You can order an aluminum slatted ceiling from us and install it yourself. In order to do the work yourself correctly and accurately, you need to study the technical manual for assembling the structure along with the lamps. Below we provide complete installation instructions. You can calculate the required amount of material for installation and place an order using the link. Delivery of components is carried out in Moscow and Moscow Region.

Suspended slatted ceiling is intended for residential premises and rooms with high humidity. In apartments, this design is used mainly for bathrooms, kitchens, balconies, and on this page we will tell you how to properly install a slatted ceiling with your own hands.

The advantage of the rack system is ease of installation, simplicity of work associated with assembling and disassembling components, which allows you to learn how to assemble the ceiling yourself without much effort.

Stages of installation of spotlights

The connection process comes down to the sequential implementation of the following steps:

Stages of connecting a spotlight.

- design and layout;

- laying and pulling cables to installation sites;

- making holes and connecting;

- connection testing.

Such a detailed breakdown into stages is due to the fact that part of the work must be performed when forming the ceiling covering.

The location of the lamps is planned before covering it with finishing material, that is, during the installation of the frame.

Design takes on special meaning when there are several levels near the ceiling. In this case, it is necessary to provide wiring to the mounting points of the lamps at each level, taking into account the distribution of the luminous flux. Lamps that are located within the same level must form one single circuit.

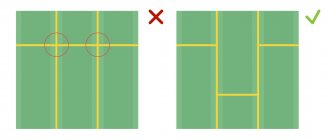

When planning the number of spotlights that will provide the required illumination of the space, it is necessary to take into account that the distance from the wall to them should be no more than 60 cm, and the distance between centers should be 25-30 cm. In this case, the lamp should be no less than 30 cm from the frame cm. If the lamp is placed closer to the frame, then its installation at the final stage may be difficult.

The device of the lamp.

The presence and location of other lighting fixtures in the room affects the final number of fixtures. The spotlight can be equipped with a rotating mechanism, with which the direction of the light flow can be changed. Therefore, they can be diverted when using several lamps at the same time.

The wiring is laid during the installation of the frame. It is placed in special boxes or fixed on it in such a way that when making holes for spots, it is not difficult to get out. If it is not possible to select locations for installing spotlights during the installation of the frame, then you can lay the cable to only 1 lamp. And connect each subsequent spotlight to the previous one, stretching the wire already in the mounted ceiling covering. But this method of laying wiring somewhat violates safety regulations, since the wires remain lying directly on the surface of the suspended ceiling.

The cable, when laid along a frame or in protective boxes, can be used with 2 or 3 cores. The loop for attaching each spotlight is left 10-15 cm in size. It is attached to the frame near the location of the spotlight using a plastic tie. But the fastening should not be tight, so as not to cause difficulties when dismantling it during final connection.

Drilling holes for each spotlight is carried out upon completion of the ceiling installation. Proper design of spots placement allows you to avoid their location on metal frame elements. In addition, if the spotlight is located at the joint between the sheathing sheets, then it should be moved or the sheets redistributed so that the joint is moved to the required distance.

Connection diagram for several groups of lamps.

The holes are drilled with a drill with a special attachment - a hole saw, the central drill of which is installed in the center of the lamp location. A perfectly even circle is formed, which avoids unnecessary gaps. The diameter of such a saw should be 3-4 mm smaller than the corresponding external size of the lamp, but 3-4 mm larger than the internal dimensions.

After all the holes are drilled, you need to remove the loop of wire that was left for attaching the spot. If such loops have not been made or the wiring for each spotlight is not connected, then it is necessary to stretch the cable to them. Pulling the wire must begin from the outermost lamp, gradually moving further along the line of their installation. This can be done using a hook, which is made of strong wire.

Box lining

Sheathing the box

Before fixing the sheathing, insulation is laid, if provided. Drywall sheets are cut to fit the box. The joints of two adjacent sheets should be placed on one CD profile. Initially, the lower part of the structure is sutured, and then the side.

The material is fixed with self-tapping screws, the heads of which are recessed by 1–2 mm to facilitate puttying.

