Home » Automation and controls » Why and how automation is needed on old-style gas boilers

The newest models of gas boilers are characterized by high power and heating speed. However, their prices are steep, to put it mildly. You can try to use a more economical option and install new automation on the old boiler or fix the old one. The operating principle and automatic design of old-style gas heating boilers will be explained in this article.

…

- 1 Why do you need gas automation?

- 2 The principle of operation of automation on old-style gas boilers

- 3 Basic elements of automation

- 4 Flame and draft sensors

- 5 The most common automation malfunctions and methods for eliminating them

Automation APOK-1 with gas burner device

Ministry of Housing and Communal Services of the Ukrainian SSR Republican Industrial Association "UkrkommunmaSh" Kiev Production Association "Kievkommuntekhnika"

Passport

Installation, adjustment, preventive maintenance and repair of the APOC-1 automation with a gas burner device (hereinafter referred to as the ALOC-1 automation) is permitted only to specialized gas industry enterprises.

PURPOSE OF THE PRODUCT

Automation APOK-1 is designed for automatic protection and regulation of thermal processes of heating water boilers with a power of up to 29 kW in accordance with GOST 20548-81 and GOST 22451-77, operating on low-pressure natural gas.

Automation APOC-1 is produced in the following standard sizes indicated in Table 1.

TECHNICAL SPECIFICATIONS

CONTENTS OF DELIVERY

PREPARING THE PRODUCT FOR OPERATION

1. Ventilate the room in which the heating boiler is installed for 10-15 minutes. Check the operation of the supply and exhaust ventilation by placing a strip of paper near the air ducts.

2. Check whether the gas valves on the downstream side of the boiler and valve 2 (see figure) after the shut-off valve in front of the burner are closed.

3. Check the presence of draft by placing a strip of paper near the ignition hole.

4. Ventilate the firebox and boiler flue for 10 minutes by opening the secondary air damper 6 located on the front sheet under the burner and the igniter window 5. After ventilation, close the secondary air damper.

5. If the boiler was stopped after normal operation, the position of the water temperature regulator indicator 4 should not be changed before lighting.

6. The boiler and heating system are prepared for start-up in accordance with the instructions for the heating boiler.

OPERATING PROCEDURE

a) open the gas valve on the descent to the boiler;

b) open the igniter window 5 and bring in a burning paper bundle;

c) press plate 7 of shut-off valve I;

d) wait until the gas on the igniter ignites and remove the paper bundle;

e) check whether the flame is well washed around the end of the bimetallic plate and close the ignition hole with a damper;

f) keep the shut-off valve plate 7 pressed for 1 minute, then release;

g/ smoothly turn the tap handle with the safety lever 3 installed on it, after the shut-off valve, while the gas should pass to the burner;

h) if the igniter circuit does not warm up the end of the bimetallic plates well or the gas along the entire igniter treadmill ignites, stop ignition and release

plate 7. Repeat ignition, proceeding strictly in the previously specified sequence.

2. Stop the boiler.

a) close the tap on the descent to the boiler;

b) close valve 2 after the shut-off valve;

c) when stopping the boiler for a short time, it is recommended to turn off only the burner by turning the handle of tap 2, while only the igniter lights up, which facilitates further ignition;

d) if the main parameters deviate beyond the established limits, the gas to the burner and igniter is automatically cut off. In this case, you must immediately close the gas taps in the order specified in points “a” and “b”;

To identify and eliminate automation malfunctions or other problems, it is necessary to call a fitter at a specialized gas industry enterprise.

MAINTENANCE

1. The temperature that the water temperature regulator 4 must maintain is set by turning the pointer to the required position. To increase the temperature maintained by the regulator, turn the pointer towards the “hot” side, and to lower it - towards the “cold” side. A thermometer must be installed on the boiler outlet manifold, which is used to control and set the temperature of the heated water entering the heating system.

2. It is prohibited to regulate the gas flow to the burner using taps located in front of the shut-off valve, including the tap on the lower side to the boiler.

3. The regulation principle carried out by the APOK-1 automation ensures a stable air temperature in the room with small external changes in meteorological conditions without outside intervention. If there are significant changes in the heat loss of the building, it is necessary to call a specialized gas service technician to re-adjust the automation.

4. Automation should be protected from mechanical damage; no objects should be placed on the automation devices.

5. It is necessary to periodically clean the igniter and burner treadmill holes to prevent clogging or carbonization of these holes.

SAFETY

1. If the smell of gas is detected, it is prohibited to start ignition.

2. While observing the combustion, do not put your face close to the ignition hole.

3. Operating a boiler with a faulty automatic safety unit is not allowed.

CERTIFICATE OF ACCEPTANCE

The APOC-1 automation system was manufactured in accordance with TU 204 of the Ukrainian SSR 124-82, tested, accepted by the quality control department and declared fit for use.

QC release date

TRANSPORTATION AND STORAGE

APOK-1 automation is transported to the customer by any type of transport.

The placement of APOC-1 automation assembly units and their fastening during transportation should ensure their safety.

APOK-1 automation systems should be stored at temperatures from +5 °C to +35 °C and relative air humidity in the range of 60-80%.

After transportation in packaging at sub-zero temperatures, the APOK-1 automation must be kept at storage temperature for 24 hours before installation on the boiler.

WARRANTY

The manufacturer guarantees compliance of the APOK-1 automation with the requirements of the technical specifications TU 204 of the Ukrainian SSR 128-82, subject to the conditions of operation, storage, transportation and installation.

The warranty period is 12 months from the date of sale through a retail network, and when supplied for off-market consumption - from the date of receipt by the consumer.

The warranty period for the operation of the APOK-1 automation system, which has been duly assigned the State Quality Mark, is 18 months from the date of sale through a retail distribution network, and for supplies for off-market consumption - from the date of receipt by the consumer.

If factory defects in the automation are detected during the warranty period, the owner should call a representative of a specialized gas enterprise to draw up a report indicating the malfunction and send: the faulty unit, report and passport to the manufacturer at the address: 252116, Kiev-116, st. .Sholudenko, 30 KPO "Kievkommuntekhnika".

Setting up the boiler yourself

Correct adjustment of a gas boiler is needed for:

- saving resources;

- comfortable stay in the room;

- increasing the service life of equipment.

