To identify problems in Bosch washing machines, there is a self-diagnosis system. If, after loading the laundry and starting the program, the washing does not start or the process is interrupted and does not resume, and an alphanumeric code appears on the display, the question arises - what does error E17 mean in a Bosch washing machine ✔.

Causes

Coding E 17 (in the newest models - F17) means that the time allotted for filling the washing machine tank with water has expired. In this case, there are no interruptions in the power supply, the start button for the selected mode is pressed, but the flow of liquid does not begin, as evidenced by the absence of the characteristic “murmuring” sound. The system reacts to a prolonged absence of water, cannot start or continue the washing process and signals this. The most common reasons why error e17 appears on the display include:

- Lack of water supply. Identified by opening any tap in the apartment, the washing process is started again or resumed after water appears.

- Complete or partial shutdown of the valve on the water supply system to the machine. Before starting the wash, the shut-off valve must be fully open, otherwise water either does not flow at all or does not have time to fill the tank in the allotted time.

- Low pressure in the water supply. Low pressure does not allow the machine to fill the tank with water in time.

- Problems with the inlet hose. This element of the water supply to the machine must be in a straightened state and clean from the inside: crushed or twisted places prevent the passage of liquid.

- The mesh filter is clogged. The part located where the inlet hose is fixed to the body of the washing machine and is designed to purify tap water from small particles periodically becomes clogged.

- Internal faults in the Bosch washing machine, including breakdown of the inlet valve and pressure sensor (pressostat).

A failure can also occur in the control unit. Sometimes it helps to fix the problem by disconnecting the device from the power supply for 15-20 minutes and then turning it on. Otherwise, the unit needs to be repaired.

Difficulties with the engine

A thorough check of the engine will be required to determine where the problem is occurring. If the malfunction occurs due to wear on the carbon brushes, it is enough to replace them. In case of other engine breakdowns, in most cases, the entire engine is replaced.

After fixing the problem, you will need to reset the error. To do this, turn the program switch to the “off” position and set the selector to “spin”. After this, wait for the code to appear on the control panel and hold down the drum speed switch button for a few seconds. Then set the switch to the “drain” position and hold down the speed switch key again. The appearance of a characteristic sound signal and the simultaneous turning on of all lights for a short period of time indicate a successful reset.

We managed to determine the cause of E21, but still need a part? Order from Samodelkin: inexpensive, fast delivery, guarantee.

View all engines »

View all brushes (current collectors) »

See all drive belts »

View all tachometers »

Causes of malfunction and ways to eliminate them

Error E17 - what is it?

Stopping the wash cycle due to lack of water supply does not always indicate a complex Bosh failure. In some situations, the problem can be solved quite simply, without requiring disassembling the washing machine and calling a technician. In rare cases, a malfunction of the washing machine may be caused by a one-time power surge or a coincidence.

In this case, a simple reboot can help - unplug the washing machine for 20-30 minutes (pull the plug out of the socket), and then turn it on and start again. If the reboot does not help, move on to diagnosing the failure.

Self-draining during washing

Self-draining is characterized by the intake and immediate discharge of water. This situation indicates a violation of the Bosh connection. This can happen either with a recently installed washing machine or with an old one that has been moved or moved to a new location.

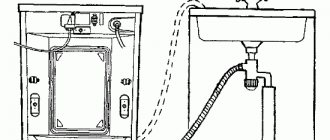

When installing the machine, the drain hose must be raised above the level of the tank. This point is stated in the instructions for the washing machine. If the hose simply spreads along the floor, the collected water will flow out spontaneously. As a result, the tank remains empty, and after a certain time the washing machine issues an alert E17 (F17).

The solution to the problem is to check that the washing machine is connected to the communications correctly.

Weak pressure

The Bosh washing machine produces water, but the process is very slow. It is necessary to ensure that there is sufficient pressure in the water supply system. You also need to see if the tap that shuts off the water supply to the washing machine is fully open.

Clogged water supply filter

If the filter is clogged, the Bosh washing machine may draw little water or not draw it at all. Functionally, a filter is a mesh that is designed to capture and retain small fractions that may be in tap water.

If water does not flow to the washing machine, you need to clean the filter. To do this, perform the following steps:

- Turn off the water supply valve to the device.

- Pull out the washing machine so as to gain convenient access to the rear wall.

- Place a rag on the floor from the back wall and place a bucket.

- Unscrew the plastic nut, disconnecting the hose.

- Carefully remove the mesh.

- Clean in water.

- Reassemble the assembly in reverse order.

When performing a test run of the washing machine, you must ensure that the connection is tight.

The device does not draw water

If the washing machine tries to draw water, but it fails, you need to make sure that there is water in the water supply. This is very easy to do - you just need to try opening the tap in the bathroom or sink. If there is no water in the system, washing will have to be postponed.