Round holes are cut in the places where the lamps are installed.

How to install spotlights yourself

If we consider in more detail the installation method of these lighting devices, it should be noted that in order to connect them during the manufacturing process of finishing structures, supply wires must be laid with a reserve (200 - 300 mm) for the convenience of further switching. For electrical safety, the conductors must be threaded through a special corrugation and not come into direct contact with the metal elements of the frame (which can damage the insulation).

In the places where the spotlight is supposed to be installed, holes are made into which the devices will subsequently be installed. Here everything depends on the type of spotlight, so the size and type of mounting hole (round, square, triangular) must comply with the manufacturer’s recommendations (usually indicated in the product data sheet).

Holes can be cut using a knife, file, or milling bit (clamped into the chuck of an electric drill), and it is recommended to do this procedure in stages. First, the hole itself is made, and then a finer adjustment is made using a file, sandpaper, or knife so that the lamp body fits tightly into the prepared hole. If the spotlight is planned to be mounted in suspended ceilings, then it is necessary to provide a protective ring on the front surface of the material. (We recommend reading about how to install spotlights in suspended ceilings in the following material: https://domgvozdem.ru/index.php/elektrika/262-ustanovka-svetilnikov-v-natyazhnykh-potolkakh)

The connection diagram for spotlights is quite simple and involves switching devices to cable cores at three points (phase, neutral, ground). Moreover, the correct electrical connection can be checked using the corresponding indicators on the terminal block of the spotlight (L, N, PE - respectively).

In general, luminaires must be connected to each other in a parallel circuit, when each subsequent device is connected by a loop from the previous one (from phase to phase, from zero to zero, etc.). Moreover, any number of branches and with any number of lamps can be connected in this way. Limitations may only apply to the total power consumption of lighting systems.

After the lamp is connected to the appropriate conductors, it is recessed into a pre-prepared hole and fixed in it using special spring-loaded brackets.

Dimensions

If we talk about the size of the box, it will depend on what you want to disguise behind it. For example, this could be wiring, water pipes, gas pipes, ventilation ducts, etc. If backlighting is to be installed, the size must be sufficient to allow installation of a power supply and LED strip.

A properly installed box will decorate the room and will last for many years.

How to install spotlights: step-by-step instructions

Like many other types of work, the installation of spotlights in drywall begins with markings - the placement diagram of spotlights, copied or saved in some other way, is transferred to the ceiling structure, and holes of the required diameter are drilled in accordance with the received marks. For these purposes, use a special crown mounted on a drill or screwdriver - you must drill carefully so as not to damage the wires with the crown.

When the mounting holes are ready, the wires previously hidden under the ceiling are taken out and the loops are cut. After that, the resulting two ends of the cable are bifurcated - you need to separate the individual wires and clean them of external insulation. This is done with a knife or a special tool.

DIY installation of spotlights

The next step is to strip the ends of the four separate wires. If the installation of spotlights (or rather, their connection) is carried out using terminals, then a small section of the wire (approximately 5-7mm) must be removed from the insulation. If you plan to twist, then it is better to strip the longer end, since long twists do not get very hot and do not pose any danger, even if they are not soldered.

How to install spotlights with your own hands - master class

The stripped ends are twisted in pairs, observing the color of the wires - blue must be connected to blue, and brown to brown. If the installation of spotlights in drywall involves grounding, then under no circumstances should it be abandoned. In this case, the wiring must be done with a three-core wire - green or yellow wires must also be twisted, observing the color scheme. The twists must be pulled tightly with pliers.

Installation of spotlights in drywall photo

Well, then everything is simple - we take the lamp and connect it to the twisted wires. The main thing here is not to confuse the grounding wire coming out of the lamp. The different colors of the wires will help in this matter - the yellow or green wire must be connected to the corresponding wire of the electrical wiring. You don’t have to worry about the other two - one lamp wire to one twist, the other to the remaining one.

