Furniture made from chipboard and MDF has long become commonplace. New, easier to process and use, cheaper materials are actively replacing traditional products made from various tree species. And this is not surprising. The performance characteristics of high-quality artificial materials based on sawdust are in no way inferior to solid wood. And in a number of parameters they are even superior.

When choosing furniture for their home or apartment or organization, many buyers ask a logical question: how reliable and durable are these materials, and what are their differences. You often hear that DSAMP and MDF are practically the same thing, made according to common recipes, and there is no point in choosing. Is it so? In order not to make a mistake when choosing furniture, you need to clearly understand the differences between these two materials. What nuances need to be taken into account when purchasing furnishings for certain needs. Let's try to figure it out together with the experts.

What are the differences between laminated chipboard and MDF?

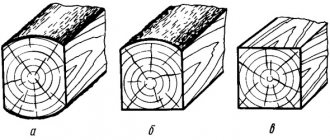

At first glance, indeed, furniture made from chipboard and MDF looks the same. The products look good, almost the same colors and textures are used. Even the shape and style of many models of kitchen, bedroom or living room sets are made according to the same design. Meanwhile, the difference between them is huge: in quality, in operating conditions, and even in price. All the differences are hidden in the depths, behind the attractive facades. They are associated with the peculiarities of production technologies for particle boards and finely dispersed fractions.

Plastic countertop for the kitchen: reviews

A plastic kitchen is presented in reviews as a budget-friendly and quite successful option for the home. Users note not only its low cost, but also its convenience and ease of installation, and a fairly long service life with proper use. Its low sensitivity to mechanical damage and heat resistance were also noted. But still, users advise not to use the tabletop as a hot plate or cutting board, since if scratches form, the surface cannot be restored.

In general, reviews of plastic kitchen countertops are positive, but there are also negative reviews. Some users noted that the surface becomes deformed after a short time, and there are places where the tabletop has swollen. This is most likely due to improper operation, as well as the choice of the cheapest CPL brand plastic. It is an inexpensive, but also short-lived material. It is better to give preference to HPL.

Disadvantages of laminated chipboard

- Due to the large number of large chips and heterogeneity of the structure, chipboards are prone to chipping of individual particles and the appearance of chips. Products can only be sawed in straight lines. They are not subject to fine milling or laser engraving. Therefore, it is very rare to find beautiful furniture facades made of chipboard, with figured cutouts, 3D relief images, and complex patterns. Mostly even, smooth doors are made from this material, suitable for modern styles.

- If water regularly gets into the joints and seams, the surface in these places swells and bulges into a hump. The product increases its volume up to 30%. The film begins to peel off. Inside the slab, the mass becomes loose, crumbles, and black mold appears. To avoid this, you should choose furniture with laser-cut edges (soldered joints). Such products are more durable. In addition, spilled liquids must be promptly removed by wiping the surface with a soft, clean cloth.

- Due to the low density of the base, the places where the fittings are attached gradually crumble. The fasteners begin to move freely in the socket. Furniture made from chipboard is not intended for frequent assembly and disassembly. It is enough to transport the set 1-2 times to a new place of residence, and it will warp in the most unimaginable way due to completely loose fastenings. To remedy the situation, you can use wood glue or use thicker screws. Or initially purchase products that use not ordinary fasteners, but bolts with wide washers.

- Low-grade types of chipboard negatively affect the health of children, adults, and pets. To produce the cheapest materials, large amounts of resins that emit formaldehyde are used. If new furniture has a specific, chemical smell, it is better to refuse the purchase. Living next to such a time bomb is simply dangerous.

Perhaps the most important disadvantage of laminated chipboard is its short service life. Such furniture lasts on average 5-7 years, subject to the rules of operation.

Features of operation

A plastic tabletop requires special care. Any dirt from its surface is removed with a damp cloth. You can use detergents, but without abrasive particles. You should refrain from using metal sponges or hard brushes, which can scratch the surface. When slicing, you should use a board to avoid scratches from the knife. When scratches occur, moisture penetrates the chipboard layer and causes it to deform or swell.

