The most reliable (but not always appropriate) option for interfloor slabs is a monolithic slab. It is made of concrete and reinforcement. Read about the rules for installing monolithic floors in this article. Analysis of the characteristics of types and applications, installation of monolithic floors.

In what cases is it necessary to install monolithic floors?

Monolithic reinforced concrete flooring is the most reliable, but also the most expensive of all existing options. Therefore, it is necessary to determine the criteria for the feasibility of its design. In what cases is it advisable to install monolithic floors?

- Impossibility of delivery/installation of prefabricated reinforced concrete slabs. Subject to conscious refusal of other options (wooden, lightweight Terriva, etc.).

- Complex configuration in plan with “unsuccessful” arrangement of internal walls. This, in turn, does not allow laying out a sufficient number of serial floor slabs. That is, a large number of monolithic sections are required. The costs of a crane and formwork are not rational. In this case, it is better to immediately move on to the monolith.

- Unfavorable operating conditions. Very heavy loads, extremely high humidity values, which cannot be completely solved by waterproofing (car washes, swimming pools, etc.). Modern floor slabs are usually prestressed. Tensile steel cables are used as reinforcement. Due to their very high tensile strength, their cross-section is very small. Such slabs are extremely vulnerable to corrosion processes and are characterized by a brittle rather than ductile nature of destruction.

- Combining the functions of overlap with the function of a monolithic belt. Supporting precast concrete slabs directly on lightweight block masonry is generally not permitted. A monolithic belt is required. In cases where the cost of the belt and prefabricated floor is identical to or exceeds the price of a monolith, it is advisable to focus on it. When resting it on masonry with a depth equal to the width of the belt, the installation of the latter is usually not required. An exception may be difficult soil conditions: type 2 subsidence, seismic activity, karst formation, etc.

Types of reinforced concrete structures and scope

Monolithic slabs are suitable for use in massive buildings made of stone or brick. In a brick house, such an overlap creates a disc that gives the building additional rigidity. When laying interfloor reinforced concrete floors, it is important to choose the type of its manufacture:

Both of these methods are common today, but gradually the first one is replacing the second one. The main disadvantages of a monolithic floor are the cost of formwork and the need to wait for the concrete to harden. The advantages include:

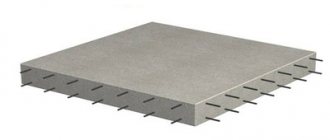

Diagram of a monolithic structure

The advantages of prefabricated technology include:

This method has slightly more disadvantages than the previous one:

Scheme of a prefabricated product

The choice between technologies for constructing floors between floors depends on the preferences of the future owner of the house and economic considerations. If the distances between load-bearing walls are far from standard, a large number of non-standard products will be required, which will lead to higher construction costs. In this case, it is better to opt for the monolithic version.

Determining the required thickness of a monolithic floor

For bending slab elements, over decades of experience in the use of reinforced concrete structures, the value of the ratio of thickness to span has been experimentally determined. For floor slabs it is 1/30. That is, for a span of 6 m, the optimal thickness will be 200 mm, for 4.5 mm - 150 mm.

An underestimation or, conversely, an increase in the accepted thickness is possible based on the required loads on the floor. At low loads (this includes private construction), it is possible to reduce the thickness by 10-15%.

Why must the parameters be met?

The quality, safety and service life of the building depend on the correct choice of dimensions of the monolithic slab. Structures with parameters suitable for the construction of residential buildings cannot be used for the construction of an industrial facility. Such a building can be dangerous. It is necessary to accurately calculate the bearing capacity and load of the coating.

It is also irrational to use stronger elements for the construction of a residential building. The structure, of course, will be stronger and more reliable, but you will have to pay significantly more.

VAT of floors

To determine the general principles of reinforcement of a monolithic floor, it is necessary to understand the typology of its operation through analysis of the stress-strain state (SSS). The most convenient way to do this is with the help of modern software systems.

Let's consider two cases - free (hinged) support of the slab on the wall, and pinched one. Slab thickness 150mm, load 600kg/m2, slab size 4.5x4.5m.