Another possible reason is turning off the water supply tap to the washing machine. Make sure that the shut-off valve is turned to the “ON” position.

A more rare, but quite possible situation is a severe bending/squeezing of the hose. It is advisable to check its condition along its entire length, including behind the furniture.

Inlet hose clogged

In order to check the condition of the inlet hose, it should be disconnected from the washing machine and from the water supply. Remove it after the water supply to the device is turned off.

If the hose is in a dilapidated condition, it is better to replace it. It may also be damaged due to mechanical impact. The hose cannot be repaired.

Fill valve problem

The fill valve has a rather complex structure - it consists of an electromagnetic coil, a membrane and a housing.

To access the valve, the washing machine will have to be partially disassembled. If the unit fails, the valve is replaced with a new one.

The valve in Bosch washing machines can be two sections - one of them is designed to draw water for washing, the other for rinsing. Depending on which section is out of order, the washer may either not rinse or not start washing.

Breakdown of the pressure switch

A pressure switch is a part that measures the water level in the washing machine tank. If the sensor fails, it does not provide objective information to the control module, and water is not drawn. The solution to the problem is to repair or replace the pressure switch.

Control unit malfunction

If the control unit fails, the Bosh washing machine does not draw water. Repair of the module is carried out by partially disassembling the washing machine and removing the unit.

In most cases, repairs can eliminate the damage. But if the module is badly burned out, it is replaced with a new one.

Wiring irregularities

If the wiring in the washing machine is defective, various malfunctions can occur. One of them is the lack of water supply. For diagnostics, the washing machine is partially disassembled to check the condition of the wires and terminals.

If defects are found, they are eliminated. These could be oxidized contacts, damaged wires, etc. If necessary, the contacts are soldered, twisted, or even the contact group is completely replaced.

What does the error mean and why does it appear?

Error E21 most often occurs when trying to start a Bosch washing machine. The unit begins to rotate the drum only in one direction or does not rotate it at all, and then issues an alphanumeric code.

The error indicates that there is a problem with the engine electrical circuit. The following reasons can cause the E21 problem:

- control board failure;

- the voltage in the home network is too low;

- physical damage to the washing machine power cord;

- foreign objects in the drum;

- carbon brush wear;

- tachometer failure;

- short circuit in the motor windings.

Some of the listed faults can only be eliminated with the help of a service. But some problems can be easily fixed with your own hands.

On some models of Bosch washing machines, the error is displayed as code F21

Attention! Sometimes E21 appears only at the moment of switching to spin mode, and washing and rinsing proceed normally.

Possible faults requiring repair

We repair Bosch washing machines every day and have accumulated a huge amount of experience. Here are the most common breakdowns that cause error E17.

| Signs | Breaking | Repair or replacement | Cost* (work only) |

| The washing machine does not draw water at all or only during rinsing. Error F17 or E17 is displayed on the case. | Fill valve. It supplies water to the SMA. The valve consists of a body, a membrane and an electromagnetic coil, which opens the membrane when water is drawn in. The coil usually fails.

| The fill valve needs to be replaced. | from 1900 rub. |

| The Bosch machine does not pour water and shows error F17 or E17. | Pressostat (level sensor). It measures the amount of water in the SMA. Maybe:

| The level sensor needs to be repaired or replaced. | from 2000 rub. |

| The washing machine displays error F17 or E 17 when turned on. Water is not being collected. | Control unit (electronic controller). In the filler valve control circuit, the tracks, microcircuit elements have burned out, or the contacts have rotted. | The technician replaces burnt elements, solders the tracks and restores rotten contacts. In difficult cases, the control unit is changed completely. | from 2500 rub. |

| Control unit firmware (SMA memory) failure. Occurs due to power surges. | The wizard reprograms the control module memory. | ||

| Wiring, contacts (in the water supply valve circuit). If the wiring is damaged, the signal does not reach the fill valve, and the machine freezes with an error. The reasons are vibrations, which cause the cable to fray. In private homes, wiring is chewed by pests (mice, rats). | The technician restores the wiring and/or solders the contacts. In difficult cases, the damaged cable and/or contact group are replaced completely. | from 1900 rub. |

*Parts are not included in the price and are paid additionally.

How to fix error f17

We should immediately warn you that in some modifications of washing machines (Bosch Maxx 5, Bosch Maxx 7) this error may be indicated by code E 17. We already know what this means, we just need to figure out how to correct the situation. First, let's perform actions that every consumer can do - check the supply valve, clean the filter and the hose itself.

If after this the error disappears, the problem is completely eliminated. But what to do if the signal resumes? There is only one thing left to do - continue to look for the problem. Let's move on to checking the internal elements.