First of all, it is necessary to correctly determine the power of the heating equipment

It is important to take into account the features of the room: the number and area of windows, doors, the quality of insulation, the material from which the walls are made. The minimum calculation is based on heat loss per unit of time

As is known, the heating power is directly dependent on the modulation of the gas burner

If you have an electronically controlled unit, then the thermostat is activated, which is connected to the room thermometer

As you know, the heating power is directly dependent on the modulation of the gas burner. If you have an electronically controlled unit, then the thermostat is activated and connected to the room thermometer.

The adjustment is carried out automatically: the thermometer measures the temperature in the room. As soon as its indicators drop below comfortable levels, it sends a signal to start the burner or increase the flame power.

In normal mode, the thermometer monitors the temperature in only one room. But if you install valves in front of each radiator, there will be control in every room.

You can adjust the burner manually by operating the gas valve. This is true for atmospheric boilers with an open combustion chamber. For example, in the Protherm Cheetah and Protherm Bear models, the valve is controlled by an electric motor. To change the settings you need to go to the service menu. Usually this work is performed by a specialist, and the user himself acts according to the instructions.

However, it is still necessary to know how to call up the hidden menu for adjustments. Let's look at a few examples.

Before going to the menu and setting up, you need to perform the following steps:

- open the taps on the batteries;

- the room thermostat must be set to maximum values;

- in the user settings, set the maximum temperature mode, which you usually set at the lowest possible temperature outside. The burner always turns off when the readings are 5°C higher than the set values. For example, at 75°C, shutdown will occur upon reaching 80°C;

- The coolant should be cooled to 30°C.

For Protherm Gepard:

- You need to hold down the Mode key on the panel. As soon as you see zero on the display, set the value to 35 by pressing “+” and “-“.

- Next, press Mode to confirm;

when d.0 lights up on the screen, you need to enter the line number in the menu. These manipulations are also performed by pressing “+” and “-” d. (number). In order to set the maximum burner power, you need to select d.53, for the minimum - d.52.

- In order to proceed to the selection of a parameter, Mode is also used, it changes “+” and “-“.

- The installation receives automatic confirmation.

- Return to the original menu and hold Mode.

While making adjustments through the panel, monitor the change in flame and temperature intensity.

Display of the gas boiler Proterm Panther

For Proterm Panther the procedure is different:

- Hold Mode for about seven seconds.

- Next, enter code 35.

- The entry is confirmed.

- When d.00 appears on the left side of the screen, you must enter a number using two buttons.

- Then change the parameter on the right side of the screen using the 3 keys.

- After confirmation, click mode to exit the menu.

What is the need for and how does automation work on old-style gas boilers?

The newest models of gas boilers are characterized by high power and heating speed. However, their prices are steep, to put it mildly. You can try to use a more economical option and install new automation on the old boiler or fix the old one. The operating principle and automatic design of old-style gas heating boilers will be explained in this article.

- 1 Why do you need gas automation?

- 2 The principle of operation of automation on old-style gas boilers

- 3 Basic elements of automation

- 4 Flame and draft sensors

- 5 The most common automation malfunctions and methods for eliminating them

What automatic settings are there?

Currently, the market offers consumers a wide selection of control devices. Therefore, you need to know what automation systems for home heating systems generally exist, and what to give preference to.

Room thermostat

According to installation criteria, there are:

- Wired thermostats. The advantage of this type is the ability to supply power up to approximately 50 meters via wires.

- Wireless thermostats. The advantage is that it is not necessary to create holes for the wires. However, they have a significant drawback - reinforced concrete walls reduce the signal power.

According to functionality they are distinguished:

- Simple thermostats. They retain the desired level of warmth.

- Programmable thermostats. Such devices are capable of setting a certain number of degrees for a whole week in advance (the period depends on the model) with maximum accuracy down to seconds. The advantages also include cost savings due to weekly programming.

Thermostats are also distinguished:

- Electronic thermostats. The kit contains three components: temperature sensor, signal transmitter, relay. The main advantage of the device is the maximum accuracy of the equipment. Don't forget ease of use.

- Mechanical thermostats. The basis of the devices is the ability to change properties under the influence of temperature levels. Due to temperature changes in the gas membrane, a circuit is closed or opened, causing certain mechanisms to work.

- Electromechanical thermostats. The mechanism of the device is much simpler than an electronic one. The main element is the relay. The node looks like a tube, which is filled with a special substance that reacts to temperature. If the boiler heats up, the substance expands; similarly, when the boiler cools, the substance contracts. And the drive, dependent on the substance, regulates the temperature thanks to an electrical circuit.

Connection can be made to:

- Kotlu;

- To the pump;

- Servo drive;

Thermal head

This is a thermostatic element that, under the influence of the external environment, slightly opens or closes the radiator. An inexpensive type of automation for heating a home. A significant advantage is that the thermal head is very convenient for local heating, and there are also significant cost savings. Of the minuses: firstly, the adjustment occurs according to standards consisting of abstract numbers, not degrees. Secondly, the sensor measures the degree of heat around the installation, but not the room, which reduces the accuracy of the device.

Weather-compensated automation

The design of weather-dependent automation for heating a house is simple: as the weather outside decreases, the temperature of the coolant increases. However, a weather-dependent installation has a very significant drawback - the system sometimes does not have time to adapt to the temperature, and, therefore, the effect is delayed. The especially mentioned disadvantage manifests itself if an addition is connected - heated floors. The disadvantages include the fact that the devices do not operate entirely correctly, approximately, so the change is noticeable only during seasonal climate changes. It is worth noting that the prices for the unit are relatively high. But the units will be very convenient in production, large-scale houses (over 500 square meters).

Why do you need gas automation?

Old-style boilers were manufactured in accordance with the gas parameters and heating system features that were in use several decades ago. These are, for example, models KChM, AOGV. At the same time, their durability allows them to be used for many years to come. But the problem with automation is that quite often it breaks down. In such a situation, there are three options:

- diagnose existing automation and replace the necessary parts;

- equip a reliable and high-quality unit with a modern automatic system;

- buy a new boiler.

The difference, of course, is in the price of the issue, the effort and time of the owner.

Let's consider the cheapest option - troubleshooting gas automation on an old boiler. However, first, let’s figure out why an automatic system is provided in the coolant in general.

Gas automation allows you to regulate and maintain the required level of coolant temperature, and also serves to automatically stop the gas supply in an emergency situation. Installing automation on an old gas boiler will allow you to be sure that if the burner flame goes out, then after a short time the system will work to stop the gas supply without your participation.

