Construction is a serious and expensive business. To save money wisely, you need to correctly calculate the amount of building material needed. Therefore, we figure out how to calculate the consumption of mortar per 1 m³ of brickwork - taking into account the ingredients of the masonry mixture and the type of brick.

The consumption of mortar is influenced by many factors, for example, the hollowness of the brick. Source sense-life.com

Mortar consumption per 1m3 of brickwork

Approximate consumption of mortar per 1 m2 of masonry

Most builders calculate approximately the consumption of mortar per 1 m2 of masonry, but there are certain subtleties that are very important to take into account. So, the consumption rates of the solution per 1 m3 of masonry can be different, and this is what will be discussed further

A little about brickwork

As you know, the use of bricks in construction is an extremely common phenomenon. Buildings made from this material are characterized by high reliability, they retain heat well and transmit much less noise compared to structures made from some other materials.

Factors affecting the cost of cement mixture

What affects solution consumption

The criteria on which the volume of mortar consumption per 1 m2 of masonry depends are as follows:

- The thickness of the walls of the structure, which can be 1, 1.5 and 2 bricks.

- The type of cement used for the anchoring base.

- A type of building material used, which can be either solid or hollow from the inside.

Principle of production of building fastening material:

Depending on exactly what components are included in it (sometimes structures such as clay, lime are used), the consumption of the solution per m3 of masonry may be different.

Professional skills of someone who mixes cement ready for installation:

- It is believed that there is nothing complicated in such work and even an inexperienced owner can do it with his own hands.

- However, a very common reason for overspending is that, due to his inexperience, the master uses more material than the instructions require.

Based on what type of cement is used in the fixing composition, some conclusions can also be drawn.

How much dry raw material is required for 1 m3 of building mixture?

Each type of cement has its own measures.

So, studying the consumption rates of mortar for laying partitions of ¼ brick, dry raw materials are used in the following quantities:

- Cement grade “M50” – 2.5 kg.

- Mixtures of type “M75” require 4 kg.

- For cement grade “M100” you need to use 5 kg.

There are some other ways to perform measurements:

- If the installation is carried out in 1 brick, then the mortar consumption per 1 m/sq. m of masonry will be approximately 75 liters.

- When constructing partitions with 1.5 elements, this parameter will change and will be equal to 110 l.

Amount of cement per cubic meter

Required amount of cement to prepare 1 m3 of building composition:

- Professional specialists use such measures very often, since volume is the basis of all calculations.

- It is believed that in order to prepare 1 m3 of the composition, at least 400 kg of cement will be required (in other words, standard 50 kg bags).

- At the same time, the consumption of masonry mortar per 1 m3 of masonry will be about 0.25 m3 of the resulting composition.

- It is these proportions that are taken as optimal and used in construction.

Expense rate

Despite this, the data in certain sources may differ slightly, which may be due to the presence of different installation options.

The previously indicated rate of mortar consumption per cube of masonry is suitable for the standard installation procedure and can be taken into account when independently constructing a brick building.

During long-term storage, the technical characteristics of the material are significantly reduced, and the price of such an error is very high:

For example, the “M400” cement brand, after six months of its acquisition, will correspond in its properties to the “M200” or “M100” brand.

Tools used to calculate train costs

When calculating the cost of cement mixture consumption for brick installation, you need to take into account the list of tools required for this procedure.

These include:

The use of cement composition when installing shell rock

First of all, it should be noted that the consistency of the fixing structure for installing shell rock must have certain viscosity parameters.

Thickness of joints in masonry

Another parameter that affects the consumption of masonry mixture. There are standard dimensional parameters for the thickness of the gaps between bricks, which craftsmen must adhere to. It is these dimensions that ensure the strength of the entire structure. Here are their parameters:

- horizontal seams should have a thickness of within 12 mm;

- vertical 10;

- longitudinal in the range of 12-15 mm;

- transverse 8-10.

It is not always possible to adhere to these indicators. Causes:

- low skill of the workman;

- climatic conditions;

- geometric unevenness of bricks.

The last reason is considered the main one. Most often, this is a criterion for excessive consumption of masonry mixture. To lay the stones evenly, you have to increase the mortar in some areas to hide the unevenness of the blocks.

So, everything is clear with the thickness of the seam. The thicker it is, the more solution you will have to use.

Thickness of joints in brickwork Source etokirpichi.ru

Types of solutions and their applicability

The connecting link between brick blocks is a mixture of the binder component with filler and water. The most common are 4 types of solutions.

