The branches left behind after tree trimming are quite an inconvenient waste. Piled up in a heap, they take up a lot of space, and you can’t put the branches into the oven right away; it takes a long time to chop them with an ax. Making a fire and just burning it in the garden is a shame. A suitable option for a thrifty owner is to make a branch chopper with your own hands to process them into wood chips. And there will be a use for it - even burn it in a cauldron, or use it for compost. We are interested in the designs of homemade crushers, since the prices of factory units are not comparable with the volumes of wood processing in an ordinary private sector.

Shredder design for branches and grass

The purpose of the unit is to quickly and safely grind plant debris. The main function is performed by the cutting block. The knives are driven by the engine directly or via a belt drive. The units are installed on a stable frame. The moving elements are covered with a casing. Two compartments are made for feeding branches and unloading chips.

Metal frame

A homemade shredder with a powerful electric or gasoline engine needs a stable, durable frame with space to install the engine and a rectangular support for the cutting unit.

To make the shredder frame use:

- profile pipe 25;

- corner at 30;

- channel.

Fasteners:

- ears for the engine,

- nuts,

- hairpins.

Engine

Full autonomy, work anywhere in the garden, independence from the outlet - the advantages of a gasoline engine. A homemade shredder for processing branches, tomato tops, and grass is equipped with a motor from a motor-cultivator or walk-behind tractor with a capacity of 6 liters. With. It is moved from one unit to another.

You need a gearbox that provides 90° rotation if the gasoline engine has a horizontal shaft and the chopper has a vertical shaft.

Electricity costs are lower than gasoline, so if there is a network on the site, an electric motor is installed on the unit. To chop branches 2-3 cm thick, a 3-phase electric motor of 2200-3500 W is sufficient. When making a low-power grass cutter, they take engines from household devices. They are removed from washing machines and vacuum cleaners.

Knives

The thickness of the branches processed by the shredder depends on the design of the cutting unit. In home-made designs, several options are implemented:

- to grind branches with a diameter of 7-8 cm, several cutters are installed on the shaft;

- hammer-type cutting block for grinding thin rods;

- the universal cutting mechanism is made of 15-30 circular saws mounted on a shaft;

- knives from factory garden equipment - brush cutters, lawn mowers;

- chop grass - trimmer line;

- stump crusher from a plane;

- two shafts with 3-4 steel knives for cutting branches of bushes and trees.

Homemade knives are made from springs.

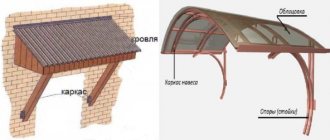

Protective cover

To prevent chips from flying around, you need a protective cover. It is made from sheet steel with a thickness of at least 1.5 mm. Tin is not suitable for this purpose. During active use of the shredder, it quickly becomes deformed from strong impacts of wood chips.

Container for receiving sawdust

Old shopping bags, boxes, buckets, and bins are used to collect small garbage. For powerful units, the bunker is welded from steel sheets and riveted from galvanized steel.

Electrical wires and start/stop button

To turn on and off a homemade unit, use a push-button station designed for the appropriate current. Its purpose:

- turning off and turning on electrical equipment;

- changing the direction of rotation (reverse).

To connect the engine to a three-phase network, you need a five-core flexible copper cable in double insulation; for a single-phase household network, a three-core cable is sufficient.

Types of units

The most common way out of this situation is to crush them into chips, and then use them at your own discretion. For example, use it for compost, mulch the soil, etc. To process branches into wood chips, you will need a garden shredder. Currently, manufacturers recommend hundreds of models of similar tools required in everyday life, but they have a common disadvantage - high cost.

You can make an electric garden branch chopper with your own hands. The main element of any garden shredder is the operating mechanism that specifically chops branches into chips. By the way, they are divided according to the design of this mechanism. To make a branch chopper with your own hands, it is best to choose one of two types of crushing mechanism: with a disk chopper or with a cutting mechanism made from a circular saw.

In the disk unit, tree branches are crushed into chips using sharpened knives that are attached to a massive flywheel. The design makes it possible to very easily divide a significant amount of branches.

The main disadvantage is the periodic need to sharpen cutting knives. Without this, operating efficiency quickly decreases and the consumption of electrical energy or fuel increases (depending on the type of drive).

Knives are made of durable, strong steel, so sharpening them is not an easy task. You may have to seek help from a specialist. In crushers of the second type, a mechanism of several dozen circulating saws literally bites into the supplied wood. Compared to a disk unit, the speed is noticeably lower, but the chips come out much smaller. You can even make briquettes from it in the form of fuel.

This type of tool does not require periodic sharpening; in case of complete wear, the cutting components will need to be replaced. On the one hand, this is comfortable, and on the other hand, it is expensive, but for the average household, when using high-quality circulation discs, the period between installation and replacement reaches 10 years.

The garden branch shredder will be driven by an electric or gasoline (diesel) motor.

Naturally, you can’t make it with your own hands; you buy it ready-made. It should provide sufficient torque and reach speeds of up to 1500 rpm.

As a rule, using a gearbox you can reduce the rotation speed and increase the torque, however, this will complicate the design of the crusher. For a disk chopper, thanks to the use of a massive flywheel, it is possible to use a drive with a small amount of force developed.