Deflection under the same conditions for a clamped slab (left) and a hinged slab (right).

The difference is in the moments of Mx.

The difference is in Mu's moments.

The difference is in the selection of upper reinforcement according to X.

The difference is in the selection of upper reinforcement according to U.

The difference is in the selection of lower reinforcement according to X.

The difference is in the selection of lower reinforcement according to U.

Boundary conditions (nature of support) are modeled by imposing the corresponding connections at the support nodes (marked in blue). For hinged support, linear movements are prohibited; for pinching, rotation is also prohibited.

As can be seen from the diagrams, when pinched, the work of the near-support section and the middle region of the slab is significantly different. In real life, any reinforced concrete (prefabricated or monolithic) is at least partially clamped in the body of the masonry. This nuance is important when determining the nature of the reinforcement of the structure.

Structural solutions

When choosing a monolithic floor design, you should focus not only on the properties and characteristics of the material used or the layout of the house being built. A slab made of monolithic concrete must withstand loads that must be taken into account and calculated.

Monolithic floors can be constructed in various ways:

- using beams;

- without beams;

- with a removable formwork device;

- on corrugated sheets.

For small residential buildings, the most acceptable option is to install prefabricated formwork.

Reinforcement of a monolithic floor. Longitudinal and transverse reinforcement

Concrete works great in compression. The reinforcement is tensile. By combining these two elements we get a composite material. Reinforced concrete, which uses the strengths of each component. Obviously, the reinforcement must be installed in the tensile zone of concrete and absorb tensile forces. Such reinforcement is called longitudinal or working. It must have good adhesion to the concrete, otherwise it will not be able to transfer the load to it. For working reinforcement, periodic profile rods are used. They are designated A-III (according to the old GOST) or A400 (according to the new one).

The distance between reinforcing bars is the reinforcement pitch. For floors it is usually taken equal to 150 or 200 mm. In case of pinching, a supporting moment occurs in the support zone. It generates tensile force in the upper zone. Therefore, working reinforcement in monolithic floors is placed both in the upper and lower zones of concrete. Particular attention should be paid to the lower reinforcement in the center of the slab, and the upper reinforcement at its edges. And also in the area of support on internal, intermediate walls/columns, if any, this is where the greatest stresses arise.

To ensure the required position of the upper reinforcement during concreting, transverse reinforcement is used. It is located vertically. It can be in the form of supporting frames or specially bent parts. In lightly loaded slabs they perform a structural function. Under heavy loads, transverse reinforcement is involved in the work, preventing delamination (cracking of the slab).

In private construction, transverse reinforcement in floor slabs usually performs a purely structural function. The supporting shear force (the “shear” force) is absorbed by the concrete. An exception is the presence of point supports - racks (columns). In this case, it will be necessary to calculate the transverse reinforcement in the support zone. Transverse reinforcement is usually provided with a smooth profile. It is designated AI or A240.

To support the upper reinforcement during concreting, bent U-shaped parts are most widely used.

Installation of floor reinforcement.

Pouring the floor with concrete.

Prefabricated slabs

In addition to monolithic slabs, prefabricated slabs of the PC, PB and PT series are often installed in the form of floors. I use them in the construction of both apartment buildings and one-story and two-story houses. PC slab stands for round-hollow and is a type of multi-hollow slab.

PB series boards are considered a new technology, and they have replaced PC boards. They are made in any shape, size and various lengths. And all thanks to the technology of continuous production, and not pouring like a PC.

The thickness of such slabs has a standard size of 22 centimeters. The total thickness of the floor slabs in a monolithic house implies the sum of other values:

- The thickness of the concrete screed is about 5 centimeters.

- Sound insulation, about 5 centimeters.

- Thermal insulation, about 10-15 centimeters.

- Flooring.

- Ceiling construction.

In total, the thickness of the ceiling ranges from 30 to 50 centimeters.