Connecting spotlights photo

Particular attention must be paid to the insulation of the twists - the electrical tape must be wound tightly and in several layers

DIY installation of spotlights

The spotlight connected in this way can only be inserted into the mounting hole

If you pay attention to the back side of the lamp, you will see two releases - they are tightened by hand and, after the lamp is slightly inserted into the hole, they are released. Then the spotlight itself takes the position it needs and is securely fixed in the mounting hole

Installation of spotlights in drywall photo

At the final stage of work, a light bulb is installed in the lamp.

DIY installation of spotlights

That's it, now you can get down from the stepladder, turn on the power supply and enjoy the work done.

As you already understand, installing spotlights is not only easy, but also simple. There is no need to call a qualified electrician for these purposes, and you can do it yourself.

Author of the article Dmitry Vorokhov

Design features of the slatted ceiling

A slatted ceiling is a structure consisting of metal strips (slats) and suspended elements that are installed on the rough ceiling using long spokes. In the future, all these slats are used to cover the ceiling with various materials.

Before installing such a ceiling, you need to determine how many lamps will be used in the room, what type they will be and at what points they will be located. The design of the lighting system is carried out at the stage of assembling the frame of the slatted ceiling!

Be sure to use corrugated pipes and sleeves in the bathroom, toilet or kitchen to protect electrical wiring from moisture and dust. In addition, if repair work is required, there will be no need to completely dismantle the cladding materials on the ceiling.

How to find “power” for a lamp?

A pressing issue for people who want to install a spotlight on their own is the source of power supply for the lamp. The most relevant options (by popularity) are:

- Power socket;

- General lighting switch;

- The actual distribution board.

The last option is used extremely rarely, as it is extremely expensive and not optimal. A similar solution is resorted to in cases where increased power consumption is implied. Modern LED spotlights are devices that are economical.

If you plan to conduct wiring from the switch, then make sure that the connection is made before the “cut-off” mechanism. If you do the opposite, the lamp will turn on and off together with the lamp or chandelier. Of course, in some cases such a solution is justified, but such tasks are rare.

If your budget allows, then choose the so-called. “smart” spotlights that can be controlled using a remote control or even from a smartphone or any other personal device. Such solutions are becoming increasingly popular, but few people know about them yet.

LEDs

The choice of ceiling lamps is quite wide. The main thing is to decide on the option that is suitable specifically for your case. To do this, consider the features of the proposed light elements. Let's start the review with LEDs.

A built-in lamp in a slatted ceiling of this type is advantageous in that it has a long service life at a minimal cost. The design of such a device does not contain spirals, glass bulbs and other elements characteristic of traditional lamps. In addition, with excellent lighting quality, there is minimal electrical energy consumption. LEDs fit perfectly into any interior and are not afraid of voltage surges. These lamps are made from high quality materials and are not harmful to health.

Connection diagram

If the owner of the house conducts electricity with his own hands, then before connecting the ceiling lamps, he must provide in advance places for all lighting devices and only then begin the connection. The choice of location and wiring diagram depend on the following factors:

- room size;

- planning;

- furniture installation.

If the ceilings in the house are high, you can connect not a ceiling lamp, but a hanging one. Typically, there is one way to connect ceiling lights. To do this, it is enough to connect the appropriate wires, insulate them, then install special devices on the ceiling that are included with the lamp. And it’s a completely different matter if the question concerns connecting ceiling spotlights.

Today, manufacturers offer a variety of lighting devices, the connection of which is not much different from a chandelier in terms of complexity. The most popular option is considered to be a spotlight, which not only provides good lighting, but is also economical in energy consumption. Such a lamp requires the use of different lamps, although the most preferred are LED lamps, which are more efficient and significantly save energy.

To connect spotlights, not one circuit can be used, but several different options, such as:

- sequential connection diagram - in this case, the connection of lamps in the suspended ceiling is carried out only on one wire, that is, in this case, the connection is made in a row for several individual lamps: the advantage of such a scheme is the ease of installation, and the disadvantage is the need to connect rectifiers in the circuit, since otherwise In this case, the voltage is supplied unevenly and the light bulbs begin to burn out one after another;

- The second scheme for connecting spotlights on suspended or suspended ceilings is that each lamp is connected to its own separate wire coming from the junction box: in this case, a rectifier is also required, but the safety and reliability of such a connection is much higher.