Types of shredders

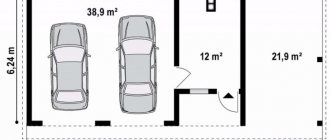

Devices for processing branches have many names: wood chipper, wood chipper, branch chopper, shredder, branch crusher, branch cutter, chopper, etc. Regardless of the name, their design is almost the same. The branch chopper device includes:

- Two bunkers. Wood for chopping is fed into one, and finished chips are unloaded from the other.

- Protective cover.

- Steel frame. All structural elements are attached to it.

- Drive unit. Gasoline, diesel and electric engines are used, from which the shaft comes.

- Cutting elements.

- Main gear. It can be on a rigid coupling or on a belt.

Homemade branch crushers are divided only by the design of the cutting mechanism. They are designed almost identically. Other items may vary in size. You can take ready-made drawings of a branch cutter (it will be easier to assemble the device with your own hands using ready-made designs).

The most common solutions:

- Several dozen conventional circular saws, which are made of a hard metal alloy, are attached to the shaft.

- The shaft is provided with several grooves with chopping knives (single core crusher). Crushing elements are made of high carbon steel. The wood is fed perpendicular to the knives.

- Branches must be fed into the disc crusher at an angle of 45 degrees. This is usually built into the bunker design.

- Sometimes a shredder is made with two synchronously rotating shafts (double-shaft crusher). The knives are mounted on them. When rotating, the blades converge with each other at one point. This design ensures self-tightening of the wood. Feeding occurs perpendicular to the knives.

An increase in torque is ensured by installing a flywheel. It is placed on one of the ends of the shaft. The only exception is the disc crusher, since instead of a flywheel it has a metal circle.

The lineup

If you still want to purchase a ready-made branch chopper for your walk-behind tractor, then we offer a small list of popular models on the market:

Branch chopper "Premium" (without wood splitter)

Branch chopper "Premium" (without wood splitter)

Characteristics:

Branch chopper with wood splitter (TYPE - 2) Premium

Branch chopper with wood splitter (TYPE - 2) Premium

Characteristics:

Branch chopper Volodar for walk-behind tractor RM-90D

Branch chopper Volodar for walk-behind tractor RM-90D

Characteristics:

Chipper for walk-behind tractor RM-90 M

Chipper for walk-behind tractor RM-90 M

Characteristics:

| Normal operation of the machine with a workpiece diameter | hard wood 60 mm soft wood 80 mm |

| Length of firewood output | 80 to 170mm |

| Unit performance | 5 m³ branches per hour |

| weight | 140 kg. |

We also suggest watching a video of the operation of a wood splitter for a walk-behind tractor:

Types of shredders by engine power

As already mentioned, for small volumes of raw materials a medium-power engine is sufficient. This means you can use an electric motor. Although such a shredder for the garden requires a connection to the power supply, it is structurally simpler than a gasoline shredder and is easier to make with your own hands.

Depending on the power of the power plant, the chopper is capable of processing branches of different thicknesses. According to this indicator, shredders can be divided into three categories:

- engine power up to 1.6 kW. A unit with such a power plant will be enough to chop branches whose diameter does not exceed 2 cm. Such devices are not suitable for high-intensity work;

- power 3-4 kW. Capable of working with material with a diameter of up to 4-4.5 cm;

- over 4 kW. Using such a device, you can grind logs 7-14 cm thick.

Keep in mind that powerful electric motors must be connected to a three-phase network. When using a single-phase home network (220 V), the output power drops by 2 times. If there is no possibility or desire to equip the site with three-phase power, it makes sense to consider assembling a device based on an internal combustion engine.

Depending on the planned volume of work, to make a garden shredder with your own hands, you can use motors from various household electrical appliances:

- from an angle grinder;

- trimmer;

- washing machine (together with the tank);

- powerful asynchronous three-phase motor (type AIR 100 L4 4 kW at 1500 rpm), etc.

Garden shredder from washing machine

An old Soviet-made washing machine with a metal body is a technique that contains almost all the necessary parts for assembling a garden shredder. You only need knives with fasteners, as well as an extension cord.

To make a cutting attachment, you can use an old wood saw.

Tools you will need:

- angle grinder;

- pliers;

- spanners;

- screwdriver;

- electric drill;

- hammer;

- tape measure with marker.

The washing machine motor has a small power (different models have different power), which is indicated in the instructions for the household appliance or on the electric motor plate. Due to the fact that its value usually does not exceed 500 watts, with the help of the created unit it will be possible to grind only straw or grass.

A shredder from a washing machine is made like this.

- The body of the machine is cut to height so that it is convenient to work with the unit.

- At the bottom side, a rectangular hole is cut in it with a grinder, 20 cm wide and 7 cm high, intended for throwing out ground plants.

- Around the slot, a kind of casing is made of tin, which will direct the herbal mass into the collection container, while preventing it from scattering to the sides.

- They make legs.

- Attach the body to the stand.

- 2 holes with a diameter of 7 mm are drilled on the electric motor shaft. Then a threaded bushing is placed on it, as well as holes at the end more than 5 cm long, securing it with bolts.

- An electric motor is secured under the bottom of the box using studs and nuts.

- Inside the casing, knives are secured to a sleeve, placing them above the grass ejection hole or at the same level with it.

- The box is attached by welding or bolts to the stand.

The result will be a technique similar to the one shown in the photo below.

The start button will come from a converted washing machine. You just need to make sure to connect the extension cord of sufficient length.

The design and operation of a grass cutter from a modern washing machine is shown in the video

Briefly about the need to process grass and branches

The garden owner does not need to explain why he needs a shredder. After each sanitary, rejuvenating pruning of fruit and berry bushes and trees, mountains of branches accumulate. A shredder is needed to grind them.

