Usually a house is built quickly, often everything is put under the roof during the summer season. After interior decoration, you can move in, improve the local area and expand the functionality of the house. In this article we will tell you how to insulate an attic from the inside if the roof is already covered. The information will help you decide on the choice of material - this often depends on the initial conditions, and will explain the subtleties of its correct use.

Insulation of an already covered roof has its own characteristics that you need to know about Source pinterest.com

After this, you will speak the same language with the builders. Which is a good incentive for them to offer and demonstrate their best and do the work even better.

General points

Let's start with the fact that the attic is a bit of a special room. Its overall structure requires a careful, meticulous approach. And the insulation of the attic roof is even more so:

- Mostly vertical or inclined surfaces . Therefore, it is better to immediately exclude all soft “pliable” materials, namely mineral wool rolls.

- It is advisable to focus on materials with low dead weight . Since the rafter system is already experiencing significant loads from wind and snow. In addition, the load on load-bearing walls will not increase much.

- Often insulation is required for gables . They are not always made by analogy with a main wall. May be made of facing material. Or the frame is simply built for insulation.

- It happens that the area of the attic significantly exceeds the size of the house itself , while part of it rests on columns. In this case, you will also have to insulate the ceiling in contact with the street.

If the attic floor protrudes beyond the house, additional insulation of the floor is required. Source metasold.com

It should be understood that the thickness of the insulation must correspond to the weather conditions of a particular climate zone, while having a small margin. To gain the required thickness, the insulation is installed in several layers, and the relatively small dimensions require joining.

Important: splicing any insulation requires a careful approach. The joints of different layers should not be concentrated in one place. To prevent freezing, they should be spaced as far apart as possible. It is important to constantly remember this so as not to spoil the material, especially when insulating a sloping roof.

Pros and cons of foam plastic

Polystyrene foam is one of the most common and inexpensive thermal insulators. With its help, it is quite easy to properly insulate the attic. This is an acceptable option at a low price. It also has other advantages:

- This material does not absorb moisture at all. You can additionally treat the foam with a special impregnation, so that water will simply drain from its surface.

- Light weight. This is another advantage that simplifies installation and transportation. This plus greatly reduces the load on the roof structure.

- Low degree of thermal conductivity. The insulation does its job well.

- The material is very easy to cut and attach. Thanks to this, even a person without the slightest experience can work with it.

We can say that polystyrene foam is an almost ideal option when it comes to insulating an attic space. But the material also has several significant drawbacks. Main disadvantages:

- Excessively low vapor permeability. Because of this, quite often it can be too hot and stuffy in an insulated attic. It also increases humidity, which becomes a catalyst for the growth of fungi and mold on the roof truss system.

- Polystyrene foam is quite often attacked by rodents. They usually make nests from it.

- After a certain time, the tree will gradually begin to shrink. Because of this, gaps will appear between individual sheets of material. There is no way to fix this, so the only option to solve the problem is to replace the thermal insulation.

Many people think that the disadvantages of polystyrene foam outweigh its advantages, which is why insulating the attic with this material is not justified. But it should be noted that this option is one of the cheapest and easiest to install. Quite often it becomes an alternative to expensive solutions.

Preparation

All wooden surfaces must be treated with antiseptic and fireproof impregnations.

All wooden components must be treated with protective materials Source remontik.org

It is necessary to immediately identify “unreliable places” on structural elements. For example, the connection of the outer rafter to a pediment made of facing bricks. Or an overlapping connection between a rafter and a screed, made without insulation. It is necessary to eliminate the shortcomings - if possible, foam them or line them with a sealant. Otherwise, they will not be able to withstand through blowing and freezing.

It is necessary to minimize the use of metal fasteners. This is especially true for metal linings secured with bolts. Of course, the bolted connections will remain, but the plates should be made from thick, durable plywood and replaced. The remaining metal parts are painted with primer-enamel and covered with a layer of polyurethane foam. Metal directly in the insulation is a source of condensation and dampness.

