Fresh indoor air is the key not only to human health, but also to the safety of many finishing materials. In most rooms, the problem of oxygen flow is solved simply by ventilation. The bathroom has no windows, so it requires the organization of high-quality ventilation - both forced and natural.

To create the first, fans are used, and with the second, doors with ventilation can help. Wooden and metal door ventilation grilles, which can be easily installed with your own hands, will help improve an already installed solid door. There are several options for door ventilation - which one is better to choose?

Why is apartment ventilation needed?

Ventilation of residential premises in most multi-storey buildings (both new and old, especially in Moscow) is carried out using exhaust vents, which the investor equipped the building with during its construction. Exhaust hatches can be seen in the kitchen, toilet and bathroom. The ventilation system of each apartment (in the kitchen and bathroom), like all other apartments, is directly connected to the central air duct. The ventilation duct starts in the basement and passes through the ceilings to the technical floor of the building, from where it is discharged outside.

The movement of air masses in central ventilation is caused by the difference in temperatures of external and internal air. Heated air masses are sucked from the apartment into the central air duct through ventilation hatches inside the apartment. Clean air is sucked in through the windows and doors of your apartment. This ventilation system existed before the widespread installation of sealed polyvinyl chloride (UPVC) exterior windows and doors.

Currently, due to the installation of window units and doors with increased tightness, the supply of clean air is severely limited, which leads to a deterioration in normal air exchange in a residential area. Dirty air in a living space is a sign of problems with the ventilation system. Deficiencies in air exchange can be corrected by installing window frames with a ventilation function, but in this case, installing a PVC structure becomes pointless (sound insulation deteriorates and street dust begins to penetrate). If, in spite of everything, we decide to install plastic windows, it would be nice to equip the apartment with a fresh air ventilation system.

Ventilation in a living space is necessary:

- Freshen the air in the room.

- Don't let dust or noise from outside enter your home through an open window.

- To introduce fresh outside air into the home.

- To stay awake in the morning.

- There were no drafts and much more.

Before installing your first bathroom door, make sure it is ventilated—whether it allows air to pass on its own, and if not, whether you can install grilles or vent rings. Find out also what are the optimal door sizes for a bathroom.

There are the following material options for bathroom doors:

- Glass. Frosted glass doors are great for wet areas - they are resistant to moisture and heat, and they look great on top. They also easily withstand a lot of heating and cooling cycles, which is quite typical for a bathroom that is constantly filled with hot steam. If ventilation holes are not made in such doors in advance, they will not let air through.

- Plastic. The cheapest option, inferior to analogues in aesthetic characteristics. Like glass, it can withstand all aggressive influences. With certain skills, you can equip such gates with a ventilation grille.

- Solid wood. It withstands humidity and temperature fluctuations the worst, but is best suited for door ventilation.

- Wooden products - laminate, chipboard, MDF - when protected with special impregnations, tolerate moisture well and it is easiest to install ventilation in them. Like the plastic models, this option is quite cheap.

Therefore, despite the low resistance to moisture, wooden options are better suited for organizing a constant flow of air - then you can even make cut ventilation grilles for bathroom doors yourself.

Creating Vents

Ventilation in the door installed in the bathroom is one of the elements of the ventilation system. It may take the form of a small hole through which moist air is removed from the room. In some apartments and houses, such holes are the only solution to the problem.

Ventilation holes in the door

Ventilation holes are often made at the bottom of the door leaf and are a through window in the form of a circle or oval. To decorate such windows, you can use special decor in the form of rings. Decoration elements can be made of various materials (metal, plastic, wood), depending on the type of door. Work on creating ventilation holes is carried out in the following order:

Decorative rings for ventilation holes come in a variety of variations. Nowadays, in addition to simple and aesthetic rings, you can find mesh components coated with soundproofing or soundproofing material.

A variety of decorative rings

Round holes in the door are not the only solution to the issue of providing ventilation in the bathroom. In everyday use you can find unique gratings. Unlike rings, this system has angled louvres that prevent drafts from getting through.

Ventilation grille at the bottom of the door

The grille is an order of magnitude larger than the ventilation rings. On the one hand, this provides better ventilation in the bathroom, but on the other hand, it is very noticeable. To smooth out this drawback, you should choose a grille exclusively to match the color of the door leaf.

