Gas heating boiler is connected to the main highway using a flexible sleeve.

Choosing and installing a hose for a boiler is a very important matter , because we are talking about gas.

An incorrect connection to the gas pipeline may result in an explosion .

To supply household gas, flexible gas hoses specially designed for this purpose are used. The use of water hoses for this purpose is strictly prohibited.

Varieties

three types used in everyday life :

- Rubber-fabric.

- Rubber reinforced.

- Bellows.

They are made from various materials, have different technical properties and service life. Each of the three types of gas hoses has both pros and cons. The choice depends on the installation location and the specific case.

Rubber

Rubber hoses reinforced with textile thread are the softest among all types of hoses. They are economical, easy to install and maintain. A wide selection of hoses of this type is available in construction stores. You can easily choose a sleeve of the desired length and diameter .

Photo 1. Rubber soft gas hose, black, is economical and easy to connect.

Rubber gas hose is mainly used in dachas. This method of gas supply is the most affordable and easy to install, but also the most unsafe. Over time, the rubber cracks, which inevitably leads to gas leakage, so the use of this type of connection is only permissible for private sector gas cylinders.

In addition, these hoses lack rigidity and are sensitive to temperature changes. This type of hose is recommended to be replaced every two years, however, in practice they are used much longer. Modern sleeves with elastic components can last up to 5 years .

Reinforced

Much more common are reinforced rubber hoses, which are similar to water supply hoses. They are braided with steel threads on the outside. The inside is made of polymer material, although they are called rubber.

Reinforced hoses are also affordable and easy to use, but they are prohibited in several European countries . Our gas specialists also do not recommend using them or doing so in compliance with a number of rules.

Photo 2. Two reinforced hoses made of polymer material, one covered with corrugated steel on top.

The polymer sleeve inside is destroyed in the same way as the rubber one. In addition, steel is an excellent conductor of current, so it is necessary to use dielectric spacers during installation. When using metal-braided tubes, be sure to turn off the gas taps; this will extend the service life of the hoses. This type of hose can be used at temperatures up to +50 degrees.

Bellows type stainless steel

This is the only type of gas hose approved for household use. It is a dense corrugated braid that is resistant to high and low temperatures, high pressure and mechanical stress. There is a single-layer and multi-layer bellows.

It is made from both metallic and non-metallic materials. The shell creates increased safety; it prevents damage from most types of impacts.

Photo 3. The bellows gas sleeve is yellow, made of non-metallic material, coated with polymer.

This type of hose is made of stainless steel. Gas hoses are sold with and without insulation. The second type is coated with a polymer that does not conduct electricity. A hose with a diameter of at least 10 cm for uniform gas supply. Bellows hoses are an order of magnitude better in quality than others.

Reference! The most reliable samples are those with a polymer coating that protects them from environmental influences. These gas hoses last up to 30 years , they are safer, but also more expensive.

Advantages of bellows hoses for gas:

Criterias of choice

When choosing, you should consider:

- device parameters;

- manufacturer.

Basic selection options

The most significant parameters that matter when choosing a bellows liner for water are:

- hose length. For normal operation, it is necessary that there is no tension when installing the hose, that is, the length is selected taking into account the margin;

- operating pressure and temperature of the device. Bellows hoses from different manufacturers are designed for different operating parameters. The pressure and temperature at which flexible hose can be used are indicated in the technical documentation;

- connection method. Manufacturers produce two types of hoses for water supply connections: with a nut-nut connection and with a fitting-nut connection. The nut has an internal thread and is usually attached to the supply pipes. The fitting is equipped with an external thread and is installed for connection to a mixer or other equipment;

Varieties by connection method

To connect washing machines and other household appliances, connectors with an angular nut adapter are used, which allows you to reduce the space between the wall and the appliance.

For connecting household appliances

thread size on connecting elements. Hoses are available with the following parameters.