Farmers and gardeners also need a shredder. It is used to process different types of plant materials:

- potato tops, tomatoes;

- stalks of corn, sunflower;

- grass, leaves.

The chopped green mass is used as livestock feed and poured into compost heaps. Large fractions of branches are used instead of firewood, medium and small fractions are used as mulch and raw material for composting.

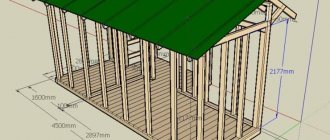

Drafting

For example, we determined that a twin-shaft shredder with a low rotor speed is suitable for production tasks.

His project necessarily includes:

- engine selection by power;

- calculation of gear ratio and selection of factory model;

- determination of the diameter and length of the rotors (based on the size of the loading window);

- calculation of shafts for strength;

- selection of bearing supports.

To do this, you will need the textbook “Machine Parts” for universities. You will also have to look at GOSTs on threaded connections, reference books on gearboxes, bearings, couplings and other assembly units.

This must be taken into account when assigning groove dimensions.

After the calculations, it is necessary to layout the components on graph paper or in an editor such as AutoCAD, determine the dimensions of the body parts and the frame.

Why is it better to make a chopper yourself?

A rational solution for disposing of branches is to use a garden shredder. This is a special tool that is produced by modern manufacturers. The equipment operates from various types of drive devices, which can be used:

- electric motors;

- internal combustion engines;

- tractor power take-off shafts.

A significant disadvantage of factory equipment is its high cost, which is associated with the use of high-quality materials for production. Not every summer resident can afford a purchase of this kind, especially since its payback will take at least 5 years. The question of how to make a simple branch chopper yourself is becoming increasingly relevant.

The method of making garden tools yourself is in demand for a number of the following reasons:

- The manufacturing procedure is not difficult if you have experience with tools such as an angle grinder, a drill and a welding machine.

- Equipment is created from improvised means. For this you will need old electric motors, cutters, crushers, jointers, etc.

- Manufacturing of tools with the required technical parameters and performance. It can be used to shred branches, grass, leaves and other garden debris.

- Price is the main reason why summer residents prefer to make a branch shredder themselves rather than buy factory equipment, the cost of which is quite high (if we talk about high-quality installations).

Naturally, one cannot fail to mention the disadvantages of making a chopper yourself. The main disadvantage is safety, since the slightest miscalculation can result in serious injury or even cost a person’s life. That is why you should get down to business only with full confidence that you can make a reliable wood chipper. A description of the different equipment options presented in the material, which functions no worse than factory products, will help with this.

Crusher for walk-behind tractor: features and types

Such a useful shredder efficiently shreds branches, logs and even grass, processing the material into a nutritious fertilizer for the soil. Using the resulting fine particles, you can “invigorate” the soil or protect it from weeds by covering the surface with a thin layer.

True gardeners probably know what mulching is. So, with the help of a chopper on a walk-behind tractor, you can create an excellent mulch that retains moisture in the ground and does not allow any pests or diseases to penetrate the rhizomes of plants.

When choosing a branch chopper, you need to pay attention to the following factors:

- Power;

- Functionality;

- Size;

- Type of crushing system;

- Funnel diameter.

As for the type distribution of shredders, they have different knife systems: milling or disk. The first one looks more like a gear. It is characterized by increased strength due to the one-piece production method.

This branch chopper for a walk-behind tractor is capable of processing branches with a diameter of up to 45 mm. Many models of this plan are equipped with another useful function: self-retracting. That is, the user only needs to place the material correctly, and then the system itself will perform all the operations.

An important point: it is better to chop leaves, grass and other greenery on a disk device, because the milling unit will not always be able to efficiently crush such soft objects.

The disk shredder/crusher for the walk-behind tractor has 2 steel cutters of the appropriate shape. The knives are driven by a shaft, so all fed materials are quickly crushed.

A similar system is relevant for freshly cut branches, leaves, grass, weeds and other relatively soft plants. Dry wood will also chip, but there is a high probability of the knives becoming dull quickly. The resulting fine fraction of waste quickly turns into useful fertilizer.

Wood chippers are also classified by engine type: gasoline or electric. The former are considered extremely powerful, and they easily process waste of any kind. But you need to work with such devices only with protective headphones, because they make a lot of noise.

Electric shredders are characterized by lower power, ease of maintenance and absolute noiselessness. But at the same time, they react very sensitively to surges in the network and can suddenly stop functioning.

These garden attachments are often attached to the front of the machine. Professional models are complemented by pneumatic wheels with treads, chain devices, steel bodies and special cleavers. On the market you can find shredders for “technical assistants” Neva, Centaur, Patriot, etc.

Today, many owners of private sectors have managed to become owners of chip cutters, so they are happy to share the operating features, tell tips and reveal the specifics of caring for the canopy using the video materials presented below.

How to start making a wood chipper

Starting work on creating a wood chipper with your own hands involves choosing the design of the equipment. After all, installations are divided into three main classes:

- Disc shredder.

- Drum - for obtaining larger fractions of material.

- Double-drum crusher - allows you to produce large-sized wood material, which can be used as a heating raw material.

The next step is to select a suitable drive device. Electric motors or internal combustion engines are used as such. The use of a gasoline engine allows you to get not only a highly productive, but also a mobile unit. However, finding an internal combustion engine of sufficient power is quite problematic, which cannot be said about electric units. If you can’t find one on the farm, you can always buy used ones at an affordable price.