The PT series is used in the form of additional slabs for floor structures using PB and PC slabs. Since they are quite small in size, they are perfect for ceilings above a corridor, bathroom, or storage room. The thickness of the PT slabs is less than PB and PC - 12 centimeters, and in total with other floor elements it is equal to 20 centimeters.

Monolithic floor thickness

In accordance with the calculations performed, we can recommend, for the installation of monolithic floors, in private houses, a floor thickness of 150 mm, for spans up to 4.5 m and 200 mm up to 6 m. It is not advisable to exceed the span of 6m. The diameter of the reinforcement depends not only on the load and span, but also on the thickness of the slab. The often installed fittings with a diameter of 12 mm and a pitch of 200 mm will form a significant reserve. Usually you can get by with 8mm at 150mm pitches or 10mm at 200mm pitches. Even this reinforcement is unlikely to work to the limit. The payload is assumed to be 300 kg/m2 - in a home it can only be formed by a large closet completely filled with books. The actual load in residential buildings is, as a rule, significantly less.

The total required amount of reinforcement can be easily determined based on the average reinforcement weight coefficient of 80 kg/m3. That is, to install a floor with an area of 50 m2 with a thickness of 20 cm (0.2 m), you will need 50 * 0.2 * 80 = 800 kg of reinforcement (approximately).

In the presence of concentrated or more significant loads and spans, the diameter and pitch of the reinforcement specified in this article cannot be used for constructing a monolithic floor. Calculations for the corresponding values will be required.

Feasibility of carrying out calculations

A monolithic foundation slab is designed as a complex structure in which concrete and reinforcement work together. The main goals of calculating any element in a building are to check the load-bearing capacity and save material. Thanks to preliminary calculations, the optimal option is found that provides the required strength at minimal cost.

Only a specialist can make the most competent decision. Slab foundations are a fairly new technology, so not every civil engineer is able to design them correctly. Calculations are performed in special programs, having previously determined the design characteristics of the soil. For a private house, it is permissible to accept the thickness and percentage of reinforcement without calculations, focusing on the load from the overlying structures.

Load collection

The initial data for designing a monolithic foundation, in addition to soil characteristics, is the collection of loads. The following values are taken into account in the calculation:

- constant loads from walls, roofs, ceilings;

- temporary loads: (short-term - snow and long-term - load from furniture and people).

Dead load determination

It is important to take into account all elements of the building. According to paragraph 1.23 of the “Guidelines for the design of frame buildings and tower-type structures,” on sandy soils the self-weight of the slab is not taken into account, on clay soils it is divided in half, and on floating unstable foundations it is taken into account completely. The mass of the walls is taken minus the openings.

The calculation loads are obtained from standard loads by multiplying them by safety factors. The coefficients are taken according to Table 7.1 SP “Loads and Impacts”. Coefficients that may be needed for calculations of an individual house are given in the table.

| Construction type | Load safety factor |

| Metal | 1,05 |

| Concrete and reinforced concrete with an average density above 1.6 t/m 3, stone, brick, wood | 1,1 |

| Concrete and reinforced concrete with an average density of 1.6 t/m 3 and below (for example, slabs ), insulating layers, backfills, screeds manufactured in factories | 1,2 |

| Concrete and reinforced concrete with an average density of 1.6 t/m 3 and below (for example, slabs ), insulating layers, backfill, screeds manufactured at the construction site | 1,3 |

Determination of live loads

The mass of snow cover depends on the type of construction site. Standard values for each are given in Table 10.1 SP “Loads and Impacts”. To obtain the calculated value, the load is multiplied by the safety factor; for snow it is 1.4.

Uniformly distributed loads are given in Table 8.3 SP “Loads and Impacts”. For residential buildings the value is assumed to be 150 kg/m². This value includes the mass of furniture and equipment. If you plan to place heavy objects, the value is taken on an individual basis. Reliability factor 1.2.

Video on calculating a slab foundation:

Determining the thickness of the foundation slab

If the slab is designed with calculations performed in full, then they are carried out according to the l group of limit states (calculations for strength) and according to the ll GPS (calculations for deformability). For individual development, the services of qualified specialists are often unavailable due to high costs, so values are taken “by eye”, taking into account the minimum requirements.