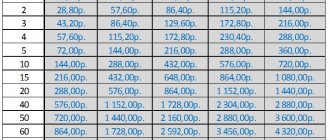

| Size in mm | Size in inches |

| 15 | 1/2 |

| 20 | 3/4 |

| 25 | 1 |

| 32 | 1 1/4 |

Typical sizes

Popular manufacturers and their features

The quality of the product largely depends on the manufacturing company. Consumer reviews allow us to determine the range of the most popular companies that produce bellows connections for water supply. These include:

- Turkish G-BEKA connections can be used to connect any equipment under any conditions. The product is durable. Warranty period of use – 3 years;

- Russian, producing products under the Aquaprof brand. The manufacturer was one of the first to produce reinforced hoses with increased wall thickness, which extends service life and almost completely eliminates the possibility of mechanical damage;

- "OSCAR-M" (China). Eyeliners at a budget price are of high quality and have a long service life;

- “Witzenmann GmbH” (Germany). Products under the Hydraflex brand are reliable, but also high in cost;

- Russian The products are characterized by minimal cost and high level of strength.

How to choose the right flexible gas tube?

It is safest to purchase a gas hose in a specialized store that has a state certificate of conformity . It is best to opt for the bellows type of sleeve.

Important! Beware of fakes of poor quality. There is a high probability of purchasing counterfeit goods on the market. This threatens that the sleeve will be made of thin, cheap rubber, which will quickly fail. Most fakes can only be distinguished from the original by a professional.

To identify a counterfeit, you need to carefully study the technical characteristics of the product, passport and certificate of conformity. You should not buy a product at a suspiciously low price.

Before purchasing, you need to take a measurement, then add 20% . You should not purchase a gas hose with a reserve. Standard sizes are 1–2 m. In everyday life, diameters of 1/2 or 3/4 inches are usually used.

The hose comes with two types of fastenings: with two union nuts with internal threads (female-female) or with a nut on one end and a fitting on the other (female-male). The thread is selected depending on the outlet on the device. It is preferable to opt for welded structures rather than those where the fitting is connected to the corrugation with glue.

Installation

The safest thing to do is contact a professional who will ensure the correct connection and provide a guarantee. After all, everyone knows from childhood that it is dangerous to joke with gas.

Flexible hoses for gas and water - simple installation and ease of use

Flexible hoses are convenient in everyday life due to ease of installation and ease of use.

With such connections for gas and water supply systems, you can easily move equipment when the need arises for its maintenance and repair. Flexible structures can be used to connect gas supplies, for convectors, washing machines and other equipment. A wide range of products raises questions among the buyer: which gas hose to buy?

, what type of eyeliner is better to choose?

Why is it better to seek help from specialists?

Only the gas supply organization has the right to install gas equipment. It will be better if the technician inspects the entire heating system and identifies shortcomings immediately, rather than this leading to problems in the future.

Gas heating is a dangerous equipment, so consultation with a qualified specialist is a must. Negligence in matters related to gas can lead to tragedy!

The main element in a flexible hose is a rubber hose. When made with high-quality connections, this hose is made from completely non-toxic rubber of a special brand EPDM, this is the so-called ethylene propylene rubber. This material, in case of contact with water, does not emit harmful substances, and it can be used for drinking water supply. It is also quite resistant to high temperatures; this property allows the use of liner when installing heating devices (up to +95 ° C).

The outer braid is the second most important element of the eyeliner. The flexible liner provides the product with sufficiently high strength in the event of external mechanical impacts and internal hydraulic shocks. That is why, externally, the hose is braided with stainless steel thread, thanks to which the flexible water supply will reliably serve for 10-12 years. A high-quality braid will allow the liner to withstand pressure up to 10 atmospheres. If, on the outside, the braid protection is made of aluminum thread, then both the service life and the strength of the product will naturally be less.

The braid is also made from galvanized steel wire; it does not withstand the action of condensation, and provided that it constantly forms, this liner will last no more than a year. Another element is the brass fitting. A fully braided rubber hose is attached to this fitting using a sleeve made of stainless steel. To install the liner, mounting elements are used, these are union nuts or a fitting.

Installation of water supply

Installation of new equipment is necessary if:

- connecting household appliances or plumbing equipment for the first time;

- a leakage of a previously installed product was detected;

- It is necessary to transfer the connected equipment and the length of the installed line is not enough.