Installation of the ventilation grille is carried out in the same way as the holes. Only it should be located exclusively in a vertical position.——-

The importance of proper air exchange

Air replacement is necessary for the following reasons:

- regulates humidity levels and temperature fluctuations in the room;

- ensures proper circulation and flow of fresh air into living spaces;

- removes toxic substances from the room.

Currently, finishing materials have high water and heat insulation properties. Therefore, ventilation grilles are increasingly being installed in doors to remove expired air and moisture from the room. Or choose any other design that needs some space. Otherwise, high humidity is created in the bathroom and toilet, which leads to the formation of fungi, mold, and destruction of plumbing products and finishing materials.

Insufficient ventilation in a room negatively affects the health of people in it:

- Suffocation occurs;

- fainted;

- dizziness;

- Drowsiness;

- fast fatiguability.

Over time, a person may develop a chronic lack of oxygen. To avoid these problems, perform air exchange calculations and install high-quality products for room ventilation.

The need for door ventilation grilles

If there is no air exchange in a home, the well-being of its occupants can be very poor. A vent in a door usually allows air to flow from one room to another. This is the best solution when the internal door fits tightly to the floor surface.

Purpose

Overflow (door) grilles are installed in the hole made in the wing of the internal door to ensure free flow of air between rooms. Thanks to this, the door can be opened constantly. As a result, the air passing through the window enters the corridor and then into the ventilation shaft. It is recommended to install this type of product in such premises:

- Bathrooms and toilets, if moist air stagnates, mold can grow there.

- Kitchen. A ventilation grille is required to supply air to the hood.

- In other rooms, if there is no gap under the door.

Such products can be used for any purpose, not just in residential areas.

Material and shape

Typically these products are shaped like a rectangle, but there are door vents that are round or even square. The model contains two frames. The inner one, on which the slats are placed, is installed in the door leaf. The slats are V-shaped, allowing air to pass through but obstructing visibility. The outer frame has a decorative function and is installed on the back wall of the door.

Overflow ventilation grilles are often made of plastic and are very practical and cheap. Available and door vents are metal, but it is best not to install them in bathrooms unless the metal is stainless steel. Ventilation grilles are often powder coated to protect them from moisture. In the production company “VTB-Engineering” you can find any models of gratings.

The shape of the grill can be round, square or rectangular. Rectangular products are most popular among buyers.

Rectangular

Rectangular ventilation grilles can be used for both kitchen doors and bathroom or toilet doors. The use of such grilles ensures proper circulation of air flow in the premises. The second option for using rectangular grilles is installation in window sills. Thanks to this, the heated air from the radiator is evenly distributed throughout the room.

Rectangular models are usually made of high-strength plastic. There are also options equipped with a mosquito net and a special damper that allows you to control air movement. An excellent option is to install a grille with a built-in fan. This model provides the best air ventilation. The designs and color options available in the market are countless. It's easy to find the right design for your door.

Round

Round grilles are designed in the same way as rectangular ones. Most often they are installed in bathroom doors.

Another purpose is to install them in cabinet doors, this is necessary when moisture and mold collect inside the furniture. Some models of round ventilation grilles can be supplemented with mosquito nets, movable dampers and a built-in fan.

How much air will pass through: about the cross-sectional area

Another characteristic of gratings is the cross-sectional area. This determines the maximum amount of air that can pass through the grinder.

For comparison, the door gap area is about 120 cm² (with a leaf width of 80 cm and a gap height of 15 mm). With normally operating exhaust ventilation, creating a normal pressure drop of 10 Pa, about 100-110 “cubes” of air per hour will pass through such a gap. This is more than enough to remove all “used” air from a room with a tightly closed door (about 30 “cubic meters per adult per hour”).

Note: For ventilation grilles, pay attention to the cross-sectional area

(designated in the specifications as F ws), i.e. through a “clean” air passage zone. This value is always approximately 30-40% less than the total grating area - thanks to the gratings.

Ideally, the cross-sectional area of the door grille (or several grilles together that stand in one door leaf) should be more than 30-40 cm². Grids measuring approximately 300x250 or 350x200 have this area. This is enough to ensure normal air flow from a room occupied by one person.

