Comfortable life in a country house is ensured by a complex of engineering communications, which includes a sewerage system. The drainage system is not limited to the internal network. Its important part is the external pipeline connecting the house with the collector or septic tank.

To organize such a pipeline, pipes for external sewage are used. Their properties affect the reliability and functionality of the entire system. In modern construction, several types of products are used; To select suitable ones, it is necessary to take into account future operating conditions.

High-quality installation of external sewerage determines the reliability of the entire system Source kanar.ru

Criterias of choice

The external pipeline operates in unfavorable street conditions. Incorrectly selected pipes for external sewerage can deform under soil pressure (during rising groundwater levels) or change properties due to severe frost. Violation of the integrity of the system will result in unexpected expenses for repairs (the damaged fragment will have to be replaced).

When designing external sewerage, they try to find a compromise between the need to ensure a long service life of the system and optimize costs. External sewerage pipes must meet the requirements for:

- strength (ability to withstand environmental stress);

- wear resistance (resistance to internal aggressive environment);

- affordability.

Types and characteristics

For external sewerage, several types of materials with different physical and chemical properties are used.

Cast iron pipes

A classic method of arranging a sewer system that has existed for decades. The widespread distribution of cast iron products was due to a complex of reasons:

- High mechanical strength and long service life.

- Resistant to temperature changes and aggressive environments.

- Easy installation.

Cast iron is expensive, heavy and efficient Source krasnodar.blizko.ru

With the development of technology, cast iron sewer pipes for external sewerage have lost relevance due to some features:

- Heavy weight, forcing the use of special equipment during assembly.

- A defect in the internal cavity, leading over time to a narrowing of the lumen.

Ceramic pipes

Ceramic pipelines have been known since antiquity. Modern factories produce ceramic products with a diameter of 100-600 mm, which have undoubted advantages:

- Service life 30-40 years.

- Easy installation and low installation cost.

- Chemical inertness, temperature stability and environmental friendliness.

- Low internal surface roughness.

Disadvantages of ceramic products:

- Fragility (before assembly they must be checked for cracks).

- Short length (increases the number of joints of external sewerage).

The fragility of ceramics is leveled by strict adherence to installation technology Source alemsohbet.co

Asbestos-cement pipes

Although the material contains asbestos fibers, their chemical bonding with cement makes the products safe. The advantages include:

- Light weight and easy installation.

- Durability.

- Low thermal conductivity (almost no problems with freezing).

- Resistance to aggressive environments.

The main disadvantage of asbestos-cement products is fragility. Mechanical loads (especially during transportation) are fraught with cracks and chipped edges.

Polypropylene pipes

Plastic polypropylene pipes (Russian name - PPR, international - PPR) are suitable for assembling an external sewer system in a country house. Their popularity is a consequence of their advantages:

- Long service life. Manufacturers guarantee 30-50 years of flawless operation.

- Light weight and elasticity. Savings on transportation and installation.

- Resistance to high temperatures (operating mode - 80°C; emergency short-term temperature of 100°C does not reduce service life).

Polypropylene - corrugated on the outside, smooth on the inside Source obustroeno.com

See also: Catalog of companies that specialize in water supply and sewerage.

- Chemical inertness. The material is resistant to corrosion and does not emit harmful substances.

- Smooth inner layer.

- Diversity. Selection of models and parts of any configuration. Options are available reinforced with fiberglass or aluminum.

Flaws.

- Products made from PPR cannot be bent. To organize bending or turning, tees and angles are used.

- A welding machine is used for connection. Thermal welding creates a seam that is uniform in structure.

Polyethylene pipes

Black smooth HDPE pipe - easy cable installation.

Laying cables in buildings requires a large number of bends, tight fastening to the surface and good protection from mechanical damage. Smooth black HDPE pipe is indispensable when laying utilities, installing video surveillance networks, alarm systems, etc. Laying flexible pipes is very easy, both indoors and on the external walls of buildings. Light pipes are very easy to lift to a height using only ladders. The use of smooth HDPE pipes guarantees complete protection of the cable from all adverse influences, in addition, a high level of safety is ensured in terms of insulating electrical wires from people. The walls of the pipes are resistant to temperature and provide the proper level of fire safety for electrical wiring.

Electricians enjoy the lightness and flexibility of the pipes, which can be quickly installed and fastened together. Pulling cables along them is also not difficult. When setting up networks, there are often situations when the cable is stretched incorrectly, resulting in it not being enough. You have to re-tighten the entire cable, which damages the walls and ceilings. If the cable was pulled inside HDPE pipes, then re-tensioning it is not a problem - it takes just a minute. It is very convenient that such pipes can be laid at smooth angles or with a large number of bends. The walls are connected using light welding equipment. When welded, the joint becomes monolithic, so seam divergence is an extremely rare occurrence.

Video description

The plastic variety (Russian name - PE, international - PE), is widely used in external drainage systems:

PVC pipes

Polyvinyl chloride sewer pipes (PVC in international transcription) are mainly used for arranging sewer systems in residential buildings. Among the advantages of such products are:

- long-term operational period (40-50 years);

- reduced flammability and ultraviolet resistance;

- resistance to corrosion and clogging;

- light weight and easy installation (easy to cut and bend).

Smooth PVC pipes are used where there is no heavy load on the ground Source yandex.by

When using, it is necessary to take into account some features of the products:

- The disadvantage that limits the use of PVC pipes is the high coefficient of thermal expansion (change in linear size under the influence of temperature). If the liquid is heated to 60°C or higher, the tightness of the joints decreases, which can lead to leakage.