In any situation, when installing the device, it is recommended to adhere to the following scheme:

- hose preparation. Before installation, it is recommended to straighten it to its full length, check the device for damage and deformation, and check the package contents;

- system preparation. Connection can only be made after shutting off the water supply. If individual taps are installed on risers in an apartment or other room, then the flow is shut off independently. If there are no taps, then to turn off the water you need to contact the management company;

Individual taps for turning off water

- dismantling equipment that has become unusable using a wrench. When removing the liner, be aware that water remains in the device. Therefore, during dismantling, it is necessary to substitute a basin or other container to collect water;

Dismantling process

If during dismantling it is not possible to unscrew the nut due to the formation of rust, then you can use WD-40 liquid or any solvent, which will remove plaque.

- sealing. When installing a new device, it is necessary to first seal the threads. To do this, you can use flax thread, FUM tape and other analogues, and also install the o-ring included in the kit;

Thread seal

- attaching a flexible hose to water supply pipes and plumbing equipment (household appliances);

- checking for tightness. If, when the water is opened at full power for 10 - 15 minutes, no leakage appears, then there are no leaks.

How to replace the eyeliner, watch the video.

To extend the service life of the bellows connection, it is necessary to turn off the water supply during a long period of non-use and systematically check the performance of the equipment and devices used for connection.

Application of flexible water line

The main application of a flexible water line is to connect corrugated stainless steel pipe to household equipment and appliances that use water. For this purpose, there are two types of flexible hoses: fully rubberized hoses with metal braiding and bellows metal hoses; the use of these materials makes connecting the equipment as simple and quite convenient as possible.

Metal-braided rubber hoses are the most common type of hose. Along with the “regular” hose, the “rubber hose in a metal braid” category also includes an anti-vibration hose. A flexible corrugated pipe or liner is, in fact, a universal material; if an accident occurs during the use of heating or plumbing systems, then, in principle, nothing terrible will happen, but if something bad happens during the operation of a flexible gas line, the consequences will be much more dire . But such accidents occur at a minimum, therefore, the flexible supply for heating or gas is made of sufficient quality to be used in absolutely any areas of increased danger.

Such a technically complex element as a universal flexible hose requires the use of only high-quality materials and modern qualified equipment. A guarantee of quality when purchasing flexible braiding is the so-called accompanying passport.

Obtaining hot water for heating and other technical needs is very important. In many cases, special hoses are used in the last section of pipelines. Ignoring strict technical requirements can lead to serious problems.

Basic rules for connecting flexible underwater hoses

After selecting a product of the required length with union nuts and fittings corresponding to the connected equipment and pipes, install the underwater hoses, observing the following rules:

- Before installation, the product is checked for the presence of gaskets, the quality of the braiding and connecting fittings.

- The hose is attached in a free hanging position without tension, twisting or sharp bends; the bending radius must exceed the diameter by at least 5–6 times.

- The supply hose is fastened manually; the presence of a leak is checked after 30 minutes with a dry cloth. In case of leaks, you can slightly tighten the union nuts and fittings with an adjustable wrench, avoiding pinching the gaskets.

- To avoid electrochemical corrosion, it is advisable to make threaded connections from identical alloys.

- After installation, the tightness of the system is checked for leaks at least once every six months; the need to replace the braided liner is indicated by the presence of peeled metal hairs on its surface.

Fig.9 Installing a bellows water line in a kitchen sink

Peculiarities

Hoses for steam and hot water pumping are widely used. They can be found:

in food production;

at an oil refining and petrochemical enterprise;

at a chemical plant.

It is imperative that the hoses successfully withstand high temperatures. The critical value is usually 210 degrees. Hoses resistant to it are used in most industries, including for steam cleaning of surfaces. Hoses for hot water and steam must successfully carry:

Installation and maintenance features

The flexible braided water hose must be installed only in such a way that it can always be accessed during further use. This will allow you to track its current condition and, if necessary, repair or replace it. When installing, it is recommended to follow the following rules:

- Before installation, make sure there are no obvious defects in the tube.