Below is an approximate table of area (total - Fo, and living compartment - F ws) for gratings of different sizes:

If the room is not always closed, then there is no need to pay much attention to calculating the cross-sectional area. “If the room is not always enclosed, then you should not pay much attention to calculating the cross-sectional area.

Also keep in mind that more air will not escape through the grill than enters the room. For example, if fresh air enters the room through a supply valve that flows an average of 35 cubic meters per hour, then there is no point in installing grilles that are too large.

Sizes used

The size of the ventilation hole is selected depending on the size of the door. In most cases, interior doors are 70-80 cm wide, and bathroom doors are 60-70 cm. Based on these dimensions, door fans are made no wider than 60 cm. They can be installed in a door leaf whose thickness is 25-50 mm. In the store you can find suitable products in the following size range. Larger grilles are difficult to find commercially and will most likely have to be ordered as needed.

- Width – from 10 to 60 cm;

- Height from 10 to 25 cm.

The diameter of the round grille is on average 15-20 cm. Models with a diameter of less than 10 cm are usually installed in a row along the lower edge of the door in several pieces.

How to install the product

The instructions for installing a rectangular grille are quite simple.

The product consists of two parts:

Round gratings have the same structure as rectangular ones, but they can be very small in size, and therefore are built into a row of several pieces. If their diameter exceeds 10 cm, then the products can be mounted not in the middle, but on the sides of the canvas - and not necessarily from the bottom, but also from the top.

Note: By the way, the same grilles can be built into the doors of linen closets to provide ventilation for their contents.

Inserting the frame into the canvas

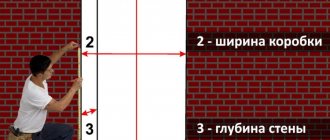

Apart from a pencil and a ruler, the process of cutting out a window for a grille in the canvas requires only one tool - a jigsaw.

Options for ventilation devices in bathroom doors

There are quite a few options for ventilated bathroom doors. Their characteristics depend, first of all, on the material from which the door leaf is made:

- Frosted glass. It is impossible to install a grille in such a door yourself, and there are practically no ready-made options. The only way to provide ventilation in this area is to drill a hole yourself;

- Plastic. The most affordable option, in which the installation of gratings is quite simple (even on your own and without special skills);

- Tree. This material is the least resistant to high humidity, but is still excellent for creating door ventilation. Thanks to the good workability of wood, it is relatively easy to cut out a grille in a door.

A bathroom door made of chipboard or MDF with a ventilation grill on the surface is one of the most economical options (see here which bathroom door to choose). Its cost is lower compared to wooden and glass structures. At the same time, the aesthetic properties of this material are better than those of plastic.

Before cutting the vent hole in the bathroom door, mark the surface of the door according to the dimensions of the grille. Add 1-2 mm to the length and width of the installed structure.

One of the most popular options is a combination door (see Sliding doors in the bathroom: advantages and disadvantages, how to install). This means that the structure is made of two materials at the same time. For example, made of plastic and glass or wood and glass inserts. Ventilation is located in the wooden or plastic part of the door.

Design Features

Metal ventilation grilles can have any shape, size and color, plus they can be installed at different heights, depending on the client’s preferences. In particular, the ventilation grille can be located both above and below the door leaf (at the owner’s discretion). It is manufactured in 3 versions:

The range of doors with ventilation grilles from are optimal, well-thought-out models for installation in any technical premises. You can always increase or, conversely, reduce the equipment, change fittings, and the number of sealing contours for any option from this category. In our work, we use powder coating of the door frame to match the leaf according to the RAL color scale to ensure a uniform appearance according to the enterprise project. Production time of any complexity and volume is from 2 to 3 weeks. You can order our products with delivery to all regions of Russia, and in Moscow and St. Petersburg any order is at our expense. We are ready to answer any questions by calling +7 (499) 322-96-32. Call now!

Source

Fastening with glazing beads or plinths

This method is rarely used and is specific to rooms with wood cladding.

Installing a ventilation grill by tightly sealing it with glue or clamps directly into the hole is easy. This is best done with glue, silicone or liquid nails. Use a special glue gun to apply glue with a slight indentation around the perimeter. Then the mesh is attached to the attachment point - the wall and fixed. After 24 hours, the glue dries and the mesh is securely attached. Remember that the wall must be dry before installation, and the adhesive fastening must be free of gaps.