Water intake valve

Before carrying out the test, turn off the water and disconnect the Bosch washing machine from the electrical network. We disconnect the hose from the inlet valve, substituting a container in advance into which the remaining water inside will drain. Remove the top cover of the washing machine and disconnect the connectors from the valve coil. We unscrew the screw, remove the valve, and inspect it for malfunction or blockage.

We install the element in the reverse order. If, when checking the car, the error code f17 clears, the problem is solved.

Pressure control sensor

This is a pressure switch that is responsible for filling the tank and sends the necessary information to the control module, after which the washing process is activated. If the sensor fails, it begins to give false readings or stops working completely. To fix the problem, remove the top panel of the Bosch washing machine, loosen the clamp, and disconnect the sensor hose.

To check the pressure switch, insert the tube and start blowing into it. If there are no characteristic clicks, the element must be replaced with a new analogue - repairing a failed sensor will not yield anything.

Control unit module

It has already been said that such a block receives a command to start the work process of washing, rinsing or spinning the laundry. If water gets on the module elements, or a voltage drop occurs in the network, the module may well fail. In this case, the Bosch washing machine faithfully issues an error signal f17.

To fix the problem, you should inspect the control board. Contacts will have to be repaired by soldering, burnt out elements will have to be replaced. As an additional measure, it is recommended to inspect the wires going to the pressure switch and inlet valve. If damage to the insulating layer is detected, we change the wiring.

Self-draining water from the tank

Due to incorrect connection of the drain, water leaves the tank by gravity, so the machine constantly takes in water.

Signs

The washing machine constantly draws and drains water, and then writes error E 17. The problem occurs in recently installed machines.

How to fix

Carefully read the instruction manual for your machine. The hose must rise above the water level in the tank when washing.

Install the washing machine according to the instructions or use the connection for washing machines.

What to do

Problems associated with external water supply elements can be eliminated by fully opening the shutter valve, cleaning or replacing the water supply hose. If after these steps the error has not been reset, you should diagnose faults inside the washing machine.

How to clean the mesh filter

You should start cleaning this part only with the device completely de-energized and the water supply valve closed. The ends of the hose are unscrewed at the junction with the machine body and the water supply; if there is any residual liquid in it, they are poured into a previously prepared container, and the part is washed. The filter mesh is removed and thoroughly cleaned of contaminants.

You can soak it for 2-3 hours in a solution of citric acid.

The filter is installed in place, both ends of the hose are screwed on. The machine is restarted, if the error is no longer displayed, then the problem has been resolved.

Intake valve repair

Before inspecting the valve, the machine is disconnected from the power supply and water supply. The inlet hose is disconnected and the water is drained from it. Remove the top panel from the machine body, which is secured with 2 screws. Check the contacts of the valve coil for damage, the wires coming from it, and use a multimeter to measure the resistance of the coil.

If the part turns out to be faulty, it is removed by first disconnecting all tubes and wires and loosening the fixing screw. The new valve is connected to the device with new clamps, covered with a panel, the washing machine is connected to the water supply and a test run is done.

Pressostat repair

The pressure sensor reacts to the water level in the tank. If it is faulty, the diagnostic system considers the tank empty, even if it is filled with water, and does not start the washing mode, displaying error E17. The pressure switch is a round part with connecting tubes attached to the exhaust valve.

To check its serviceability, remove the pressure hose from the pressure switch fitting and put a tube of suitable diameter on it. If you blow lightly into it, the part that has not failed will respond with a click. The pressure switch is also checked with a multimeter. When connecting a working sensor to the relay contacts, the device readings should change. The broken part is disconnected from the washing machine, the wires are marked to make it easier to connect the new part correctly.

Reasons not related to the operation of the equipment itself

- Lack of water in the water supply system or insufficient pressure (below 1 bar). It’s unlikely that anything depends on you here. All you can do is call the service company and find out why the water is turned off. Or why the pressure of the water supply system is reduced. Wait for the technicians to fix this problem.

- The water supply tap to the machine from the water supply network is closed. This is a “mechanical” error associated with your carelessness. Next time, before turning it on, check that the tap is open.

If these are not the reasons, then error F17 is issued due to problems with the control system of the machine itself. You may not be able to do this without Bosch service. However, we will continue to look into it.

Call the master

In cases where a problem with a Bosh washing machine can be fixed on your own, there is no need to call a technician.

Without a specialist, you can easily correct situations that do not require disassembling the device. To solve more serious problems, preparation is required, including the selection of the necessary tools.

Depending on the complexity of the breakdown and the pricing policy of a particular company, the cost of the work is determined. The customer pays separately for new parts needed for replacement, as well as consumables (wires, gaskets, etc.).

You can find a washing machine repair company on the Internet. It is also advisable to read reviews about companies there. Among trustworthy companies, it is better to give preference to those that have been operating for a long time and value their reputation.