- Cement-sand. It is diluted with water, its proportions depend on the brand of cement and the method of laying. When hardened, this option is the most durable, but if the technology is deviated from, it is prone to cracking;

- Limestone - in it cement is replaced with quicklime; it is plastic, but is washed out by rain, so it is only suitable for installing internal walls;

- Mixed - cement and sand are diluted with liquid slaked lime (lime milk). The combination combines the best qualities of the first two options;

- With a plasticizer - a polymer additive is mixed with cement and sand (fraction 2 mm) to increase the plasticity of the mixture. It is easier to make such a solution from a dry construction mixture by adding water according to the manufacturer’s instructions.

Despite the composition, the requirements for the quality of the mixture are almost the same. All ingredients are cleared of lumps, the sand is sifted, and the liquid lime is filtered. To prepare the solution, first thoroughly mix the powder components, then slowly pour in cold liquid (20 o C) and mix thoroughly so that setting does not occur. The process is accelerated using a concrete mixer or a hammer drill with a whisk attachment.

Mortar consumption per cube of brickwork

How long does it take to prepare mortar for laying a wall? This is determined by several conditions:

- the skill of a mason;

- the structure of the brick block - products with voids take more mortar mixture;

- type of brick - hyper-pressed and facing silicate absorbs less mortar than ceramic or ordinary silicate with a rough surface;

- wall thickness.

The average consumption of mortar per 1 m3 of brickwork with a standard joint thickness (12 mm) is approximately 0.23 m3. Table 1 provides more accurate information.

Cement consumption for bricklaying

The composition of the mixture for constructing a brick wall varies depending on the quality of the original components, weather conditions, and the number of storeys of the building. To mix the ingredients correctly, you should know: a 10-liter bucket holds 14 kg of cement or 12 kg of sand.

- Cement mortar is flexible in proportions. It is characterized by the degree of strength: the lower it is, the lower the required grade of cement and the lower its percentage (1 part to 2.5 - 6 parts of sand). For M400 cement the ratio is 1.3, for M500 – 1.4. The volume of water (on average 0.5 - 0.7 liters per 1 kg of cement) depends on the desired thickness of the mixture, the type of brick, air temperature - in the summer heat the solution should be more liquid. To increase its plasticity, experienced masons add a little washing powder or dishwashing detergent to the water. For 1 cubic meter of ready-made mortar 1.4, 410 kg of M500 cement and 1.14 m3 of sand are needed. Knowing that for 1 cubic meter of an ordinary wall, one brick made of a silicate block 250 x 120 x 65 takes 0.24 m3 of mortar, the cement consumption per cubic meter of brickwork is determined as follows: 0.24 x 410 = 98 kg. Accordingly, when using M400 cement (proportion 1.3) a cubic meter of the mixture contains 490 kg of cement, and 117 kg of it is consumed per 1 m3 of masonry.

- Cement-lime mortar is suitable for use within 5 hours, and in the summer at +25 o - no more than an hour, so calculation is also desirable for it. For 1 cubic meter of mixture, 190 kg of cement M400 - M500, 1.5 m3 of sand, 106 kg of hydrated lime and 475 liters of water are required. For a cubic meter of masonry you will need an average of 46 kg of cement.

Consumption of cement for laying bricks during cladding

In this case, the developer is interested in how much binder mixture will be consumed per square meter of wall. This depends on the water absorption of the building material, the season of work, the hollowness and porosity of the blocks. The standards are laid down in SNiP 82-02-95, but the real numbers are always higher, so you should buy ready-made mortar or cement with a reserve.

To save on consumables, 2 factors should be noted:

- the larger the dimensions of the brick, the less mortar will be needed;

- The higher the % of voids and pores, the higher the mixture consumption will be.

From this point of view, it is optimal to use ceramic or silicate double bricks of sufficient strength. This choice will allow you to achieve savings of 20% of the mortar mixture. Table 2 shows comparative data on mortar consumption per square meter of wall.

How much will it take?

When facing brick work, developers are interested in the required mixture consumption per 1 m². All standards are laid down in SNiP, but in reality it turns out that the real numbers are always higher.

The thicker the walls, the larger volume of cement mortar will be needed . For example, when building walls whose thickness is equal to a quarter of a brick, then 5 kilograms are needed per 1 m² of masonry when using M100 grade cement.

The volume of cement will decrease to 4 kilograms if you mix the mixture using M75 cement.

The consumption of cement powder will be significantly reduced when other components are added, such as limestone, marble or clay.

For example, for 1000 bricks you will need 0.9 cubic meters of cement masonry mortar . Afterwards, it is not difficult to calculate the consumption per square meter of wall of a building under construction. For convenience, you can order calculations from professional builders or use online calculators.