As a rule, an industrial grille is attached using gaskets on springs to the prepared hole. This method is simple and does not take much time.

Do not forget that for residential premises you should choose ventilation grilles made from environmentally friendly materials that are harmless to the human body. If the grille is located outside, the material must be weather resistant.

Installation

Installing a ventilation grille in a door leaf is not difficult and you can easily do it yourself.

To install the grille, do the following:

- Determine the appropriate product size for a specific door;

- Make a hole of the required size in the door leaf and install the grille.

You will need very few tools to get the job done. Prepare a ruler and pencil, jigsaw, screwdriver or glue in advance.

The work is best done in the following sequence:

- Using a ruler, measure the exact parameters of the purchased grille;

- Mark on the door where the grille will be installed. Keep in mind that the length and width of the hole for the grille should be 1-2 mm larger than the dimensions of the grille;

- Make 4 holes in the corners of the markings on the door leaf using a round drill;

- Using a jigsaw (for wooden doors) or special tools (for doors made of other materials), you need to cut a hole according to the markings on the door;

- Place it on both sides of the resulting grill hole. Secure them with glue or self-tapping screws. The mounting option is indicated in the product instructions.

To summarize, we can say with confidence that by installing ventilation grilles you will not only restore the necessary air circulation in the apartment, but also get a stylish and original decorative element that will give the interior a more modern look.

Types of ventilation grilles

Depending on the installation location, the gratings can be divided:

- external, installed on the external wall of the building at the exit from the ventilation opening;

- internal, usually located in the kitchen, bathroom and toilet in the openings of the ventilation shafts;

- overflow walls or doors that regulate air exchange between adjacent rooms.

Outdoor models tend to be very durable, resistant to outdoor weather conditions, and relatively heavy. They have a rigid frame that fits into the vent and is secured using anchors or factory grommets. This method ensures maximum installation reliability and product durability.

Products for indoor installation are most often chosen for aesthetic reasons. They are characterized by light weight, pleasant appearance and small size. In the bathroom it is better to install a ventilation grille made of lightweight waterproof materials.

Design Features

There are several types of ventilation structures:

- with adjustable and non-adjustable blinds;

- inertial;

- slotted.

Air speed depends on the time of day, year and weather conditions. If during forced air exchange this parameter is regulated by the fan rotation speed, then during natural air exchange it is regulated using blinds. The position of the slats is changed by moving a special lever. Depending on the gap, the air speed can be increased or decreased. Both incoming and outgoing air flow can be adjusted.

These devices are often installed on foundation openings, supply and exhaust air ducts. The disadvantage of these products is the need to periodically dismantle, clean and lubricate the moving mechanisms.

Inertia grilles or products with a check valve prevent the flow of air from the ventilation system into the room during reverse draft. The backflow preventer is a thin plate mounted in the center. When the air is flowing correctly, the plate opens, and when it doesn't, it closes the hole. Such a valve can be installed in any grille. The simplest option is made in the form of a thin sheet of plastic.

There is no clear opinion on whether a valve is needed or not. The main argument is the possibility of flakes sticking. Over time, dirt accumulates on the grate, forming flakes and blocking air flow. This problem can be resolved by simply cleaning the device. However, in some cases it is necessary to use a check valve. For example, when natural ventilation and forced ventilation are installed in the same duct.

Sometimes slot structures are placed behind suspended ceilings. They have an oblong shape. More widely used in public places and office buildings. At home, ventilation rings are installed on the doors.

Ventilation grille

Ventilation grilles are used where it is necessary to ensure air flow from one room to another - therefore the grille is mounted in doors, partitions, partitions between rooms, etc. These structures consist of two frames, usually made of aluminum: an outer frame and an inner frame. The internal frame consists of V-shaped (i.e. angled) slats that should not impede air flow, but at the same time interfere with visibility.

Punchable ventilation grilles

Planks equipped with a knife of this type are “screens” with slots of the same size. They are located at equal distances from each other. A special production method - punching - allows you to achieve a sieve effect. To do this, you need to use special equipment - a coordinate press. The technologically advanced AMADA model is used.