The average cost of work in the capital is:

- restoration of wiring - about 2,000 rubles;

- repair/replacement of the control module – from 2,500 rubles;

- repair or replacement of a pressure switch – from 2,000 rubles.

After the repair, the master issues a guarantee for the work performed.

Error F21 in Bosch machines without a display

Bosch washing machines without a screen indicate error F21 by flashing indicators. Here are the lights that flash depending on the car model.

- Bosch Classixx washing machines (for example, models WLF20(16)260 and WS10F260) report code F21 by flashing the second light from the bottom (the “Rinse” indicator).

- The Bosch Maxx 4 series flashes the first and third indicators from the bottom in a vertical row. These are the “Ready” and “Finish” lights.

- In the Bosch Maxx 5, 6 or 7 , the first, third and fifth spin speed indicators from the bottom light up. Depending on the model, this is 1200 or 1000 revolutions, 800 and “No spin”.

Adviсe

In addition to the low quality of equipment and technical wear and tear of its elements, as well as violation of the rules for using the unit, malfunctions can also be caused by objective factors that directly affect the functioning of household appliances - the quality of water and electricity supply. These are the ones that most often lead to errors.

Any changes in the network have the most unfavorable effect on the operation of the washing machine, leading to its rapid failure - which is why the problem must be eliminated. At the same time, you should not completely rely on the built-in surge protection system inside the most modern machine models - the more often it operates, the faster it will wear out. It is best to get an external voltage stabilizer - this will allow you to save money on equipment repairs in case of problems in the electrical network.

The fact is that tap water has high hardness, the salts it contains settle on the drum, pipes, hoses, pump - that is, on everything that can come into contact with the liquid.

This entails damage to the devices.

To prevent the appearance of limescale, you can use chemical compounds. They will not be able to cope with significant “salt deposits” and will not remove old formations. Such compositions contain a weak concentration of acid, so the equipment should be processed regularly.

Folk remedies act more radically - they clean quickly, reliably and very efficiently. Most often, citric acid is used for this, which can be purchased at any grocery store. To do this, take 2-3 packages of 100 g each and pour them into the powder compartment, then turn on the machine at idle speed. When the work is completed, all that remains is to remove the pieces of fallen scale.

However, manufacturers of household appliances claim that such measures are fraught with the most dangerous consequences for machines and cause damage to their parts. However, as evidenced by the reviews of many users who have been using acid for many years, such assurances are nothing more than anti-advertising.

Which means to use is up to you.

In addition, breakdowns are often the result of human factors. For example, any forgotten metal item in your pockets significantly increases the risk of equipment failure.

In order for a Bosch machine to serve faithfully for many years, it requires regular maintenance. It can be current or capital. The current one is done after each wash, a major one needs to be done every three years.

When carrying out major preventative maintenance, the machine is partially disassembled and the degree of wear of its parts is checked. Timely replacement of old elements can save the machine from downtime, breakdowns and even flooding of the bathroom. These rules apply to all Bosch machines, including the Logixx, Maxx, Classixx series.

Prevention measures

Problems with your Bosh washing machine that are associated with water intake from the water supply can be prevented using preventive measures.

These include:

- Organizing the correct connection of the washing machine to communications. This applies not only to the drainage system, but also to the water intake system, as well as to electricity.

- One of the factors that lead to control module burnout is power surges in the network. It is possible to prevent equipment breakdown by connecting the machine through a voltage stabilizer.

- If the water quality in the water supply is very low, it is advisable to install a filter at the entrance to the apartment. This will prevent fractions in the water from entering the washing machine and will extend the life of the equipment.

Hall sensor malfunction

To check the tachometer, the washing machine is disconnected from the network, after which the back panel is dismantled and the drive belt is removed.

The Hall sensor is located on the motor housing and can be removed and inspected. There may be traces of grease or oxidation on the inner surface of its ring that must be removed. Next, the sensor is checked using a multimeter. If the tachometer is faulty, it must be replaced.

Recommendations

The following tips will help you diagnose and repair your washing machine:

- The mesh of the inlet filter becomes clogged when the quality of the water is low, the presence of scale, rust, etc. If it is in a neglected state, you can soak it for a couple of hours in a concentrated solution of citric acid. This will help clean it better.

- It is advisable to check possible faults due to which water does not fill, starting with the simplest ones, gradually moving on to more complex ones.

- All repair and diagnostic activities that require opening the case should be carried out when the device is disconnected from the electrical network and from the water supply.

- You should not begin serious repairs and disassembly of components if you do not have a set of tools and skills for repairing household appliances.

- When calling a technician to your home to repair a washing machine, it is advisable for the company dispatcher to indicate not only the brand, but also the model of the device.