If you want to change the automation, keep in mind that domestic manufacturers produce models that are suitable for almost any old coolant. Imported automation cannot be installed on everything. In addition, when installing foreign automation on old-style gas boilers, not all of its functions may work - the design features of the boiler will not allow it.

Cleaning methods

Cleaning is carried out in two ways: mechanical and chemical

Mechanical cleaning

The cleaning method is imperfect and involves mechanical action. Soot should be carefully removed so as not to damage the internal surface of the boiler and parts, which can subsequently lead to metal corrosion. Often the tools come with the boiler - these are pipe cleaners, brushes and scrapers. It is also possible to use air cleaning, when warm air is supplied under pressure.

Dry cleaning

It is recommended to apply cleaning agents while wearing PPE (personal protective equipment); rubber-based gloves are usually used, this will protect the skin from interaction with harmful substances. Chemicals clean not only soot, but also metal, which can further lead to its destruction. This method is best used on minor dirt and small areas of contamination.

Hydrodynamic cleaning

Hydrodynamic cleaning or how to clean soot from a diesel boiler.

It is used in boilers with a small thickness of contamination, as well as when speed of execution is required. Equipment for such washing consists of:

- pump and

- containers with water supplied under high pressure.

Thanks to this cleaning, soot and soot are removed quite quickly, but this method can only be used by specialists and is not recommended at home.

Booster cleaning

The procedure for flushing the heat exchanger with a booster (using the example of cleaning a Zhukovsky boiler from soot):

- First you need to disconnect the pipes from the heating system.

- Next, connect a booster hose to one of them to supply the reagent.

- We connect the second pipe to the second end of the hose. The spent reagent will be removed through it. This closes the system and the reagent will circulate through the pipes.

- After cleaning, the solution must be drained from the tube.

- Rinse the heat exchanger itself with sufficient water.

Booster is a device for chemical cleaning. Thanks to it, the reagents circulate autonomously.

During such cleaning, it is recommended to change the reagent several times, since the old one gradually reduces its properties. This method is most often carried out by specialists.

The principle of operation of automation on old-style gas boilers

Frequent problems when heating a room with gas boilers are flame attenuation in the burner and gas pollution in the room. This happens for several reasons:

- insufficient draft in the chimney;

- too high or too low pressure in the pipeline through which gas is supplied;

- the flame on the igniter goes out;

- leakage of the pulse system.

When these situations arise, the automation is triggered to stop the gas supply and prevent the room from becoming gas-filled. Therefore, installing high-quality automation on an old gas boiler is basic safety rules when using it to heat a room and heat water.

All automation of any brand and any manufacturer has one operating principle and basic elements. Only their designs will differ. Old automatic machines “Plamya”, “Arbat”, SABC, AGUK and others work according to the following principle. When the coolant cools below the temperature set by the user, the gas supply sensor is activated. The burner starts heating the water. After the sensor reaches the user-specified temperature, the gas sensor automatically turns off.

On a note! When using modern automation, it is possible to save heat up to 30%. Old-style automation is non-volatile and does not require electricity. Its adjustment, connection and disconnection are carried out by a person. Commands are transmitted using electromagnetic pulses.

The video explains how the automation of gas boilers AOGV and KSTG works.

By material and type of heat exchanger

Heat exchangers can be:

- cast iron;

- copper;

- aluminum-silicon;

- made of carbon or stainless steel.

The design of the heat exchanger may also vary.

The most popular are separate heat exchangers. Heating water flows separately, and water for residents’ household needs passes separately. They are a little more expensive, but more reliable.

A bithermic heat exchanger looks like a pipe within a pipe. In the inner pipe there is DHW water, which needs to be heated, and in the outer pipe the heating coolant circulates.

The third type is a heat exchanger in which a coil is built in. The container with water is heated by the coolant flowing in the coil. An indirect heating system is good for everyone, but in the summer you will either have to heat the boiler or live without hot water.

The bithermic option is not recommended for use where there is hard water. And be prepared that every time scalding water will flow out of the tap first, and only then at the temperature you need.

Basic elements of automation

The main elements of automation for a gas boiler are:

- thermostat;

- shut-off valve;

- traction sensor;

- flame sensor;

- igniter tube;

- igniter;

- burners.

Let's try to clearly explain how automation for a gas boiler works, breaking it down into its main elements and talking about their functions.

The gas passes through a gas purification filter. Next it goes to the solenoid valve, which regulates the fuel supply to the burner. Temperature and draft sensors are located next to the valve, monitoring the indicators and signaling if they exceed acceptable standards. Also, the automation kit for gas boilers includes a thermostat with a bellows and a rod, designed to set the desired temperature. A special button is used to adjust the indicators. When the water is heated to the temperature set by the user, the thermostat is activated, the gas supply to the burner is stopped, while the igniter continues to operate. When the water cools by 10-15 degrees, the gas supply is resumed. The burner lights up from the igniter. The automation is started manually.

Elements of safety and comfortable operation

The group of automatic devices for boilers includes many elements that can be divided into two large groups: mechanisms that ensure safe operation, and devices that facilitate comfortable operation of the boiler.

The following parts are responsible for safe operation:

- thermostat;

- draft and flame control sensors;

- safety valve.

The flame control sensor consists of a thermocouple and an electromagnetic gas valve that shuts off or turns on the gas supply.

The flame temperature regulator (thermostat) maintains the required coolant temperature and also provides protection against overheating. This module turns the boiler on or off as soon as the coolant reaches a critical point (maximum or minimum).

The draft control module stops gas supply to the burner as soon as the location of the bimetallic plate changes due to increased temperature (it bends when heated, blocking the pipe through which the fuel is supplied).

The safety valve is used to regulate, distribute and shut off the gas flow

In a heating system, a safety valve is an integral component of pipeline fittings, which is important in controlling the volume of coolant involved in the circuit. The hole in the valve through which gaseous fuel moves is called the seat

To turn off the device, you need to block it with a disk or piston

The hole in the valve through which gaseous fuel moves is called the seat. To turn off the device, you need to close it with a disk or piston.

Depending on the number of operating positions, gas valves can be one-, two- and three-stage, as well as modeling:

- Single-stage devices have only two operating positions: on/off.

- The two-stage device is equipped with one input and two outputs, and the valve opens when it is turned to an intermediate position, due to which the switching occurs more smoothly.

