If you are the owner of a Vailant gas boiler, do not wait until something breaks to study the error codes. He who is forewarned is forearmed.

After all, a gas boiler is a complex technique; in the event of an emergency, competent actions will determine how the Vaillant boiler will operate in the future.

Malfunctions most often require a professional approach, but you can do something yourself.

Vaillant error F28: what is it?

If you look at the instructions, there is information about this error, but it is difficult to give an exact definition. The malfunction is related to the gas burner. What happened to her needs to be examined individually.

Probable reasons:

- Gas is not supplied.

- The valve has fallen out.

- No grounding.

- The electrodes are broken.

- The electronic board is outdated.

The error is common and most often indicates a problem with the valve. This is the weak point of boilers; they have a certain operating life. If the equipment, for example, has been used for more than five years, then you should not be surprised.

Video on the topic

Gas autonomous heating systems are the most common and optimal from an ergonomic point of view today. But due to not the best operating conditions, they are often subject to various breakdowns, regardless of the country of origin and the price of the unit.

For example, a Vaillant boiler, the malfunctions of which are often associated with poor gas purification, may not last even one season, although it costs a lot of money. And this is not the fault of the manufacturers, because the equipment is designed for optimal conditions and cannot always effectively deal with problems arising due to the fault of public utilities.

Boiler inspection and maintenance

Gas boiler maintenance is recommended annually. Basically, maintenance comes down to visual inspection and preventive cleaning of the main components: heat exchangers, combustion chamber, coarse filters and the condition of the expansion tank.

The outside of the primary heat exchanger is cleaned of soot with a soft brush. Under no circumstances should you use brushes with metal bristles, because... The copper plates are treated with a special anti-corrosion coating and its damage will lead to a serious reduction in service life. Due to their design features, primary heat exchangers from the inside in most cases cannot be washed; their service life can be seriously reduced by the use of antifreeze or frequent replenishment with high-hardness tap water.

The secondary heat exchanger (DHW), due to the constant flow of water through it, is more susceptible to the formation of deposits and scale, but it can be successfully washed at regular intervals. Heat exchangers are washed with special installations (boosters) using special equipment. The process involves long-term (sometimes up to several hours) pumping of chemicals that help dissolve and wash away scale. Valiant recommends washing with regular acetic acid.

The expansion tank is designed to compensate for the thermal expansion of the heating system and is also subject to annual maintenance. It consists of measuring its pressure. The measurement must be taken on an empty boiler and, if necessary, pumped up to the static pressure of the system (approximately 1-1.2 bar). If water comes out of the control fitting, this indicates that the tank membrane is not sealed and needs to be replaced.

It is necessary to wash and clean heat exchangers in a timely manner, because dirt and scale deposits reduce thermal conductivity and flow area, which leads to a decrease in the efficiency of the boiler and overheating, and subsequently an expensive replacement.

It is recommended to set the hot water supply temperature so as not to dilute it with cold water, thereby ensuring minimal heating. The lower the temperature of the hot water, the lower the intensity of scale formation.

Coarse filters are meshes, so their maintenance is reduced to removing and rinsing under running water to the desired condition.

Over time, a gas burner can become clogged and coated with combustion products; cleaning it, as a rule, can be easily done with a soft brush and a vacuum cleaner. If there is severe contamination, it can be easily removed.

Basic error codes (f28, f75) and their brief explanation

There are a lot of codes for various errors or malfunctions.

Let's look at the most common of them:

| Code | Decoding |

| F00 | Supply thermistor circuit open |

| F01 | Open return thermistor circuit |

| F02-03 | Opening the temperature thermistor or storage sensor |

| F04 | Return thermistor break |

| F10 | Supply thermistor short circuit (exceeding 130°) |

| F11, F14 | Short circuit of the return thermistor (exceeding 130°) |

| F22 | Dry running (pump fault) |

| F23 | Lack of water. Determined by the temperature difference between the forward and return lines |

| F27 | Parasitic Flame |

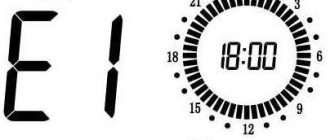

| F28 | Ignition lock |

| F29 | Failure in operating mode (occurs when the flame goes out and the ignition attempt fails) |

| F35 | Error in gas outlet |

| F37 | Unstable or abnormal fan speed |

| F72 | Error in forward and/or return line sensor readings |

| F75 | The pump is unable to raise pressure |

| F76 | Primary heat exchanger overheating |

IMPORTANT!

