When choosing an interior door, the buyer pays attention not only to the appearance, but also to its practical qualities. After all, during operation, the door can fade, fade, bubble, and the door itself can swell due to unsuitable material and high humidity in the room. Doors with an eco-veneer surface are gaining increasing popularity today, a wide range of which is presented in almost every specialized department of construction stores. What it is, what are the pros and cons compared to other materials - we will tell you in this article.

Laminated interior doors

Laminated doors are doors coated with a special film that imitates the texture of many natural materials. There are 2 lamination methods:

- On a paper layer impregnated with a special composition based on thermosetting synthetic resins. A film with a maximum thickness of 0.2 mm obtained in this way is called melamine. The coating looks beautiful, but is subject to abrasion, and even changes color under ultraviolet rays. This product should be handled very carefully, because... the surface of the door leaf covered with melamine film is difficult to clean from dirt, and the paper sometimes peels off. The advantage of the material is its low cost.

- PVC laminating film is a more expensive option due to its considerable cost. This durable film layer, 0.4-0.8 mm thick, is glued to the door leaf using the cold method. It is called artificial veneer, eco-veneer, two-chrome or fiberglass laminate. The material is produced in reels. As a result of processing using electron radiation, the film acquires a number of properties:

Laminated interior doors

- resistance to abrasives and household chemicals;

- ability to withstand the effects of ultraviolet radiation and mechanical damage;

- uniformity of color and texture within the batch;

- light weight - from 10 to 13 kg.

The basis of the door is a wood frame. The second component is the cladding, which is usually used as MDF boards. The space between the plates is most often filled with cardboard, which reduces their sound permeability. This is the main advantage of laminated doors over hollow laminated ones. Some models are inlaid with glass inserts.

Attention: laminated doors do not lose their original shape in a room of any humidity level, but they can only be cleaned with liquid chemicals.

How to distinguish a quality design and expose a cheap option?

Experts advise that before paying for your purchase, pay attention to:

- manufacturing material. No chipboard, otherwise the door will quickly disappear into oblivion! MDF with filled honeycombs will last a long time;

- cladding Find out exactly what material is used for the coating and choose the one that suits your purposes;

- quality. Carefully examine the canvas and box. Scratches, swelling and peeling are a sign of an unscrupulous manufacturer.

- joints. A common joint defect is easy to detect before purchase. There should be no peeling of the coating at the ends of the door.

What are veneer doors

Under this general term there are 3 types of finishes:

- natural veneer;

- artificial or eco-veneer;

- engineering or Fine Line is a type of natural veneer.

They are all different in properties, characteristics, and price categories. Thin slices of expensive wood are natural veneer. They are attached to the door leaf with special wood glue using the hot pressing method. Veneer is produced by sawing, peeling and planing. The structure of the wood and its unique pattern are completely preserved.

Veneered doors

Sliced veneer with a thickness of 0.2-5 mm is mainly used as a covering for the door leaf. The starting material for it is oak, walnut, acacia, yew, beech, Karelian birch, elm, ash and other valuable species. To protect such an expensive coating from adverse influences and to give the doors sophistication and respectability, the surface is varnished. The price of a veneered door is cheaper than that made of solid wood. Natural veneer has 2 disadvantages:

- decent cost when compared with laminated coating;

- poor resistance to sunlight, which makes the surface darker over time.

Reconstructed or fine-line veneer

obtained by using special technology and using fast-growing tree species as raw materials: abashi, poplar. This wood has almost no flaws as a result of the fact that while it is growing, knots are removed from the trees. Due to its unique structure, “Fine-Line” does not resemble any wood pattern existing in nature, because it is created artificially. For production, peeled veneer is used, forming it into blocks and ultimately obtaining a material of rich colors with all kinds of patterns and sizes.

Fine-Line is applied using the “cold” and “hot” methods. In the first case, a special water-based glue is used. The second contains some types of formaldehyde adhesives. Under the influence of ultraviolet radiation, this veneer behaves in the same way as natural veneer, and besides, it is still only a fake of expensive wood. It contains from 92 to 94% natural wood, the rest is glue and dye. Among the positive characteristics we can note:

- more affordable cost compared to veneer made from valuable wood;

- almost complete absence of knots, knots and cavities;

- the ability to imitate any rare breed.

When choosing, pay due attention not only to the design, but also to the quality of the door

Advantages and disadvantages

ElPorta doors gained their wide popularity due to many positive characteristics. These include:

- high-quality imitation of valuable wood species;

- high strength;

- long service life;

- excellent sound and heat insulation;

- wide model range.