The thickness of the branches that can be chopped depends on the electric motor used. The greater its power, the correspondingly higher the capabilities and service life. When choosing an electric motor for making a wood chipper, you need to consider the following:

- If the power of the unit is up to 1.5 kW, then it is capable of handling sticks with a diameter of up to 20 mm.

- If a more powerful unit up to 3-4 kW is used, then it is capable of crushing branches up to 40 mm thick.

- To crush workpieces from 70 to 150 mm, electric motors with a power of 4 kW are used.

It is worth considering that the more powerful the unit, the greater the electricity consumption. If you are wondering how to make a branch chopper with your own hands for your home and garden, then choosing an engine with a power of more than 2 kW does not make sense. Logs with a diameter of 40 mm or more can be cut with a chainsaw and used as heating material.

This is interesting! When choosing an electric motor for a shredder, consider how it is connected to the electrical network. When connected to a single-phase network, the power is reduced by 1.5 times.

When the design of the shredder and the electric drive of the appropriate power have been selected, you can begin to prepare the necessary parts. Usually, to obtain these, you cannot do without the help of a turner, but it all depends on the selected device configuration. The final stage in the production of a garden shredder is the preparation of the frame on which the drive and shredding mechanism will be placed.

Manufacturing Guide

The first thing you need to understand is that without plumbing and welding skills and the appropriate tools, you will not be able to make even a simple branch chopper from circular saws. In addition, for the manufacture of shafts and housings for bearings, you will have to go to a lathe, unless you manage to find a ready-made unit from an old machine. The whole process is divided into the following stages:

- Choosing a shredder design.

- Selection of motor for drive and calculation of main gear.

- Preparation of metal and parts that need to be turned on a lathe.

- Frame assembly.

- Installation of the drive, cutting mechanism and belt drive.

- Installation of the protective casing and hopper.

Note. We are talking about a belt drive as the easiest to manufacture and safest to use. In the event of an accident or overload, the belt will slip or jump off without any consequences. The same cannot be said about a rigid connection through a chain (gearbox).

Design of a disk crusher with removable knives

As for choosing the design of a homemade wood chipper, the recommendations are simple:

- a unit made from circular saws is the best option when you need to get small wood chips at minimal cost;

- if you plan to chop branches of small diameter into a larger fraction, then a cutting mechanism such as a jointer is suitable;

- when you need to chop branches up to 5 cm in size in large quantities, it is better to make a disk crusher.

For reference. Small shavings and wood chips are often used by gardeners to make compost and mulch. You can also make fuel briquettes from it for heating a country house.

Knife shaft and its principle of operation (like a jointer on a circular saw)

When the type of wood chipper is selected, you can begin to prepare parts, materials and equipment. But first of all you need to do...

Selection of engine and calculation of belt drive

Drive power is an indicator that determines how thick a branch you can process on a homemade crusher. Here are some tips for choosing an engine:

- An electric motor with a power of 2.5-3.5 kW, minimum 2 kW, is ideal for your purpose. The 1.5 kW motor can be used to assemble a shredder for grass and small branches.

- The power of a gasoline or diesel engine should be 5-6 liters. With. These are installed on household walk-behind tractors and mini-tractors.

- There is no point in buying an electric motor that is too powerful, unless you have one sitting idle in your shed. It will consume an amount of electricity that does not correspond to the work done.

Note. The number of revolutions of the electric motor does not play a big role, since we will obtain the required rotation speed of the knives due to the V-belt drive.

In order for your wood shredder to reliably chop branches, the blade shaft must be given a speed of no more than 1500 rpm by selecting the diameter of the drive and driven pulleys. The decisive factor here is not the speed of rotation of the knives, but the developed torque (force). The distance between the pulleys and the length of the belt also does not play a big role. Unless a belt that is too long reduces transmission efficiency and is less easy to tension.

Calculation example. There is a 2800 rpm electric motor that needs to be installed on the crusher. The optimal solution is to reduce the shaft speed by half, to 1400 rpm. Then the diameters of the pulleys will differ by 2 times. For example, the size of the driving pulley is 100 mm, then the diameter of the driven pulley (standing on the working shaft) will be 200 mm.

Advice. When ordering pulleys for a V-belt drive from a turner, it doesn’t hurt to think about the future. It is better to make pulleys with 3 or 4 grooves, so that the speed on the working shaft can be changed by rearranging the belt. Then the chopper can be adjusted to different operating conditions, for example, for crushing stalks of corn, sunflowers, and grass.

Pulleys with several grooves are more convenient to use; you can change the rotation speed and force

Preparation of materials

The best way to save money on making wood chippers is to find suitable materials around the house. The following types of rolled metal are suitable for assembling the frame:

- single equal angle corner with a width of 50 to 63 mm;

- 2 corners of 35 mm, welded in a “box”;

- profile pipe measuring 40x40 mm;

- channel No. 6.5—10;

- round pipes with a diameter of 32-48 mm.

The electric motor is mounted on a steel sheet with a thickness of 10 mm and dimensions corresponding to the distance between the mounting holes on its flange (with a margin of 30-50 mm on each side). To tension the belt, 2 types of devices are used:

- The holes in the plate for mounting the engine are made oblong so that it can be moved back and secured with bolts.

- The plate is installed at one end on a hinge, then the belt is tightened due to the weight of the electric motor. On the other hand, it is fixed with nuts on studs, as shown below in the photo of a homemade chopper.