In addition to error codes marked with the letter F, there are status codes marked with the letter S. They inform about the ongoing process and are not errors.

Why does blood pressure drop?

The pressure drop in the boiler has a single cause - a coolant leak. If, after several attempts to increase the pressure using the supply valve, no positive results appear, you should look for a leak in the boiler itself or in the heating circuit.

Difficulty may arise if the boiler is a condensing boiler and is connected to a floor heating system.

Finding leaks in such conditions is extremely difficult. It may turn out that the fault is hidden in the discharge valve connected to the sewer system.

The optimal way to search for causes is to consistently eliminate possible causes of leaks, so that ultimately only one, the correct one, remains.

NOTE!

Certain information can be obtained if you try to determine the intensity of the leak and analyze the throughput capacity of the boiler elements involved.

Gas path diagnostics

When connecting a building to a main pipe

If we are talking about a residential building, and “blue fuel” is chosen as the main energy resource, in the house, in addition to Vaillant, there is a gas stove. After the pipes have been laid, there are no devices in the section of the circuit up to the boiler. Therefore, you can control the flow of gas without leaving the kitchen.

The check comes down to igniting all the burners on the stove at maximum mode. Flames with a characteristic shade will indicate the absence of problems with the fuel supply, and their intensity and stability will indicate the constancy of the pressure and its normal value. If the stove does not light up or does not work correctly, you need to look for a fault in the section between the main line and the place where the gas pipes are laid (the method is described below).

With autonomous gas supply

Check what

- Shut-off valve. If the Vailant boiler is taken out of service at the end of the heating season, the owner of the property, as a rule, blocks the main line and then forgets about it. Perhaps it is the gas valve that is causing the f28 Vaillant error.

- Shut-off valve. Triggered when the voltage is turned off; A “normally closed” type device is installed on the gas pipeline. It must be moved to the working position manually.

- Gearbox. Insufficient insulation of the head of a gas tank or an outdoor cabinet with a cylinder group causes icing of this device - the pipeline is blocked. Contamination of the channel is reflected in the pressure - when its value is below the response threshold of the gas valve of the Vaillant boiler, error f28 appears.

- Filling the tank. As the “blue fuel” is consumed, the pressure in the pipe also gradually drops. The most typical case of error f28. The igniter fires, the Vailant boiler starts, but the burner goes out. And so several times, as if she was missing something. Namely, normal gas flow.

Another option is the formation of an ice jam on one of the sections of the highway outside the building. But this defect must be dealt with (and eliminated) by specialists.

Solutions:

Checking the air supply channel:

— when drawing air from the room, it is necessary to ensure an intensive inflow under any conditions.

— when the channel is brought out, the head is checked and a mesh is placed on the pipe to prevent dust and small debris from entering the boiler.

If the error appears during periods of change in wind direction, you should change the air duct laying scheme: route the pipe in a different place, cover the head.

— Condensate removal channel: for normal operation of the Vailant boiler, the accumulated liquid must be drained periodically.

The electrodes often become contaminated with soot and burnt dust, and often it is enough to wipe them with your fingers and the boiler’s operation is restored. If the electrode has not been serviced for a long time, you need to clean its tips with abrasive paper with minimal grain.

— Vaillant connectors have miniature latches. Users often break them when removing the valve from the boiler.

— A special lubricant is applied to the rod. Which one exactly is not an idle question.

— You can reset the Vaillant fittings according to the gas pressure at the inlet to the boiler burner.

Inspect the board for damage (oxidation, dark areas, moisture, characteristic smell of burnt tracks and modules, remove excess dust); all operations with the board must be carried out using antistatic gloves.

Installation recommendations

The Vailant gas boiler may issue error F28 due to incorrect installation of the unit. Therefore, the installation of the device must be coordinated with the gas distribution company.

It is also necessary to correctly determine which hole in the wall the chimney will go through. Some parts of the home's structure may be too strong and thick for this type of equipment.

When connecting the boiler for the first time, it is necessary to use a voltage stabilizer. It is important to pay attention to the polarity.

In order not to encounter the fact that the Vailant boiler displays error F28, it is necessary to make the connection correctly. You need to understand that only professional specialists will be able to carry out this procedure in accordance with all requirements.