- A three-stage device is equipped with boilers that have two power levels.

- Modulating valves are used to smoothly change the power rating of devices.

Automation, used for convenience, includes options that are usually performed by users of heating systems. These include auto-ignition of the burner, self-diagnosis, selection of the optimal operating mode, and others.

Flame and draft sensors

Flame and draft sensors work on this principle. The draft sensor reacts to deteriorating smoke draft and transmits an impulse to the control system. It is located in the smoke hood. Equipped with a plate made of an alloy of two metals: iron and nickel. When draft deteriorates, flue gases accumulate and heat the plate. It becomes deformed, the contacts open, and the flow of fuel into the combustion chamber stops. When the temperature decreases, the plate returns to its normal state.

The temperature sensor works on the same principle. When the water in the boiler heats above the set temperature, the lever mechanism is activated and the temperature regulator valve closes. The gas supply stops and the burners go out.

When the water cools, the sensor bellows contracts, the lever mechanism is activated, the temperature regulator valve opens, gas begins to flow, and the burners light up.

Elements of safety and comfortable operation

The group of automatic devices for boilers includes many elements that can be divided into two large groups: mechanisms that ensure safe operation, and devices that facilitate comfortable operation of the boiler.

The following parts are responsible for safe operation:

thermostat; draft and flame control sensors; safety valve.

The flame control sensor consists of a thermocouple and an electromagnetic gas valve that shuts off or turns on the gas supply.

The flame temperature regulator (thermostat) maintains the required coolant temperature and also provides protection against overheating. This module turns the boiler on or off as soon as the coolant reaches a critical point (maximum or minimum).

The draft control module stops gas supply to the burner as soon as the location of the bimetallic plate changes due to increased temperature (it bends when heated, blocking the pipe through which the fuel is supplied).

We examined temperature, draft, pressure and flame sensors in more detail in this article.

The safety valve is used to regulate, distribute and shut off the gas flow

In a heating system, a safety valve is an integral component of pipeline fittings, which is important in controlling the volume of coolant involved in the circuit. The hole in the valve through which gaseous fuel moves is called the seat

To turn off the device, you need to block it with a disk or piston

The hole in the valve through which gaseous fuel moves is called the seat. To turn off the device, you need to close it with a disk or piston.

Depending on the number of operating positions, gas valves can be one-, two- and three-stage, as well as modeling:

Single-stage devices have only two operating positions: on/off. The two-stage device is equipped with one input and two outputs, and the valve opens when it is turned to an intermediate position, due to which the switching occurs more smoothly. A three-stage device is equipped with boilers that have two power levels. Modulating valves are used to smoothly change the power rating of devices.

Automation, used for convenience, includes options that are usually performed by users of heating systems. These include auto-ignition of the burner, self-diagnosis, selection of the optimal operating mode, and others.

The most common automation malfunctions and methods for eliminating them

Before setting up the automation on the boiler, it is necessary to diagnose it. As a rule, serious malfunctions occur that will require specialist intervention. The adjustment can also be entrusted to a gas technician. Or you can do it yourself by reading the instruction manual.

Attention! Before each seasonal operation, it is necessary to check the operation of the safety sensors.

Most often, the filter becomes clogged, problems arise with the valves, sensors burn out due to power surges, and a gas leak is detected. Proper cleaning of the filter should be done by a professional. You can try to replace electronic elements yourself by carefully studying the operating instructions for your boiler.

In order to replace the temperature sensor, you need to turn off the gas boiler and cool the water to a temperature of 40 degrees. Shut off the flow of coolant, remove the control knob by unscrewing the screw. Next, remove the PTV adjustment screw. Remove the sensor bellows with the support washer. Unscrew the union nut of the sensor thermal bulb. Install the thermal bulb of a working sensor into the boiler jacket and screw it tightly. Install the sensor bellows into the pipe socket, install the support washer on the bellows, install the PTB adjustment screw and adjust the temperature.

If problems arise with igniting the igniter, then one of the possible causes is a malfunction of the draft sensor. In this case, it must be dismantled, diagnosed, checked contacts, cleaned, and, if necessary, replaced with a new one.

Also, common reasons why the pilot light does not light may be:

- gas valve malfunction;

- clogging of the hole in the igniter nozzle (it can be cleaned with wire);

- strong air draft;

- low gas inlet pressure.

When the gas supply is turned off, it is necessary to check the chimney (it may be clogged), the electromagnet, and the gas pressure at the inlet to the gas boiler.

Attention! To diagnose and repair the gas boiler automation, you must invite a specialist. Inept actions can aggravate the problem and lead to undesirable consequences.

For the automation of AGUK, AGU-T-M, AGU-P systems, the most common problem is the burnout of the bimetallic plate, which is used as a sensitive element.

In Arbat and Orion, you can only replace the thermocouple and draft sensor, as well as the solenoid valve (rarely). The automation unit is practically beyond repair. In Arbat, the system shutdown button often breaks down.

Typical problems for SABC automation are damage to the main valve membranes and drying out of the thermostat stuffing box, resulting in gas leakage. Impulse tubes, bimetallic plates, and ball valves are subject to control.

In conclusion, I would like to emphasize once again that automation is designed to maintain the operation of heating equipment in a safe mode. Therefore, it is simply necessary for owners of gas boilers.

This video shows how to troubleshoot an automatic boiler AOGV, step-by-step assembly process and testing the result.

The most popular models of safety systems for boiler equipment

Today, the Russian market of climate control equipment offers more than a dozen automation models from different brands. The popularity of a particular brand depends entirely on the demand for heating units of the same brand. Many owners of domestic boiler equipment ask how the automation works in a Lemax gas boiler? These installations use EvroSit automation from an Italian manufacturer. It is this automation system that ranks first in popularity among domestic manufacturers of heating devices.

EuroSit

Models in this line have good functionality and are easily integrated into almost any boiler design. Standard functions: gas pressure control; monitoring the presence of flame in the burner and on the igniter; control of coolant temperature and chimney draft. Using the automation of this brand does not cause any particular difficulties for owners, but requires some skills.

- Before starting the device, you must press the adjustment and ignition knob and at the same time the piezoelectric element button.

- After igniting the igniter, it is necessary to hold the knob pressed for 5 to 10 seconds to heat the thermocouple.

