding the time for filling water due to clogged filters and valves;

- F 18 – water is not supplied due to a clogged drain valve or a breakdown of the water level controller;

- F 19 – heating does not occur if the heating element or thermostat is broken, or there is insufficient voltage;

- F 20 – the water does not heat up due to a broken thermostat;

- F 21 – drum failure due to a malfunction of the relay or tachogenerator;

- F 22 – short circuit or broken circuits and wires;

- F 23 – activation of the Aquastop option due to water leakage into the pan;

- F 25 – failure of the turbidity controller;

- F 26 – analog sensor does not work;

- F 27 - signaling device failure;

- F 28 – failure of the compression sensor;

- F 29 – incorrect operation of the electric motor;

- F 30 – no engine rotation;

- F 40 – electrical equipment does not synchronize due to mismatch of power supply parameters;

- F 50 – insufficient or excessive flow rate;

- F 51 – the door is not closed;

- F 53 - functional protection malfunction;

- F 54 and F 63 - failure of the control module.

If the machine does not heat the water when washing

Oh, these villi! They can also clog the pressure switch tube.

The task of the pressure switch is to give a signal to the control unit that the required water level has been reached, the inlet valve can be closed and the water heating can be turned on. If the pressure switch tube is clogged with laundry fluff or animal hair, the connection between the pressure switch and the control unit is disrupted. The water will fill up, but the heating will not turn on, the washing program will continue. In any case, if there is no heating, it is useful to remove the pressure switch tube and blow it out.

Indication of all error codes (video + table)

For Bosch washing machine models that do not have a display, error codes are displayed using certain combinations of indicators on the main panel with buttons. Let's look at the main display options and their meaning.

| Code indication on screen | On a device without a screen | Description of the error |

| F16 | The door is not closed | |

| F17 | Exceeding the time for collecting water into the tank | |

| F18 | Exceeding drain duration | |

| F19 | Exceeding the heating time | |

| F20 | Excessive heat | |

| F21 | Failure of the control system, uneven operation of the engine, the motor does not transmit rotation to the drum | |

| F22 | NTC sensor failure | |

| F23 | Aquastop option enabled | |

| F40 | Inability to sync | |

| F63 | Device functional protection failure |

The video provides instructions on how to reset error F21 on a Bosch washing machine without a display.

Tags

Bosch washing machines Bosch drying machines Bosch dishwashers Bosch washing machine Bosch washing machine turns on the machine lights up this Bosch washing machine Bosch washing machine Bosch washing machines Repair of washing machines starts the washing machine Washing machine starts the washing machine Washing machine If the washing machine breaks down the washing machine Repair of refrigerators Repair of washing machines Repair of dryers Repair of dishes ochechnye Repair of cookers Repair wind Vacuum cleaner repair

technology article

How to recognize a breakdown if there is no code?

Bosch washing machines have a device diagnostic option, thanks to which you can independently determine the cause of the failure and eliminate it. Here are step-by-step instructions on how to carry out such diagnostics:

- close the door;

- set the program selection scroll to the Off position;

- after a few seconds select Spin;

- If done correctly, the Start indicator will start flashing;

- hold the Speed button until the Start light starts flashing;

- turn the selector to the Drain position;

The selector should only be turned in a clockwise direction so as not to cause damage to the equipment.

- release the RPM button and select the option that requires a test.

If the diagnostic cannot be started, the fault is in the control module and you need to call a specialist.

To check manually, scroll the selector; each number is responsible for testing a separate element:

- 3 – check the motor;

- 4 – pump testing;

- 5 – heating element;

- 6 – hot water valve;

- 7 – cold water valve;

- 8 – main wash valve;

- 9- valve for pre-wash;

- 10 - sound indication;

- 11 – FCW autotesting;

- 14-15 - quick self-testing.

To exit test mode, press Start and turn the selector.

To return from the mode, scroll to the Off position.

Shock absorber wear

Shock absorbers in a washing machine are needed to “absorb” vibrations during operation. When used for a long time and/or the machine is overloaded with laundry, the shock absorbers gradually fail due to which the machine begins to knock and rattle.

| Signs | How to fix | Cost* (work only) |

| The machine rattles, knocks, jumps during the spin cycle, but does not gain momentum. It is possible that knocking noises can also be heard during washing. | Worn shock absorbers are replaced with new ones. Note! Both shock absorbers are replaced at the same time to distribute the load evenly. | from 2800 rub. |

*The price is only for the work of the master, without taking into account the cost of new shock absorbers.

Trouble-shooting

We will give you the main malfunctions and methods for eliminating them on your own.

Repair of drain pump and filter

To clear the filter from clogging:

- the drain filter is located at the bottom of the washing machine body, under the front cover or behind the technical hatch;

- place the container, as waste water will flow out when opened;

- turn the cap counterclockwise and pull out the filter;

- rinse it under pressure from the tap;

- put it in place.