The weakest point of a plastic kitchen is the joints, which must be treated with sealant. Also important is the plinth, especially at the junction of the tabletop with the apron.

If you place a hot frying pan on a plastic surface, nothing will happen. But with prolonged thermal exposure, the tabletop can still become deformed. Therefore, it is better to use special hot mats.

Advantages of MDF

- Since formaldehyde resins are not used in the production of MDF boards, they are much safer than chipboard. In fact, it is the same wood, with a small content of natural or urea resins, only more uniform and durable. The material is used in the manufacture of children's furniture, cribs and changing tables for newborns, products for children's and medical institutions. By purchasing furniture made from high-quality MDF, the buyer can be completely confident in its safety for health.

- MDF, even in its natural, uncovered form, is not afraid of water. Its dense structure simply does not allow liquids to be quickly absorbed, unlike some types of natural wood and, especially, chipboard. And an additional protective coating in the form of a laminating film or veneer gives it excellent moisture-resistant characteristics. Even many hours of exposure to puddles of water or other liquids are not dangerous for MDF surfaces. That is why furniture made from this material is recommended for “wet areas” - kitchens, bathrooms, swimming pools, toilets, dressing rooms.

- Dense sheets can be bent if necessary: they do not break or crack, and retain their shape perfectly. This feature is widely used in the manufacture of curved or concave facades and other elements.

- MDF sheets, thanks to their homogeneous structure, make it possible to produce richly decorated furniture facades. They perfectly withstand all types of processing: sawing, shape cutting, milling. The possibilities of milling this material are limited only by the designer’s imagination. Craftsmen form products with relief figures and designs, carve complex recesses and patterns, apply entire pictures to slabs, and make carved platbands and moldings.

- The edges and front part of the products have no joints or seams, as they are covered with one sheet of protective and decorative material. That is why products made from MDF successfully resist moisture and chemicals. The coating is so dense that it is very difficult to scratch or make a dent.

- You can spill water, caustic fruit acids, or soda solution on MDF countertops and kitchen aprons. If you wipe up the resulting puddle in a timely manner, there will be no consequences for the coating.

- Furniture made from MDF perfectly withstands repeated assembly and disassembly when moving and moving to other rooms. In this respect, it is comparable to products made from natural solid wood.

- Consumers are offered a huge number of finishing options: PVC film with the most fantastic shades and textures; glossy, mirror, matte and semi-matte coatings; products with metallic, mother-of-pearl effects, interspersed with sparkles and metal threads, patina; veneer from elite wood species; surfaces that perfectly imitate any type of wood, stone, textiles, leather. Even the most picky buyer will definitely find a product to his liking!

pros

Plastic countertops for the kitchen, photos of which are presented above, have many advantages in addition to their low cost.

The advantages of a plastic kitchen are as follows:

- affordable price - for example, the cost of a domestically produced laminated board measuring 60 x 24.5 cm and 28 mm thick can be purchased for 1,500 rubles, 38 mm thick and 3 m long - 4,000 rubles;

- a variety of colors, textures and decors from classic style to trendy high-tech;

- high-quality material lasts a long time, does not fade and is not subject to mechanical stress;

- the material is not afraid of high temperatures (you can even place hot dishes on it), is easily cleaned of dirt and does not absorb moisture or odor;

- plastic is resistant to chemical treatment.

Additional advantages include the fact that any design or even a photograph can be printed on the plastic surface.

What are the disadvantages of MDF?

- Quite a high price compared to chipboard - 30-50% higher. High-quality MDF boards, coated with natural veneer, elite types of plastic or durable enamel, are close in cost to solid wood. However, they last two to three times longer than products made from chipboard or even solid wood.

- Plates consisting of small, homogeneous particles are prone to burning, even despite special impregnation with fire retardants.

- Dense material has more weight than particle boards, which affects the weight of the finished products. This must be taken into account when transporting and choosing an installation location.

To reduce the final cost of products and increase the number of sales, furniture manufacturers offer compromise options:

- cabinets for kitchens, living rooms, and bedrooms are made from straight, laconic chipboard plates;

- and beautifully decorated, carved facades are made from MDF.