- If, after releasing the handle, the igniter does not go out, then you can proceed to turning the washer to adjust the gas pressure. After this, the main burner is ignited.

Further, the boiler operates fully automatically.

Honeywell

Automation of this brand is quite widespread in the Russian market of climate control equipment due to its relatively low cost, good functionality and wide model range. Standard functionality: maintaining coolant temperature in the range from 40 to 90°C; control of pressure and fuel supply; automatic stop of the device in the absence or occurrence of a backdraft effect; control over the presence of flame in the burner.

AOGV

Rostov products today are in demand by domestic users on a par with European automation models due to their reliability and low cost. The functionality of automatic AOGV systems is also quite rich. The standard capabilities of this equipment make it possible to stop the operation of the boiler unit if the following situations occur: the temperature of the coolant exceeds the set level; failure of flame in the igniter and burner; low pressure and lack of coolant in the system; any failure in the gas supply system; decrease in fuel pressure below the established norm; in the absence or insufficient traction. How does the automation of a gas boiler AOGV work? The operation of the gas valve is controlled by the voltage generated by the thermocouple. It is this voltage that acts on the valve coil and keeps it open while the burner is burning. Temperature regulation occurs due to a thermostat and valves, which, when the temperature rises or falls, opens or shuts off the fuel supplied to the burner. The exhaust gas removal is monitored by a draft sensor. Making the right choice of automation for gas boilers is quite difficult. We strongly recommend seeking professional help.

Flame sensor - draft sensor - bimital plate APOC-1

APOC-1 Mechanical thrust-flame sensor. (bimital plate)

-

- Remove this product from my favorites list

- Add product to Favorites

- Seal

- More details

- Reviews

Flame sensor - draft sensor - bimital plate APOC-1

For safe and automatic operation of the gas heating boiler, a protection and automation system is provided. It is responsible for maintaining the specified temperature conditions, as well as for the safe operation of the unit. One of the main elements of unit protection is the gas boiler draft sensor.

1 Purpose of the draft sensor

2 Design and principle of operation of the draft sensor

3 Reasons why the traction sensor is triggered

4 Popular models of draft sensors for gas boilers

Purpose of a draft sensor A draft sensor or thermostat is a device for determining the intensity of draft in the chimney of a gas boiler. Its main function is to provide a timely signal about an unacceptable amount of draft in the boiler.

A malfunction of the traction sensor can result in an emergency. After all, sufficient draft is necessary not only for drawing out smoke, but also for efficient combustion of gas. If there is no draft, then the combustion will be unstable, and this can affect the integrity of the entire unit. Poor draft can cause a gas boiler to go out.

Design and operating principle of a draft sensor There are 2 types of gas boilers: with natural and forced draft. The traction sensors in them are also different. Boilers with natural draft use an open combustion chamber, and draft is created by selecting the correct dimensions of the chimney (height and cross-section). Such units use a traction sensor based on a bimetallic element. This is a plate of certain dimensions with a contact attached to it. It is installed in the gas path of the unit and reacts to temperature changes. If the draft in the boiler is good, the temperature will be low. As the thrust intensity drops, the temperature will begin to rise and cause the metal of the plate to expand. Its material is selected in such a way that when a critical temperature is reached, the contact is disconnected and the gas valve closes. After the temperature drops, the valve closes again. The critical temperature is set by the gas boiler manufacturer and can be located in the range of 75-950C.

On a note. “Backdraft” - this phenomenon occurs in the absence of vacuum in the combustion chamber. It can only be observed in boilers with natural draft and an open combustion chamber. During normal operation of the boiler, air is constantly sucked into the combustion chamber, and if the draft disappears, the smoke will flow in the opposite direction, not from the room, but into it. This is “reverse thrust”.

Boilers with forced draft have a closed combustion chamber, and the draft is created by the operation of a fan. Therefore, in such boilers a draft sensor in the form of a pneumatic relay is used. It provides control over the operation of the fan and the intensity of removal of combustion products. The sensor is a membrane that bends under the influence of the flue gas flow created by the smoke exhauster. If the flow weakens, then the membrane voltage drops, at a certain moment the contacts open and the gas valve closes.

Reasons for the draft sensor to be triggered Various factors can cause the draft sensor to trigger: Clogging of the chimney. Incorrect installation of the chimney for a gas boiler, or an error in calculating its dimensions. The gas boiler was installed incorrectly. Fan stop (in forced draft boilers).

Attention! If the traction sensor triggered, then there were good reasons for this; you should look into them carefully. But it is strictly forbidden to forcibly close the contacts of the draft sensor to resume boiler operation. It is also not permissible to operate the boiler without a working draft sensor.

A temperature sensor for boilers with natural draft and a pneumatic sensor for boilers with forced draft are reliable elements of protection for gas heating boilers. For additional protection, you can install an external air gas analyzer to detect gas contamination. This will ensure complete control of the boiler operation, even if one of the sensors malfunctions.

Single-circuit or double-circuit?

The design of heating units depends on the number of circuits - liquid supply and discharge lines - in its composition. Single-circuit ones have a low cost. When installed, fuel costs will be low. Therefore, they are considered less expensive. These devices are only suitable for heating small rooms. If hot water is required for household purposes, a boiler is installed.

The double-circuit heats the room and supplies hot water. But simultaneous operation of both systems is impossible. For example, when a hot water tap is turned on, the heating system turns off. If a small volume of liquid is required at a time, a double-circuit flow-type boiler is well suited. If you need a large amount of hot liquid, you need to choose models with a boiler.

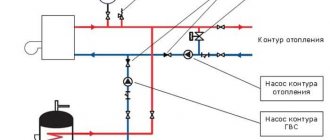

Gas unit operation diagram

How does a gas heating boiler work? Central systems use natural gas as a source of energy and heat. There are two combustion options: methane and a mixture of propane and butane. It is worth examining the main aspects of the operation of heating equipment.

Operating principle of the boiler

The operating principle of all gas heating boilers can be described as follows:

- In equipment connected to the gas supply system, the ignition system is activated.

- A spark from electricity ignites the burner.

- The igniter ignites the main burner, which can have different designs.

- The fire heats the water jacket and coolant. As a result, the heat exchanger heats the water to a certain value specified by the user. After which the burner turns off.

- If the temperature drops, the sensors send a signal to the automation, which resumes operation of the system until it reheats.