If the installation is carried out independently, then it is necessary to draw up a design for the heating system and have it certified by the relevant authorities. Do-it-yourself or poor-quality installation can cause serious problems.

Expert advice

There are some expert tips to consider. In particular, a number of tips concern prevention and initial use of the boiler. Recommendations:

- the model must meet the needs of the heating system;

- connection must be made strictly according to the instructions;

- any small deviations from the operating cycle should be checked immediately;

- Before the first operational start, diagnostics must be carried out;

- Equipment installation is carried out by professionals; otherwise, problems may occur during the first operating cycles.

Important! Any type of boiler must receive full maintenance. Otherwise, the work cycle will begin to deteriorate over time.

Most users have questions during operation that only specialists can answer. Also, for every question there is an answer that allows you to solve the problem. Adviсe:

- If there is no response to turning on the water and a set of sounds that come from the equipment itself, it is worth checking the gas supply line, as well as the gas meter.

- When pressure jumps occur due to the expansion tank, you can simply pump it up.

- If the pressure sensor does not work correctly, error F75 appears. To eliminate this, you can simply press the supply tap.

- When switching off the equipment and supplying either hot or cold water, it is worth setting the minimum pressure.

- If there are delays in switching the boiler from one mode to another and sounds that resemble gurgling, it is necessary to pump out excess air.

- In addition to water, you can only use a coolant specially selected for the boiler. There should be no other liquids.

- When the equipment stops completely and the panel goes dark, you need to check the fuses.

- If the flame icon flashes and does not turn on, you need to clean the filters and check the sensors.

- If there is good pressure of cold water, but hot water flows poorly, then you will need to check and replace the heat exchanger.

Diagnostics and boiler failures

It should be noted that Vaillant equipment is one of the safest among all others. The number of settings, parameters, and checks here is significantly greater than in boilers of other brands. Boilers with displays can display status codes, diagnostics (two levels), faults and setup programs. The average user will only be interested in error codes, so everything else is mainly intended for service specialists.

The Vailant automation also stores a history of all errors, this makes it very convenient to diagnose and troubleshoot the boiler. At any time you can view the last 10 errors that occurred on the boiler (use the “info” and “-” buttons to display the list).

Next, we will consider the most common errors of Vaillant boilers and recommendations for eliminating them.

What checks are carried out before the first start-up of the boiler?

For further normal and safe operation, as well as maintaining the warranty, any equipment requires compliance with a number of conditions:

- voltage in the network according to the PUE standards and mandatory grounding of the boiler (ideally there should be no potential between zero and “ground”, Vaillant allows no more than 1.5 Volts)

- compliance of the system as a whole with the power of the installed equipment (lack of heating or hot water capacity prohibits start-up). Constant operation of the boiler at maximum power will quickly lead to failure of the unit.

- checking compliance with chimney installation standards (for atmospheric boilers, presence of draft, for coaxial chimneys, pipe extension and slope towards the street)

The installation manual also requires installing a coarse filter on the cold water supply to the boiler and on the return pipe of the heating system, as well as a gas filter.

It is better to study the commissioning process in more detail in the instructions for a specific boiler model.

The selection of the test program (airing, filling the system) is started by turning on the boiler and simultaneously holding the “+” button for 5 seconds. The selected program is activated with the “i” button. For TEC series boilers, five programs are preinstalled.

Useful tips

In order not to rack your brains over how to resolve error F28 in the Vailant gas boiler, you must carefully study the instructions before starting to operate the device. It is quite simple and intuitive even for a novice user. Additionally, the device is equipped with a special display, which displays all codes with the name of certain problems.

If any error occurs, you must check its number and read the annotation in the instructions. Some of the problems can be fixed on your own, but in most cases only specialized assistance may be required. To avoid troubles, before each heating season, it is recommended to call a technician who can check the boiler for leaks, as well as for proper performance.

Incorrect pressure in the unit is the most common cause of error F28 in the Vailant gas boiler. What to do in this situation? First of all, experts recommend maintaining the pressure level on the middle gray strip of the sensor. If the arrow moves into the red zone, this indicates that the indicator is decreasing very much. This can seriously affect the operation of the system.

Unit connection diagram

The connection diagram of the unit will depend on several factors, the first and most important, of course, is the type of heating system. There are three types of them:

- Those that use natural circulation. The movement of heat is ensured by the difference in water pressure that occurs in the line due to the expansion of coolants due to increased temperature. Installation of such a line is cheaper, but you will not be able to regulate the temperature using a radiator; accordingly, the second type is used on higher-quality automation.