What is polyurethane foam

Polyurethane foam (abbreviated as PPU) was created in Germany in the late thirties of the last century for the needs of the aviation and military industries. Later it began to be used for thermal insulation of freezers and refrigerators, and by the seventies of the twentieth century it began to be used for insulation of residential buildings.

Polyurethane foam is a plastic permeated with millions of tiny air bubbles. The insulation consists of two components, which are mixed directly at the insulation site in a special apparatus.

The components are supplied in separate containers attached to a special spraying apparatus. When the mixture is sprayed and interacts with carbon dioxide contained in the air, a light foam is formed that adheres well to any surface. After some time, the foam hardens, and the insulated surface is covered with a continuous layer of durable material - polyurethane foam.

In this way, an insulating layer is created that protects the premises from energy loss.

Polyurethane foam layer

Insulation of the rafter system

It’s great when the insulation of the attic from the inside was planned in advance, or “just in case” the constructive points for this were observed by the builders:

- A roofing membrane is mounted on the rafters.

- A counter-lattice is provided.

- The pitch of the rafters is maintained corresponding to the common length or width of the insulation.

It is convenient to carry out insulation if it was planned at the construction stage Source bamban.ru

It is worth noting that these are ideal initial data that allow you not to look for a “way out of the situation” and to insulate the maximum volume of the attic efficiently without extra costs. Such conditions make it possible to use vapor-permeable insulation. And these are comfortable living conditions.

See also: Catalog of projects of houses with an attic presented at the exhibition “Low-Rise Country”.

2.3 Spraying technology

Insulating an attic with polyurethane foam probably has only one significant drawback: using such insulation with your own hands is impossible for most people. The reason is the high cost of special equipment - the installation with which polyurethane foam is applied to the surface.

The simplest compact model costs approximately $2000-2500 (the same cost for insulating the blind area around the house), so purchasing it for treating one building is unprofitable. In addition, the operation of such an installation requires some experience, and the correct preparation of the insulation itself is also not a task for an inexperienced person.

Let's consider the sequence of work stages:

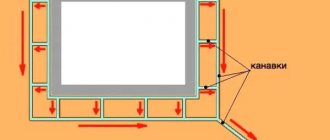

- The attic room is completely emptied of contents. Insulated surfaces are completely cleaned of finishing materials, thermal insulation, dirt, dust, mold. If possible, detected leaks, cracks, holes in the roof must be repaired. Logs are installed on the insulated surface. Polyurethane foam is prepared on site. Between the logs The composition is sprayed. After the first layer has completely hardened, the next ones are applied if necessary. After applying the required number of layers along the joists, the facing material is installed and further finishing is carried out.

As you can see, in addition to the insulation, the thermal insulation layer does not contain a waterproofing layer - it is simply not necessary, due to its resistance to moisture. This reduces both time, effort and money for work.

Insulation of an unprepared roof

When the decision to insulate is forced, the roof is usually not prepared. There is nothing terrible about this, it is even possible to choose the following options:

- Insulate with materials that do not require waterproofing.

- Build a special frame for living space.

In case of insulation of a roof that is not prepared for this, special compounds can help Source paspraypros.com

Foamed polyurethane foam can play a special role here. Although equipment is required to apply it, insulation occurs in a continuous layer and does not depend on the design features of the roof.

Foamed polyurethane foam is one of them Source da.decorexpro.com

This also includes ecowool. Although its installation requires a roofing membrane, it is quite possible to make a continuous layer of insulation.

Basic mistakes

All the positive aspects of insulation can be negated by errors in their installation:

- Carrying out work at low temperatures. This leads to insufficient drying of the glue and loss of strength of the insulating layer.

- Wrong choice of material thickness. Insulation of insufficient thickness will not give the desired effect, and a layer that is too thick will lead to unnecessary material costs.