The machines of this Japanese company are distinguished by a wide range of metal processing and versatility. The high level of automation minimizes the direct need for human intervention in the production process. This reduces the scrap rate to a low level and increases the speed of order fulfillment.

The AMADA punching press is a high-class hydraulic machine with a force of 20 tons. It not only punches simple holes for gratings, but also creates patterns and reliefs on metal. High precision stamping makes the structure strong and rigid. At the same time, stamped ventilation technical doors look neat and aesthetically pleasing.

Basic Concepts

Indoor air movement is often limited by closed doors. This prevents both temperature and humidity from being distributed evenly. One solution to this problem is the use of ventilation grilles.

This type of door design refers to cross-flow ventilation devices. They consist of several structural elements:

- Lattice. This part is made in the form of a durable frame, between which strips are located at a certain angle. This allows air to move freely.

- Decorative overlay. The product is a small structure that repeats the shape of the previous element. Install it on the other side of the door to hide the places where the hole was cut.

You can install overflow grilles in almost any door, but they are often found only in a few rooms:

Kitchen

This is important if the hood is constantly running here. It removes dirty and hot air, and a fresh stream enters the room through the holes in the door.

Bathroom and toilet

In such places, ventilation systems are used very often. This is especially important for the bathroom, where a large amount of moisture collects. And to prevent the formation of mold, surfaces should be thoroughly and constantly dried.

Interior doors. This approach is relatively rare. These structures are used in large offices where it is necessary to create comfortable conditions for workers. Such doors can also be seen in large archives or libraries, where it is necessary to maintain optimal conditions for storing paper.

How to choose ventilation in the bathroom door

To achieve proper ventilation in a door leaf, there are several considerations that must be taken into account when choosing design and installation:

- gate leaf dimensions;

- type and texture of door material;

- dimensions of the installed mesh;

- installation method, complexity and labor intensity of the work.

In some cases, the design of the interior and doors plays an important role, since it is not always permissible to install a rectangular grille. The door material is also important for the installation process. For glass doors, it is not recommended to install grilles and rings yourself.

It is better to entrust this work to professionals; glass requires special equipment and knowledge of processing technology. It is important not only to cut a hole of the required size, but also to process it - remove the chamfer, grind the inner surface.

In the case of solid wood doors, it is necessary not only to drill holes, but also to treat the wood with a protective agent. For MDF, make sure the plastic parts are sealed to each other and to the board during installation to prevent moisture from entering the internal cavities.

In addition, ventilation grilles on doors must provide sufficient fresh air flow into the room. The minimum opening must be at least half the surface area of the ventilation duct.

Materials

Air door systems can be found in almost any hardware store today. They are made from several basic materials:

- Plastic. The most common products, as the substance perfectly resists moisture. Plastic does not rot or crack, and its service life is almost unlimited.

- Metal. Transfer systems made from this material are quite rare, since the products resist water very poorly. The optimal solution is only stainless steel gratings.

- Tree. Designs of this type are very difficult to find on the market; almost all such models are made to order. Wooden devices are perfect for interior doors, but it is recommended to install them in bathrooms.

Do-it-yourself ventilation in the bathroom door

For self-installation you will need:

- Ruler/manager.

- Pencil/marker.

- Drill with a small diameter drill.

- Electric jigsaw.

- Screwdriver/screwdriver – if the grille needs to be screwed on.

- Glue – if the grille is glued to the door leaf.

- File.

The process of installing a ventilated bathroom door has some peculiarities. The work will require special tools and glue, and in some cases, wood antiseptic.

The first step when installing the grille or rings is to mark the installation location. This can be determined visually using masking tape - the outer part is simply glued to the door, thus establishing the installation location.

Next, the operating algorithm is as follows:

- The door was torn off its hinges;

- Precise marking of the installation location is made at the bottom of the tape;

- Holes are drilled into the door structure;

- When installing the grille, a hole is cut with a jigsaw;

- The edges of the neckline are processed;

- Glue is applied and plastic parts are inserted;

- After removing the remaining adhesive, the door structure is reinstalled.

A correctly installed ventilation grill should not affect the strength of the sash; the supporting structure should remain intact.

After installation, use a piece of paper to check the air flow; A properly installed vent ensures uniform air flow, even if the structure is equipped with an anti-drop mesh.