Judging by the reviews, ElPort's doors also have their drawbacks. For the most part, they relate to sliding and folding models. The problem lies in low sound insulation rates and significant heat exchange between the separated rooms. In addition, if such doors are closed incorrectly, the roller often jams in the space of the guide profile. This is a design flaw.

What's better?

The characteristics of both laminated and veneered doors are similar. They have the same internal structure - a wooden frame plus filling. The advantages and disadvantages of both types are clearly visible in comparison:

- An expensive version of a laminated door maintains a constant texture and color. It has a perfectly smooth surface, high resistance to moisture, temperature changes, abrasion, mechanical damage, and does not deform. However, if there is serious damage to the laminate, it is impossible to restore the door. The design solution of all existing models made of polymer material is the same. Due to its high performance characteristics, this type of interior doors receives many positive reviews.

- A veneered door can be made of any wood, but its mechanical characteristics undergo changes after some time of operation. It is environmentally safe, and if the surface is damaged, its structure can be restored. Some models have complex geometry, but in the case of convex doors it is difficult to bend the veneer. Their installation in rooms with high humidity levels is contraindicated, so the list of places where they can be installed is limited. Over the years, the door fades and becomes darker.

Tip: in order not to confuse natural veneer with eco-veneer, look at it closely. The latter gives off a plastic texture that has a less respectable appearance.

About the manufacturer

appeared on the Russian market relatively recently. But even in a fairly short period of time, she managed to gain great popularity. Today the brand occupies a leading position in the number of wholesale and retail sales. This once again proves that customers appreciate the products of this brand.

ElPorta doors deserve only positive reviews. This is explained by an individual approach to the client, unique product design, as well as the use of safe natural materials.

PVC doors

The polyvinyl chloride from which these doors are made is a chemically stable, environmentally friendly thermoplastic plastic. They have a lot of advantages:

- Attractive appearance.

- Small mass.

- High wear resistance.

- Durable even with heavy use.

- Reliability and ease of replacing any worn part.

- Environmentally friendly - the surface is antibacterial, does not cause allergies, and can even be installed in a nursery.

- Easy care - dust is not attracted; you can use any household chemicals to clean the fabric from dirt.

- High heat and noise insulation properties.

- Resistant to temperature changes.

- The ability to maintain a beautiful appearance in both dry and damp rooms, because... they do not dry out and do not absorb moisture. Finishing films allow you to decorate PVC doors to resemble wood or other natural materials.

- Resistant to scratches and dents.

PVC doors

The disadvantages often include the versatility and great popularity of the product, so fans of interiors with pretensions to luxury refuse them. For others, oddly enough, the reason for abandoning this type of door was the relatively low price, thanks to which they appeared in many offices, but many do not want to carry this official attribute home. Although the assortment of reputable stores includes models specially made for the home. Due to the fact that this is still not natural wood, a number of characteristics are inferior to solid wood, but the cost is also incommensurable.

Production

Where are el'Porta brand products produced? The doors of this manufacturer are manufactured in our country using foreign equipment. Thanks to well-thought-out production technology, it is possible to comply with all quality standards. Expensive materials make the brand’s products more popular and durable.

The workshop for the production of ElPorta doors is located at the Ryazan factory. From there the goods are distributed throughout the country. The use of various technological operations helps to achieve unique characteristics of the door leaf. It becomes similar to natural wood. The use of an edgeless system guarantees resistance to abrasions, long service life of the doors, as well as excellent performance characteristics of the product. Japanese polypropylene coating provides ElPorta doors with additional protection.

How to choose the right interior door

When choosing a door, you should focus not only on its appearance, quality, but also on some other points:

- Do not lose sight of the fact that doors can be opened on the right or on the left. To determine which door is in front of you, stand facing it and try to open it towards yourself. If it’s convenient to do this with your right hand, then the door is right-handed, and if you do it with your left hand, then you got a left-handed door.

- When you plan to install a door in a room where a humid environment prevails and the supply ventilation is weak, then choose a model with holes or grilles at the bottom. This option will reduce the humidity to normal and get rid of mold and mildew.

- When changing a door, focus on the existing doorway. With a width of 800-900 mm, a single-leaf standard sliding or swing door is suitable. For an opening more than 1.1 m wide, it is advisable to buy double doors, and if the opening is very high, then you may additionally need a transom, which is installed above the door leaves.

- Make sure that the connecting seams on the box and the canvas are smooth, without any gaps or roughness. The door frame and the door leaf itself must be made of the same material.