To learn how to calculate the amount of cement, see the video below.

What compounds are used

The most famous and popular mixtures:

- Traditional universal building composition of sand and Portland cement. The standard ratio of components is three to one or four to one;

- A working mixture of sand and quicklime. Applicable only for interior masonry work;

- Mixed composition for brickwork. These are quartz sand, cement and slaked lime;

- Cement mixtures with plasticizer additives.

General standards according to SNiP II-22–81: sand must be washed and sifted, milk of lime must be strained, cement must be fresh and without lumps. All compositions are mixed with clean technical water. Water is added to the dry mixed ingredients in portions until the required consistency is achieved.

Cost of solution per cubic meter of partition

The solution consumption rates per 1 m3 are affected by the following process parameters:

- Base thickness and quality of brick blocks;

- A type of brick - it can be solid or hollow;

- Climatic conditions - air temperature and humidity, sunny or cloudy day.

Practice shows that for a 1m2 building made of ordinary brick, 75 liters must be prepared. A structure of one and a half bricks will require the preparation of 115 liters of working mixture, a base of half a brick will take 40 liters of cement composition per 1 m2.

According to SNiP 82-02-95, which show that the mortar consumption rates per 1 m3 of brickwork are as follows:

- 0.19 cubic meters for half-brick masonry;

- 0.22 cubic meters for laying one brick;

- 0.235 cubic meters for masonry in one and a half blocks;

- 0.24 cubic meters for laying two bricks;

- 0.25 cubic meters for masonry in two and a half blocks.

More accurate and expanded data is contained in SNiP II-22–81.

Wall mortar - how much is needed per 1 m2

How to find out the consumption of mortar per 1 m2 of brickwork? To avoid doing the calculations, there is a table of all the components included.

It takes into account the consumption of mortar for laying bricks from different materials:

| Variety | Compound | Proportions of components for the layer | ||

| Spray | Priming | Covering | ||

| Slaked or quicklime | Lime milk and quartz sand | 1,0:(2,5-4,0) | 1,0:(2,0-3,0) | 1:(1,0-2,0) |

| Portland cement | Portland cement and quartz sand | 1,0:(2,5-4,5) | 1,0:(2,0-3,5) | 1,0:(1,0-1,5) |

| Clay | Quartz sand and clay | 1,0:(3,0-5,5) | 1,0:(3,0-5,5) | 1,0:(3,0-5,5) |

| Lime-cement | Portland cement, lime milk and quartz sand | 1,0:(0,3-0,5): (3,0-5,0) | 1,0: (0,7-1,0): (2,5-4,5) | 1,0:(1,0-1,5):(1,5-2,5) |

| Gypsum-lime | Lime milk, gypsum and quartz sand | 1,0:(0,3-1,0): (2,0-3,5) | 1,0:(0,5-1,5):(1,5-2,5) | 1,0:(1,0-1,5): (1,5-2,5) |

| Clay-lime | Lime milk, clay and quartz sand | 0,2-1,0:(3,0-5,0) | 0,2-1,0:(3,0-5,0) | 0,2-1,0:(3,0-5,0) |

| Clay-cement | Portland cement, clay and quartz sand | 1,0:4,0:12,0 | 1,0:4,0:12,0 | 1,0:4,0:12,0 |

Consumption rates for building mixtures for different types of building blocks

About 0.0108 m3 of composition is consumed per unit, and 0.054 m3 of mixture will be needed to cover 50% of the seam. The arithmetic mean of these two values is 0.08 m3. This value determines the consumption of mortar per 1 m2 of brickwork.

For different masonry this parameter will be equal to:

- When erecting a half-brick partition - 0.04 m3;

- Private - 0.82 m3;

- One and a half - 0.125 m3;

- Double - 0.164 m3.

The table shows the mortar consumption rates for brickwork made from blocks of different sizes for partitions of different thicknesses:

| Type of work | Scope of construction work | Volume |

| Masonry work | 1 m2 with a base thickness of a quarter of a briquette | 14 liters |

| 1 m2 with a base thickness of half a brick | 35 liters | |

| 1 m2 with a thickness of one brick | 75 liters | |

| 1 m2 with a wall thickness of one and a half bricks | 115 liters | |

| Plastering | 1 m2 of mantel without grouting using fine gravel | 13 liters |

| 1 m2 of plaster of internal surfaces | 17 liters |

In this case, the solution consumption per 1 m3 will be equal to:

- When working in half a brick for 53 building units - 0.19 m3;

- For single masonry for 102 blocks - 0.22 m3;

- One and a half for 153 units - 0.23 m3;

- Double for 204 blocks - 0.24 m3.