Single-circuit boiler

Gas boiler design

Models from different manufacturers may differ slightly in design and arrangement of components, but they have several common parts:

- Valve for supplying or shutting off fuel.

- Burner.

- Electrical block.

- Fire sensor.

- Gas combustion chamber.

- Fan.

- Heat exchanger.

- Set of sensors.

- Expansion tank.

- Water filter.

- Set of valves.

- Bypass.

- DHW filter.

It is worth considering the operation of the main components separately in order to understand the operation of the boiler as a whole.

Gas burner and smoke removal system

The burner is the main module that provides heating of the coolant. In most modern devices, it can regulate the volume of gas supplied. The adjustment occurs under the influence of a thermostat, which gives a signal when the temperature is too hot or the temperature drops.

Gas is supplied through a valve. It is regulated by an electric power unit, which is controlled by the automation system in the boiler. This allows you to control most of the DHW operation processes.

Heat exchangers

There are two types of heat exchangers in the system: primary and secondary. The first is located above the burner and includes several copper pipes through which the coolant circulates. The secondary one is needed to heat water from hot water supply. It looks like a set of lamellas, in the spaces between which liquid circulates from the primary and secondary heat exchanger.

Double-circuit boiler

DHW system

This system is the main difference between double-circuit elements. It is through this that you can quickly gain access to hot water. It is provided by a secondary heat exchanger, several valves and sensors that control the operation of the device. The main sensor is the flow sensor.

The liquid begins to heat up in the main heat exchanger. Afterwards, it moves inside the housing with the help of a pump, passing through a secondary system of lamellas, in which it is additionally heated.

Bypass

This bypass pipe connects the forward and return pipes. Additionally, a valve is attached to it, which opens if necessary, and part of the water begins to move into the return pipeline.

Expansion tank

This part of the system is required to stabilize pressure during heating. Due to increased pressure, water expands, which can damage equipment. The tank consists of 3 components:

- container for water;

- membranes;

- space for gas.

Due to the bends of the membrane, it balances the pressure in the system.

Control board and sensors

The control unit is a mandatory module required for the operation of the boiler. It is through this module that you can set the required operating mode and regulate the operation of the elements.

Diaphragm tank

Block - security

The safety unit consists of a shut-off valve, a draft sensor, a flame sensor with an igniter and impulse tubes. As can be seen from the diagram shown in Fig. 17, the gas enters the shut-off valve into the space above the small membrane and does not pass further. When igniting, the plate of the shut-off valve is pressed, its rod rises, the gas is directed to the igniter, where it is ignited with a match or torch, through the throttle it is supplied under the large membrane and then along the impulse tube to the emergency mode sensors - the draft sensor and the flame sensor. No gas is supplied to the burner because the gas valve is closed. [2]

The boiler safety block with its valve cuts off the gas supply to the burners according to pulses received from the vacuum control sensors 13, the water temperature in the boiler 17, the presence of flame 16 - 18, and thanks to the original device of the vacuum sampling chamber, all of the listed pulses activate the safety block valve through its vacuum control device. [3]

A safety block has been created for high-force crank presses, which is a stand adjustable by means of a screw, which is placed on the presses in the socket of the frame. [4]

Each security unit is equipped with a switch, the contacts of which are connected in series to the alarm line connecting the boiler room to the control room. When any of the shut-off valves of the safety unit are triggered, the contacts of its switch open, which causes the alarm line to de-energize. At the same time, a red light on the control center console lights up and a sound signal sounds. The alarm line is supplied with 24 V DC through the alarm unit. [5]

A number of presses are equipped with safety blocks that ensure safety when finishing and repairing the die without removing it from the press. The safety block (Fig. 85) consists of a housing 5 with a handle and a screw 6 screwed into it, the rotation of which adjusts the overall height of the block. The block is installed on bracket 2, rigidly fixed to the press frame. In the top 7 and bottom 8 plates of the die, areas of 150X150 mm in size or 150 mm in diameter must be provided for installing blocks when finishing or repairing dies directly on the press. To remove the block from the bracket, it is necessary to disconnect the connector by rotating the nut of the plug connector 1. In this case, the control circuits of the presses are broken. The press can be put into operation only after installing the blocks in place and connecting the connectors. [6]

Each boiler has a safety block 8, which is a shut-off valve on which are mounted: a gas pressure control device, a vacuum control device, a signaling device and a fuse. [7]

The safety of the installation is ensured by a boiler safety unit and a gas pressure monitoring device or a general boiler safety unit. [8]

The pressure pulse from the gas pipeline is supplied to safety block 6 through a tube and through throttle Dr. Tube a is connected to tube b, which in turn is connected to the vacuum pulse sampling chamber 11 of each boiler. During normal operation of the boilers, tubes a and b are sealed and block 6 records the pressure in the gas pipeline. In the event of sharp pulsations (pops and explosions) in the boiler furnace, a valve connecting the tube b to the atmosphere is activated. In this case, the pressure in tube a drops, which leads to the gas supply to the burners being cut off. [9]

The pressure pulse from the gas pipeline is supplied to the safety unit through a tube (o) through a throttle. Following the continuation of this tube (b), the pulse is supplied to the valve of the KOR vacuum extraction chamber for each boiler. During normal operation of the boilers, tube a is sealed and the safety unit records the pressure in the gas pipeline. If sudden pulsations (popping) occur in the boiler furnace, the KOR valve is activated. In this case, the pressure in tube a drops, which leads to the gas supply to the burners being cut off. The boiler is fed by a pump connected to a feed valve. [10]

The pressure pulse from the gas pipeline is supplied to the safety unit through a tube and through a throttle. Along the continuation of this tube b, the pulse arrives at valve 16 of the vacuum sampling chamber / COP for each boiler. During normal operation of the boilers, tube a is sealed and the safety unit records the pressure in the gas pipeline. In this case, the pressure in tube a drops, which leads to the gas supply to the burners being cut off. [eleven]

The pressure pulse from the gas pipeline to the safety unit is supplied through tube a through the throttle, then through tube b the pulse is supplied to the valve of the KOR vacuum sampling chamber for each boiler. [12]

The automation system performs the functions of protection (safety unit) and regulation. The safety unit is designed to ensure proper ignition of the boiler and shut off the gas supply to the burners in the absence of draft and the flame goes out, or the impulse lines are broken. Regulation is carried out based on the water temperature at the boiler outlet. [13]

If there is a violation of any of the monitored parameters of the boiler safety unit, then the contact of the corresponding relay de-energizes the 2PA boiler emergency relay, breaking the common power circuit of the windings of all three gas solenoid valves. The control and working solenoid valves are closed, and the section of the gas pipeline between them is switched by the ignition-purge valve to the safety plug. [14]

To activate the automatic boiler safety system, turn the safety unit handle counterclockwise until it stops. After 5 - 10 seconds, the handle is returned to its original position. [15]

Working with AOGV

It begins when the gas supply is blocked - the corresponding valve closes. And this is a general principle for similar work with any boilers and columns.