Do not run equipment without a filter, so as not to cause significant damage.

To clean or replace the pump:

- pull out the powder tray;

- unscrew the bolt in the corner and pull out the bottom cover;

- remove the hatch seal and panel;

- To access the pump, remove the wires. If there are foreign objects in the pump, remove them;

- If the pump is not working, replace it and reassemble all parts in the reverse order.

Water does not fill

Actions in this case:

- check the connection to the pipeline and the presence of water;

- check the hose for damage and kinks;

- if the level controller is faulty, replace it: remove the top panel, it is located in the right corner;

- Pull out the sensor by pressing the latches and remove the wires. Then install the new sensor.

Replacing the heating element

The part needs to be replaced if too much scale has accumulated on it, it has burned out or overheated. To replace the heating element you will need:

- unscrew the back panel, under the drum there is a heating element with a shank and a bolt in the center;

- unscrew the bolt and disconnect the wiring;

- pull the heating element towards you, put a new one in its place and screw the lid back on.

Replacing bearings

For this procedure you will need to almost completely spin up the washing machine. We recommend not completely disconnecting the wiring from the electronic board. Place it on the frame or hang it on a hook to avoid snagging wiring and terminals. You can make such a hook yourself from 3 mm steel wire.

After this, remove the tank with the drum by unscrewing the springs and mounting bolts. To disassemble the tank into two halves, you need to unclip the latches. Using a hammer and a wooden block, knock out the bearing axle shafts with gentle blows.

When selecting bearings, pay special attention to suit your specific model. We recommend removing the bearing and showing it to a consultant in the store in order to purchase the exact spare part you need. The following video shows in detail how a specialist spins a washing machine and replaces the bearing. Watch the video before the procedure to ensure everything is done correctly:

When the problem is not a breakdown

- Poor water quality. When moving to another house and connecting a BOSCH washing machine after washing, traces of dirt and rust may appear. If a dirt filter is not installed, the likelihood of contamination increases. It happens that after repairing pipes, rusty water begins to flow, which also stains things, but this is temporary. The main problem is hard water, since the powder dissolves less well in it and does not foam. It is recommended to install a filter and use water softeners.

- Changing washing powder. A very common situation is when a powder of poor quality or not intended for washing machines is chosen. Vending machine detergents contain active ingredients and a reduced level of foaming. When purchasing, you need to pay attention to the labeling of the powder, and when washing, choose the appropriate amount. On average, this is 1 tablespoon per 1 kg of laundry. With a smaller quantity, things will not be washed, and with a larger quantity, whitish stains will appear on them.

- Pollution. Hard water often causes the formation of sediment and scale on the structural elements of BOSCH washing machines. The laundry stops being washed well even when mold appears, which usually accumulates under the rubber cuff of the hatch. It is recommended to periodically clean the cuff, use special products and wash the machine without laundry at high temperatures.

- Wrong mode. Heavily soiled items should be washed at a temperature of +90° C, having first examined the clothing label indicating the permissible temperature. If these are delicate fabrics, they can be washed by hand washing or soaking. To remove stains, you can apply a cleaning agent to the stains in advance and then load them into the drum. There is one more nuance. When the economy mode is selected, the amount of water during the rinsing process is reduced. As a result, detergent may remain in the laundry.

Fault prevention

To extend the life of the washing machine and prevent the need for major expensive repairs, adhere to the following rules when using:

- the equipment must stand on a horizontal surface;

- It is recommended to connect equipment directly to the network, without using tees and extension cords, which can lead to power outages;

- choose the washing program and mode wisely, follow the recommendations regarding the correct load weight;

- clean and rinse the drain hose, pipe, filter;

- Observe the minimum rest interval for equipment between washes - half an hour. Thus, the equipment will last longer without significant breakdowns.

Bosch washing machines are reliable, but they are also prone to malfunctions. The material presented typical breakdowns and methods for eliminating them on your own at home. For more serious breakdowns, it is recommended to call a specialist who will carry out in-depth diagnostics and promptly eliminate the malfunction. Also, do not forget to regularly clean washing machine parts that may become clogged with small objects.

Blockage in the drain tract

The drain path becomes clogged with threads, coins, buttons and other small parts from clothing pockets. The RemBytTech masters even encountered small things that slipped into the tank. Places of blockages - drain pipe, filter, pump, drain hose, sewer.

| Signs | How to fix | Cost* (work only) |

| The machine drains water too slowly or does not drain at all. The malfunction may be accompanied by codes F03, F18, E18. | It is necessary to check the drainage pipe (pipe, drain filter, pump, drain hose and sewer), find the blockage and remove it. | from 1400 rub. |

*The price is only for the work of the master, excluding the cost of spare parts.