Cement consumption during construction work

The use and consumption of this binder depends on its viscosity, density, and drying time. The material is used to prepare mortars used for foundations, brickwork and other purposes. Also, consumption depends on the brand of material:

- To lay 1m3 of brick you will need approximately 250 kg of mixture. The amount of cement depends on the brand, the requirements for the solution (ratio of cement to sand). If you need a mortar of the M100 brand, which is most often used for masonry, then the cement consumption will be 75-100 kg. A lot here depends on the professionalism of the builders;

- when arranging a cement screed, the cement consumption is approximately 575 kg per “cube” of the mixture when using grade 400, if grade 500, then 460 kg will be enough;

- for the construction of a foundation, provided that grade 300 cement is used, the consumption will be 320 kg per “cube” of the mixture;

- for plastering an area of 1 “square”, 0.005 cubic meters is enough. m of cement, provided that the layer thickness does not exceed 1 cm. Consumption will also depend on the amount of lime or plasticizers added.

Carefully selected components included in the mixture are the key to preparing a good solution. The durability of any structure, be it a house, a fence post or a garage, directly depends on its quality. Construction recommendations should be taken into account and the appropriate type of mortar should be drawn up for each type of construction work.

Brick by brick

How much cement is needed per 1 cubic meter of brickwork also depends on what masonry material is to be worked with.

The use of large bricks (one and a half and double) allows you to reduce the volume of mortar, but this statement is not entirely true for hollow stone. When mixing cement, you need to be extremely careful and careful. A mixture that is too liquid will penetrate into the voids, which, firstly, neutralizes the heat-saving and noise-insulating effect of the brick, and secondly, increases the consumption of sand-cement mortar.

Experts recommend mixing the mixture in such a proportion that during work it is easy to apply it with a trowel to the working area of the masonry, and sealing the seams does not become backbreaking work. The amount of cement consumed also depends on how much mortar is applied to the brick.

For masonry that will subsequently be hidden under the finishing (siding, decorative plaster, lining), it is usually enough to apply a cement mixture to the central part of the brick. Then there is no need to design the seams, which also have very specific requirements. So, vertically located ones should not exceed a width of 8-15 mm, and horizontal ones - 10-15 mm.

Calculation of cement for brickwork

The need for cement is determined as follows:

Compositions of mortars for brickwork.

- the total volume of brickwork is calculated;

- the total volume of the required mixture is determined;

- Taking into account the selected ratio of components, the amount of cement is calculated.

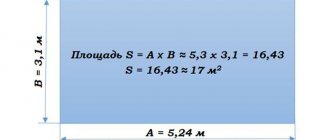

For example, you need to find out how much cement will be required to build the external walls of a one-story house 10x12 m with a ceiling height of 3.2 m, if ordinary brick and 2-brick masonry are used.

The first step is to find out the total volume of the masonry. To do this, the length of the walls is multiplied by the height and thickness of the masonry: (10+10+12+12)*3.2*0.51 = 71.808 m3. From Table 1 it is clear that 0.240 m3 of mortar is required per 1 m3. Therefore, for the example given, you will need: 71.808 * 0.240 = 17.233 m 3 of cement-sand mixture. To prepare a mortar for masonry in a ratio of, for example, 1:3, you need to buy: 17.233/4 = 4.308 m 3 of cement.

Since the hardener is sold in 50 kg bags, this value must be converted to kg. To do this you need to know the density of cement. Usually the average density value is used, which is 1300 kg/m3. That is, to build walls you need to buy: 4.308 * 1300 = 5600 kg, or 5600/50 = 112 bags of cement.

When purchasing cement, you should note that it is not recommended to choose material in simple two-layer packaging. They do not protect cement well from moisture, so its quality will be significantly lower than that declared by the manufacturer. In this case, you will not be able to achieve the required structural strength, which will reduce its service life.

Cement is different from cement

Why is this cement consumption per 1 cubic meter of brickwork approximate, and you should not blindly rely on the above formula. How to create an estimate for ordering all the necessary materials needed to mix the mortar is a question that often haunts inexperienced builders. As for ordering cement, you should know that it is sold in bags, their weight is 50 kg.

If you make calculations by weight, then to mix 1 m3 of M150 grade mortar from M400 cement you need to take 400 kg of cement, and for a mortar with a strength of M 200 the same cement will need 490 kg. When cement of grade M 500 is purchased, its consumption to create a solution of grade M 150 is 330 kg, and grade M 200 is 410 kg. These data are the consumption of cement for laying bricks in 1 cubic meter, which are taken from generally accepted building standards.