Where is it installed?

The overflow grille is mounted directly into the door leaf.

Most often - in its lower part: carbon dioxide (which we exhale) is heavier than air. As a result, “exhaust” air accumulates at the bottom, where it needs to be removed. If the inflow point is located close to the overflow grille (on an adjacent wall), then the overflow grille must be mounted at the bottom of the door leaf. This is done so that fresh air is not immediately removed from the room (and this will happen if the re-sharpening and supply are located too close).

List of tools

For self-installation you will need:

- Ruler/tape measure.

- Pencil/marker.

- Drill with a small drill diameter.

- Jigsaw.

- Screwdriver/screwdriver - if the grille is attached with bolts.

- Glue - if the grille is glued to the door leaf.

- File.

Installation of a door grill using the example of a Dvervent valve (video):

Installation of conventional overflow grilles is carried out in the same way, with the difference that it is not necessary to install a silencer.

https://youtube.com/watch?v=zbmg4WHjhSU

Installation of a surface-mounted fan

In small bathrooms, removing humid air is much easier. To do this, simply install a standard surface-mount fan. The most important thing is to correctly determine the required power of the device, otherwise all efforts may be in vain. For a rough estimate, experts recommend using the following formula: the area of the room should be multiplied by 6 if the room will be regularly used by less than 3 people, or by 8 if more than 3 tenants live in the house. The value obtained in this way will correspond to the required power of the device.

The device is installed with the power off. Start by attaching the floor box. Then connect the contact terminals to the mains using a two-core cable with a diameter of approx. 0.2 mm. Then you can begin installing the device body. Usually it is equipped with special latches, so it does not require additional fasteners. Upon completion of work, the effectiveness of the installed devices is checked. Surface fans differ from each other in design, but are assembled in accordance with the described scheme.

Methods of regulation

Depending on the design of the valve mechanism, the flow of supply air on ventilated plastic windows can be adjusted or have constant parameters. Optimal indoor climate conditions can be created using a manual or automatic valve. The latter is more convenient, based on a humidity sensor that monitors the humidity value in the room. The humidity sensor measures air flow by changing the cross-section of the opening until the duct is completely closed. The maximum cross-section corresponds to the highest humidity value. This type of control reduces heat loss because the air is only ventilated when people are in the room and the humidity in the room is increased. When the room is empty and the humidity decreases, the valve closes completely.

Choosing a manual control method involves constant thought about how long to ventilate, in what order to ventilate the room, and when to open the valve needed to ventilate. Manual controls can only restrict airflow in gusty winds. This setting is coarser and may cause drafts in the room.

Criteria for choosing window ventilation valves

For effective operation of the fresh air damper on plastic windows, the versatility of the device is necessary. To determine the class of vent valves, the following critical features exist:

- Provide the necessary air exchange parameters: The valve must operate with an external air supply of at least 30 m3 / h (per 1 person).

- Ensuring the required noise level: for standard plastic windows, this indicator is set to 30-35 dB.

- Specifics of winter operation: this parameter depends on the material of the valve structure, the difference between external and internal temperatures, and air flow parameters. For efficient operation of ventilation fittings and prevention of icing, it is important to maintain high quality thermal insulation of the fitting structure and use a so-called “thermal spacer” made of plastic between the outer and inner surfaces of its metal body.

- Type of regulation: it is possible to install a supply damper for plastic windows with automatic, manual and mixed regulation (tandem of the two previous types).

- Valve location: Installation options on windows and walls are possible. Installation on the wall significantly increases the cost of punching holes in the building envelope and disrupts the appearance of the facade due to the appearance of foreign elements. The window version is more economical, simple and discreet.

- Installation method: installation on an existing plastic window with insulated glass or replacement of the window with a double-glazed unit with insulated glass of a new smaller size.

Note: Valves not equipped with a control option should not be considered as the need to change the air supply is dictated by practice.

Combining ventilation and windows

People who care about their own health are wondering about the possibility of maintaining proper air exchange in an apartment with plastic windows.

There are many options for upgrading natural ventilation systems in residential buildings. Some of the most effective methods are those that are installed on the double-glazed windows themselves or are already attached to the window structure at the factory.