- Consider the color scheme of the door covering - it should not be a foreign spot against the background of the interior of the room, but, on the contrary, fit into the design harmoniously and naturally.

- Check the equipment, it is different for all manufacturers. The optimal choice is doors assembled in production, then you won’t have to select the fittings yourself and assemble the door block using improvised means.

- Don’t forget about the warranty; if it lasts for 3 years, this indicates that the manufacturer is confident in the quality of its products. When ordering a door, it is better to pay for their installation, and after it is completed, accept the work by signing the document, then the promised guarantee will begin to apply from that moment.

- When choosing, adhere to the rule that the price must be in full accordance with the quality. To do this, clearly define what you need doors for and for what room. The cheapest ones are quite suitable for the pantry, and where they are visible, they carry a certain aesthetic value and should last at least 10 years, try not to save.

- When finances allow, buy not one door at a time, but all at once, otherwise later either the desired model may not be found, or the color will turn out to be different. It is advisable that there is only one door manufacturer, then they will not differ in design.

- Check for quality certificates; well-known companies must have them, which is evidence of the high reliability of their products. Small companies usually ignore the certification process and you cannot be completely sure of the quality of their products.

Tip: stained glass will add individuality to your interior doors. The main thing is that its style matches the overall design of the room

Models

How to choose suitable ElPorta doors? Customer reviews of products from this brand note a large number of models with different styles and technical characteristics. Among the product lines of this manufacturer there are models with additional fittings and other elements. There is also a whole series of glass doors that will help give the room originality and uniqueness.

Today on sale you can find models belonging to the following series:

- Porta-Z.

- Port-X.

- "Soft".

- "Classico".

- Legno.

- Vetro.

- Twiggy.

Reviews

Before choosing a specific interior door, it is useful to consider the various options provided by company websites, look at magazines, read reviews of people who have long purchased and are using some domestic or foreign model:

MDF doors

- The man decided to save money, bought the cheapest interior doors, and this is how he speaks about them 4 years later: “I don’t want to look at them. There was no appearance - everything was stained, and when they tried to wash it, they began to peel off. I’ll have to replace it with new ones, but now I won’t save money.”

- “For all the rooms of the apartment, I chose MDF doors coated with eco-veneer, made in Ulyanovsk at the Okean factory. They look stylish, the tinting is perfectly even, they fit well into the design, and even those placed at the entrance to the bathroom and kitchen are not deformed at all. It cannot be said that all family members treat them with care - children sometimes hit them with a ball and slam them, but they have been serving them flawlessly for 5 years.”

- “We have had laminated doors from the Europan brand in our office for a long time. Performance characteristics are excellent. I’m thinking about installing the same ones in the apartment, especially since the load on them will be much less. Of course, they will be different in appearance, but the finish is the same, and the quality of the construction was impressive.”

- “When buying interior doors, we made a choice based on the manufacturer. I have long heard that the highest quality doors are from Italy. My wife liked Legnoform. Expensive, at first I was upset, but now I’m happy - the product is really cool. It opens and closes silently and looks solid.”

- “A friend who works in a door salon suggested that their most popular brand is the Finnish brand Fenestra. I didn’t like that the model range wasn’t particularly diverse, but I still found a suitable option for myself. Now I know why these doors are popular - that the price, that the quality - everything is at the level. We’ve had them for three years and we’re happy with our choice.”

- “All my interior doors are Spanish from the Portadeza brand. I wanted quality, decent, but not as expensive as Italian ones. I settled on these, of course, their design is somewhat conservative, the construction is simple, but, as it turned out, reliable and durable, although they are made of chipboard.”

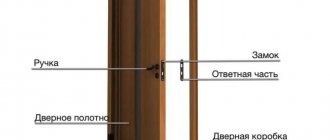

Remember that you need to choose not only the door itself, but also the frame and fittings. The quality of the installation also plays a significant role. Only if these factors coincide will the result be good.

Advantages

Foamed PVC products have the following advantages:

- Low density of the material, resulting in low weight.

- Resistance to mechanical damage and chemical influences.

- Good moisture resistance, allowing the doors to be used in bathhouses, bathrooms, shower rooms and so on.

- The non-flammability of the material is confirmed by fire certificates. Foamed polyvinyl chloride ignites at a temperature of at least 390 degrees.

- Good sound and noise insulation. The porous, hollow structure of the material provides good sound insulation. To ensure complete sound insulation, a sealing contour is installed around the perimeter of the box.