Mortar consumption per 1m3 of brickwork

Approximate consumption of mortar per 1 m2 of masonry

Most builders calculate the consumption of mortar for masonry approximately, but there are certain subtleties that are very important to take into account. So, the consumption rates of the solution per 1 m3 of masonry can be different, and this is what will be discussed further

A little about brickwork

As you know, the use of bricks in construction is an extremely common phenomenon. Buildings made from this material are characterized by high reliability, they retain heat well and transmit much less noise compared to structures made from some other materials.

Factors affecting the cost of cement mixture

What affects solution consumption

The criteria on which the volume of mortar consumption per 1 m2 of masonry depends are as follows:

- The thickness of the walls of the structure, which can be 1, 1.5 and 2 bricks.

- The type of cement used for the anchoring base.

- A type of building material used, which can be either solid or hollow from the inside.

Principle of production of building fastening material:

Depending on exactly what components are included in it (sometimes structures such as clay, lime are used), the consumption of the solution per m3 of masonry may be different.

Professional skills of someone who mixes cement ready for installation:

- It is believed that there is nothing complicated in such work and even an inexperienced owner can do it with his own hands.

- However, a very common reason for overspending is that, due to his inexperience, the master uses more material than the instructions require.

Based on what type of cement is used in the fixing composition, some conclusions can also be drawn.

How much dry raw material is required for 1 m3 of building mixture?

Each type of cement has its own measures.

So, studying the consumption rates of mortar for laying partitions of ¼ brick, dry raw materials are used in the following quantities:

- Cement grade “M50” – 2.5 kg.

- Mixtures of type “M75” require 4 kg.

- For cement grade “M100” you need to use 5 kg.

There are some other ways to perform measurements:

- If the installation is carried out in 1 brick, then the mortar consumption per 1 m/sq. m of masonry will be approximately 75 liters.

- When constructing partitions with 1.5 elements, this parameter will change and will be equal to 110 l.

Amount of cement per cubic meter

Required amount of cement to prepare 1 m3 of building composition:

- Professional specialists use such measures very often, since volume is the basis of all calculations.

- It is believed that in order to prepare 1 m3 of the composition, at least 400 kg of cement will be required (in other words, standard 50 kg bags).

- At the same time, the consumption of masonry mortar per 1 m3 of masonry will be about 0.25 m3 of the resulting composition.

- It is these proportions that are taken as optimal and used in construction.

Expense rate

Despite this, the data in certain sources may differ slightly, which may be due to the presence of different installation options.

The previously indicated rate of mortar consumption per cube of masonry is suitable for the standard installation procedure and can be taken into account when independently constructing a brick building.

During long-term storage, the technical characteristics of the material are significantly reduced, and the price of such an error is very high:

For example, the “M400” cement brand, after six months of its acquisition, will correspond in its properties to the “M200” or “M100” brand.

Tools used to calculate train costs

When calculating the cost of cement mixture consumption for brick installation, you need to take into account the list of tools required for this procedure.

These include:

The use of cement composition when installing shell rock

First of all, it should be noted that the consistency of the fixing structure for installing shell rock must have certain viscosity parameters.

Brick construction

Despite the fact that there is now a large selection of new building materials, brick remains the most popular, widespread and familiar building material for the construction of long-term and reliable structures.

Here is a list of the most common types of bricks for any construction needs:

Ceramic bricks (clay), depending on their purpose, are divided into facade, ordinary and clinker. For ordinary (backfill) bricks, less than ideal geometry is allowed, so it is mainly used for laying rough walls of houses, plinths, garages, which are then plastered, painted and protected with facing coatings. There are also no mandatory requirements for its color.

Facing brick (facade) is intended for the construction of walls without any additional covering in the future. Facade brick is able to withstand high mechanical loads and adverse atmospheric influences, so it is usually used for paving paths, building all kinds of retaining fences, stairs, and walls.

Clinker brick has an ideal smooth surface, can have different shades of red and black colors and has a high density.

Sand-lime brick differs from ceramic brick in that it is not fired during the manufacturing process. It is a light-colored lime-silicon artificial stone. It has increased hygroscopicity and therefore plinths and basements. In addition, it is not used in the construction of furnaces, pipes, chimneys and foundations, since it is not able to withstand external destructive loads.

Fire bricks are used to build structures that are exposed to high temperatures, such as stoves, fireplaces, chimneys and smelters.

