The service life of many building materials, especially wood, is significantly reduced in conditions of high humidity. In residential buildings, the floor of the first floor is in direct contact with the basement, where it is damp and cold all year round. In this regard, many customers ask the question: is it necessary to make vents in the foundation of a wooden house?

Vents in the foundation Source aireng.ru

What will the lack of air lead to?

Vents, or vents, are through openings (holes) located above the surface of the ground in the foundation, in the walls of the basement or on the floor of the basement. Openings made in accordance with building codes provide sufficient air ventilation, resulting in evaporation and release of moisture to the street.

The lack of ventilation in the foundation leads to the following:

- Accumulation of large amounts of condensation, 100% humidity.

- Condensation settles on wooden beams, ceilings, and boards of the rough floor structure.

- Fungi, mold and other living microorganisms actively reproduce.

The result is rotting and destruction of materials.

Rotting as a result of moisture accumulation Source chng.kf.ru.net

Due to the above, you should never close the vents, including during the cold season. But to reduce heat loss, the floor should be properly insulated.

Existing forced exhaust systems in the kitchen

A recirculating hood passes air through a filter and returns it back to the room.

Forced exhaust (ventilation) differs from natural exhaust in that it is more efficient at removing contaminated air. Based on the method of processing air masses, the models on the market are divided into two types:

- Units equipped with filter elements that pass air exhausted to the street through them.

- Exhaust devices operating on the principle of recycling (reuse).

In the first samples, the air after cleaning is not retained in the room and is discharged outside. Models of the second type contain built-in carbon filters, after which the cleaned masses are returned to the kitchen. To increase the efficiency of ventilation, the location of the hood above the gas stove is important. First of all, this concerns the height of its removal from the heating plane. According to regulatory requirements, this figure for gas stoves should not be less than 75 cm. This distance will protect the unit from thermal radiation and will not affect the operation of heating equipment.

Video description

The need for vents and the intricacies of their design are described in more detail in this video:

Radon

Another serious reason to vent is the accumulation of radon gas in an unventilated basement, which, sometimes very actively, is released from the soil. If the gas has nowhere to go, it begins to leak through micro-cracks into the living space.

Radon is a natural gas characterized by radioactivity and is dangerous to human health.

See also: Catalog of companies that specialize in foundation repair and design.

Reasons for high humidity in the presence of vents

There are quite a few known cases where vents were made in the foundation, but the humidity in the underground remained at an unacceptably high level. This can happen for the following reasons:

- The equilibrium relationship between temperature and humidity is disrupted. In the summer, a large amount of warm air flows through the vents into the cold room under the floor. The temperature difference contributes to the process of air condensation and the appearance of water droplets on the inner walls of the foundation. The accumulation of moisture is explained by the insufficient total area of the existing vents; as a result, all the moisture does not have time to evaporate.

- Increased evaporation of water from the soil under the foundation, abundant groundwater passing high, close to the surface of the earth. A lot of moisture also enters the subfloor, which does not disappear.

- Water flowing underground during heavy rains or when snow melts.

Water leakage is one of the reasons for high humidity Source aireng.ru

High humidity can be avoided if the ventilation holes are properly organized.

Subtleties of proper operation

It should be remembered that the movement of dry air eliminates condensation. High-quality ventilation is possible with proper operation of the ventilation system.

It is necessary to constantly monitor the weather conditions and carry out simple measures:

- Close the air dampers during long rains and melting snow in the spring.

- Regularly treat the inner surface of the foundation with lime or special antifungal impregnations;

- To combat excess moisture, you can use boxes with sawdust, sand, and salt, periodically replacing the filler with dry ones.

The basement should be ventilated in the dry summer heat, and in winter leave small gaps in closed sinuses for draft.

In winter, it is imperative to clear the snow from the walls around the entire perimeter of the house so that when the spring melts, water does not flood the foundation.