- Forced circulation is carried out by special pumps, so you can freely regulate the amount of heat. Accordingly, the method is the most effective of those on the market, but the connection diagram is much more complicated and installation is more expensive. In addition, the system is completely dependent on electricity, and if it is turned off, the unit simply ceases to perform its functions.

- Hybrid circulation. Nowadays there are practically no devices with this type of heating on the market, but such a device combines the advantages of both of the above. In the event of a power failure, the boiler freely switches to the mode of natural distillation of water through pipes.

You might be interested >> Gas-independent boilers from Conord

Accordingly, the connection diagram is available depending on the type of heating selected by the user.

Vaillant boiler error F28: how to fix

If you don’t want to understand the reasons and finances allow, of course, you can take the equipment to a service center. However, DIYers recommend not to give up and try to carry out repairs at home.

Please note that we are talking about gas equipment, so precautions must be taken. The unit must be turned off to completely protect itself.

My actions during a breakdown:

- There is a “reset failure” button.

- Equipment dismantling.

- Carrying out diagnostics.

- Boiler disassembly.

I am familiar with the structure of gas equipment and the first thing I check is the electrodes. My first thought is that the wiring is damaged. If there are exposed contacts, this is the easiest problem to fix. Take a blowtorch, everything falls into place. However, during the first inspection I did not find any problems with the wires; the electrodes are all in place (in theory, the electronic board should receive a signal).

The second point is grounding. It is checked using a tester. The most difficult thing is the valve; according to the instructions, it must withstand a certain pressure. In my case, he was clearly acting up and didn’t even know what to do. I decided to simply replace the element, error f 28 disappeared by itself.

Vaillant boiler: error F28

If we talk about this code, it can indicate several malfunctions at once. For example, the cause of this phenomenon may be a breakdown of the gearbox, which is responsible for gas pressure. The meter could also be faulty.

In some situations, the Vailant gas boiler generates error F28 when the gas is oversaturated with air. It is also necessary to monitor your blood pressure. To change these values, you must check the settings yourself.

Some users accidentally close the gas valve, which can also cause an error. In addition, the cable often breaks. The gas magnet can also fail. Additionally, you need to check the ignition transformer and make sure that there is no carbon deposits inside the system.

Most rarely, this error occurs when there is a breakdown in the control board. Therefore, regardless of whether the 24 kW Vailant boiler or another model produces error F28, it is recommended to check some components and make sure that the unit is being operated in the correct mode.

Ignition transformer

Failure to start the Vailant boiler is due to the lack of a spark or its insufficient power. If there are no wire defects, the Tr winding is checked with a multimeter: open – R = ∞, short circuit – R = 0. With interturn, the device will show resistance, but if the value does not correspond to the passport data, the spark is weak, insufficient to ignite the burner. Error f29 can be eliminated by replacing the transformer.

Burnt ignition electrode of Vaillant boiler

Control board

Self-repair is possible for a user with specialized education, but it will take time. Error f29 can be eliminated by replacing the Vaillant boiler assembly.

Useful tips

Vaillant boiler error f28 what to do?

This error can occur either randomly or require the intervention of a service technician. Error f28 occurs when unsuccessful attempts are made to ignite the gas burner.

What could be the reasons for error f28 of the Vaillant boiler:

- no gas is supplied to the burner

- low gas pressure at the gas valve outlet

- gas valve is faulty

- problem with the ignition electrodes and the flame presence electrode

- incorrect grounding of the boiler

- malfunction of the electronic board (repair of the boiler board is possible)

To begin with, you can use the Failure Reset button (flame with a cross). Perhaps the ignition failure was accidental and the boiler’s operation is returning to normal.

If error f28 appears again, we recommend calling a service technician because further checks will require special equipment and knowledge. It is not recommended to disassemble the gas valve yourself.

You can check the integrity of the wires coming from the electrodes to the control board and, during the next start-up attempt, check visually that the electric spark strikes the burner body and not somewhere else.

Service specialists check the reliability of the boiler grounding and the serviceability of the electrodes, as well as the pressure at the outlet of the gas valve. If all components are normal and there are no violations, then diagnostics of the electronic board will most likely be required.

There is no need to change the control board right away. In most cases, it can be successfully repaired. Repairs will cost significantly less.

