Design and principle of operation of Leopard boilers

The Leopard double-circuit gas boiler from Proterm is a device capable of operating from both natural and liquefied gas, equipped with a bithermal heat exchanger. The throughput of liquid from the tap is 8 liters per minute, heated to 35 degrees.

Power consumption 135 W. Equipped with a built-in processor, it monitors the operation of the device by comparing sensor readings. If a problem is detected, the gas supply is stopped and a failure code is displayed.

This device is easy to operate, the efficiency during the heating season is 90%. Depending on the modification, it may be with natural or forced removal of combustion products.

Types of Proterm gas boilers are the most interesting for the domestic market

There are many modifications on sale. The most common are gas two-chamber boilers with biometric heat exchangers: Leopard and Lynx. The equipment is made at a high technological level and complies with EU standards. However, no matter how good the technology is, it has the ability to fail at the most inopportune moment. Read below about malfunctions of heating devices and troubleshooting methods.

Do you know how to properly arrange the chimney of a domestic gas boiler? Find out: are there gas boilers without a chimney?

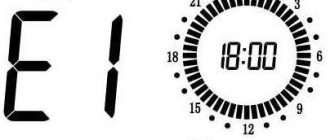

Basic error codes

Next, we will consider the most common errors of the Leopold gas boiler, and we will figure out what needs to be done to eliminate them.

a6

Error a6. Occurs due to low temperature in the room where the boiler is installed. The temperature in the room where the device is installed should not fall below 0 degrees; if this happens for some reason, install an electric radiator there.

f0

Error f0. Occurs when the pressure of the circulating fluid drops below 0.7 bar.

You need to do the following:

- Increase the pressure in the heating system to the required value (1.5 bar). This can be done using a make-up tap.

Automatic heating system make-up valve

- Then check all pipes for leaks. To do this, take a small piece of fabric and check all the connecting elements.

- Check if the fluid pressure sensor is working properly.

- Check to see if the expansion tank is working properly.

- If the fall continues and you are unable to find the cause, contact a qualified professional for help.

- Reboot the device using the restart button.

- Check the gas pressure, if you are using liquefied gas, it may have run out in the storage tank.

- The electrical connection may be broken; turn the plug over in the socket.

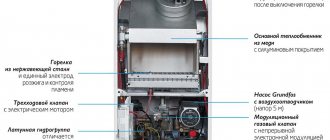

Fan for boilers Leopard - The fan may be broken and due to overheating, the lock will be triggered.

f1

Error f1 (f1). Flame extinction. Occurs due to automatic blocking of the gas supply to the burner, since when the gas is open, a signal about the presence of a flame from the ionization electrode is not sent to the processor.

Necessary:

f5

Error f5. Damage to the outside temperature sensor. And if it is absent, it signals low voltage.

Try the following:

- Use a multimeter to check the electrical circuit of the sensor and the boiler for a break; if found, repair it. If the problem still persists after this, contact a qualified technician for help.

- To equalize the voltage, connect the device through a voltage stabilizer.

- Perhaps the problem lies in the sensor itself, or rather, in its malfunction; replace it with a new one.

- Also, the problem may lie in a faulty board; have it tested and, if necessary, replace it with a new one.

Leopard boiler control board

f6

Error f6. Indicates that the traction sensor is open.

Check the following:

- The traction sensor is faulty.

- Check the sensor circuit with the board for an open or short circuit.

- Check to see if the gas valve is working properly.

- Check for a short circuit to the frame.

- Test the fuse for serviceability.

- The sensor that monitors heat exchanger overheating may be faulty.

Leopard boiler heat exchanger

f7

Error f7. Indicates a fault in the connection between the display and the board.

Check the following:

- Try restarting the boiler.

- Check the circuit board - display for an open or short circuit.

- The phase is mixed up with zero, swap the plug.

- The pressure in the coolant system has dropped below the permissible minimum. Top up the system to the 1-2 bar mark.

f8

Error f8. The gas valve has failed.

Check the following:

- Integrity of the gas valve power connector.

Gas valve - Check the resistance in the gas valve coil.

On a note!

- Protherm Leopard boilers are available in several modifications. The difference is in power, type of combustion chamber and method of smoke removal (BTV - forced, BOV - natural draft). In all other respects, the design is identical, and therefore errors for all versions of heating equipment of this brand are interpreted in the same way.