Such furniture is affordable and lasts longer, thanks to durable, high-quality facades that take the brunt of the impact.

Production technology

For its production, chipboard sheets, sometimes MDF of various thicknesses, are used, which are covered with a thin but very durable layer of decorative plastic - melamine (HPL). It, in turn, is made from several layers of craft paper, which is impregnated with resins and then pressed. The joining of both materials occurs under high temperatures and pressure using the so-called postforming method. This allows you to smoothly bend the polymer layer onto the front edge of the tabletop and thereby achieve a perfectly flat and smooth surface without any joints.

Kitchen surfaces made of natural wood

When choosing a kitchen set, each of us dreams that the work surface in the kitchen will not only be durable, high-quality and beautiful, but also not harmful to health. Countertops made of natural wood, most often made of oak or bamboo, have these qualities. Kitchen sets made from these materials are not only incredibly beautiful, they are also durable and will last for quite a long time.

If you choose from cheaper countertops, you should note such materials for their manufacture as walnut, birch, pine and others. Products made from this wood are cheaper, lighter, and affordable for people with average income.

When humidity is high and water gets on the wood, it swells and loses its shape, so it is thoroughly impregnated with oil solutions and covered with a layer of varnish, which provides additional protection.

Also, kitchen countertops can be made not from a solid wooden board, but by gluing several wooden parts together. Thanks to gluing, the strength of the surface increases and the chance of deformation under the influence of certain factors decreases.

No matter how high-quality a wooden tabletop is, it still needs care and respect. This surface should be protected from scratches, cuts and splits, which most often occur from cutting products without a special cutting board. To care for wooden furniture, you must use appropriate detergents.

Pros:

- Great looks.

- There is no harm to health when using such countertops.

- Moisture resistance subject to basic care rules.

- Quite a long period of use.

- They are in the middle price category and remain affordable for most families with an average income.

- Wood has disinfecting properties, so bacteria and other harmful living organisms will not multiply on the surface.

Minuses:

- A small selection with beautiful wood textures, a limited color palette.

- Relatively low resistance to high temperatures, high risk of ignition.

- Instability to strong mechanical influences, which may result in defects in the form of dents and cracks remaining on the slab.

- They require regular care (use of special products, surface polishing, varnishing).

- Unresistant to various chemicals and dyes.

How to choose: basic tips

To make such a product pleasing to the eye and last for many years, it is better to listen to the advice of experts when purchasing, namely:

- pay attention to the quality of end processing. It is better to give preference to products made using the postforming method, i.e. with plastic folded to the back. This will protect the chipboard from accidental moisture and accordingly extend the life of the countertop. Another important detail is the presence of a so-called drip tray, which in case of serious leaks will not allow moisture to seep into the thickness of the slab;

- the thickness of the tabletop itself - the larger it is, the more solid it looks, and its strength and reliability also depend on this. Most often, manufacturers offer countertops with a thickness of 2.8 cm to 4 cm. However, if desired, you can order a product with a thickness of 6 cm or more. If you need to get to the top drawers, for example, to put things in order, you can safely stand on such a table top, etc.;

- The thickness of the plastic layer is also an important criterion when choosing such a product, because it indicates the wear resistance of the material. This indicator can vary within the range from 0.4 mm to 0.9 mm;

- color scheme - the choice depends not only on the interior of the kitchen, without a doubt, it should be in harmony with the furniture and decoration of the walls, floors, etc. The color of the countertop also affects its practicality. On a dark background, all dirt, stains, dust, dirt, etc. are visible, which cannot be said about light models.

Advice. If you don’t want to constantly worry about the appearance of the kitchen, then it is best to choose a plastic countertop that is light in color or dark, but with pronounced light inclusions, for example, like granite or quartz;

- texture is also of great importance. Experts recommend avoiding pronounced wood structure, gloss, etc. Countertops with a relief texture are very difficult to clean, and on glossy ones any defects and fingerprints are noticeable.