Codes that appear most often

Errors that appear on Vailant brand boilers are most often caused by incorrect installation and adjustment work. Thus, in order to adjust the burner and gas valve, it is necessary to use a special gas analyzer. Similar work needs to be done every time F28 appears on the monitor.

The most common types of failures:

- the circulation pump is in poor condition;

- modulation mode stopped;

- the heat exchanger is clogged.

If the setting is performed incorrectly, this will negatively affect the technological mode, which is prescribed by the manufacturer in the attached documentation. All documents are included with the equipment.

Most often the following are in poor condition:

- Gas shut-off valve.

- Control block.

- Igniter.

- Engine.

If an error occurs during boiler operation, information is displayed on the control panel.

Adjustment features

Boilers from this manufacturer are easy to control. However, this does not mean that every person can cope with such a task on their own. It is best to make adjustments together, when one person turns the tap and the other monitors the position of the pressure arrow. To adjust the water or heating temperature, you can use special valves located on the control panel. In this case, how hot the water is will be displayed on the display. Thanks to this, you can increase or decrease the temperature by turning the tap to the desired position.

Also, the fact that the time has come to figure out how to eliminate error F28 in the Vailant boiler can be signaled by special light sensors on the device panel. The green light comes on when heated water is being used. A yellow indicator indicates that gas is burning. If the red LED lights up, this indicates a problem with the system. It is also worth paying attention that only water is poured into the boiler. There is no point in doing experiments.

Possible causes of failure

Most Bosch washing machines are equipped with a self-diagnosis system. If a problem is detected, the alarm code F29 appears on the display. It’s worth figuring out what this code means and what is causing the tank to fill up.

Incorrect installation of the unit

If code F29 appears on the display when you first connect the washing machine, the cause of the error is incorrect installation of the equipment.

The inlet hose must be located 50 cm above the floor and be connected correctly. If the technician installed the machine incorrectly, the system will drain water into the sewer.

Weak pressure or no pressure

Insufficient pressure in the water supply is a common reason for the lack of water in the machine. To check the pressure, you need to lower the inlet hose into a basin or sink. If the pressure is always weak, you should call a plumber to solve this problem.

If water does not flow into the tank, check the shut-off device between the water supply and the hose of the machine. Open the lock and water will fill the tank.

Faulty inlet hose

If the error appears during operation of the washing machine, check the serviceability of the inlet hose. It should not have cracks or kinks, as well as rigid fixation. In this case, free access of liquid to the system is blocked.

Filter clogged

The reason for the obstacle to filling the system with water can be a clogged filter - a mesh connecting the hose and the valve. The filter must be cleaned regularly, just like the hose itself.

Faulty door

Bosch washing machines do not take in water if the drum is not completely sealed. Make sure the door is closed tightly (you should hear a characteristic click).

Another reason is a breakdown of the hatch locking device (checked by a tester).

Commissioning sequence for Vaillant boilers

- Before filling, it is necessary to thoroughly rinse the heating system (large particles remaining after installation work can damage the actuators)

- check the condition of the automatic air vent on the circulation pump; if it is closed, unscrew it 1-2 turns

- shut-off valves on heating radiators or thermal heads must be fully open

- fill the heating system to a pressure of at least 1 bar (usually 1.3 – 1.5 bar)

- turn on the boiler and check the pressure, if necessary, recharge the system

- Be sure to check the gas deflector for leaks

- Vaillant requires filling the system with prepared water with a hardness of no more than 20 units according to the German calculation system and prohibits the addition of antifreeze or corrosion inhibitors to the system.

After the system is filled, it is necessary to carry out the P0 air removal program, in which only the pump will operate in a specially designed mode and remove excess air from the heating and domestic hot water circuit

Pressure check

This is another procedure that you can perform yourself if a problem occurs. In order to check the pressure, it is necessary to remove the unit casing. After this, you need to fold back the junction box and close the gas shut-off valve. The next step is to loosen the sealing screw located on the gas valve. After this, a digital pressure gauge is connected. Next, you can open the gas shut-off valve and put the device into operation. After this, the pressure is measured. If these manipulations do not help, then you can try other methods.