Here the tension occurs under the weight of the electric motor.

To make the simplest shredder design, buy 20-25 circular saws with carbide tips and the same number of spacer washers with a diameter of 20 mm. This will give you a working area of about 80mm wide, which can be made larger or smaller if desired by adding or removing saws.

Note. The thickness of the teeth of a circular saw is greater than the steel base, so it is impossible to fasten the tools close to each other. To compensate for the width of the teeth, washers are used, which are placed between the saws.

The shaft driven by the belt must be turned on a lathe from a steel rod. But before you make this part, find 2 bearings whose fit size will fit the shaft. You will also have to make bearing housings with mounting flanges. Sometimes they can be bought ready-made on the secondary market or in specialized stores.

Advice. As an option, you can use rear axle bearings with a mounting diameter of 25 mm from classic Zhiguli models, and use a ready-made stud with nuts as a shaft.

To install circular saws on the shaft, you need to cut a thread. As a flywheel, use a circle of steel with a thickness of 10 mm or more, or a large pulley from some kind of agricultural machinery. You will also need a steel branch support plate to act as a counter knife. Cut it from a sheet at least 10 mm thick.

Knife shaft drawing with dimensions - front view

If you have chosen the design of a branch chopper with chopping knives, then you can take the drawing of a knife shaft for a jointer as a basis. Just change the diameters of the axles where you need to press the selected bearings. It is better to reduce the width of the working part to 100 mm, because you are not going to put whole logs into the crusher. Wood chipping knives are usually made on a milling machine from car springs.

Shaft drawing for 3 knives - end view with groove dimensions

To assemble a disk-type chipper, in addition to a shaft with bearings and knives, you will need:

- steel circle 15-20 mm thick with a diameter of 40-50 cm (depending on the power of the electric motor);

- sheet metal of at least 5 mm for the casing, the front wall of which serves as a counter knife;

- the same, 1-2 mm thick for welding the bunker;

- bolts M12—16 with nuts for fastening.

The cutting device of a disk chopper with fastening knives is shown in the drawing:

The number of knives can be changed (put 2 or 4 pcs.)

Frame making

Regardless of what type of crusher you choose, you need to make a base for it - a frame, where the drive and chipping mechanism will subsequently be installed. Weld it from corners or pipes using the following recommendations:

- Select the height to suit your height so that it is convenient to place branches in the bunker.

- The structure must be stable. Therefore, make the frame width at least 500 mm, and the length is arbitrary.

- Give the frame rigidity by welding cross members between the uprights.

- To easily move the unit to the frame, it is advisable to attach a pair of wheels and weld a handle.

Methods for installing an electric motor - under the tabletop and on the side of the frame (photo on the right)

Think about where you are going to install the electric motor. For a shredder made with your own hands from circular saws, the recommendation is this: place the motor in the frame so that it does not protrude beyond its dimensions. The same applies to other types of crushers.

Chopper assembly

First, let's assemble a chip cutter from a package of circular saws, following the following order:

- Assemble the saw blades onto the shaft by placing washers between them and tightening them with nuts on both sides.

- Press the bearings onto the shaft and then into the outer housings. Bolt the latter to the frame, having previously made holes in it.

- Place the pulley and flywheel on the ends of the shaft and fasten them securely.

- Place a steel plate – counter knife – close to the saw teeth.

- Install the electric motor and final drive, and tighten the belt properly.

Advice. Before assembly, be sure to lubricate the bearing cages by removing the plastic caps. Place the saws so that the tooth profiles do not coincide.

It is better to fasten the counter knife not by welding, but by bolting through oval-shaped holes. The point is to adjust the gap between the edge of the plate and the working teeth, which allows you to change the size of the chips within small limits. The direction of rotation of the saws is “toward”, that is, the teeth should “run” onto the counter knife.

After installing the parts, make and install a protective casing made of thin metal, and a receiving hopper in front. The dimensions of these elements are arbitrary, the main thing is ease of use and safety. Finally, connect the unit to the power supply with a power cable through a 25 A circuit breaker.

Assembling the knife crusher is carried out in the same order, only first you need to install and secure the knives in the grooves of the shaft. There is one subtlety here: the more the cutting edges protrude beyond the surface of the shaft, the larger the chips will be at the exit. The hopper is welded in such a way that the branches are fed at an angle of 90° to the cutting mechanism. How to do this correctly is shown in the video:

Advice. The unit can be improved by making an additional tightening device. It is necessary to make a second shaft of smaller dimensions, weld metal strips along it and connect it to the main mechanism via a belt or chain drive. The speed of the tightening shaft must be reduced, otherwise the branches will hit your hands during loading.

Homemade mechanized drive that pushes branches towards the shredder blades

There are also no special tricks in making a disk shredder for branches; it is enough to follow the drawings and securely fasten all the components. The only point: when making the outer casing, try to make the front wall along which the knives rotate thicker and the gap between them smaller. Otherwise, the flexible thin sticks will be pulled inward by the mechanism and screwed onto the shaft.

Assembly drawing of a direct drive crusher

The rear wall of the casing must be firmly attached to the frame at least at 4 points, for which additional brackets will need to be welded, as shown in the assembly drawing.