Protherm Leopard control panel discontinued

Protherm Leopard control panel

- Whatever code appears on the Proterm Leopard display, you need to start the investigation by turning off and restarting the boiler. This is done with the main switch (on the lower end of the device, at the place where the pipes are connected: indicated by REZET). Access to it is free; you do not have to remove the casing.

Other faults

The boiler does not turn on due to:

- no power supply, check the serviceability of the network connection, the network voltage, if it is less than 220V, install a transformer;

- low pressure in the gas line, contact the gas utility;

- the gas supply is shut off, open the tap;

- there is no draft, make sure that the chimney is not clogged and the fan is working properly;

- the electrode is not installed correctly relative to the jets, adjust the value between the electrode and the jets;

- The gas valve is faulty, replace it with a new one.

The boiler is usually humming due to a large amount of deposits in the heat exchanger, flush the heat exchanger, air may get into the system, remove air, the fan or pump may be faulty, check their operation.

Proterm boiler diagram

Insufficient water pressure in the hot tap, check and wash the filters, if they are deformed or torn, replace them.

The flame is orange and burns unevenly - this happens if the burner and jets are dirty, clean them of soot with a brush and rag, blow the jets with a hairdryer.

F1. Loss of flame.

The error appears when there is no gas supply to the burner.

Probable Causes

- The shut-off valve has tripped. In emergency situations, it blocks the main pipe and the boiler stops. After eliminating any error on the Proterm Leopard display, do not forget to put the lever into working condition.

- Clogged gas filter mesh.

- Problem with the counter. It is sealed, and you will have to call a technician.

- A sharp drop in pressure in the line. In this situation, nothing depends on the owner of the facility connected to the central gas supply system; just call the emergency service. If Proterm Leopard receives “blue fuel” from a gas tank or from a cylinder group, the solution is clear - refuel, change the empty tank.

A flame loss error that appears during the initial start-up of the boiler indicates a problem with the chimney: an incorrectly drawn up diagram, unprofessional installation. Poor draft, blowing out the burner with gusts of wind lead to an emergency stop of the Proterm Leopard.

Connecting a room thermostat

A room thermostat allows you to more accurately adjust the indoor microclimate . Its sensor checks the air temperature, which gives more accurate results than checking the extract air temperature, which is produced by the boiler electronics.

Using a room thermostat allows you to turn off the boiler when the set values are reached, when the device’s own sensors are not yet ready to give a command to stop heating.

The thermostat is connected to a special gap in the control board, the contacts of which are closed by default with a jumper.

To connect, turn off the boiler, open the lid and remove the jumper . Then the room thermostat is connected in the required order and a test switch is performed.

If the device operates normally, close the lid and proceed to further operation of the boiler with additional equipment. If problems are found, they are corrected immediately.

IMPORTANT!

Detailed instructions for connecting a room thermostat are available both on the device itself and in the user manual for the boiler. Under no circumstances should you act at random.

How to run self-diagnosis

The self-diagnosis system operates in constant mode. The start-up occurs simultaneously with the start of the boiler, and the system can only be stopped when the unit is stopped. Therefore, no special actions are required to enable self-diagnosis .

There is no need for special contact with the system; if a problem occurs, it will immediately report it, and if no notifications are received, it means that the boiler is operating normally and no problem points have been detected.

Pro Tips

Imported equipment is sensitive to supply voltage parameters. Heating boilers are no exception, often producing false errors. To minimize the risk of Proterm Leopard stopping for this reason, it is recommended to connect it to the network via a UPS. The advantage of this solution is that the power supply will ensure uninterrupted operation of the unit even if the power supply is temporarily interrupted. During what period depends on the total capacity of the UPS batteries: from 4 hours or more.

When searching for the cause of an error on the boiler display, it is necessary to check the tightness of the plugs and the reliability of the electrical contacts. During operation, the structural parts of Proterm Leopard vibrate slightly and the quality of the connection may be impaired. According to statistics, about 45% of problems are caused by this factor.

If the result of self-diagnosis of the boiler and heating system is negative, the fault is in the Proterm Leopard electronic board. You'll have to contact a specialist.

Did you like the article? A repost will be the best thanks.