Even if the foundation of the house is protected by an effective wall drainage system, regular snow removal is required. During frosty periods and heavy rainfall, ventilation vents should not be covered with snowdrifts.

Organization rules

A sufficient number of vents of a certain area, especially in combination with an exhaust riser, guarantees optimal air movement, which prevents premature destruction of wooden structures, in this case the floor.

First of all, it is necessary to perform the calculations correctly.

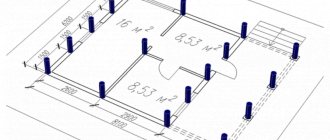

Vent location diagram Source nashdim.org

Quantity

The number of vents is determined per unit volume of the basement according to SNiP 01/31/2003. According to this document, in a basement of 400 m3 it is necessary to create at least one opening for ventilation. In areas characterized by a climate with high humidity, form air in the amount of 1 pc. for every 100-150 m3.

There are also vents in the foundation walls; in one inner wall there should be one large through hole, or several, as in the outer walls.

Vents are located both in the outer walls of the foundation and in the piers Source zen.yandex.ru

For better ventilation, vents with access to the street are made not only in the walls, but also in the floor. They must ensure free movement of air and draft.

How to fix the situation

What to do if there is a foundation, but they forgot to make vents or their sizes are insufficient for normal ventilation - fungus, high humidity and other “charms” have begun to multiply in the underground. There are several ways to solve the problem:

- Increase the size of existing ones or drill new ones. Drilling into a monolithic foundation is not an easy task. This can be done either using a crown of a suitable size. If you don’t have a crown, you can take a long, large-diameter drill and use it to drill many small holes around the perimeter of the vent. Then the remaining gaps are drilled, and the uneven surface is then either sanded or simply covered with a grid. Another way is to order diamond drilling. In this case, special equipment is used, holes are drilled much softer, without shock loads.

Diamond drilling in the basement of a building - If it is not possible or desirable to make new or expand old vents, you can improve draft by connecting one or more pipes from the vent to the roof. Due to the pressure difference, the draft will be better and the humidity will decrease.

- Make forced ventilation. To avoid turning it on/off manually, you can set a timer or a differentiated thermometer. It will turn on the fan when the temperature in the underground is higher than outside (a condition for condensation).

- Reduce the amount of moisture entering the subfloor. Most often, the source is soil, especially when the groundwater level is high. It is covered with a vapor barrier. Thick polyethylene film (thickness from 150 microns) is suitable. It is laid so that one sheet overlaps the other by 10-15 cm. The joints are taped with double-sided tape (you can do it twice - at the beginning of the “overlap” and at the end). The film is placed on the walls by 20-30 cm and secured with a strip. To prevent the film from being damaged during further use, a layer of sand is poured over it or a skinny screed 3 cm thick is made. If the foundation, blind area and base are insulated, this gives a good effect - in combination with a ventilation pipe leading to the roof. If there is no insulation, condensation will form on the film. By making a slope in one direction, moisture can be collected and removed outside the subfloor. This option, although worse, works.

- For ventilation of the underground in a bathhouse (heated) or in houses with stove heating, there is another solution - install the stove so that the air is drawn from under the floor (make a vent below the level of the finished floor).

Ventilation of the foundation by taking air into the furnace from the underground - No underground floor - no ventilation needed. To implement this axiom, the entire space from the ground to the subfloor is filled up. The most affordable material with good heat-insulating properties is used. Usually this is expanded clay. Its disadvantage is that it is hygroscopic and is capable of “pulling” water from the ground. If the groundwater level is high, if you do not provide high-quality waterproofing on the ground (film extending onto the walls), things can only get worse. There is a second suitable material with better thermal insulation characteristics and is completely non-hygroscopic - granular foam glass or broken glass. This material appeared relatively recently and few people know about it. For this case - an excellent choice. True, it is more expensive than expanded clay, but it is also many times warmer and safer (expanded clay is often environmentally unsafe).

What you need to know about creating vents in a strip foundation

Vents are created at the stage of foundation construction. The complexity of the work depends on the material from which the strip structure is made. Each option has its own nuances.