Advantages of finishing

Can be built in backlight

- Drywall is a safe and environmentally friendly material, its use is safe for health.

- The design allows you to create any geometric shapes and serves as an important element of ceiling decor.

- Possibility to integrate additional lighting.

- Easy to process and install.

- High degree of fire safety.

Installation of spot and LED lighting

The connection diagram for spotlights is also not particularly difficult. When installing, maintain a distance (minimum 10 cm) between the base and suspended ceiling covering.

Proper installation of lighting fixtures will cover all wiring connections. The housings will not be visible.

Point ceiling devices require a certain voltage. For this, several transformers are used, which reduce the voltage and do not affect the ceiling sheet.

Connection:

- simple installation - several light bulbs running separately are connected to one wire. To prevent light bulbs from burning out, take care of the rectifiers in the circuit;

- another option. From the distribution box there is a connection via a separate wire to each light bulb. In this case, a rectifier is not needed.

Connecting LED ceiling lights does not require any special skills. The installation is not difficult to do yourself.

LED ceiling lighting fixtures differ from other options in that the LEDs are mounted directly into the lamp body. If the light bulb stops working, then it will not be possible to replace it - you need to completely replace the failed lamp.

To connect LED lights on the ceiling, you need to calculate their number and determine the location on the ceiling. The diagram should show how to connect light bulbs in a suspended ceiling. Choose light bulbs based on wattage.

Connecting LEDs cannot be called easy. How to do it:

- make holes in the hanging panel for LED connectors;

- after connecting the wires, secure them with dowels to the base surface;

- The connection of all lamps must be carried out with a stranded wire and according to the diagram. The wires must be soldered before installing the suspended covering;

- After connecting to the network, secure the LEDs to the ceiling by snapping them into place.

Make sure that the bulbs do not get too hot. Otherwise, the ceiling canvas may be damaged.

Photo

In combination with a stretch ceiling

With stretch ceiling

Spot lighting

Hidden LED lighting

With lighting in the kitchen

Box with niche

There is a niche for lighting along the perimeter

Ventilation box

Figured box with lighting

Box with side spot lighting

Installation with ceiling hook

Typically, a hook for securing lighting fixtures is installed during construction work. In this case, before hanging the chandelier on the ceiling, you need to check its strength.

Mounting hook

To check, for some time a load corresponding to the weight of or slightly heavier than the chandelier is suspended from the installed hook. If the attached load has not shifted, you can safely hang the chandelier in place. If the fastening hook has moved, or even fallen out, you can carry out the installation work yourself.

Testing the hook with the weight of a chandelier

To do this you need:

- use a puncher to make the required hole (if it does not already exist);

- a properly selected metal anchor or a folding spring dowel with a ring is inserted into it. It should fit snugly against the inner surface of the drilled hole;

- It is enough to screw a strong self-tapping hook into a wooden ceiling.

Read: DIY ceiling lighting

This is the simplest method that describes how to attach a chandelier to the ceiling.

Schematic mounting of the holding element

If the ceiling is finished with plasterboard or a tension fabric is installed, the work of attaching the chandelier to the hook may become more complicated.

Plasterboard sheets are quite durable, so a small lamp can be mounted directly onto the material itself, but it is worth considering small nuances:

the weight of the attached lighting device should not exceed 6 kg; It is worth paying attention to the fact that when replacing lamps, you can damage the sheets or accidentally touch a low-hanging lamp with your hand.

If this has not been done, then you can hang the chandelier on a spring dowel or a special butterfly installed in a drilled hole. The dowel will need to be tightened with a special nut, and the butterfly spacer will need to be tightened with a self-tapping screw until it clicks. All fasteners must be equipped with a pin or hook to which the chandelier is attached.