Checking and setting the minimum amount of gas

Particular care must be taken during the initial connection and commissioning of gas equipment. To check the minimum amount of gas and avoid subsequent errors, you need to perform several simple manipulations:

- turn off the boiler;

- loosen the sealing screw located on the gas valve;

- connect the pressure gauge;

- press the button with the plus symbol on the display and, while holding it, set the assignment switch “i”;

- continue to hold “+” until the value “P.0” appears on the device screen;

- press the button with the “+” sign again and wait for “P.2” to appear;

- press the “i” button and start the automatic diagnostic system, then the boiler can be switched to the minimum gas supply;

- press the “i” button and wait for a digital value from 0 to 99 to appear;

- Press the “+” or minus button several times until the pressure is set to the correct value.

- To save the changes made, to do this you need to hold down the “i” button for about 5 seconds.

In this case, the unit will automatically exit the diagnostic mode. After this, you can turn off the device, remove the pressure gauge and reinstall the sealing screw.

Is it possible to carry out repairs yourself?

Current regulations prohibit self-repair of gas equipment. This point must be taken into account when starting restoration measures. However, there are many ambiguities in this issue - there are other components in the boiler design that are not directly related to gas equipment.

If the secondary heat exchanger or boost fan fails, the gas supply system will not be affected in any way. To solve such problems, you need to call a technician from the service center. He has all the necessary approvals and permits; gas service inspectors will not have any questions.

Another issue to consider is the validity of the warranty agreement. The conditions are quite strict - installation and initial start-up must be carried out by employees of the warranty workshop (service center), routine repairs or maintenance of the boiler must also be carried out by specialists.

Independent intervention in the boiler design is regarded as termination of the warranty agreement at the user’s initiative, and you will no longer have to count on free repairs. Even replacing the plug on the power cord can be considered such an intervention, therefore, in any situation, it is recommended to immediately call a service technician.

If you repair it yourself, the boiler will be removed from the warranty.

If there is no way to contact specialists, you have to act at your own peril and risk. When purchasing a boiler, you must immediately find out where the nearest service center is located and whether there is a possibility of quickly solving possible problems.

If the warranty workshop is located too far away and a technician does not come to your home, it makes no sense to conclude a warranty agreement.

Checking the functioning of the boiler

And after the unit has been installed, it is also necessary to perform several manipulations to ensure that the performance of the unit is at the required level. To do this, you need to connect the device and check the gas supply lines, heating installations and other pipelines for leaks.

You also need to make sure that the burner flame indicators are in the correct position.

Error f33 vaillant how to fix and what to do?

Occurs only in turbocharged boiler models. The source of the error is the pressure switch in the exhaust pipe. The operating logic of all modern gas boilers is approximately the same. When a request for ignition is received, the control board turns on the fan (smoke exhauster), which creates a vacuum. When the required draft is achieved, the contacts of the differential relay close and thereby transmit a signal to the board to open the gas valve and ignite the burner. Accordingly, if there is no signal from the relay or it is in a closed state after the fan is turned off, the vaillant automation generates error f33.

Vaillant boiler error f33

causes:

- The fan does not work (can be checked visually)

- breakdown of the pressure switch (condensation may accumulate in the tubes, which, flowing into the sensor, renders it unusable;

- error when installing the exhaust pipe (condensation can also accumulate and flood the relay)

- clogging of coaxial pipelines, preventing normal air flow

- pitot tube clogged (accumulated dirt or insects)

You can check the operation of the relay by creating a vacuum yourself through the tube (a characteristic click should occur). It happens that the relay “sticks”, i.e. in normal condition it will be closed, which can be checked with a conventional multimeter. In this case, it will have to be replaced.

It happens that the tubes themselves or the pitot tube are damaged, for example, from exposure to high temperatures.

The slightest change in shape can affect the readings and cause error F33.

It is worth noting that this is a problem with almost all gas boilers. Some manufacturers solve this by installing a special extension (this is what BAXI did) to collect condensate, and some even make heated tubes to evaporate it.

Briefly about the main thing

When operating Vaillant boiler equipment, malfunctions sometimes occur, which the unit signals by the appearance of an error on the screen. The instructions will help you find out whether the signal indicates a minor failure or a serious breakdown. Some problems can be solved on your own. You should start by rebooting the boiler, since the cause of the message is often a system failure.

If rebooting does not help, pay attention to the external sign of the problem. They may be unusually loud noise when the boiler is operating, or low temperature of hot water. Overheating of the system causes an emergency stop; pressure surges indicate leaks. Sometimes a Vaillant gas boiler produces errors (for example, f8) due to improper operation.