Concrete foundation

It is easier to make round vents in a concrete foundation. To form them, plastic or asbestos pipes are used, the diameter of which is determined according to the calculation rules presented above.

A plastic pipe is inserted into the reinforcing frame and fastened together with wire. The main thing is that the resulting assembly units (future vents) are installed in the formwork to pour concrete in the right place and in the required quantity.

Vents in a concrete foundation Source rekvartira.ru

The pipe is first filled with sand, which protects it from breakage. After the concrete solution has hardened, the sand is removed, creating a round through hole in the foundation wall.

Sometimes through openings in concrete are made using wooden blocks, which are installed in the formwork before pouring the mortar. You can't do that! It is very difficult to remove wooden elements after the concrete has hardened. They have to be knocked out using sufficient force, which damages the integrity of the foundation itself.

Brick or block foundation

In such a foundation it is advisable to construct rectangular or square vents.

When organizing openings, it is necessary to use a reinforcement cage. Its rods in the foundation are placed along a horizontal plane, in this case it serves as a support for the upper parts of the masonry.

Brick vents Source superarch.ru

In a brick foundation, half or part of the brick is used to provide ventilation during installation, resulting in a square or rectangular opening.

Is it difficult to vent a finished foundation?

Sometimes situations arise when ventilation was not done at the stage of building the foundation. In this case, it is formed into a ready-made structure.

The main difficulty of the issue is the availability of specialized tools, because to create a hole you will need diamond drilling. If the necessary tool is not available, and its cost is quite high, it is better to turn to professionals - this will not only save on the purchase, but also ensure better quality work.

Supply and exhaust ventilation device

Now let's look at how to make ventilation in the basement. The easiest way would be to make ventilation in the cellar or basement of the supply and exhaust type or forced.

First, let's do the calculation.

For 1 m2 of area there should be 25 cm2 of the cross-section of the air duct.

As the ceiling height or humidity increases, the diameter of the duct increases. A wooden box can be divided into two halves for supply and exhaust ventilation, but it is best to use plastic pipes or metal corrugated boxes.

Wooden ventilation parts must be treated against mold and painted.

The supply and exhaust ventilation device can be supplemented with a deflector on the roof of the house. It will create additional vacuum in the pipe and improve the release of warm air.

A controlled forced system will be much more effective with comparable labor costs. To do this, we will need special duct fans that operate on a voltage of 36 V. This feature is associated with the category of all basements that allow the use of only such currents.

Therefore, a transformer is installed in the electrical panel, reducing the voltage from 220 V to 36 V. And the wiring must be laid in cable channels. These and other rules can be found in SNiP 41-01-2003 heating, ventilation and air conditioning.

For small rooms, only one such fan per exhaust arm will be sufficient. The flow of fresh air will be carried out due to the vacuum in the basement. But the efficiency of the system will be much higher if you install a second supply pump and combine their work into one control panel.

Now on sale you can find programmable control panels with temperature and humidity sensors, and the duct fans themselves are available in all sizes and are compatible with almost any ventilation ducts. For convenience, they are already built into the body, have a protective grille and replaceable filters.

It is preferable to use PVC as pipes for ventilation ducts in your own home. They are strong and lightweight enough to be attached to walls and ceilings using regular dowels. They are not afraid of moisture and temperature changes, and the cost is lower than steel structures.

Condensation will always form in the exhaust ventilation ducts, which must be removed periodically. To do this, you can provide a special hole for draining water. Excess moisture leads to corrosion of metal structures and increases the likelihood of air duct freezing in winter. If this happens, you should definitely clean and defrost the channel.

Functionality check

Determining air circulation is quite simple. To do this, you can use the open flame of an alcohol burner or candle, or attach a sheet of paper to the opening of the exhaust duct. A good hood will hold the leaf securely. A thermometer installed in the area of the supply air duct will not do any harm.