How to clean the burner of an AOGV gas boiler? After shutting off the gas, this element is removed from its position. The burner has a nozzle

It is carefully unscrewed and carefully cleaned with a brush. The burner itself is cleaned by blowing using a special pump. Then the nozzle and burner are returned to their place

Then the nozzle and burner are returned to their place.

These are general criteria. And the details are presented on the next two models.

First. AOGV 11.6-3. This is a reliable and practical device.

But after a certain period of operation, it is thoroughly cleaned. The process goes like this:

The burner block is removed

To do this, the pan of the apparatus is rotated, and three tubes are disconnected from the automation unit: contact, gas and thermocouples

Carefully unscrew the nuts located on the fittings of the automation mechanism. The paronite gasket on the main gas pipe is removed and its conditions are studied

If it is damaged, it needs to be replaced. The marked pallet is taken out through the groove, which is as close as possible to the tubes

The casing is also pulled out along with it. When fixing the lower part of the tray, point it towards you and remove the remaining holders (two pieces) from the engagement. This entire assembly falls to the floor. The main burner is examined and cleaned. The igniter nozzle is inspected. The wick and thermocouple are unscrewed. The box-shaped casing is separated from the pilot burner. This clears the way to the nozzle. If it is brass and there is plaque on it, it can be removed with fine-grained sandpaper. Cleaning the nozzle. To do this, thin copper wire and a blowing method under high pressure are used. The second action is carried out by a special pump from the side where the tube is connected to the tee

The same sandpaper is used to very carefully clean the bend of the thermocouple tube.

After this work, all the parts are assembled using the reverse algorithm. Smoothly, avoiding distortions, lift the entire block. The burner should be inside the housing, and the igniter and thermocouple should not touch the casing flange.

From the side of the tubes, the entire assembly should be tilted towards itself with a slight downward slope. The opposite side of the tray should rise.

Then feed it forward and simultaneously put on a pair of distant holds. They should be on the casing flange. The nearest hook goes to a cut groove. After it enters there, the entire pallet rotates in the opposite direction to the clockwise direction. The gas pipe should be positioned only under its branch pipe of the automation unit.

Next, it is tested how correctly the gaskets fit, and all the tubes are returned to their places. The wrench tightens the nuts on two tubes: the igniter and the gas tube.

Before reassembling the thermocouple tube, its contact areas are carefully but carefully cleaned. The nut here is tightened with your fingers.

The final stage is to check the tightness of all connections for potential leaks. If they are absent, the boiler turns on. If available, these places are covered with sealant, the nuts are tightened.

The second model is AOGV-23.2-1 Zhukovsky.

It works like this:

- The nut is unscrewed so that the gas pipe passes through.

- The angle, igniter and thermocouple are unscrewed.

- All burners in the set stretch outward and extend to the side towards the user. If there are difficulties with their movement, loosen and unscrew the studs with pliers. Clean all jets and other components.

- Disassembly of burners. To do this, unscrew 4 pins on both sides.

- The plates with slots are removed from the top of the burners, then the springs. All parts are thoroughly cleaned.

- Reassemble all elements in reverse order.

After reassembly, a leak test is carried out to examine how tightly the burners adhere to the body.

Portal about construction

Statistical studies show that at least 50% of heating equipment runs on natural gas.

This popularity is due to objective reasons - convenience and ease of use and the relatively low cost of the energy carrier (natural gas).

Talking about an automatic gas boiler in this article, we will immediately make a reservation that any modern gas boiler is automatic, that is, it does not require daily cleaning and loading of fuel like boilers running on solid fuel or periodic refueling like boilers running on liquid fuel.

The difference is that “simple” boilers are equipped with a standard set of automation and protection, while “complex” boilers are equipped with additional options that improve their maintenance and configuration.

Commissioning of a wall-mounted boiler

For installation and initial start-up of a wall-mounted gas boiler, it is better to contact the organization of the specifics in question. The presence of all approvals and appropriate qualifications for the installation of water heating equipment on the part of the service center will allow you to purchase a warranty, as well as extend it with proper operation in subsequent years. All this must be accompanied by documentation in the form of an act or card with a stamp and signature.

In addition to the provided warranty, when contacting specialists, another advantage is the safe installation and adjustment for economical operation of the gas boiler. Safety means the absence of gas leakage and the risk of unwanted ignition.

Installation features

According to SNiP requirements, the heating boiler must be connected to the gas main using a copper pipe or a stainless steel bellows hose. The presence of a gas shut-off valve is mandatory. It is also possible to use various types of adapters and fittings for connection. We must not forget about the presence of gaskets and sealing materials at the joints.

Gas boilers can only be mounted on fireproof walls at a distance of at least 2 centimeters. Otherwise, a fireproof material (plaster, metal or ceramics) must be placed between the boiler and the wall. The distance to the wall should be more than 3 centimeters, and the sheet area should exceed the dimensions of the heating installation in width and height.

Another important condition for placing a gas boiler is the presence of a hood and a window with elements of free air access. After installing the heating boiler, it is necessary to check for gas leaks using an electronic device or a soap solution.

Commissioning

The sequence of actions when starting a wall-mounted gas boiler may differ slightly and be as follows:

Gas boiler safety automation

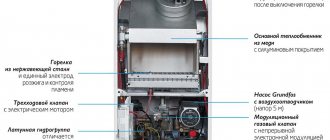

In general, the automation of a gas boiler consists of the following components and parts:

- Thermal balloon. It is a small container filled with a special gas. When heated or cooled, the gas increases (decreases) in volume and this activates the “accordion” of the bellows, which presses the gas supply “button”. Installed on the top of the heat exchanger or coolant reservoir. Depending on the temperature, it turns on or off the gas supply to the gas burner.