Materials

Used to assemble a garden unit:

- sheet steel from 0.8 to 2.5 mm for housing and receiving hopper

- steel angles, channels

- fastening elements

- engines from old machines

- belts, pulleys

- knives, circular discs

- Welding machine, grinder, electric drill, hacksaw, pliers, screwdrivers

- Hammer, wrenches

- Ruler or tape measure, marker

Step-by-step instructions and nuances of work

1.Select your own version of the mechanism

2. A diagram is drawn to fully represent the dimensions of the unit and its parts

3. The engine is selected: electric or diesel

4. All components are manufactured

5. The frame is assembled

6. The cutting part is installed in the main body, the choice depends on the thickness of the branches and the volume of work

7.Protects the motor and belt drive

8. The engine is connected, the operation of all elements is checked

If you have experience using a welding machine, grinder and drill, then the work itself will not create any special difficulties

A do-it-yourself branch crusher is easily created according to drawings from the remains of agricultural equipment, unclaimed sheets of iron and parts from old machines and machines.

The cost of the created device will be much cheaper than a new one

You can assemble and disassemble the mechanism, remake it if you don’t like it, improve it, add a strong engine, etc.

Criteria for choosing a wood chopper for a walk-behind tractor

If you decide to buy a chopper for a walk-behind tractor, you should know what criteria to choose:

- engine type;

- unit power;

- funnel diameter;

- type of crushing system;

- what types of garden waste does it process?

- chopper weight;

- functionality.

The main thing is to focus on the blade system (disc or milling) and the type of engine (electric or gasoline). https://www.youtube.com/embed/wvfoWAYlh3s

Electric shredders are quiet, easy to maintain, but sensitive to power surges, and process branches up to 4.5 cm in diameter

Gasoline engines are powerful, process virtually any waste, but are noisy

Electric shredders are quiet, easy to maintain, but sensitive to power surges, and process branches up to 4.5 cm in diameter. Gasoline engines are powerful, process virtually any waste, but are noisy.

Schemes and drawings

Before searching for components and assembling them, it is necessary to draw up a diagram or drawing of the chopper. This is necessary to avoid errors when assembling and operating the shredder, otherwise improper operation will lead to injury to the operator. When drawing up a diagram or drawing, all stages of grinding are taken into account:

- Loading the device.

- Grinding branches.

- Accumulation of crushed particles, as well as their removal.

It is not necessary to draw up a drawing according to ESKD standards; it is enough to correctly note the location of the elements and their dimensions. According to the diagram, a list of necessary components is compiled, as well as the order of assembly of the chopper.

In addition to drawing up your own drawing, you can use a ready-made one from the Internet. The advantage will be that all the nuances have already been thought out and reflected in the diagram. The disadvantage is that the drawing is prepared for other parameters: performance, type of branches. In addition, the finished drawings may contain elements that are not at hand - this will increase the cost of the project.

Common mistakes when assembling a chopper

Incorrect assembly of the wood shredder leads to problems during its operation. The most common mistakes are:

- The shaft diameter does not match the saw hole. If the saws rotate freely, this will create additional vibration, which will lead to destruction or deformation of the shaft.

- Rigid fixation of belt or chain drive. This can lead to rapid belt wear and failure. In addition, the inability to adjust the gear tension makes it difficult to transfer power to the shaft, which degrades the performance parameters of the equipment.

- Incorrect sharpening of knives. This is the most common mistake that craftsmen make when making cutting devices from car springs on their own. You can either entrust this operation to professionals, or independently adjust the rotation parameters of the cutting mechanism with great care.

- No protective cover. This is a disregard for labor protection requirements. Flying wood waste can injure a person (it is especially dangerous if it gets into the eyes).

Thus, it is quite possible to make a shredder for branches and grass yourself. All you need to do is find a drawing on the Internet, purchase or find the necessary materials and carry out the work. Particular attention should be paid to welding and the process of making knives. Most mistakes are made at this stage. If you follow safety rules and assembly instructions, the branch crusher will work for a long time, and your summer cottage will always be clean.

Homemade electric shredder

You can make your own chopper if you have the necessary elements. The most practical is considered to be a branch crusher consisting of two shafts. For manufacturing, a drawing is created according to which the assembly is carried out.

Initially, the necessary material and tools are selected:

- electric motor with rated power up to 4 kW

- a pair of steel plates up to 10 mm thick

- two gears made of high-strength steel

- a couple of pulleys

- shafts, hardened and machined

- bearings for reliable shaft mounting

- direct cutting steel blades

- metal case

- steel pipe of the required diameter

- set of wrenches

- welding machine

- powerful drill or hammer drill

From a square blank we grind shafts on both sides. In the center we drill holes for 4 knives, threads are cut into them. The rounded edges are inserted into bearings. The drum is made from 4 studs and two steel plates in which holes are cut for the bearings.

Bearings and pulleys are firmly secured to the shaft, and gears are installed on the opposite side. We install the housing with the cutting mechanism and the engine on the pre-prepared frame. The transmission of torque from the drive will be carried out using belts through pulleys on the motor shafts and knives.

The receiver body is made of sheet metal, cut in the shape of 4 trapezoids. Using a welding machine, they are fastened together in the form of a truncated pyramid. The box is connected to the cutting mechanism body using a bolted connection.

Attention! Must be tested without load before use.

Garden shredder from washing machine

To assemble a branch chopper with your own hands, you need to carry out the following manipulations:

- The activator is removed from an old type washing machine.

- A pre-made knife is installed directly on the motor shaft.

- The size of the working tool is made slightly smaller than the diameter of the drum.

- A hole is cut in the lower part of the body from which the wood chips will spill out.

- The housing is attached to the hole.

This design allows you to process small debris, grass, or tops of small plants, with a relatively low power.