It is more convenient to summarize the approximate values of what thickness is accepted for buildings made of different materials in one table.

| Building type | Thickness of the foundation slab , mm | Reinforcement |

| Small buildings (verandas, garages, equipment storage rooms) | 100-150 | grids in one row |

| Residential two-story houses made of lightweight materials (frame, aerated concrete) | 200-250 | volumetric in two rows |

| Residential two-story houses made of logs, timber, concrete or brick with massive floors | 250-300 | volumetric in two rows |

The values given in the table are suitable for soils with sufficient load-bearing capacity. For floating swampy foundations, the thickness should be increased.

The minimum diameter of reinforcing bars is 10 mm for light buildings on good foundations. To reinforce the foundation slab for a two-story brick house, it is optimal to use rods with a diameter of 12-16 mm. The mesh cell size is 10 cm or more. For vertical reinforcement, the minimum diameter is 8 mm.

Load Definition

During the construction process, and subsequently during operation, the beam is subject to various types of loads. When calculating, we are interested, first of all, in dynamic and statistical loads arising as a result of the movement or pressure of temporary forces caused by the movement of people, vehicles, the operation of mechanisms and permanent components caused by the mass of building elements. When performing calculations, to obtain the required safety margin, the difference between these types of loads can be neglected.

According to the nature of the load, they are differentiated into:

- distributed chaotically and unevenly;

- point;

- equally distributed.

When calculating the floor slab, it is enough to focus on uniform loads. For concentrated loads, forces are measured in newtons, kilograms (kg), or kilograms force (kgf).

In the case of equal distribution, it is important to use data on the load acting on the meter. For residential buildings, the uniformly distributed load parameter is on average 400 N/m2. With a slab thickness of 10 cm, its mass will create a load of about 250 kg/m2, and taking into account the screed or the use of ceramic tiles, it can increase to 350 kg/m2. Thus, the load is calculated with a safety factor of 20%, amounting to:

Q = (400+250+100)*1.2 = 900 N/m

This value of load capacity will ensure strength under various variations of static and dynamic loads. If there are stairs or concrete flights resting on a floor slab, it is necessary to take into account their weight and not lose sight of the dynamic load during operation. The design of country houses should include the installation of large objects on the stove, for example, fireplaces, the weight of which can vary from 1 to 3 tons. To ensure strength in such cases, local reinforcement is used - reinforcement or a separate beam is provided.

Pouring concrete

Before pouring concrete into the formwork, it is necessary to check its reliability and check the presence of all technological holes. The latter include chimneys, ventilation ducts, openings for pipes, cables - ducts, embedded parts, and other solutions are provided for all.

The concrete mixture is usually supplied through the distribution hose of a concrete pump. Before delivering concrete to the site, you need to find out whether the automixer kit includes a sleeve of sufficient length.

To accept concrete, two people are required: one delivers a hose with concrete to the desired place on the formwork, the other levels the mixture to a given level. If the plasticity of the concrete mixture is low, the operator can add a little water to it - this will not affect the quality of the concrete, and it will be much easier to level and distribute the mixture to the farthest corners.

Concrete is compacted using a deep vibrator; it can be rented; the cost is low, especially considering that it is needed for several hours.

After pouring the entire formwork, the concrete is finally leveled and smoothed.

Errors and difficulties, their consequences

Almost no one does the calculation of a monolithic slab on their own; it is performed when designing a house using a software package . This is due to the fact that the calculation is quite complex even for many engineers, and errors made during the calculations have a high cost, and sometimes become catastrophic for the entire building.

The most common mistakes are made in the following cases:

- The beam calculation scheme and errors in determining the supports were incorrectly adopted.

- Inaccurate measurements of actual span.

- The thickness of the monolithic slab was calculated incorrectly, exceeding the ratio of 1/30.

- Violations of calculations for bending moments.

- The indicators for the reinforced frame were incorrectly determined.