- The plasticity of the material decreases at low temperatures. Operation of the pipeline without insulation is allowed in the range from 0 to -15°C.

Insulation of sewer pipeline

The efficiency and durability of external sewerage largely depends on properly performed insulation. This is especially important in northern regions and when pipes are laid above the freezing level. To understand how important insulation is, you need to imagine how the system works in the cold season.

During the passage of liquid, which always has a positive temperature, the pipe is partially filled with liquid waste. Water vapor also fills the pipe.

In winter, at subzero temperatures, the part of the pipe located closer to the surface cools, which leads to the formation of condensation, and then frost, which rushes to the center of the pipe, which often causes blockages.

Molded insulation is selected based on the diameter of the pipe, before laying the sewer line, it is simply put on top

High-quality insulation of the pipeline allows you to avoid the formation of frost and blockages, as well as protect the system from freezing. It can be done using different materials that are abundantly available on the market today: foamed polyethylene, polystyrene foam, isover, thermal insulation and others.

Insulation materials can be rolled or molded. The first are wound onto the pipe while it is being laid in the basement. Thermal insulation shell made of foamed polyethylene has a similar application.

They are not used as thermal insulation for underground lines. Mostly molded insulation is used, which is made for a specific pipe diameter. Thermal insulating material of the required diameter is simply placed over the sewer pipe.

One of the most popular insulation materials is Energoflex, which is made from extruded polystyrene foam. The closed cell structure of the material prevents the penetration of groundwater, which can significantly reduce the insulating properties. Foil casing enhances efficiency

If the temperature in the region is very low, then insulation alone is unlikely to be a reliable protection of pipes from freezing. In this case, a heating cable is usually used, which is laid along the outside of the pipe inside the heat-insulating material.

When using a heating cable, you need to ensure that the joints are completely sealed to prevent moisture from leaking inside.

Image gallery

Photo from

Laying sewerage in a cold basement

Application of thermal insulation shell

Using a heating cable

Laying pipes below the freezing level

Advantages of sewerage with PVC pipes

The economic benefits of installing and using such a sewer system consist of:

- reducing transportation costs;

- saving consumables;

- low labor intensity during assembly;

- no operating costs.

Environmental safety during operation is also a valuable quality of products.

The appearance of PVC pipes has greatly simplified the organization of drainage Source remontsami.ru

External sewerage: sequence of work

- Preparing a trench for sewerage. Its depth depends on the depth of soil freezing, the occurrence of groundwater and other features of the site. According to SNiP P-G.3-62, laying is carried out 0.5 m below the freezing mark. For pipes with a diameter of 110 mm, the trench width is 0.6 m.

Checking the slope angle is an important part of installation Source oxu.az

- Pipeline installation. Starts from the foundation of the house; the pipes are connected in a suitable manner and laid with a slope. If the sewerage system is laid shallow, the pipeline is insulated. At the exit from the building, the pipe must be insulated.

- The slope angle is checked , then the trench is backfilled.

Check valve device

Improper installation and violation of the rules of operation of the drainage system leads to an emergency situation - a blockage. The contents of the pipes can move back with all the ensuing consequences on the 1st floor. Installing a sewer check valve helps avoid dramatic events.

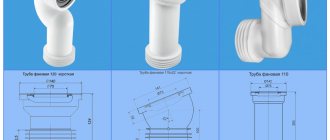

A check valve allows fluid to flow only outward; the return flow of wastewater is reliably shut off. A valve with a diameter of 110 mm is mounted on a common pipe, and a valve with a diameter of 50 mm is mounted on each PVC drain pipe.

Valves are made from cast iron, brass or steel. Due to the widespread use of PVC pipes, the demand for cheap and durable PVC valves has increased. By design, check valves are:

- PVC valve. Mounted on both horizontal and vertical pipes. Inside there is a reciprocating locking part - a plate fixed at a slight angle. It bends under the pressure of the escaping liquid, and the reverse flow presses it, blocking the return movement.

- Ball valve. The locking mechanism is a metal ball. If back pressure occurs, it is pressed against the hole and blocks the flow.

Cross-section of a ball check valve Source aglant.ru

Size and diameter of sewer pipes for a private house or apartment

Before deciding which pipes to use for sewerage and buying them, you should take care of drawing up the project. It must accurately indicate all drain points and the type of plumbing equipment. Such a plan will help you figure out what pipes are needed for sewerage in the house, what length and diameter of the product will be required. It would also be a good idea to determine how many auxiliary parts are needed. Their number depends on how many turns and branches there are in the pipe. We must not forget about the possible change in the diameter of the pipeline in certain areas - for underground sewerage it is better for the pipe to be wider.

Depending on which plumbing fixture will be connected in a particular case, it is necessary to select pipes with different diameters, for example:

- washing machine, dishwasher - 25 mm;

- bath, shower, kitchen sink - 40-50 mm;

- sink, bidet - 30-40 mm;

- outlet from the riser - 65-75 mm;

- pipe distribution - 40-50 mm;

- central riser, toilet pipe - from 110 mm.

Important! When purchasing, it is better to add at least 10% reserve to the calculated length.

It is also worth calculating the distance from the central riser to each drain point. If it is too large, it is better to consider the presence of connectors and vents, which are often used for sewerage.

We recommend purchasing siphons immediately. It is better that they are made of the same material as the pipes - in this case there will be no problems with the connection.