Homemade grinder grinder

Making a branch chopper with your own hands from a grinder is divided into several stages:

- We take a 20 liter bottle, cut off the bottom part, and enlarge the hole in the top. This will be the receiver.

- We pass the axis of the device from the side.

- We install the cutting element on top of the shaft and securely fasten the entire structure.

Important! When rotating the knives, the blade should not touch the walls of the receiver body. To start chopping, the branches are loaded from above and the grinder is turned on at minimum speed.

Trimmer crusher

For a branch chopper made with your own hands from a garden trimmer, you need to prepare the following necessary elements:

- container made of plastic or metal with a volume of up to 50 l

- several metal pipes with a diameter of up to 20 mm

- steel network with an area of about 1 sq.m. with a small mesh

- scrap of wooden board or plywood

- you need to purchase metal clamps for fastenings

- wooden blocks and screws for fastening them

- directly the trimmer itself of any design

As an auxiliary tool, it is recommended to prepare:

- screwdriver

- anvil

- drill

- jigsaw

- plumber's hammer

In order to make a chopper, you must follow the step-by-step instructions:

- Initially, prepare the container of the veterinary chopper. To do this, holes in the form of trapezoids are drilled and cut out at the bottom. The edges are processed.

- The mesh is secured to the bottom using bars. This creates a membrane.

- The container is placed at a low height using a pipe structure.

- The trimmer motor is mounted on the board.

- The rod of the device is shortened slightly and also installed on a base with a drive.

- A cutting tool is placed at the end of the rod.

- Before carrying out actual work, tests must be carried out. You can use different attachments to chop branches of different thicknesses.

From a walk-behind tractor

It is impossible to make a full-fledged main working unit from a walk-behind tractor; it only acts as an engine. To do this, you will need additional elements: drive, shaft. Tools such as a channel bar and a plane (electric) are suitable. In addition, you will need bearings and a pulley to operate the shaft. A walk-behind chopper is one of the most difficult devices to assemble yourself. It will be necessary not only to select a rotating device, but also to connect it to the walk-behind tractor, and also to design housing protection elements.

From circular saws

The most common grinding mechanism is disc cutting. Circular saws are used for assembly: 20-30 pieces per 1 chopper. They are located on the shaft one after another, due to which the entire width of the input “pocket” is filled. The spacing of the disks one behind the other must correspond to the required size of the crushed particles. Adjacent disks are positioned diagonally relative to each other so that branches do not slip past and are cut at an angle.

Twin shaft design

The most complex design is two-shaft. It uses only disc cutting elements, which are located in the housing on two shafts. Due to this, the chopper is able to grind large branches: first it pulls them in, and under the force of the discs on both sides, large pieces are crushed. The design is similar to a disk chopper, which is complemented by a second shaft.

The arrangement of the disks is chosen in a checkerboard pattern and diagonally to completely eliminate clogging and friction of the disks against each other. Shredders work on a similar principle: they place blades in several shafts that crush and cut the incoming raw materials.

From a drill

Many home craftsmen prefer a drill to washing machines and electric planers when making a garden shredder. The operating principle of such a device will be in many ways similar to a vegetable cutter. To make a structure of this type, the following steps will be required.

- Take an old stool. Drill a hole in it, its diameter should be 12 mm. On the other side of the stool, attach the housing part with the bearing.

- Place a bucket of suitable diameter on the stool and securely secure it with self-tapping screws.

- Insert the bearing into the hole. A shaft with steel knives installed will be placed on it. Closer to the end half of the shaft at the bottom of the stool, attach a dual-mode drill using a keyless chuck.

- Place soft materials into a fixed bucket and start the electric drill. After careful crushing to the required fraction, the mulch will need to be removed from the container. Please note that a unit with such a device will only be designed for a small amount of waste and debris.

Special attention should be paid to all stages of manufacturing and sharpening the knife. The sharpening must be one-sided. The ground base should be located at the bottom.

To chop freshly cut grass, it is advisable to use a knife whose shape follows a diamond shape (the blades should be slightly rounded). Thanks to this feature, the grass can easily slide along the cutting edge of the knife without wrapping around it.

From a plane

Many home craftsmen make reliable and practical shredders from certain planer parts. There are a lot of options for execution using this tool. Let's consider one of them.

When combined with elements of an electric planer, you can use a walk-behind tractor. The single combination produces a fairly powerful and productive machine. To assemble it you will need:

- electric planer knives;

- walk-behind tractor;

Types of cutting attachments used

Homemade products, like factory units, are equipped with cutting attachments of various types:

- disc (with three blades);

- milling-turbine (universal).

The first type is flat blades. When they rotate, they grind plant debris. If you have to process branches, then such blades quickly become dull. Milling knives are a cutting shaft in the form of gears from circular saws. They grind dry waste from branches and grass well, and clog the cutters with wet waste. Milling-turbine cutting attachments can cope with thick and undried branches, but making them yourself is difficult.

At home, knives from lawn mowers or made from wood saws are often used.

It should be taken into account that the degree of processing of plant waste directly depends on the installed cutting attachments. The output is pieces of branches from 10 cm long or shavings or dust.

Operating homemade equipment

From all of the above, we can come to the conclusion that making a garden shredder with your own hands is easy and simple. Almost any user can handle this. However, it is important not only to know how to assemble such equipment, but also how to operate it correctly. Let's consider the intricacies of using a homemade device.