- Sliding of thermal insulation due to insufficient fastening. This leads to the appearance of unprotected places and intense penetration of cold through them.

- Lack of vapor and waterproofing. In this case, the insulation will get wet, absorbing moisture, and will quickly lose its properties.

- Installation of steam and waterproofing films with sagging. These materials should be attached with slight tension.

- Lack of ventilation. In an unventilated attic, condensation forms on and inside the walls, damaging the insulation.

When carrying out work on thermal insulation of the attic yourself, it is necessary to take a responsible approach to all stages - from developing the project to attaching the final finish. In this case, a room created with your own hands will delight the owners with comfort for a long time.

Effective insulation

Next, we will consider the most effective materials that do not require serious equipment in order to efficiently insulate the attic.

Stone wool

Due to their elasticity, the mats adhere well between the rafters and allow installation without additional fastening. And the relatively dense structure of stone wool prevents its shrinkage over time. Therefore, it has proven itself well on vertical surfaces.

Stone wool mats come in different thicknesses, and you can choose the one you need based on climatic conditions and other materials used Source pallazzo.su

To further reduce the risks, every 3 meters of height it is necessary to arrange supports for the insulation - add a horizontal frame element.

Features of expanded polystyrene

Extruded polystyrene foam is very similar in structure to polystyrene foam. Their operational and technical characteristics are almost the same. The only difference is in the installation technology. Sheets of foam plastic must be laid between the rafters, and polystyrene foam is placed on top of them, which eliminates the risk of gaps and cracks.

Most manufacturers make slabs that have stepped joints. Thanks to this, the connection is much more reliable and durable. This fixation is an excellent option for insulating the roof above the attic.

This material has high strength characteristics and is also resistant to various external influences. Despite this, it is very light in weight. The service life of building materials is quite long if you follow the installation technology.

Expanded polystyrene does not decompose or rot , which is especially important for roofing work. On top of it, you can immediately apply absolutely any coating that can create a pleasant appearance for the room, and also additionally protect against the penetration of cold into the room.

Working with this material is quite simple, so installation can be done alone. Various adhesive mixtures are usually used for fastening. And sometimes a regular construction stapler is used. This allows you to reduce the final cost of insulation due to savings on expensive elements.

Expanded polystyrene has one, but very serious, drawback. It has a high degree of flammability. This means that special care must be taken when laying communications. Electrical wires must be of high quality, and their cross-section must be correctly calculated.

Manufacturers, of course, are trying to combat this, but at present the issue of flammability is still open. People who use polystyrene foam for insulation must take good care of safety, as lives may depend on it.

This material is often used to insulate balconies. It has a very low degree of thermal conductivity, and in this room, polystyrene foam has almost no contact with electricity.

Proper completion of work

The insulation has been installed, but the process must also be completed correctly. It must be protected from damp vapors from the room. For this, a vapor barrier film is installed. Moreover, the overall result greatly depends on the thoroughness of execution. Although each package is supplied with instructions, let us briefly repeat:

- The subsequent canvas overlaps the previous one by at least 15 cm.

- The joints are taped with special tape.

However, attic vapor barrier has a dual purpose. Oddly enough, it also protects the residents themselves. The fact is that vapor-permeable insulation is not strong enough and can be slightly weathered. From the outside this is not so important, plus it is protected by the roofing membrane. And inside it is necessary to exclude even the minimal possibility of the insulation components being released into the air - to reliably cover it.

The final stage is covering the insulation with canvases, on which the finishing is subsequently applied. Source obustroeno.com

Of course, this does not apply to Penoplex. But it is also recommended to protect against it; an effective material is penofol.

As for insulation of any type. In addition to the vapor barrier device, a technique that at first glance is unnecessary, but effective, is often used. Before finishing, intermediate, seemingly unnecessary material is installed. It can be OSB, GVL or GKL - it depends on the design. Moreover, the technology is fully observed - all joints are carefully sealed. This is an additional barrier against the unwanted effects of materials.