One of the options for mounting a chandelier if the ceiling is made of plasterboard

When installing a stretch ceiling, you must take care in advance of how to secure the lamp. It must be remembered that a stretched canvas cannot serve as a fastening base for a chandelier. When installing a suspended ceiling, workers, before cutting a hole for attaching a lamp, glue a thermal ring in advance. If this is not done, then it will be impossible to hang the chandelier from the ceiling, since the stretched fabric will tear. Connecting wires are routed through the cut hole.

With this option, you first need to hang the chandelier on a hook, and then connect the electrical wires, after which the attachment point is covered with a decorative cap of the lamp.

Mounting diagram for suspended ceiling

Finishing

Puttying the box

Work on finishing a plasterboard box begins with priming the entire surface. After drying, it’s time for the starting putty. Applying putty is a responsible and complex procedure; incorrect finishing will spoil the overall impression of the appearance of the structure. To perform the job efficiently, professional craftsmen use two spatulas - a working one and an auxiliary one; it is worth taking into account their experience and preparing a wide and narrow spatula. A layer of putty is applied with the auxiliary tool, and leveled with the main tool.

Simple box

The corners of the structure are formed with a metal corner attached to the starting putty. It is necessary to press the element to ensure a tight fit to the box. After removing the corners, the connecting seams are glued with mesh and filled with putty. When the finishing of the joints has dried, putty is applied to the entire surface of the box. This procedure occurs more than once, each layer gradually removes all irregularities. The finishing layer is very thin. Another secret is to use starting and finishing putty from the same manufacturer, this guarantees compatibility of materials. Dried putty requires sanding the surface. To do this, use first coarse and then fine sandpaper.

Connecting a halogen lamp

Chandeliers with halogen-type lamps do not always operate from a 220 V alternating voltage network - these can be products designed for an alternating voltage of 6, 12 or 24 V. Therefore, in the second case, a step-down transformer will be needed.

Sometimes the manufacturer in each model of a lighting device operating on halogen lamps builds in special transformers to reduce the current.

In this case, the circuit is already assembled and all that remains is to install it. 2 cables remain unused, which are connected to the ceiling wiring, and the connection is made arbitrarily.

The diagram shows the principle of connecting a chandelier with an electronic transformer. This variation of the lamp has a controller unit. On the back of its case there is a connection plan. In the diagram: PE – ground, N – zero, L – phase

Chandeliers, which include a remote control, can be of various modifications: with halogen, LED or incandescent lamps.

There are also models of combined type. This device is complicated by the presence of a radio control unit. Essentially, this controller is a wireless device that is controlled via a remote control or a standard key switch.

Connecting such a lighting device is carried out similarly to the previous model, however, another wire will be added here, the thinnest of all.

This is an antenna through which the communicating actions of the remote control and controller are reproduced. It remains unchanged inside the glass of the chandelier.

Requirements

The lamps, fixed at the same level with the ceiling surface, according to their technological parameters, have a 30-degree lighting angle. Therefore, to create brightness, they must be installed at intervals of up to a maximum of 1 meter, and the distance from the last lamp should not exceed 60 cm to the wall. Provided that the ceiling height in the room is standard - 2.5 meters.

To create sufficient brightness for lighting the room, preliminary calculations are made so that the intersection of the corners of each spot is at a certain height, taking into account the height of the furniture and the configuration of the suspended ceiling.

Materials and accessories

To install and connect spotlights, you will need the following materials and tools:

- long nose pliers;

- construction tape;

- stationery knife;

- a regular screwdriver and with an indicator;

- wire stripper;

- wire VVgng 3x1.5 mm2;

- perforated mounting tape;

- electrical clamps;

- perforator;

- thermal rings;

- dowels

Making an embed for a lamp

Embeds for spotlights

At the very beginning of the installation of lamps, a mortgage is made. There are ready-made products for such purposes:

- universal;

- for a specific diameter.

In universal products, a hole is cut in accordance with the diameter of the lantern. After that, still below, the body is fitted to it in order to avoid sudden problems when stretching the ceiling fabric.

The largest distance between the bottom edge of the profile and the base ceiling is measured. This is necessary in order to cut the perforated tape to the required length.