- If it is necessary to increase the length of the line, the hose can only be extended by connecting with fittings.

- It is unacceptable to perform installation with twisting, bending, stretching and compression.

- Installation of liners through ceilings is prohibited.

- During operation, no objects should rest or hang on the hose.

To avoid leakage, the flexible line must be periodically inspected and replaced at the end of its service life.

Sewerage and water supply

Modern high temperature hoses vary greatly depending on the nuances of use. Thus, for hot water pumped over open areas in the cold season, frost-resistant communications are mainly used. In domestic conditions, if it is necessary to supply liquid at temperatures down to -40 degrees, polyurethane hoses are used. This material is resistant to oil and gasoline, allowing you to pump even sea water and thick mud.

According to experts, it is best to use corrugated hoses for sewer systems. Their increased flexibility is important. Moreover, special ribs also increase the strength of communications. These properties allow you to confidently lay the sewer line to a considerable depth. Adaptation to sudden changes in terrain will not be an obstacle.

Briefly about the main thing

The bellows tube is often made of an inner rubber and outer metal shell. There is also a pure steel corrugated model. Flexible hoses have a wide range of applications - in plumbing, heating and cooling systems, fire extinguishing equipment, drainage and gas appliances. Among its main advantages are flexibility, lightness, installation, and durability. Disadvantages: insufficient tensile strength and limited temperature.

Flexible braided water hoses are classified according to several criteria:

- Purpose.

- Features of the shell device.

- Type of braid material.

- Types of fitting material.

When choosing a liner for a specific application, not only the diameter and length are taken into account, but also its compliance with external and internal conditions, flexibility, weight and harmlessness. Installation and operation of hoses must be carried out strictly in accordance with the recommendations.

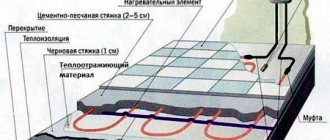

Warm floor

Heat-resistant hoses for heated floors differ from water hoses in that they can also be designed for other liquids. In some cases, antifreeze is poured into these systems. When choosing flexible communications for a heated floor, you need to take into account how much insulation is required. This depends on the climate of the area and how high the temperature will have to be maintained. Metal-plastic elements are mainly used because they last a long time, make almost no noise, and are resistant to strong heat and mechanical stress.

Which faucet liner to choose: rigid or flexible?

Hard eyeliner

A rigid connection for the mixer can be chosen as the most reliable option for connecting water. It will look like metal pipes made of copper, brass or steel.

The rigid liner is mounted on one side to the pipeline, and the other to the mixer using a threaded connector. Metal of this design is resistant to temperature fluctuations, chemical disinfections and some mechanical loads.

If you choose a rigid water line, then, if installed correctly, it will have the following advantages over a flexible system:

- Service life is about 20 years;

- Not subject to corrosion;

- Relatively convenient installation;

- Does not accumulate dirt, easy to clean;

- Comfort of use;

- Resistant to alkalis, chemicals and temperature fluctuations.

However, the disadvantages of such an eyeliner will be:

- Possible installation difficulties;

- The rigidity of the structure means that it cannot be moved.

If you decide to choose a rigid line, then it will be connected to the water supply directly without the use of adapters or using angle valves and connecting fittings.

The length of such an element for a mixer, as a rule, varies from 20 to 50 cm. The connecting thread is available in two versions:

- With fitting and half-inch union nut with internal thread.

- With standard M10 thread for faucet or half-inch union nut with internal thread.

Most often, hard liners are chosen in public spaces with high traffic volumes and strict sanitary standards:

- Schools;

- Hospitals;

- Stations;

- Clinics;

- Kindergartens;

- Sanatoriums;

- Airports;

- Boarding houses;

- Stadiums;

- Sports centers.

Replacing a hard water line is not particularly difficult and can be done on your own.

Flexible eyeliner

This type of connection can be chosen in more common situations. It can be used with any plumbing equipment, and will also ensure the delivery of water to equipment located at a distance from the stationary points of its supply.