For reference: the most common standard brick size: 250-120-65 mm (length - width - height), the so-called first “normal form” (1NF).

Bricks are solid (volume of voids no more than 25%), hollow and porous-hollow. At the same time, recesses and voids in the material not only reduce weight, but also significantly increase the overall strength of the masonry by increasing the adhesion area between the brick and the masonry mortar.

Tolerances for calculations

The calculator is designed to calculate walls made entirely of brick. For this reason, structures that have voids or are filled with insulation must be calculated using other methods, since the result will be greatly overestimated. Another factor influencing the result is the thickness of the seams. Let's say that a 10-millimeter gap is included in the calculation, but in practice the builders slightly reduced or increased it. In this case, the greater the volume of masonry, the greater the error in the calculation.

It is recommended to multiply the number of bricks obtained during the calculation by a factor of 1.05 - 1.07, adding 5 - 7 percent to the original quantity. This way you can insure yourself in case of detection of a defect, a battle or your own mistake.

Instructions for using the calculator

Initial data

Step 1: The calculator is designed to calculate building and facing bricks of any type. To begin, select brick sizes from the drop-down list. If the required sizes are not in the list, set your sizes by selecting the appropriate item. Be careful here: set the length, width and height of the brick in relation to how the brick will lie in the masonry. Next, enter such building parameters as the height of the wall and the total length of the wall along the outer perimeter of the building.

“Old-father method” or current SNiP?

Experience is a good thing, but we should not forget about building regulations. They take into account all the factors associated with the preparation of mortars and concrete (purity, coarseness, moisture content of sand and crushed stone, cement activity and water quality).

Therefore, when preparing for work on pouring a foundation, screed or laying walls, do not be lazy to look at the GOST tables. You only need one or two lines in them. They clearly describe what the cement consumption per cube of mortar should be to obtain the required strength (grade).

| Cement brand | Brand of solution | Cement consumption rate for making 1 m3 of mortar |

| M400 | M200 | 490 kg |

| M500 | M200 | 410 kg |

| M400 | M150 | 400 kg |

| M500 | M150 | 330 kg |

Here is a simple “squeeze” from SNiP, which will help you prepare a high-quality mortar for masonry and screed. After studying it, remember that the given consumption rates differ slightly from practical values.

The reason is that they are produced from standard preparation conditions (air temperature +23C, medium-grained sand, ideally clean, its humidity no more than 7%, etc.).

It is not realistic to ensure standard parameters for mixing at a construction site, so it is better to purchase cement with a small reserve (10-15%).

The answer to the question of how much cement and sand you need per cube of concrete will be given by the following standards:

| Concrete grade | Cement consumption M500 kg/1m3 |

| M100 | 170 |

| M150 | 200 |

| M200 | 240 |

| M250 | 300 |

| M300 | 350 |

| M400 | 400 |

| M500 | 450 |

When making concrete, it is important to know not only the amount of cement, but also the standard volume of sand and crushed stone. The following table will be useful for calculations

Volumetric proportions for various grades of concrete

| Concrete, brand | Ratio of cement/sand/crushed stone in liters | |

| cement M 400 | cement M 500 | |

| 100 | 1,0 : 4,1 : 6,1 | 1,0 : 5,3 : 7,1 |

| 150 | 1,0 : 3,2 : 5,0 | 1,0 : 4,0 : 5,8 |

| 200 | 1,0 : 2,5 : 4,2 | 1,0 : 3,2 : 4,9 |

| 250 | 1,0 : 1,9 : 3,4 | 1,0 : 2,4 : 3,9 |

| 300 | 1,0 :1,7 : 3,2 | 1,0 : 2,2 : 3,7 |

| 400 | 1,0 : 1,1 : 2,4 | 1,0 : 1,4 : 2,8 |

| 450 | 1,0 : 1,0 : 2,2 | 1,0 : 1,2 : 2,5 |

The required sand consumption per 1 m3 of solution is 1 cubic meter. Some developers are mistaken in believing that the volume of cement increases the volume of the finished mixture. This is wrong.

The cement is very finely ground, so it is distributed in the voids between the sand, without increasing the total volume of concrete and mortar. Therefore, for 1 m3 of sand we can add 200 and 400 kg of cement, obtaining the same 1 cubic meter of solution.

Water is added to the mixture according to a simple proportion - half of the total weight (not volume!) of cement. In this case, you need to take into account the actual moisture content of the sand and pour water in small portions so that the solution or concrete does not turn out to be too liquid.

The consistency of the solution according to the standards is determined by the amount of sediment of a standard metal cone lowered into the mixture. You are unlikely to be able to conduct such a test on a construction site.