Floor insulation process

Scheme

*

During the procedure, it is necessary to avoid mistakes that may lead to harmful consequences. If the installation process is not performed correctly, the ceiling on the floor below may suffer.

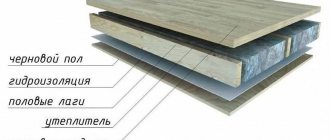

Let's consider each stage of installation of thermal insulation material separately. Stages of attic floor insulation:

- First you need to create a vapor barrier layer. The surface that has been prepared in advance must be covered with a specially designed membrane. The membrane will protect against condensation that rises from the lower floor. When laying a special film, it is necessary to make an overlap of 20 cm. The film is attached using a stapler.

- Installation of heat insulator. Thermal insulation is installed in the spaces between the joists. Pay special attention to the gaps that form between the plates. Therefore, make an overlap of 2 cm.

- The next layer of vapor barrier membrane is laid from the top to the heat insulator. Mounting is carried out on a flat surface; the insulation is secured to the joists using staples or nails.

- A lath covering is created to lay the floor boards.

- Then the wooden flooring is laid. Laying is carried out on top of the crossbars. To do this, you need to use veneers or edged boards. Staples, screws or nails are used to fasten the joints between the planks. This flooring is called a subfloor.

- Carrying out final finishing of the lower plane.

Since the work is carried out using wood, such material needs fire-fighting and antiseptic treatment. Thanks to this, you will protect the surface from rotting due to moisture. And the level of fire safety will be increased.

Attention! A layer of 50 mm should be created between the vapor barrier and waterproofing layers. Thanks to this, the service life of the lower plane will be increased.

Factors that must be taken into account when choosing a product: weight, vapor permeability, sound insulation level.

The attic and its subtleties as a construction project

A little interesting history to make it easier for you to understand why attics are so problematic in terms of heat.

The concept of an attic was first brought into this world by the French architect Francois Mansart in the 17th century, who proposed using the attic space for household and residential purposes. And already from the beginning of the next century, the poorest people began to live under a usually uninsulated roof. And only much later - bohemia, i.e. rich youth, free artists and poets.

The joy of the Parisians can be understood: at that time, the tax for a house was taken based on the number of floors, but the attic was not considered a floor. Those. It made sense to equip this nice room because of the savings, and therefore the fashion for a residential attic came to Russia much later. It was only in the 1990s that they began to take up the attic in earnest: the market suddenly became flooded with a variety of insulation materials and new building materials.

And today, the attic as a living space is recognized by modern building codes and regulations (SNiP), which state that this term can be used for that attic where the line of intersection of the facade and the roof plane is no lower than 1.5 m from the floor level. But we can tell you with all confidence that the technology for insulating and waterproofing an attic is the most complex and demanding of all existing ones.

Answers to popular questions

What is the best insulation for an attic under metal tiles?

Metal tiles do not place any special requirements on insulation. All types of mineral wool and foam plastics are suitable. The main condition is a sufficient layer of insulation, reliable waterproofing and vapor barrier.

Soundproofing insulation should be installed under a metal roof. Basalt wool and polystyrene foam have these qualities. In addition, roll and block insulation materials with a soundproofing substrate are produced.

How to insulate an attic if the roof is without waterproofing

If there is no waterproofing, it should be installed. With a cold roof, the absence of a water barrier is not critical - if there is no difference in the external and internal temperatures, there will be no condensation, as well as ice dams.

If you install a roofing pie for a warm attic without waterproofing, the insulation will get wet and lose all its performance properties.

The waterproofing film can be laid from the inside, securely connecting the joints. In this case, the need for ventilation under the roofing should be taken into account. Therefore, there must be an additional sheathing above the waterproofing film to create a ventilation gap. If there is no gap, the roofing material is laid on the rafters, then it must be removed.

Waterproofing is laid on top, connected without gaps, sheathing is made and the roofing is installed.