The flexible line is made from a hose of the required length, which is wrapped with metal braiding to increase strength. Fittings are installed at the ends of this structure. Most often, rubber is chosen as a material for flexible hoses, as it is well suited to modern requirements for environmental friendliness and safety. It also has a fairly long service life without emitting toxic substances. Since rubber is resistant to high temperatures, structures based on it can be used not only for hot water, but also for heating.

The flexible hose has a brass fitting, which is attached to the hose by means of a sleeve. The connection to the water supply system occurs through a union nut or fitting.

If you decide to choose a flexible water line, it will have the following advantages:

- Safe operation;

- Reliability and good quality;

- Higher practicality relative to its rigid counterpart;

- Installation and dismantling is carried out with a couple of tools and is not difficult;

- Sufficiently long service life;

- The flexibility of the product allows it to be moved relative to the mixer without damage;

- Possibility of creating an aesthetic interior (flexible hoses can be hidden in a box inside the wall).

Flexible eyeliner also has disadvantages:

- Strong bending, twisting and stress can cause warping and leaks;

- If the flexible line is made of a bellows, then the water in it will make noise when used in different rooms at the same time.

Read material on the topic: Ball valves wholesale: criteria for choosing a product and supplier

Heating

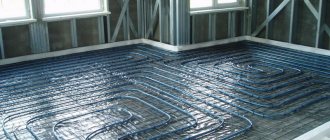

Heat-resistant flexible pipes for heating are in most cases made of stainless steel. Their advantage is that during operation the chemical composition of the circulating water does not change. The corrugated type of hoses is very resistant to harmful mechanical influences, including hydraulic shocks. But it is critically important to select only impeccably high-quality products. The slightest defects, even the most insignificant manufacturing defect, will have a sharply negative impact on the quality of the heating system.

Stainless steel heating hoses are connected using fittings. Then seals must be used. In addition, you can join parts using:

It should be taken into account that the flexible heating supply may also include rubber hoses. They use only EPDM rubber, which does not have even a slight toxic effect. The design can withstand heating up to 95 degrees. A mandatory component of the liner is a reinforcing braid. If it is made of high quality, from stainless steel, then its service life can be guaranteed for up to 10 years; aluminum or galvanized steel are much worse.

Characteristics, pros, cons

Elastic hoses with metal braid are characterized by the following number of parameters:

- Service life - at least 3 years for a product with steel or aluminum braid, about 10 years - for a stainless alloy, over 15 years - for nylon.

- The maximum pressure in the water supply system - specimens with braided steel and aluminum operate up to 5 bar, with stainless steel - 10 bar, with nylon - up to 20 bar.

- The maximum temperature of the internal environment is no more than 80-90 °C for aluminum, 95 °C for steel alloys, and 110-120 °C for nylon.

Flexible liner differs primarily in diameter Source fittingi-trubi.ru

- The minimum bend length is 60 mm.

- The maximum torque when tightening the connecting nuts is 50 Nm.

- Rubber hardness – 75 units. according to the Shor system.

At the same time, the dimensions of hoses for flexible water supply - diameter, minimum and maximum length - can vary significantly. Thus, their length is in the range of 0.3-5 meters, the diameter of the internal section is 15-65 cm.

Among the main advantages of bellows hoses are the following:

- Flexible, light and compact. The combination of such qualities eliminates the cluttering of space, as happens with the installation of standard steel pipes, which is especially important in small bathrooms, kitchens, baths and showers. This also gives more freedom when choosing a place to install plumbing equipment - since the liner can be made without much difficulty at any distance from the main pipe.

- The ability to rearrange equipment without replacing the pipeline - thanks to the flexibility and elasticity of the liner.

- Elementary installation. Connection does not require the use of complex welding technologies, equipment and tools.

To connect the flexible hose, one wrench is enough Source xn--80ac1bcbgb9aa.xn--p1ai

- Reliability and durability. With initially high quality and compliance with operating conditions, flexible hoses can last for several decades in trouble-free mode.

- The elasticity of the material and the absence of sharp transitions in the structure make the bellows more resistant to water hammer and external mechanical damage compared to a standard pipeline.