- Thermocouple. It is a bimetallic plate located in a “wick” gas burner. The thermocouple is electrically connected to the main automation unit and is designed to open or close the gas supply depending on the presence or absence of a flame. It should be noted that the potential difference in the thermocouple (signal to open the gas supply) occurs after it has completely warmed up for 20-30 seconds.

- Main automation unit. It consists of a manual coolant temperature regulator, a main gas supply button and an emergency button. When you press and hold the main button, the gas supply to the “wick” burner opens, and when you press the emergency button, the gas supply immediately stops.

Automatic gas heating boilers. Automation operating principle

The operating principle of conventional automation is very simple and if all parts and components are in good working order, the automation does not require daily or even monthly attention. Starting the boiler and its subsequent operation is carried out as follows:

- The ball valve located on the main supply pipeline opens.

- The temperature regulator is set to min. Usually this is the number “0” or “1”.

With one hand, press and hold the main feed button located on the main automation unit. If this is the first start of the boiler (after a summer or other long-term stop), before starting the ignition process, you must hold the button for 2-3 minutes.

This is necessary so that the pipeline from the ball valve to the burner is filled with gas.

Readiness control - slight smell of gas. By holding the button, the “wick” burner is ignited (with a match or piezo ignition).

After making sure that the gas is burning, to warm up the thermocouple, we continue to hold the button for another 20-30 seconds. Better 1 minute. Let's release the button. If everything is in order, the thermocouple gives a signal to the main unit, the main gas supply to the burner(s) opens, the boiler starts operating in automatic mode.

At the same time, automatic gas burners for boilers, as a rule, consist of three burners - a “wick” burner, which burns constantly as long as there is a gas supply, the main one, which heats the coolant to the set temperature, and an “economical” burner, which maintains combustion and turns off when the main burner is turned on.

Depending on what temperature of the coolant the temperature regulator is set to – numbers from “0” to “6”, the coolant is heated to a temperature of 20 to 70 degrees Celsius.

After heating the coolant to a certain temperature, the main burner turns off, the economical one turns on, the coolant cools down to the temperature of the differential setting of the temperature controller, the economical burner turns off, the main burner turns on - the cycle repeats.

We looked at the general case - the simplest automation system for a gas boiler. It should be noted that there are more complex automatic systems, the design of which includes all of the above and additionally:

- Thermostat to turn off the boiler in case of emergency increase in water pressure.

- Traction control sensor.

- Remote ambient temperature sensors.

- Sensors for monitoring external air temperature.

- Boiler blocking in case of emergency decrease in gas pressure.

- Power control unit.

- And other options and “excesses”.

Varieties

There are two options for SABC automation; their operating principles are different. Non-volatile systems use mechanical sensors that open and close the gas supply valve based on a signal from the thermostat.

Volatile systems allow more efficient regulation of boiler operation. Volatile devices include room thermostats, which can be:

- Simple. This option regulates the operation of the burner depending on the temperature in the room, maintaining a stable temperature set by the owners.

- Programmable. These are complex devices that allow you to change the temperature in rooms depending on the time of day or day of the week. For example, you can set a mode in which the room temperature will automatically decrease at night or during the working day while no one is at home.

Technological features

It should also be noted that all previously discussed units must be household and not industrial. They should also be based on an injection burner. The operating principle of the latter is based on the fact that during the combustion of fuel, the required volume of air mass is “sucked in” naturally due to a special design. Again, the lack of a forced ventilation component means that the gas-air ratio is not always strictly met. Therefore, in one case there is an excess of fuel, and it does not burn completely. In the second case, more air is already produced, and the natural gas is not completely burned.

Advantages and Disadvantages of Launching

The advantages of boilers with electric ignition are obvious to those who value the quiet operation of the unit, the absence of soot and soot, and significant fuel savings. Electrical equipment is quickly installed and commissioned. The main thing is to follow the recommendations given in the instructions.

Complete dependence on the electrical network is the only serious drawback. When installing the structure, immediately pay attention to this fact, especially if you often encounter power surges and power outages.

Gas equipment for KChM 630 EUROSIT

In distant post-Soviet times, when natural gas for the population cost nothing, solid fuel boilers began to be produced with gas fittings of the APOK-1 type, which replaced solid fuel in the form of coal and wood. The gas supplied to the KChM had a complex and cumbersome device with burners that consumed gas within large limits. Nowadays, they have begun to produce more modern and economical gas boilers that consume less gas, but not all owners of private houses can afford them. Of course, old KChM boilers are not so aesthetically pleasing and modern, but if they are modernized, they can serve as heating devices for many years.

KSU-2P control kit.

The following modifications are available for boilers operating on gas fuel:

- KSU-2P-1-G (as part of control and signaling units BUS-1 and switching element unit BKE-1) - for boilers with natural circulation with vacuum;

- KSU-2P-2-G (as part of blocks BUS-2 and BKE-1) - for boilers with natural circulation with pressurization;

- KSU-2P-3-G (as part of blocks BUS-3 and BKE-2) - for direct-flow boilers with supercharging.

The supply voltage of the kit is a three-phase network 380/220 or 220/127 V with fluctuations ranging from +10 to -15%. The supply voltage is set using jumpers on the block located in the control and signaling unit (BUS). AC frequency 50 ± 1 Hz. Power consumption no more than 300 VA.

KSU-2P, together with sensors and actuators, provides: two-position regulation of the main technological parameters of the boiler (stabilization of the water level in the drum - for KSU-2P-1-G and KSU-2P-2-G; stabilization of steam pressure - for all modifications); safety automatics (gas supply to the boiler is stopped in case of emergency decrease and increase in gas pressure, decrease in air pressure, increase in steam pressure at the boiler outlet, absence of burner flame, emergency increase and decrease in the level in the boiler drum - for KSU-2P-1-G and KSU-2P-2-G, lowering the vacuum in the boiler furnace - for KSU-2P-1-G, in case of an emergency increase in the temperature of the steam at the boiler outlet and the temperature of the exhaust gases - for KSU-2P-3-G); light and sound alarms with storage of the root cause of the accident; issuing signals to the control panel about turning on the set and stopping the boiler; automatic start and stop; working alarm.

The BUS contains functional blocks. On the front panel of the BUS there are operational control and alarm controls (figure below). In addition, the BUS includes intermediate relays used to control the boiler actuators and magnetic starters of the BKE unit 16, as well as to switch the BUS circuits during the execution of the control program.