Therefore, just remember that the thickness of the masonry mortar should be such that it is not too hard, but rather flexible and does not leak out of the seams.

For the screed, the mortar and concrete must be of medium thickness so that they can be easily compacted and leveled according to the rule.

Subtleties of kneading

Sand, the second important component, is also sold in bulk from bases and quarries. This material will require several times more to complete the work, so it is not practical to talk about purchasing sand by the kilogram; we will be talking about tons.

Competent specialists convince us that when mixing sand-cement mortar, it is important to make a mixture of suitable thickness that would be comfortable to work with. It is sand that gives the necessary plasticity to the solution; on the contrary, cement is very finely ground, which is why its particles are not able to significantly affect the thickness of the mixture.

Water should be poured into the solution in small portions, based on the weight, but not the volume of cement. However, you should not pour out all the liquid at once, so that later you do not have to correct the situation by mixing the components again and again by eye. The fact is that it is impossible to predict in advance how clean the sand will be, what its humidity will be, as well as the weather conditions in which construction will take place.

In addition to sand, water and cement, the mortar may contain other components: lime, clay, mixtures that help prevent the mixture from freezing, as well as additives that prevent the formation of efflorescence (whitish spots) on the walls.

Types of solutions and their applicability

The connecting link between brick blocks is a mixture of the binder component with filler and water. The most common are 4 types of solutions.

- Cement-sand. It is diluted with water, its proportions depend on the brand of cement and the method of laying. When hardened, this option is the most durable, but if the technology is deviated from, it is prone to cracking;

- Limestone - in it cement is replaced with quicklime; it is plastic, but is washed out by rain, so it is only suitable for installing internal walls;

- Mixed - cement and sand are diluted with liquid slaked lime (lime milk). The combination combines the best qualities of the first two options;

- With a plasticizer - a polymer additive is mixed with cement and sand (fraction 2 mm) to increase the plasticity of the mixture. It is easier to make such a solution from a dry construction mixture by adding water according to the manufacturer’s instructions.

Despite the composition, the requirements for the quality of the mixture are almost the same. All ingredients are cleared of lumps, the sand is sifted, and the liquid lime is filtered. To prepare the solution, first thoroughly mix the powder components, then slowly pour in cold liquid (20 o C) and mix thoroughly so that setting does not occur. The process is accelerated using a concrete mixer or a hammer drill with a whisk attachment.

Mortar consumption per cube of brickwork

How long does it take to prepare mortar for laying a wall? This is determined by several conditions:

- the skill of a mason;

- the structure of the brick block - products with voids take more mortar mixture;

- type of brick - hyper-pressed and facing silicate absorbs less mortar than ceramic or ordinary silicate with a rough surface;

- wall thickness.

The average consumption of mortar per 1 m3 of brickwork with a standard joint thickness (12 mm) is approximately 0.23 m3. Table 1 provides more accurate information.

Cement consumption for bricklaying

The composition of the mixture for constructing a brick wall varies depending on the quality of the original components, weather conditions, and the number of storeys of the building. To mix the ingredients correctly, you should know: a 10-liter bucket holds 14 kg of cement or 12 kg of sand.

- Cement mortar is flexible in proportions. It is characterized by the degree of strength: the lower it is, the lower the required grade of cement and the lower its percentage (1 part to 2.5 - 6 parts of sand). For M400 cement the ratio is 1.3, for M500 – 1.4. The volume of water (on average 0.5 - 0.7 liters per 1 kg of cement) depends on the desired thickness of the mixture, the type of brick, air temperature - in the summer heat the solution should be more liquid. To increase its plasticity, experienced masons add a little washing powder or dishwashing detergent to the water. For 1 cubic meter of ready-made mortar 1.4, 410 kg of M500 cement and 1.14 m3 of sand are needed. Knowing that for 1 cubic meter of an ordinary wall, one brick made of a silicate block 250 x 120 x 65 takes 0.24 m3 of mortar, the cement consumption per cubic meter of brickwork is determined as follows: 0.24 x 410 = 98 kg. Accordingly, when using M400 cement (proportion 1.3) a cubic meter of the mixture contains 490 kg of cement, and 117 kg of it is consumed per 1 m3 of masonry.

- Cement-lime mortar is suitable for use within 5 hours, and in the summer at +25 o - no more than an hour, so calculation is also desirable for it. For 1 cubic meter of mixture, 190 kg of cement M400 - M500, 1.5 m3 of sand, 106 kg of hydrated lime and 475 liters of water are required. For a cubic meter of masonry you will need an average of 46 kg of cement.

