The main function of a thermal imager is to monitor the changing temperature distribution on any surface. All received information is displayed on the display as a color field, where each color corresponds to a specific temperature value. Modern models of thermal imagers can be stationary or portable. Using stationary devices, various technological processes performed in industrial enterprises are controlled. Handheld thermal imagers are used in specific environments where speed and ease of use are critical.

Operating principle of a thermal imager

Thermal imagers are suitable for operation in any weather conditions. With their help, thermograms are compiled, the quality of room insulation is checked, the coldest or warmest places in the rooms, sources of drafts and places where water accumulates due to temperature changes are determined. But, despite all the positive qualities, very few can purchase it for personal use due to its rather high cost. Therefore, many craftsmen are trying to make a thermal imager with their own hands from scrap materials.

Thanks to their ability to identify heat waves, thermal imagers have become popular in many areas of people's lives and activities. All inanimate objects, along with living beings, emit electromagnetic waves in a fairly wide range of frequencies, including the infrared spectrum. Infrared radiation is often called thermal radiation. The degree of its intensity depends on the temperature of the object and practically does not change with different degrees of illumination.

This property is the basis for the operation of a thermal imager, which not only records the thermal radiation emitted by objects, but also converts it into a form accessible to visual perception. For this purpose, a special lens with germanium optics is installed in the device. This material is used to make lenses that freely transmit thermal radiation. Regular glass cannot be used because it blocks infrared rays.

Passing through the lens system, infrared waves are delayed by a special matrix. It is made in the form of a microcircuit consisting of photosensitive diodes that can change resistance depending on the intensity of exposure to infrared rays. Modern technologies make it possible to create a compact matrix with low energy consumption. To improve image quality, it is cooled using software and hardware.

Current messages passing through the matrix are read by the processor and converted into a video signal, which is displayed on an external monitor or thermal imager display. The temperature difference between the object and the environment gives a very clear outline of the image. Each wave, depending on the temperature, is displayed using different colors. For more convenient use of the device, in some models a scale is displayed on top of the frame, displaying the correspondence of different points of the image to the values of the absolute temperature of the object. Additionally, minimum and maximum temperature values can be displayed.

Settings

After installing the software on the controller, you need to turn on the assembled device and configure it. 3 dots should appear on the computer screen: one dot should be in the center of the screen, and one in the corner.

The additional point is a laser beam. It is this that needs to be combined with the central point. Calibration completed.

This device is very bulky due to the use of a tripod. But it can easily be installed on a car or a rigid base, for example, on the roof of a house. The cord for connecting to a computer can be extended or purchased ready-made. The main feature of this device is that there is a large scope for modernization. This thermal imager can easily be used as a burglar or fire alarm. The only drawback of the device lies in the slowness of data transfer. This is due to the frequency of interaction between the controller and the webcam.

DIY thermal imager from a camera

One option is to independently manufacture a thermal imager based on a camera, which includes a matrix with a structure similar to that of a real device.

Initially, each camera is configured in such a way that a person receives images in their natural form. For this purpose, a special filter is installed that reflects or absorbs infrared rays. As a result, the sensitivity curve of the matrix becomes identical to the curve of the human eye. In order for the camera to function as a thermal imager, the infrared filter must be removed from it. Sometimes a visible spectrum filter is installed instead, which is of little importance and does not affect the image quality. In the same way, you can make a thermal imager for hunting with your own hands.

The finished thermal imager can be used at home. With its help, it is easy to detect places where cold air enters the room, eliminate drafts and heat leaks.

Bluetooth and Wi-Fi

If the thermal imager has built-in Bluetooth or Wi-Fi, then all important diagnostic measurements can be instantly transmitted directly to other devices. Or, conversely, data from other devices can be transmitted to a thermal imager, which indicates them in the images taken, like temperature. This feature greatly facilitates the process of transferring the necessary information. Secure your investment

Give preference to cameras that have extended warranties. In this case, you can protect your own investments.

Technical support and training

Naturally, this factor plays a huge role when choosing a camera, especially if you are not well versed in its functions. That is why it is worth paying attention to the availability of high-quality technical support and instructions. Ergonomic features

If you need a camera for long periods of work, you'll likely want to opt for a lighter, more portable option that will reduce the strain on your shoulders. Many models are equipped with a lens system. Thanks to this, the camera can tilt its axis up to 120 degrees. This option allows you to keep the screen always in front of your eyes. It is also worth paying attention to the convenience of the buttons and menus. Additional buttons make working with the thermal imager much easier, as it eliminates the need to constantly use menu options.