Windows with a window

The ventilation system for PVC windows, for example, from such companies, is most often used with a fan. Ventilation ensures a constant supply of clean air. It mixes with the air removed from the room, diffusion occurs, which normalizes the microclimate.

Natural ventilation prevents drafts and condensation on windows. The window sash can be fixed in several positions. However, this design has many disadvantages:

- Ventilation for plastic windows is installed at the design stage of the window opening. Improving ventilation after installing the entire structure is impossible.

- Such ventilation of plastic windows significantly increases the weight of the structure, which can negatively affect the house itself. Cracks may appear in the walls and window openings of a private home, so it is better to consult with specialists from a construction company before calling an appraiser.

- Adding a vent increases the cost of the structure.

- Increasing the plastic partitions in the window frame darkens the structure, and the light in the room becomes much less.

Plastic windows with self-ventilation

Plastic windows with a ventilation system using a self-ventilation system are the best solution for both residential buildings and private houses. A fan for plastic windows is also installed in industrial buildings, as it supports the operation of the main ventilation system.

Such ventilation in NRPVC windows is represented by slot holes in the upper or lower part of the NRPVC window frame. This slot ventilation ensures a constant flow of clean air into the room through the openings. And thanks to the special arrangement of the holes in the frame, cold air is heated and enters the already heated room.

Self-ventilation in windows has several disadvantages:

- This ventilation mode does not work in apartments on the upper floors and in private multi-storey buildings. When installing ventilation after a home has been built, careful consideration must be given to how to improve ventilation on higher floors without using this method.

- This ventilation system cannot be installed in already installed double-glazed windows, so the entire window structure must be changed.

- High cost of self-ventilating windows. Manufacturers increase costs threefold or more due to the complexity of the production conditions of such structures.

Therefore, most people resort to using specialized ventilation valves in the form of plastic window handles or combs.

Supply valve on a plastic window

Ventilation in a private house with plastic windows is mandatory if the homeowner cares about the health of family members.

It is necessary to regularly ventilate the apartment, especially if another ventilation system does not give the desired effect. The best way to normalize air exchange in an apartment is to install ventilation valves on plastic windows.

The ventilation valve combines several functions, and for proper ventilation it is necessary to select the desired class of device.

Installation of the valve requires complete dismantling of the double-glazed window or replacement of the part of the window responsible for ventilation. Such modernization makes the structure heavier and significantly affects the cost of the window. However, installation takes place in less than an hour, and air exchange is normalized within 24 hours, which indicates the undoubted advantage of this design.

After installing the air intake valve, you will need to decide whether you want automatic, manual, or mixed control.

Manual ventilation mode allows the owner to independently control the movement of air masses in an apartment or house. Partial ventilation can be used in those parts of the house where it is really needed.

And in automatic mode, no owner participation is required. As soon as the sensors in the valve respond to a change in temperature, the system supplies fresh air. The temperature returns to normal, and with it the air exchange.

Mixed mode valve control allows you to switch between manual and automatic control as needed.

Handle valve for plastic window

Air exchange in sealed structures can be improved by installing a special valve with a window handle.

The handle with the valve is installed in the window profile instead of the traditional plastic handle. This installation system has many advantages:

- The damper does not protrude beyond the window profile, does not load the structure and does not interfere with the free opening of the window.

- Condensation often collects in places where the window profile is most vulnerable. The handle is drilled directly into the profile itself, and condensation collects there. The presence of a valve handle eliminates the formation of condensation and improves air exchange in the cold season.

- When using forced ventilation, installing a damper will create additional comfortable conditions and completely eliminate stagnation of exhaust air.

- The manual valve is a design with a direct flow of clean outside air into the room. With direct air supply, the valve does not freeze in winter due to the absence of condensation.

- Only purified air will be sucked in from the street, since an air filter is installed on the valve, which can even remove allergens. Such a filter will not cause much trouble: even in a stuffy metropolis you will not have to change it more than a few times a year.

This method is new in the world of ventilation systems for PVC structures, so not all professionals know about its existence and the possibility of its installation.

However, this does not mean that installing a manual valve in itself is difficult. You can buy a template from large DIY stores and instructions are always included with it. By following the rules for assembling and drilling the profile, you can easily install a ventilation hole in a few minutes.