Consumption of cement for laying bricks during cladding

In this case, the developer is interested in how much binder mixture will be consumed per square meter of wall. This depends on the water absorption of the building material, the season of work, the hollowness and porosity of the blocks. The standards are laid down in SNiP 82-02-95, but the real numbers are always higher, so you should buy ready-made mortar or cement with a reserve.

To save on consumables, 2 factors should be noted:

- the larger the dimensions of the brick, the less mortar will be needed;

- The higher the % of voids and pores, the higher the mixture consumption will be.

From this point of view, it is optimal to use ceramic or silicate double bricks of sufficient strength. This choice will allow you to achieve savings of 20% of the mortar mixture. Table 2 shows comparative data on mortar consumption per square meter of wall.

Types of masonry mixture

There are four main types of masonry mortar used in construction:

- Cement-sand . A classic mixture of cement, sand and water. If the proportions are correct, the solution will be strong.

- Limestone . Here, instead of cement, slaked lime is added. After drying, the seams can “go limp” from getting wet, so usually this mixture is used only for the construction of internal walls and partitions.

- Combined . That is, both cement and lime are added to the solution, which makes it possible to use the solution for the construction of external walls.

- With the addition of plasticizers . In fact, these are all three varieties indicated above, to which a liquid polymer additive is simply added, which increases the plasticity of the masonry mortar.

The most expensive ingredient in mortars is cement. Accordingly, cement-sand will cost the most, since it contains more of this binder. If the goal is to save money, then it is better to choose a combined solution, and for partitions - lime mortar.

The best option is with the addition of a plasticizer. The additive, of course, increases the cost of the solution, but not by much. Plus, the plasticity of the mixture increases, which helps to achieve an accurate thickness of the mortar layer, as well as its uniform distribution over the brickwork.

Classic masonry mortar based on cement and sand Source masteravannoy.ru

The main problem in preparing a high-quality solution is to know exactly and follow the proportions. But recently, manufacturers have made life easier for customers by offering ready-made dry mixtures that simply need to be diluted with water. Mixtures of the M50-M200 brand are suitable for laying bricks. On the packaging, the manufacturer must indicate the consumption of the solution per masonry.

How to use the table?

Since when preparing concrete and masonry mortars it is generally accepted to operate with the volumetric characteristic “1 m3”, we calculate (reduce to 1 m3) the amount of cement for the preparation of 1 m3 of mortar with the “cement-sand” ratios of 1:3 and 1:4.

When making practical calculations of the amount of cement, novice developers make a serious mistake. They believe that if it is necessary to prepare a solution from 1 part cement and 3 parts sand, then the weight of 1 m3 should be divided by 4 and thus obtain the number of components. Actually this is not true. Since cement particles are much smaller than sand grains, it fills the voids between the sand grains, so more cement is needed. To carry out any calculation of the components of cement and sand, we will accept the following assumptions:

- One “cube” – 1000 liters;

- The volume of a bag of cement weighing 50 kg is 36 liters;

- The weight of one “liter” of cement is 50/36 = 1.4 kilograms;

Option for cement:sand ratio 1:3

To prepare the solution you will need 1 m3 of sand and 1.3 m3 of cement, which corresponds to 333 liters of cement. 333x1.4=466 kilograms of cement will be required to mix 1 m3 of masonry mortar.

Option for cement:sand ratio: 1:4

To prepare the solution, 1 m3 of sand and 1.4 m3 of cement are required, which corresponds to 250 liters of cement. 250x1.4 = 350 kg of binder will be required to mix 1 m3 of masonry mortar.

Using the obtained calculation data and the table data, as an example, we calculate the amount of cement required to mix the amount of masonry mortar per cubic meter of brickwork from a single brick of a normal format with a thickness of “1.5 bricks”.

For 1 m3 of the specified masonry, you will need to spend 0.234 m3 of solution (table). Therefore, the amount of cement solution with a ratio of 1:3 is 466x0.234=109 kg; for a ratio of 1:4 – 350x0.234=82 kg.

Using the given technology and tabular data, you can calculate the required amount of cement for masonry mortars of any ratio of components - just substitute your data.

You can also use the calculator to calculate the required amount of bricks for your home, garage or outbuilding.

Building brick calculator

The online brick calculator is used to calculate the amount of building and facing bricks, as well as masonry mortar and masonry mesh required for the construction of a house, garage, or cottage. In addition, the calculations take into account the dimensions of the building’s gables, window, door and additional openings. Instructions for using the calculator.

When working, pay special attention to the units of measurement of the entered data!