- Easy product care. They are resistant to various cleaning chemicals.

- Foamed PVC is resistant to the appearance of fungus and mold, so doors made from it can be used in buildings with high humidity.

- Ease of installation. For installation work on installing PVC doors, you need the same tools as when installing wooden ones.

- Affordable price compared to natural wood, thanks to which almost anyone can install it in their home.

Peculiarities

Modern equipment, the use of high-quality materials and advanced technologies allow us to produce doors that are not inferior to the European quality level. Even when exposed to moisture and mechanical stress, the canvas does not deform or crack. Good sound insulation, silent closing and opening of the door is achieved through special rubber seals.

At each stage of production of El Porta interior doors, products undergo quality control. A streamlined production scheme allows us to produce products in a short time and allows our customers to order products according to individual sizes.

The products of the El Porta factory are a guarantee of high quality, unique solutions for projects of any purpose and a pleasant price category.

El Porta Company

The Russian company El Porta has gained enormous popularity in the domestic market. It uses high quality raw materials and modern techniques in production. Products under the above brand are manufactured using European innovative equipment from Italy and Germany. Interior door leaves of various shapes and colors are manufactured in Ryazan.

In order to offer customers an affordable price for goods, in addition to foreign materials, the factory also uses Russian raw materials. Factory workers are true masters of their craft, thanks to whom each unit of production meets high international quality standards.

Installation in a doorway

As can be seen from the recommendations, the question of how to install an accordion door yourself will not be difficult even for an inexperienced craftsman.

Choose the right material for sliding doors, fittings for them, take into account all the features of these structures, and they will serve you well.

How to install an interior door

Required measurements

- 1. Treat the door block with a primer, after sanding it with sandpaper.

- 2.Before installation, try on the door in the doorway to check its dimensions and opening direction.

Right angles are not observed

- 3.Check the horizontal and vertical position of the door using a level.

- 4. After measuring the diagonals, make sure that right angles are maintained.

Installing a door in an existing wall

For all types of installation

- 4.Install the door block in the opening and secure it with wooden wedges. 5.Check the horizontal and vertical level, gaps and right angles of the door block.

- 6.Fix the door block using plaster, mounting adhesive or mounting foam.

If you are using spray foam, wait 30 minutes before removing excess foam. After 45 minutes, the hardened foam can be sanded and puttied.

Installing a door during the construction of an interior partition

- 1.Draw lines on the floor to indicate the exact location of the door.

- 2.Install the door block and secure it in place, having first checked the horizontal and vertical levels.

- 3. In order to fix the door block in a vertical position, insert between its upper edge and the ceiling a cross made of two wooden wedges connected to each other in the center with thick rubber (for example, from a car inner tube).

Installation of a door block in a partition made of gypsum blocks or cellular concrete blocks

- 1. Secure the bottom edges of the door frame with plaster or corners.

- 2. Cut the plaster blocks so that they fill the entire space around the door frame. Secure the blocks to the top crossbar of the door frame using mounting adhesive.

Installing a door block in a partition with a wooden or metal frame

1. Insert the vertical parts of the frame into the grooves of the door frame.

2. Screw the door frame from the inside to the frame.

3. Cover the frame with sheets of plasterboard.

Final finishing

After the door is installed, you can use embossed or flat trim for decorative finishing.

Paint the door with paint, varnish or tinting wax. After applying the first coat of paint, it is recommended to lightly sand the surface.

If the doors will be glazed, install the glass before applying the final coat of paint.

Do-it-yourself installation of plastic doors

Not every owner can install plastic doors with his own hands without errors. To avoid mistakes, it is advisable to call a measurer at least once, in a conversation with whom you can learn about the key features of this work, which can determine the final result of self-installation.

However, it is not enough to know all the nuances of door installation work.

In addition, the owner will have to figure out what tools and materials he should have available.

If he planned to install an entrance door, then the structure should be equipped with elements such as reinforced fittings, mortise locks, etc. If he installs a door in the room and on the balcony, he will not have to buy too many additional accessories, which will help save money.

El Porta Company

The Russian company El Porta has gained enormous popularity in the domestic market. It uses high quality raw materials and modern techniques in production. Products under the above brand are manufactured using European innovative equipment from Italy and Germany. Interior door leaves of various shapes and colors are manufactured in Ryazan.

In order to offer customers an affordable price for goods, in addition to foreign materials, the factory also uses Russian raw materials. Factory workers are true masters of their craft, thanks to whom each unit of production meets high international quality standards.