Picture in Picture (PiP) or Image Fusion

This functionality helps create a combination of thermal images and photographs taken in visible light. This way you can create clearer reports.

Programs for processing reports

Some thermal imagers are capable of generating detailed reports on their own using built-in software. If this function is present, then the need to enter data into MatLab or Excel tables yourself may completely disappear.

Do-it-yourself thermal imager from a smartphone

The smartphone itself cannot be turned into a thermal imager without the use of additional equipment. However, recently a special attachment, Seek Thermal, has begun to be produced, which is essentially a mobile miniature thermal imager, with dimensions no larger than a matchbox.

This mini-device is capable of working with many smartphones based on Android version no lower than 4.3. It performs the same functions as real branded thermal imagers and is connected via standard connectors. It turns out to be quite easy to assemble with your own hands. Despite its small size, the camera lens is equipped with a focusing ring, as well as a sensitive sensor in the form of a 32 thousand pixel matrix, the shooting frequency of which is 9 Hz. The main advantage of the device is the operating temperature range ranging from -40 to +330C.

Necessity for hunting

A thermal imager is a multifunctional device, but, in addition to being used as stationary equipment (for monitoring various industrial processes), its portable and portable version is most useful. The above fully applies to the use of the device for hunting - moreover, it is desirable to design the device in the form of a shock-resistant and lightweight monoblock, providing a high range of visible visibility (on professional models it is 1.5 km and has a protection level of over IP54). If the device is assembled using digital rather than analog optics (which makes it difficult to distinguish a hot fire from cold snow at a distance of 100 meters), the hunter will have the opportunity to find an animal or bird in the most unfavorable conditions for ordinary human vision. These include darkness, thick fog, rain, and even thickets that camouflage animals that are frozen and not moving.

Ready thermal imager

For a thermal imager, the body radiation of warm-blooded mammals or birds will look like a bright spot on the monitor, which simply will not allow the prey to go unnoticed.

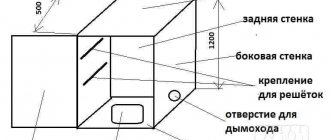

Do-it-yourself thermal imager from a video camera

One of the ways to make a thermal imager yourself is to use a video camera. To do this, you need to prepare all the necessary materials in advance. You should stock up on a regular infrared thermometer, a set of RGB LEDs, an Arduino board and the video camera itself.

The solution to the problem of how to make a thermal imager with your own hands is quite simple, with the exception of the board programming features. At the very beginning, you connect the infrared thermometer to the Arduino board. This element allows you to determine the temperature of an object at any specific point. The board itself performs an intermediate function. Pre-prepared LEDs are connected to it. The entire system then needs to be programmed to match the thermometer reading to a specific color that the LEDs will produce. If adjusted according to generally accepted standards, high temperatures will be red and lower temperatures will be blue.

The functionality of the entire structure is checked by pointing the beam of an infrared thermometer at the wall. In this case, the LEDs should light up in the specified colors. However, such a check will be incomplete due to the lack of a display. This problem can easily be solved using a regular video camera set to slow motion. Pictures are taken every 2-3 seconds, capturing the lighting coming from the LEDs. The corresponding colored spots are shown on the display.

Types of devices

The thermal imager is such a popular and multifunctional device that it has two technological design options:

- Stationary. Devices in this category are intended for use in industrial enterprises to monitor technological processes. A nitrogen cooling system is a fairly common device that is equipped with such a thermal imager. Its operating temperature characteristics are very impressive: from −40 to +2000 °C. These systems are usually based on devices assembled on matrices of semiconductor photodetectors.

- Portable (portable). Innovative developments have made it possible to move away from the use of bulky cooling equipment, moving to the production of thermal imagers based on uncooled silicon microbolometers. Such devices have all the advantages of their predecessors, which include, for example, a small temperature step during measurement (0.1 °C). It is also possible to use a thermal imager of this class for complex assessment work that requires both ease of use and portability of the device. Many portable thermal imagers have the ability to connect to a PC for rapid processing of data from them.

The use of a thermal imager in a particular area leaves certain imprints on the required operational characteristics of this device. Therefore, before purchasing this device, you should evaluate the conditions under which it will be used. The instructions will help with this. A thermal imager purchased without proper knowledge of the operating instructions may not suit your needs at all. For example, thermal imagers used for hunting must have an impact-resistant light alloy housing with a protection degree of at least IP54.

It is desirable that it be a monoblock design with indication on the viewfinder and LCD screen. And the visible range of hunting thermal imagers should reach 1500 m, while in the construction industry such requirements are not imposed on thermal imagers.