Next, you need to bend the cut paper tape, giving it a U-shape. The dimensions directly depend on the diameter of the lamps used. Next, the tape is attached to the mortgage using small self-tapping screws (“bugs”).

After assembly, the entire structure is attached to the main ceiling. Holes are drilled using a hammer drill, according to the previously made markings, and the embedded platform is screwed using dowels.

Connecting the cable

Wiring for spot lighting

The supply cable for the VVGng marking is laid before stretching the fabric in accordance with the route for placing the light points. The minimum cable cross-section is 1.5 mm2. It is impossible to use less even with light loads.

At the location of the lighting device, it is necessary to leave a supply of cable in the form of a small loop (this will be cut later). This loop should go down to a level of at least 10 cm from the finished ceiling.

Terminal blocks and piercing clamps

The cable loop is cut in half, the protective insulation of 10 mm is removed from the wires and they are connected back through the terminal block. The remaining free terminal will serve to connect the power cable from the light spot itself. This type of connection is called parallel.

If you use piercing clamps instead of terminal blocks, you do not need to cut the cable loop. When using them, only the upper protective sheath is removed from the cable, the internal conductors remain intact. They must be inserted into the piercing clamp, into its upper part, and the device must be snapped into place. Integrated knives automatically pierce the insulating layer, forming a reliable contact. The wires to the light spot are connected to the bottom of the clamp using the same method.

Installation of thermal ring

The thermal ring protects the ceiling from overheating and allows you to carefully cut a hole for the lamp

After connecting the cables, you need to place a thermal ring of the required diameter on the canvas, using special glue for this. These rings are made of heat-resistant plastic. It is able to withstand temperatures up to +90 degrees for a short time.

The thermal ring has two main functions:

- protection of the canvas from the temperature effects of lighting devices;

- mechanical protection - before making a hole in a suspended ceiling for a spotlight, be sure to glue a thermal ring; it will not allow the fabric to separate at the cut points.

The glue is applied evenly around the entire perimeter of the ring. There should be no un-glued areas. There is no need to move your finger along the ring while pressing it to the ceiling; due to the glue, it may move to the side. A simple squeeze is enough.

Then, using a stationery knife, the canvas is carefully pierced and a hole is cut inside the ring.

Types of drywall

How to choose drywall

A sheet of drywall is a building material based on a hardened layer of gypsum with filler. Both sides of the sheet are covered with paper, which serves to protect the inside and ensures stretching of the material during operation. The versatile and inexpensive material has become widespread. Depending on the purpose, it is divided into moisture-resistant, material intended for normal humidity, and fire-resistant. Cellulose-reinforced gypsum fiber sheets have excellent strength characteristics.

Recommendations for selection

Before you begin designing a future lighting system, be sure to perform special calculations. Make sure that the system you choose will fully meet the requirements for it and fully perform its basic functions. This must be done even if we are talking about a bathroom with two spotlights.

A minimum amount of illumination will be appropriate in the recreation area, but in all other rooms it will negatively affect the performance, mood and psyche of a person as a whole. For such rooms it is better to take lighting fixtures with a reserve!

If zoning is carried out, then the calculations must be approached with even greater responsibility. In the recreation area, try to provide two operating modes - light for reading and dim lighting for sleeping (you won’t turn on bright lights at night if you go to the toilet).

Decide on the required illumination in the room, calculate how much power is required for each lamp and how many of them should be per square meter (don’t be alarmed, the result may not be a whole number, so round up).

When choosing the lighting spectrum, try to bring it as close to natural as possible and ensure the best color reproduction. The last parameter is designated Ra and for residential premises should be in the range of 80–100%.

If you find it difficult to make your own calculations, consult with qualified electricians and builders. Even if you are able to install lighting fixtures yourself, it is advisable to entrust the calculations to professionals.

Suspended structure components

The main elements of suspended ceilings are:

- stingers - strips necessary for fastening cladding panels;

- suspensions - spring type with spokes (needed to attach the suspended structure and prevent deflection);

- intermediate and guide profiles - ceiling frame;

- cladding materials (decoration).