Comfortable conditions in any living space directly depend on the temperature maintained during the heating season. High-quality thermal insulation of the building helps to ensure the optimal temperature level at minimal cost. This is why it is important to choose effective insulation to protect the structure.

One of the recently emerging options for the basis for thermal insulation is polyethylene foam, which provides reliable protection for any structure. Insulation with a reflective layer under the Penoflex brand is a prominent representative of insulation based on polyethylene foam. The material combines heat-shielding properties, impermeability to moisture and water vapor, non-flammability, and inertness to aggressive influences.

Structure and properties of insulation

Foamed polyethylene is formed during a polymerization reaction with a decay mechanism. At the beginning of the process, additives are introduced into the reaction mass to form a porous structure. As a result, the polymer body is uniformly filled with air pores with a diameter ranging from several hundred microns to a millimeter. This structure of the pore system allows the polymer to perfectly retain heat and resist its loss, and also practically deprives it of permeability associated with the open nature of the pores.

As a result, the thermal conductivity of Penoflex materials is low, which helps to effectively protect the treated surface from heat loss. The presence of a foil layer with a thickness of at least 14 microns ensures effective reflection of heat into the room. The adhesive composition applied to the surface of polyethylene foam makes it easy to secure the material to any surface.

Price

In construction stores, this insulation product is sold in packages. How many pieces does the package contain? Each individual package contains 4-20 pieces. The number of pieces in one package depends on the thickness of the heat insulator. The weight of one package is usually 15 kilograms.

According to information provided by online stores, the wholesale price per cubic meter (10 m3) is:

- Comfort – about 4000 rubles;

- roofing – 4300-4400 rubles;

- base of the building (foundation) – 4200-4300 rubles;

- penoplex - 5500 rubles.

So, we can assume that Penoplex is one of the materials that is used for insulation. The service life is almost 50 years. The structure obtained as a result of manufacturing helped to make a product with low mass and low thermal conductivity. You can carry out insulation using thin layers of the product. But be aware of the risk of fire and solve this problem in advance.

Basic parameters of materials

As with other thermal insulation composites used to protect buildings from internal heat emission, Penoflex polyethylene foam has a number of requirements. The main technical characteristics of this material include:

- almost zero permeability for water vapor at the level of 0.0015 mg/m*h*Pa;

- thermal conductivity no more than 0.045 W/mK;

- high elasticity under mechanical stress;

- density from 35 to 65 kg/m3;

- low volumetric water absorption, not exceeding 0.8%.

Due to its complex spatial structure, insulation with a reflective layer does not support combustion.

When polyethylene foam is heated, carbon dioxide trapped in the pores is released, which helps extinguish open flames. That is why such thermal insulation is well suited for wooden buildings.

Flaws

Penoflex insulation does not adhere well to any surface. This is due to the insufficient thickness and stickiness of the adhesive layer. But this is not the only disadvantage of this material. Due to the small thickness of the canvas, it is unsuitable for high-quality thermal insulation of premises. The use of penoflex is justified if the temperature in the room does not fall below +5°C. In such conditions it is able to retain heat, but at lower temperatures it is useless.

Types of thermal insulation

The basic characteristics of polyethylene foam-based materials may vary depending on their purpose. So, for additional thermal insulation, it is best to choose a material with a thickness of 10 mm. A larger layer of porous polyethylene becomes unstable due to the low strength in the polymer body due to the developed pore structure.

As a vapor barrier, protection from wind and external moisture, an option with a thickness of 2–4 mm is more suitable. To effectively dampen sounds, the polyethylene layer must be at least 6 - 8 mm.

Foil products

Applying a layer of foil on both sides allows you to improve the insulation characteristics and use Penoflex for external insulation of building walls. Reflection of external heat protects the structure in summer, preventing it from overheating. And in winter, the internal reflective surface becomes an effective barrier, helping to retain heat in the room.

Perforated film

To protect communications and create ventilation ducts, special perforated types of reflective insulation are used. Such materials have greater permeability and therefore effectively regulate air flow.

It must be remembered that when installing complete thermal insulation, such material may not be enough. Therefore, it is often combined with more traditional insulation, using it as waterproofing, as well as an additional barrier to heat, wind and sound.

Mounting technology

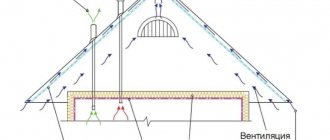

Insulation installation diagram

Installation of this thermal insulation product includes fastening using construction adhesive to a surface that must be flat and dry. Therefore, before starting the procedure, it is necessary to prepare the surface, that is, level it. After securing the installation of insulating boards, protection must be carried out. Decorative cladding products are used as a protective layer. To strengthen the adhesive fastening, you need to use umbrella dowel nails. Typically, this technology for installing insulation boards is used for walls or ceiling surfaces.