However, along with a large number of advantages, the bellows water hose also has a number of specific disadvantages:

- Despite good elasticity and flexibility, a braided hose does not have sufficient resistance to tearing and twisting. Therefore, if such factors are present during installation or operation, it is easily damaged.

- If the hose comes into direct contact with a very hot object or flame, despite the outer metal sheath, the internal structure is destroyed and leads to a leak.

- If the water supply is not properly connected, even a flexible line can begin to vibrate and produce an unpleasant low-frequency background hum.

If used incorrectly, the integrity of the flexible hose is compromised and the liner leaks Source pikabu.ru

Recommendation! The flexible hose is so versatile that it can even be used to drain wastewater, for example, from household washers and washing machines. Large diameter products - 2 or 2 ½ inches - are ideal for this task.

See also: Catalog of companies that specialize in engineering systems (heating, water supply, sewerage and others) and related work

Recommendations for selection

When selecting food hoses for hot water and steam, primary attention must be paid to their strength, throughput, and thermal parameters. But chemical properties are no less important. They also check the method of fastening and the length of the structure. A high-temperature steam hose is most often reinforced with wire. Only with minimal steam pressure is it permissible to use lines reinforced with fabric.

According to experts, the highest operating pressure should be 10 times lower than the burst pressure. Most steam generator hoses are made with a cross-section of 2.5 or 3.2 cm. You should definitely check what substances they are made of. If the mixture settles near the fittings, steam leakage is inevitable. Hoses rated for 100 degrees are impractical; it is best if they can withstand temperatures up to 220 degrees.

Insulated hoses are more correctly called pipes. A heating cable can be used as a heating means. Occasionally, shell coating made of polyurethane foam or polystyrene foam is used. Typically, a protective layer is used for underground routes. Surface pipelines are made mainly with cables.

For heated towel rails, flexible hoses are not used at all. It is better to adjust the location of the pins. Coils for moonshine stills are mainly made of silicone. We must carefully check that PVC is not sold under the guise of silicone. Many sellers themselves do not understand the difference.

For heat removal of air, only hoses that meet sanitary standards are selected. The frequency of air exchange and the intensity of ventilation are taken into account. Calculate the optimal thermal regime. It is necessary to compensate 100% of heat loss.

Selection rules

When choosing a flexible water line, not only its dimensions are important - length and diameter, so that the connection is made, if possible, without additional adapters - but also the following number of equally important factors:

- Compliance with the operating parameters of the system and the environment - temperature, pressure, location of hot objects or open flames nearby, humidity level.

- Flexibility. The higher the parameter, the easier the installation and the higher the quality of the product.

- Weight. Steel specimens are much heavier than aluminum ones. However, the latter are short-lived.

- Smell. The hose and all its components must not contain components harmful to health, emit a characteristic unpleasant odor and transfer it to water.

Installation subtleties

Bending of the water and steam line is undesirable. If possible, bend it without mechanical stress. We must not forget that the hose must sag. Nuts and other fasteners are partially tightened. Only after checking that everything is in order, tighten it with a key.

The joints must be perfectly clean. Avoid contact with sharp parts. Of all welding methods, plasma welding is the most effective. Not everyone can do this kind of work, so it’s better to turn to specialists. The connection using flanges is made without threads; it is needed where regular inspections and prevention are needed.

To learn how to choose a flexible eyeliner, see the following video.

What is a bellows water line and its scope of application

A bellows is a corrugated shell made of various materials, which may contain one or several layers and does not lose its physical and chemical properties under the influence of mechanical deformations, internal and external pressure, temperature changes and their combinations.

Easy installation, high performance characteristics and the ability to dampen vibrations allow the use of bellows water supply in the following cases:

- Connecting household plumbing equipment (faucets, toilets) to the water main.

- Water supply to showers and kitchen heads.

- Connecting water supply equipment - hydraulic accumulators, electric pumps, boilers, various plumbing fittings.

- Use in heating systems for connecting storage tanks and radiators.

- For draining water from washing machines and dishwashers.

- For connecting gas stoves, domestic and industrial gas boilers, boilers, etc. to gas mains.

Fig. 2 Bellows flexible liner - main types