Review of the Proterm brand series

If we consider gas-fired equipment, then according to the installation location, all boilers can be divided into two large categories:

- wall mounted – “Lynx Condence” and “Lynx”, “Panther”, “Jaguar”, “Cheetah”;

- floor-standing – “Bear” (series KLOM, KLZ17, PLO, TLO), “Bison NL”, “Grizzly KLO”, “Wolf (Volk)”.

Despite the Turkish and Belarusian assembly, the quality of the equipment is high in European style.

Among the wall-mounted models are 1- and 2-circuit, atmospheric and turbocharged, with a power of 11-35 kW.

Floor-standing models are made of steel or cast iron, equipped with injection or fan burners, and can operate on natural and liquefied gas. The power range is wide – 12-150 kW – so choosing a device for specific conditions is easy.

The main purpose of the equipment is to organize hot water supply and heating in private residential buildings, and some units are designed for industrial use

Each series has distinctive features regarding design, dimensions, installation method, technical characteristics, additional functions:

- “Lynx” - condensing models are 12-14% more economical than non-condensing models, therefore they are recognized as energy-efficient devices for heating country houses and cottages.

- "Panther" - the latest models are available with a convenient eBus communication bus and an updated security system

- “Jaguar” - the main advantages are the low price of the unit and the possibility of separately adjusting two circuits - heating and hot water.

- “Cheetah” is a popular wall-mounted model that can be installed outside the city, in a country house or cottage, or in a city apartment.

- “Bear” - among the representatives of various series - are reliable units with a built-in boiler, a cast-iron heat exchanger and a power of up to 49 kW.

- “Bison NL” are universal models in terms of the fuel used: they operate equally efficiently on gas, fuel oil or diesel fuel, power up to 71 kW.

- "Grizzly KLO" - capable of heating private houses and office premises with an area of up to 1500 m², maximum power - 150 kW.

- “Wolf” is an electrically independent boiler with a steel heat exchanger that stably supplies heat to country houses and residential buildings even in the absence of electricity.

According to consumer reviews, Proterm units are reliable, efficient, easy to install and operate, and with regular maintenance they hardly fail.

However, durable materials, good fuel and excellent assembly do not guarantee impeccable service, so boilers of all the listed series sooner or later require replacement of spare parts, cleaning or repair.

F6.

Problem with traction. If the boiler is a BTV series (turbocharged), then the cause of the error should be sought in the area where the fan is located. The electronic board does not receive a signal from the corresponding sensor.

Check what

- Condition of electrical circuits.

- Fan performance. It may not be receiving voltage. Breakdown is a rare occurrence. When the blades rotate freely, mechanical defects are excluded; only the electrical part. It is not difficult to ring the motor winding.

Recommendation:

If the cause of the error is not identified, two options are possible - a malfunction of the electronic module or the fan (turn-to-turn short circuit). You can't figure it out on your own, call a professional.

F0. Pressure drop in the heating circuit.

Its normal value for Proterm Leopard is 1.5 bar. It is easy to replenish the volume using a special valve at the bottom of the boiler (blue). But if the unit stops again after a short period of time and the same error appears on the display, you need to figure it out.

Probable Causes

Recommendation:

It’s not difficult to identify, you just need to carefully inspect the entire route. Wet spots and puddles on the floor will indicate the “culprit” for the F0 error.

Recommendation:

Remove the pump from the boiler and carry out maintenance. If the heating system with Proterm Leopard has a low-quality coolant, then in most cases it helps restore the functionality of the pump.

How to turn it on

The boiler is started by pressing the round “main switch” button to the right of the display.

Power supply to all boiler systems begins. Usually the boiler is in standby mode, i.e. There is no preparation of coolant and hot water. The display shows the current state of the device, so the user can immediately determine what the boiler automation is currently doing.

To start the process, you need to set the temperature of the heating agent or hot water supply, after which the burner will start and the coolant will begin heating.

These actions will be accompanied by characteristic sounds of pump operation, water movement, and burner startup.

The boiler is stopped by simply pressing the main switch.

How to connect to electricity

The electronics of gas boilers are demanding on the correct connection of the phase, zero and ground electrode.

If the contacts are reversed when connecting, the boiler will not start. Therefore, it is important to use a special plug and socket that does not allow you to connect the device in any other way. When running the cable, you need to check the correct distribution of the electrodes in the socket.

To check, use a probe screwdriver or other special devices.