The following signs indicate poor ventilation in a basement or garage:

- Condensation appears on the walls , and humidity exceeds 95%. The permissible maximum humidity for storing workpieces and crops is 85-90% at a temperature of 3-40C. For residential premises and garages, humidity levels should not exceed 40-50%;

- Mold and fungal growths on walls and ceilings;

- Unpleasant smell in the room and heavy stale air;

- Sudden changes in temperature indicate an incorrect design of supply and exhaust ventilation or errors in calculating the cross-section of the channels;

- In warm weather, condensation may not be noticeable, but in winter the walls will be covered abundantly with frost;

- Carbon dioxide can accumulate in the cellar with vegetables. You can identify it by a dying candle or match. In this case, it is necessary to open all the dampers and ventilate for 24 hours, without going into the room without protective equipment.

Ventilation in the bathroom and toilet: selection and installation of an exhaust fan - detailed article.

How to flush the heating system in a private house with your own hands: instructions.

The installation of ventilation systems will be much more effective if, together with it, measures are taken to maintain the microclimate:

- Periodic ventilation with the opening of all doors and hatches. This requirement is especially relevant for cellar owners. It is best to do this in the summer, and remove all wooden objects from the cellar;

- Regularly treat walls with lime or special compounds. They will protect against mold and unpleasant odors in the room. An approximate recipe for this composition: 3 kg of lime and 50 g of copper sulfate per bucket of water;

- Excess moisture in the air can be dealt with using a box of sand , sawdust, salt, and quicklime. Periodically, the box is taken out and thoroughly dried in the sun. In the cellar, you can leave the hole unlocked and cover it with old blankets or mattresses to improve air circulation;

- Installing an additional heat source (small stove, brazier, air heater, lamp) or just a burning candle helps;

- Waterproof the basement or cellar with bitumen compounds;

- Install adjustable dampers for supply and exhaust ventilation. With their help, it will be possible to eliminate drafts and freezing of the basement in winter;

- If the cellar is located in a garage, then it should have a separate ventilation system. High humidity in a vegetable cellar is contraindicated for a car;

- Install a regular home fan.

How to close the vents

Through openings should be covered not with blind, but with air-permeable grilles. Plugs are required to be installed; they protect the underground from the penetration of rodents, cats, birds and other animals.

Plastic ventilation grille Source roomester.ru

There are many different types on sale that are mounted on a street hole:

- large openings are covered with bars made of steel reinforcement with corners or metal mesh, including stainless steel;

- plastic products differ in shape (including in the form of an outlet at an angle of 90), sizes, and have an aesthetic appearance;

- In the workshops, gratings are made to individual orders.

When choosing a product, you need to pay attention to the presence of a check valve. For foundation ventilation, the valve is an unnecessary element (it must always be open, and this will have to be monitored). You should choose options without it.

Grilles with decorative design Source luxury-kamin.ru

When venting is not necessary

Conditions have been identified whose presence makes it possible to do without vents:

- the inside of the foundation is filled with sand, while a concrete slab is installed on the foundation walls;

- the soil under the house is covered with a vapor barrier film, which does not allow moisture to penetrate inside;

- the underground is equipped with an independent, high-performance ventilation system, the foundation and basement are well insulated;

- the underground floor is directly connected to the heated room (additional space is created for storing items).

The question often arises: are vents needed in a foundation without a basement? If at least one of the first three points is fulfilled, there is no need for vents. In other situations, vents are required.

Advantages and disadvantages

Let us note the positive aspects of using ventilation systems in the basement and ground floor:

- Comfortable microclimate in the house , no feeling of dampness on the ground floor;

- The ability to arrange a pantry in which a constant temperature and moisture content in the air is maintained;

- The service life of load-bearing structures of a residential building or cellar increases, especially if they are made of wood;

- Operation of gas and heating equipment is not possible in an unventilated area for safety reasons;

- A dry basement will never develop mold spores , which cause ARVI, allergies and asthma.