If you must insulate the floor, there are other recommendations. First you need to build up the subfloor. This can be done using DSP and GVL boards. A waterproofing layer is laid on the subfloor. Then the joints of the rolled insulation are overlapped using construction tape. This is done so that the concrete solution cannot seep into the wall product. There should be thermal insulation gaps between the walls and the subfloor; upon completion of installation, they are foamed with polyurethane foam.

Important! Winter grades of polyurethane foam contain substances that contain toluene. This substance is destructive to polystyrene foam.

During the procedure for thermal insulation of the wall surface, it is necessary to fill the gaps that are located between the penoflex and the walls of the structure using construction foam. The top is protected using a heat-reflecting foil film. It is the film that will be firmly held on the polyurethane glue. The joints of the film must be glued using metallized tape. Thanks to this, you will be able to achieve the performance of a thermos.

Advantages of insulation

Polyethylene as a chemical compound is inert to most aggressive substances found in nature and human life. That is why it does not decompose during operation and does not release harmful substances into the atmosphere, water or soil. Such material is harmless to both humans and the environment.

Due to its low thermal conductivity and the presence of a foil layer, the insulation perfectly reflects internal heat, preventing its emission through the main elements of the building. Penoflex does not require the use of special waterproofing films and membranes.

Installation of such a composite also does not require special skills; it is fastened using an adhesive layer applied on the polyethylene foam side and can be completed in 3-4 hours.

Installation of thermal insulation based on polyethylene foam

Due to their high flexibility, Penoflex insulating materials can be attached to a surface of any level. This insulation does not require careful preparation with leveling the walls, floor and ceiling. With a thickness of 10 mm, the insulation can hide some defects in the treated surface.

During installation, the sheets of material are attached end-to-end, the seam must be treated with sealant and covered with waterproofing tape. Overlapping fixation can lead to the formation of condensation at the joints, which promotes the development of mold and various microorganisms.

Taking into account the low permeability of the insulation, when attaching it, it is best to make a lathing that creates a ventilation gap of 20 mm between the insulation and the base, as well as the finishing material.

Types of penoflex

There are 5 types of thermal insulation material Penoplex. Types of Penoplex:

- "Foundation-35". This product does not contain fire retardant additives. The scope of application of this variety is basements, basements, and foundations of buildings. A similar material is Penoplex GEO.

- "Wall-31". The area of use of that brand is the external surfaces of basement walls, basements, and roofs that have a pitched structure.

- “Roof-35” is a brand that is suitable for insulating roofs of absolutely any design. Thanks to the special chamfer on the edges, precise connections can be made without any problems.

- Penoplex brand "Comfort-31". Area of use: walls, basements, roofs that have a pitched structure.

There is another brand - “Penoplex-45”. It is used in places where it will be subject to increased mechanical stress. Such places can be asphalt pavement, industrial facilities, and so on.

Features of using insulation

A material based on polyethylene foam with a reflective layer can become independent thermal insulation for a balcony or loggia, as well as an attic intended for living in the summer and off-season.

It must be remembered that foamed polyethylene alone is not enough to ensure complete insulation, so it is often combined with mineral wool as a vapor barrier and protection from external moisture and weathering. When used in combination with extruded polystyrene foam, such materials make it possible to reduce the layer of basic insulation by approximately 1.2 - 1.5 times, which significantly reduces the cost of protecting the structure from heat loss.

Where is Penoplex made? Reliable manufacturers you can trust

Penoplex is produced in Russia, so the material is sold in an affordable price segment. If we talk about brand representative offices, you can pay attention to the following cities:

- Kirishi . The production line has been operating since 1998, specializing in the production of standard size insulation. Currently, there are four lines involved. Total capacity up to 600,000 m3 annually.

- Perm branch . The plant was launched in 2005. Now, this is the most productive enterprise, supplying the market with about 650,000 m3 annually.

- Novosibirsk . The enterprise was launched for residents of the Siberian region of the country, specializing in the production of Penoplex with increased thermal insulation and water resistance.

- Taganrog . The plant produces about 500,000 m3 of insulation annually and, accordingly, fully supplies the residents of the Southern and Central regions with products.

It is worth noting that the products of these branches are subject to mandatory certification and undergo multi-stage quality control at all stages of production.

Share the post “Standard sizes of Penoplex. Types and characteristics. Comparison with analogues." by copying the link: https://kaksdelatsvoimirukami.ru/standartnye-razmery-penopleksa/