- You should only start chopping branches if you are wearing safety glasses or a mask. You will need a hat and a tall pair of shoes. It is advisable to send branches into the machine with bare hands or with gloves, but very narrow and tightly fitting on the hands.

- Do not put your hands below the opening of the waste bin. If necessary, you can push through the debris with a further batch of rods. It is permissible to use a special stick for this, which has branches at the end.

- The dimensions of the branch that you send for processing should not be more than half the center distance between the shafts. When selecting wood particles that you plan to dispose of, it is very important to take into account the knives used in the technique.

- Experts recommend installing a separate differential automatic machine for such equipment. This part will protect the device from possible electrical damage if unforeseen circumstances occur.

- Both during assembly and during operation of a homemade mechanism, it is very important to adhere to safety rules. Take care not only to protect your hands, eyes and feet, but also to ensure that all parts of the shredder are securely fastened.

- When working with a homemade shredder, you need to ensure that no inclusions such as stones or glass, metal or plastic get into its receiving hopper. These elements should also not be present in the container during storage. They can seriously damage the structure of the device.

- Twin-shaft units are most effective at shredding raw branches. If you need to process elements of dense rhizomes, then they will need to be thoroughly cleaned of dirt.

- If the snare drum is jammed due to wooden inclusions stuck in it, then the device will need to be immediately disconnected from the network. It is permissible to remove stuck waste in the future only when the device is de-energized. Otherwise you will put yourself in serious danger.

- During operation of the shredder (either branded or homemade), it is very important to ensure that the power cable of the device is not in the area where crushed waste is emitted.

- If you want your homemade shredder to last as long as possible, then it will need to be thoroughly cleaned after each waste crushing job performed on the site. After this, the device should not be thrown outdoors. Select a shed for it or equip a shed.

- Make sure that the knives of the device are always well sharpened. Thanks to such care, using the device will be much easier and more pleasant, and its main components will not be subject to a large load.

Only if all the listed operating features are observed, can we talk about the durability and wear resistance of the shredder that you made with your own hands. Of course, the quality of all the components that you use during manufacturing also plays an important role. Treat this equipment with care and attention. Do not forget to constantly clean it so that crushed waste does not accumulate (in advanced cases, it can be quite difficult to remove it). In addition, you should remember about your own protection while working with this equipment.

Under no circumstances should you begin cleaning or repairing it while it is still plugged in.

Crusher with a matrix of circulating saws

This is also an easy-to-make device. In order to make a garden shredder of this type with your own hands you will need:

- 20 pieces of high quality circular saw blades, preferably carbide tipped.

- Metal fasteners.

- Separating washers for saws. You need 19 pieces with a thickness of 4–5 mm.

- Rolled metal sheets for the production of bunkers and casings with a protective function.

- Finished frame or material for its manufacture.

- Two bearings No. 307.

- Shaft with a diameter of 20 mm with thread.

- Bearing races.

Your own wood chipper is ready!

As you can see, the kit in most cases overlaps with the materials for the production of a disk chopper. A matrix of saws is assembled on the shaft by sequentially arranging saws and separating washers. Then this structure is clamped with nuts.

In order to eliminate the possibility of unwinding during work, after tightening, the threads are tilted or specialized locking washers are used. The subsequent sequence of actions is similar to the work on the manufacture of a disc crusher.

Safety precautions when working with homemade garden crushers

No matter how easy it may seem to use garden shredders, working with them can lead to injury:

- Always make sure that there are no small children near it when using a homemade shredder.

- Never load metal, glass objects, or construction waste into the unit.

- Do not put your hands inside during operation.

- If something gets inside or the size of the branches exceeds the power of the device, you need to turn off the engine and remove the unnecessary using some tongs.

- Always wear gloves, a protective mask and safety glasses.

- If the garden shredder is powered, it should be located as far as possible from water sources to avoid short circuits.

- Do not store homemade shredders in places unprotected from moisture or at low or high temperatures.

- Before using the shredder, always check its serviceability, reliability of fastening of parts, and integrity of the wires.

- After using the shredder, clean the body and blades of any remaining garden debris. Damaged knives should be replaced immediately with new ones.

Making cutting knives

As a material, you can use a used KAMAZ spring. We cut the workpiece to the specified dimensions. If necessary, we level and impart the necessary hardening in the forge and let it cool. We drill holes in the workpieces for fasteners. After these operations, we sharpen the working part of the knives at an angle of 45º on a sharpening machine. We apply markings on the disk - these are the places where the knives are attached. We drill holes in the disk and cut the threads. We assemble the structure. It should look like this:

After the working chamber is ready, the gears should be stuffed onto the shafts and secured. We mount the structure on the frame, bolted fasteners. We fasten and connect the engine to the network. We tension the belts if we use pulleys. The final step will be to attach the branch receiver. For safety, we will add a protective casing. This will protect the rotating elements of the chopper from accidental entry of foreign elements. All stages are completed. Only after this we carry out the first launch. If there are no extraneous noises, vibrations or knocks during operation, this means that the equipment is working correctly.

Drive design

In factory crushing plants, two methods are used to transmit rotation from the motor to the gearbox:

- Direct drive (via clutch). Torque transmission occurs without loss, the design is compact in size. If you manage to select a ready-made geared motor, the dimensions and weight of the installation will be even smaller. However, in this case, it is necessary to provide for manual (and ideally automatic) reversing in case of jamming of the rotors.

- Belting. Efficiency losses and relatively high dimensions are compensated by the smooth start of the mechanism. If the shredder becomes jammed, the only risk is that the belt will break or slip.